Section 7: Non Ferrous Metals

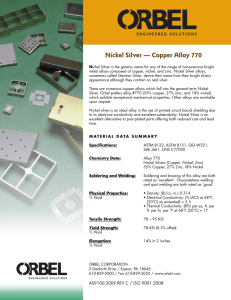

advertisement

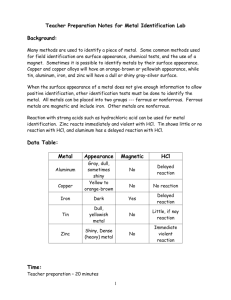

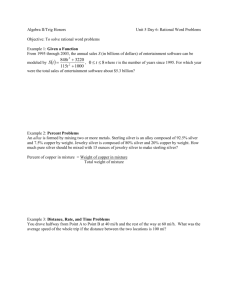

Section 7: Non Ferrous Metals Non-Ferrous metals Aluminium and its alloys Copper, brass and bronze Nickel alloys Zinc Tin Lead Titanium Magnesium Refractory metals: Tungsten, Iridium Precious metals: Gold, Platinum, Silver Special metals: Uranium, Mercury Metal 1998 world usage estimates mt (1000) Unlike pure metals, most alloys do not have a single melting point. Instead, they have a melting range in which the material is a mixture of solid and liquid phases. The temperature at which melting begins is called the solidus and the temperature when melting is complete is called the liquidus. However, for most alloys there is a particular proportion of constituents which give them a single melting point or (rarely) two. This is called the alloy's eutectic mixture. London Metals Exchange ($) Steel 776000 Steel Aluminum 30106 Aluminium Aluminium Alloy Copper 14200 Copper Zinc 8160 Zinc Lead 5940 Lead Nickel 1130 Nickel Tin modulus, and electrical and thermal conductivity, of an alloy may not differ greatly from those of its elements, but engineering or mechanical properties, such as tensile strength and shear strength may be substantially different from those of the constituent materials. This is sometimes due to the sizes of the atoms in the alloy, since larger atoms exert a compressive force on neighboring atoms, and smaller atoms exert a tensile force on their neighbors, helping the alloy resist deformation. Alloys may exhibit marked differences in behavior even when small amounts of one element occur (Steel). Some alloys are made by melting and mixing two or more metals. Brass is an alloy made from copper and zinc. Bronze, used for statues, ornaments and church bells, is an alloy of tin and copper. Phase diagrams (equlibrium diagrams). This page is an in-depth explanation of how a phase diagram is made (and what it really means). http://www.chemguide.co.uk/physical/phaseeqia/snpb.html Link to info Production Info Here is a (slightly) simplified equilibrium or phase diagram for Tin and Lead (Sn/Pb). Al Tin Commodity Prices, Precious Metals (Aug 2008) Name Quote Feed URL 822.00 $US/Troy Gold gold.txt oz 286.00 $US/Troy Palladium palladium.txt oz 1436.00 $US/Troy Platinum platinum.txt oz Silver 13.38 $US/Troy oz silver.txt Commodity Prices, Base Metals (Aug 2008) Name Quote Feed URL Aluminum 1.24 $US/lb aluminum.txt Copper 3.52 $US/lb copper.txt Lead 0.86 $US/lb lead.txt Molybdenum 33.25 $US/lb molybdenum.txt Nickel 9.38 $US/lb nickel.txt Uranium 64.50 $US/lb uranium.txt Zinc 0.81 $US/lb zinc.txt Get current prices here: http://dollardaze.org/feeds/ Assume we cool a liquid (molten) mixture containing about 67% lead and 33% tin by mass. This is what happens... ALLOYS An alloy is a solid solution or homogeneous mixture of two or more elements, at least one of which is a metal, which itself has metallic properties. Alloying one metal with others often enhances its properties, especially strength. The physical properties, such as density, reactivity, Young's There are lots of things to look at: Notice that nothing happens at all at the normal freezing point of the lead. Adding the tin to it lowers its freezing point. Page 1 of 5 Freezing starts for this mixture at about 250°C. You would start to get some solid lead formed - but no tin. At that point the rate of cooling slows down - the curve gets less steep. However, the graph doesn't go horizontal yet. Although energy is being given off as the lead turns to a solid, there isn't anything similar happening to the tin. That means that there isn't enough energy released to keep the temperature constant. The temperature does stop falling at 183°C. Now both tin and lead are freezing. Once everything has solidified, the temperature continues to fall. The special 62%Sn/38%Pb mixture cools like this... Fig 1. Uses of Copper, 2005 (Data from Brook Hunt, 2005) After iron and aluminium, copper is the third most commonly used metal. Most of the produced copper finds its way into electrical wire rod or copper tubes for plumbing. This particular mixture of lead and tin has a cooling curve which looks exactly like that of a pure substance rather than a mixture. There is just the single horizontal part of the graph where everything is freezing. However, it is still a mixture. If you use a microscope to look at the solid formed after freezing, you can see the individual crystals of tin and lead. This particular mixture is known as a eutectic mixture. The word "eutectic" comes from Greek and means "easily melted". The eutectic mixture has the lowest melting point (which is, of course, the same as the freezing point) of any mixture of lead and tin. The temperature at which the eutectic mixture freezes or melts is known as the eutectic temperature. Electrical Applications The primary use of copper is for electrical applications. Copper is the best non-precious conductor of electricity (only silver is superior) and sets the standard to which other conductors are compared. Compared to copper, aluminium has worse conductivity per unit volume, but better conductivity per unit weight. Gold is sometimes used to plate fine wire applications not because it is a better conductor, but because it is extremely resistant to surface corrosion. Copper is used in both insulated and non-insulated power cables for all regular voltage applications. While optical fibre has displaced copper over long-haul applications, the telecom industry still demands copper, as it is still the preferred carrier for the last segment. Additionally, it is used for domestic carrier lines, wide and local area networks and connectors. HDSL (High-Speed Digital Subscriber Line) and ADSL (Asymmetrical Digital Subscriber Line) technology allows existing copper to carry high-speed data up to 1 giga-byte per second. Copper is also starting to be used in the semiconductor industry instead of aluminium because it allows microprocessors to operate at higher speeds and reduces energy demand. COPPER Construction Applications Copper is one of the few metals that can be found in nature as an uncompounded metal (called native copper - i.e. not as rusty or corrroded ore). Copper became popular around 2500 B.C., and it hasn't slowed... Building construction accounts for more than 40% of all US copper consumption with residential construction accounting for two-thirds of that figure. The average 2,100 sq.ft. single-family home uses 439 pounds of copper, most of which is for wiring and plumbing. Copper is still the preferred metal for plumbing applications because it suppresses the growth of the Legionella bacteria, the microbe responsible for Legionnaire's disease. Transportation Applications Today's average automobile contains between 50 to 60 pounds of copper. A Boeing 747-400 contains nearly 9,000 pounds, representing about 2% of the plane's total weight. A typical diesel-electric railroad locomotive uses about 11,000 pounds of copper. The latest and most-powerful locomotives manufactured by General Electric Company and General Motors Corporation use more than 16,000 pounds. Page 2 of 5 Copper-nickel alloys are use for hulls of ships to reduce marine biofouling of mussels and barnacles. Zinc Production Known worldwide resource estimates for copper are estimated at 5.8 trillion pounds of which 0.7 trillion pounds (~12%) has been mined. Twothirds of that is accessible on land and the remainder is available as deepsea mineral rich nodules formed from undersea volcanic activity currently too expensive to retrieve. Global production of zinc has increased by 42% since 1995. Zinc metal output is forecasted to increase by 4.9% next year, but many industry experts expect a supply deficit.China is the world's largest producer, consumer and refiner of zinc by a large margin. Canada and Australia are important exporters of zinc. The largest consumer of zinc, China, accounts for 30% of global demand, nearly three times that of the next closest country, the United States. Chile is the world's copper king in terms of reserves, production and refining capacity. Zinc coating and galvanising are extremely toxic when welding. Welding zinc plated steel in enclosed area can kill in minutes. Copper's recycling rate is the highest out of any other engineering metal (around one-third of the US annual demand is recycled) From http://dollardaze.org/blog/?post_id=00044&cat_id=6 Global Resources and Production From http://dollardaze.org/blog/?post_id=00052&cat_id=20 ALUMINIUM ZINC Current prices for zinc are hovering around its all time nominal high of US$2.082 per pound. From its 2003 low of $0.34 per pound, zinc has climbed nearly 500% to a $2.062 per pound close on Nov 24, 2006. It takes a lot os electricity to smelt aluminium. Read this link: (Including all 12 pages linked on the side) http://sam.davyson.com/as/physics/aluminium/site/index.html This is occurring at a time when physical zinc stores at the London Metal Exchange (LME) have been dropping at a more or less steady pace since March 2004. For the last year zinc stocks at the LME have dropped over 80%. Zinc's many different applications rank it as the 4th most commonly used metal behind iron, aluminium and copper. http://www.lme.co.uk/aluminium_industryusage.asp SILVER Silver is both a precious metal and an important industrial metal. While nearly all of the 155,000 tonnes of gold that have ever been mined are still in the form of above-ground stocks, most of the silver has been consumed in industrial applications. Silver used to serve a monetary role alongside gold. It was more applicable for everyday goods and services due and subsequently was widely used by the general population. Only government, banks and the wealthy dealt in gold coin. Fig 2. Uses of Zinc for 2005 (Data from Brook Hunt, 2006) The largest use of zinc is for the galvanization of steel. Nearly 60% of the world's annual consumption of over nine million tonnes is used to protect about 100 million tonnes of steel. The second largest use of zinc is as for making brass alloys. The remaining zinc consumption is for making paint, chemicals, agricultural applications, household appliances and fittings, in the manufacture of electrical components, in the rubber industry, TV screens, fluorescent lights and for dry cell batteries. Silver has many properties that make it useful as an industrial metal: high strength, malleable, ductile, highest thermal and electrical conductivity of any metal, sensitivity and high reflectance to light, chemical stability (does not corrode), ability to endure extreme temperature ranges. Together, industrial, decorative and photography consume 95% of the annual silver supply. Page 3 of 5 Other Uses Superior power-to-weight batteries use silver oxides (both AgO and Ag2O) as the cathode silver-zinc primary and rechargeable batteries.Steel bearings are electroplated with high purity silver for greater fatigue strength, load-bearing capacity, and to significantly reduce friction.Silver is useful in dental alloys for fittings and fillings where it is alloyed with tin, copper and zinc.Many high-end musical instruments use silver for higher tone quality. NICKEL http://en.wikipedia.org/wiki/Nickel http://www.nickelinstitute.org/index.cfm/ci_id/13.htm Sterling silver (92.5% Ag, 7.5% Cu) is used in the manufacture of jewellery and silverware. The origin of the word "sterling" comes from the term "easterling" which referred to coins issued by the Hanseatic League, a group of trading cities in Northern Germany, which contained large proportions of silver. The British 'pound' originally had the value of one troy pound of sterling silver. It has since lost over 95% of its value. Electrical Applications Silver is the best electrical (and heat) conductor of all the metals and is used in conductors, switches, relays, circuit breakers, contacts and fuses. Printed circuits use silver paints, computer keyboards use silver electrical contacts, and silver is used in high voltage contacts because it can minimize arching due to carbon-polymer formation that occurs to other metals. In the home, wall switches, timing devices, thermostats, sump pumps, and virtually all electrical appliances use silver contacts. A typical washing machine requires 16 silver contacts to control its electric motor, pump, and gear clutch. A fully equipped automobile may have over 40 silvertipped switches to start the engine, activate power steering, brakes, windows, mirrors, locks, and other electrical accessories. Catalysts An estimated 700 tons of silver are in continuous use as catalysts in the plastics industry. Silver is the only known catalyst for forming ethylene oxide (an intermediate chemical for polyester) from ethylene gas. It also serves as a catalyst in oxidation reactions such as the formation of formaldehyde (the building block of solid plastics) from methanol and air. Nickel is used in many industrial and consumer products, including stainless steel, magnets, coinage, and special alloys. It is also used for plating and as a green tint in glass. Nickel is pre-eminently an alloy metal, and its chief use is in the nickel steels and nickel cast irons, of which there are innumerable varieties. It is also widely used for many other alloys, such as nickel brasses and bronzes, and alloys with copper, chromium, aluminium, lead, cobalt, silver, and gold. Nickel consumption can be summarized as: nickel steels (60%), nickelcopper alloys and nickel silver (14%), malleable nickel, nickel clad, Inconel and other Superalloys (9%), plating (6%), nickel cast irons (3%), heat and electric resistance alloys, such as Nichrome (3%), nickel brasses and bronzes (2%), others (3%). In the laboratory, nickel is frequently used as a catalyst for hydrogenation, most often using Raney nickel, a finely divided form of the metal. Nickel has also been often used in coins, or occasionally as a substitute for decorative silver. The American 'nickel' five-cent coin is 75% copper. The Canadian nickel minted at various periods between 192281 was 99.9% nickel, and was magnetic. Nickel(III) oxide is used as the cathode in many rechargeable batteries, including nickel-cadmium, nickel-iron and nickel-metal hydride, and used by certain manufacturers in Li-ion batteries. Light Reflection Silver's unique optical reflectivity, and its property of being virtually 100% reflective after polishing, allows it to be used both in mirrors and in coatings for glass, cellophane or metals. Low quality mirrors use aluminium backing. One out of every seven pairs of prescription eyeglasses sold in the U.S. incorporates silver. Silver halide crystals, melted into glass can change the light transmission from 96% to 22% in less than 60 seconds and block at least 97% of the sun's ultraviolet rays. Photography Silver nitrate made the first photograph in 1813 possible. Photosensitive chemicals silver chloride and silver bromide are prepared by adding sodium chloride or sodium bromide to a very pure solution of silver nitrate. While still a significant user of silver, film photography is in decline due to the advent of digital cameras Soldering and Brazing In 2005, 42.3 million ounces of silver were used for soldering and brazing. Silver is used as a superior solder than lead for air-conditioning and refrigeration equipment due to its greater ductility. Other uses include ceramic-to-ceramic joints and silicon chips to metallic surfaces. Silver-based alloys used in brazing (above 600°C) are suitable for nearly all steels and nonferrous metals except aluminium, magnesium, and titanium. Page 4 of 5 replaced in the early 20th century by the use of aluminium foil, which is now commonly referred to as tin foil. LEAD TIN http://en.wikipedia.org/wiki/Tin http://www.lme.co.uk/tin_industryusage.asp Tin, like copper, was one of the first metals mined and its excellent qualities and shiny finish made it a highly sought after commodity. Particularly liked for its fusion abilities in the making of alloys, notably bronze, and its non-toxic qualities, tin was soon traded in many parts of the world. Today it is still used in the production of bronze, pewter and die-casting alloys and, in modern engineering, to make tungsten more machineable. However, the largest uses for tin are for the production of solders and for tin plating (providing an attractive coating to iron and steel products). Tin bonds readily to iron, and has been used for coating lead or zinc and steel to prevent corrosion. Tin-plated steel containers are widely used for food preservation, and this forms a large part of the market for metallic tin (as in"tins" or "tin cans"). Some important tin alloys are bronze, bell metal, Babbitt metal, die casting alloy, pewter, phosphor bronze, soft solder, and White metal. The most important salt formed is stannous chloride, which has found use as a reducing agent and as a mordant in the calico printing process. Electrically conductive coatings are produced when tin salts are sprayed onto glass. These coatings have been used in panel lighting and in the production of frost-free windshields. Window glass is most often made via floating molten glass on top of molten tin (creating float glass) in order to make a flat surface (this is called the "Pilkington process"). Tin is also used in solders for joining pipes or electric circuits, in bearing alloys, in glass-making, and in a wide range of tin chemical applications. Although of higher melting point than a lead-tin alloy, the use of pure tin or tin alloyed with other metals in these applications is rapidly supplanting the use of the previously common lead–containing alloys in order to eliminate the problems of toxicity caused by lead. Tin foil was once a common wrapping material for foods and drugs; http://en.wikipedia.org/wiki/Lead Lead is a major constituent of the lead-acid battery used extensively as a car battery. A coloring element in ceramic glazes, notably in the colors red and yellow. Lead is used as projectiles for firearms and fishing sinkers because of its density, low cost compared to alternative products and ease of use due to relatively low melting point. Lead or "sheet-lead" is used as a sound deadening layer in such areas as wall, floor and ceiling design in sound studios where levels of airborne and mechanically produced sound are targeted for reduction or virtual elimination. Lead is used as shielding from radiation, e.g. in x-ray rooms. Molten lead is used as a coolant, eg. for lead cooled fast reactors. Lead glass is composed of 12-28% lead oxide. It changes the optical characteristics of the glass and reduces the transmission of radiation. Lead is the traditional base metal of organ pipes, mixed with varying amounts of tin to control the tone of the pipe. Lead is used as electrodes in the process of electrolysis. Lead is used in solder for electronics, although this usage is being phased out by some countries to reduce the amount of environmentally unfriendly waste. Lead is used in high voltage power cables as sheathing material to prevent water diffusion into insulation. Lead is used for the ballast keel of sailboats. Its high weight-to-volume ratio allows it to counterbalance the heeling effect of wind on the sails while at the same time occupying a small volume and thus offering the least underwater resistance. It does not have the weight-to-volume ratio of many heavy metals, but its low cost increases its use in these and other applications. Lead is added to brass to reduce machine tool wear. Lead has many uses in the construction industry, e.g. lead sheets are used as architectural metals in roofing material, cladding, flashings, gutters and gutter joints, and on roof parapets. Detailed lead mouldings are used as decorative motifs used to fix lead sheet. Lead is frequently used in scuba diving weight belts to counteract the diver's natural buoyancy and that of his equipment. Lead is often used to balance the wheels of a car; this use is being phased out in favor of other materials for environmental reasons. Lead is still widely used in statues and sculptures. Toxicity: Many lead containing products now banned/replaced. Leaded petrol, leaded paints etc. Lead has been commonly used for thousands of years because it is widespread, easy to extract and easy to work with. It is highly malleable and ductile as well as easy to smelt. In the early Bronze Age, lead was used with antimony and arsenic. (Lovely mixture..!) Lead is mentioned in the Book of Exodus (15:10). Industrial Lead consumption http://www.lme.co.uk/lead_industryusage.asp Page 5 of 5