Metal Scaffolding Training

advertisement

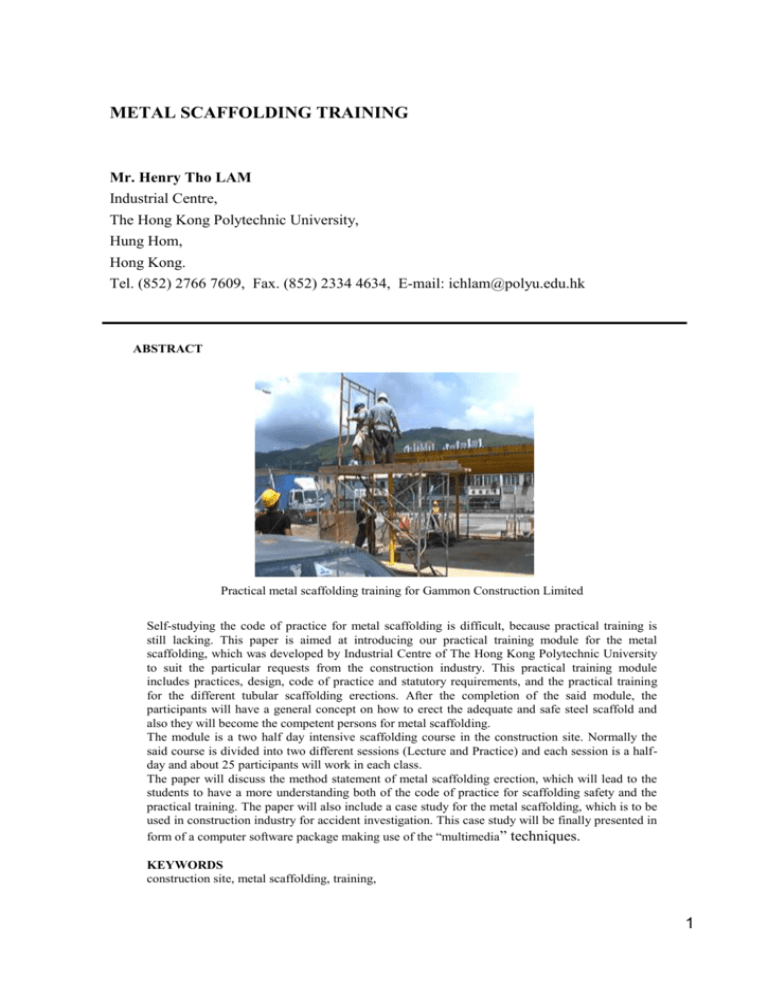

METAL SCAFFOLDING TRAINING Mr. Henry Tho LAM Industrial Centre, The Hong Kong Polytechnic University, Hung Hom, Hong Kong. Tel. (852) 2766 7609, Fax. (852) 2334 4634, E-mail: ichlam@polyu.edu.hk ABSTRACT Practical metal scaffolding training for Gammon Construction Limited Self-studying the code of practice for metal scaffolding is difficult, because practical training is still lacking. This paper is aimed at introducing our practical training module for the metal scaffolding, which was developed by Industrial Centre of The Hong Kong Polytechnic University to suit the particular requests from the construction industry. This practical training module includes practices, design, code of practice and statutory requirements, and the practical training for the different tubular scaffolding erections. After the completion of the said module, the participants will have a general concept on how to erect the adequate and safe steel scaffold and also they will become the competent persons for metal scaffolding. The module is a two half day intensive scaffolding course in the construction site. Normally the said course is divided into two different sessions (Lecture and Practice) and each session is a halfday and about 25 participants will work in each class. The paper will discuss the method statement of metal scaffolding erection, which will lead to the students to have a more understanding both of the code of practice for scaffolding safety and the practical training. The paper will also include a case study for the metal scaffolding, which is to be used in construction industry for accident investigation. This case study will be finally presented in form of a computer software package making use of the “multimedia” techniques. KEYWORDS construction site, metal scaffolding, training, 1 1. Introduction Safety is a basic human need. To be zero accident is a common goal that every body would like to see. However it is not easy to attain it and we still have much to work towards it. In fact, construction safety can be further developed and continually improved by providing adequate and practical training to the relevant workers of the contractors. This paper is aimed at not only introducing the relevant regulations and the code of practice for scaffolding safety, but also describing how the metal scaffolding training program was developed by the Industrial Centre of The Hong Kong Polytechnic University to meet such requirements and industry needs. In view of the current trend of Hong Kong construction industry, not only the safety regulations and codes of practice but also the practical training programs are necessary to enhance the degree of safety awareness. 2. The accident statistic from Hong Kong Labour Department The statistics made by Labour Department on the occupational injuries in all workplaces in 1998 (analyzed by major economic activity) indicate that construction industry has the highest injury accident figure (31%) and fatal accident (29%) as shown in Table 1. Major Economic Activity No. of % of Total of No. of % of Total of Injuries Injuries Deaths Deaths Agriculture and Fishing 100 0.2% 2 0.8% Mining and Quarrying 15 0.02% 1 0.4% Manufacturing 7689 12.1% 30 12.5% Electricity and Gas 93 0.1% 1 0.4% Construction 19674 31.0% 70 29.2% Wholesale & Retail Trades, Restaurants and Hotels 16855 26.5% 17 7.1% Transport & Related Services, Storage and 5587 8.8% 33 13.8% 3496 5.5% 47 19.5% Community, Social & Personal Services 9901 15.6% 39 16.3% Activities not adequately defined 116 0.2% 0 0% TOTAL 63526 100% 240 100% Communication Financing, Insurance, real Estate and Business Services Table 1 - Occupational Injuries in All Workplaces, 1998 As far as the type of accident in construction industry is concerned, it can be seen that most of the fatal accidents mainly came from fall of person from height (55%) and struck by falling object (16%) as shown in Fig. 1. Further analysis does show that fall of person is mainly caused by metal scaffolding work. The main reason for this is because there were lots of the contractors who did not provide proper training and safe working procedures to their employees. To prevent the said accidents, a practical training together with a safe system of work with written procedures and guidelines for the metal scaffolding operation, should be devised and implemented along side with the regulations. 2 Industrial Fatal Accidents in Construction Industry Analyzed by Type of Accident, 1998 ( ) = the figure in bracket denotes the number of deaths T rap p ed b y collap sing or overturning ob ject 7% (4) S truck b y falling ob ject 16% (9) S truck b y moving vehicle 5% (3) S triking against or struck b y moving ob ject 2% (1) C ontact with electricity or electric d ischarge 9% (5) T rap p ed in or b etween ob jects 4% (2) S triking against fixed or stationaey ob ject 2% (1) F all of p erson from height 55% (31) Fig. 1 - Fatal Accidents in Construction Industry 1998 This paper aims to take a closer look at the safety of metal scaffolding with respect to the existing regulations, code of practice and the relevant training programs. Moreover, the curriculum of the metal scaffolding training course developed by the Industrial Centre of The Hong Kong Polytechnic University will also be discussed. 3. Metal Scaffolding Regulations Part VA of Construction Site (Safety) Regulations (Chapter 59I) of the Factories and Industrial Undertakings Ordinance in Scaffolds, Working Platforms and Ladders etc. has been amended and enacted on 1st October 1999. The amended regulations identify the following issues: safety scaffolding inspection, boatswain's chairs (not power operated), interstice of metal platforms, and intermediate guard-rail To have a quick glance between the old and the amended regulations, a summary of their differences is shown in Table 2. 3 Old Regulation Amended Regulation 38K (1)(a)(i) Inspection of scaffolds 38F 1(a)(iv) Inspection of scaffolds The scaffold shall not be used on a construction site The scaffold has been inspected by a competent unless it has been inspected by a competent person person at regular intervals not exceeding 14 days within the immediately preceding month. immediately preceding each use of the scaffold. 38I (1)(a) Boatswain's chairs (not power operated) 38G Boatswain's chairs (not power operated) The boatswain’s chair or similar plant or equipment shall The contractor responsible for a construction site not be used unless it is of good construction, sound shall ensure that no boatswain’s chair or similar material, adequate strength and free from patent defect. plant or equipment is used on the site. 38L (a) Construction of working platforms, gangways, Third schedule - Requirements with which certain runs, etc, safety equipment must comply 2(2)(a) Every working platform, gangway or run from which a Working platforms, consisting of open metal work person is liable to fall a distance of more than 2 metres having interstices none of which exceeds 4000 shall be a platform consisting of open metal work having square mm in area. interstices none of which exceeds 3800 square mm in area. Code of Practice for Scaffolding Safety 1995 Third schedule - Requirements with which certain 5.3.2 (d)(vii) safety equipment must comply 6(b) Toe-boards and end toe-boards should be of such a The height of a guard-rail above any place of work height that the gap between the top of the toe-board and on a working platform, gangway, run or stairway the guardrail does not exceed 700 mm. shall be in case of an intermediate guard-rail, not less than 450 mm and not more than 600 mm. (not for bamboo scaffold) Table 2 - Comparison between the old and amended regulations of Construction Site (Safety) Regulations. 4. Metal Scaffolding Training Course Industrial Centre of The Hong Kong Polytechnic University developed the first course for construction industry in 1995. Since then, a total of twelve courses of about 300 participants (Site Agent, Engineer, Safety Officer, Safety Supervisor, General Foreman, Foreman and worker) has been conducted. The Course contents have been recently revised to meet the amended regulations. The metal scaffolding training course consists of two different sessions: Lecture and Practice. Each session is a half-day duration and can be conducted in the Centre's workshop or at the construction site. The practical session aims to back up the lecture part. In the lecture session, the participants will be taught with the concept of metal scaffolding as well as the relevant regulations, code of practice, design principles and safety measures. In the practical session, the participants will practice the job skill by erecting the metal scaffold including how and where to tie in the scaffold throughout the whole process. Figures 2 and 3 show the course participants attending the lecture session and undertaking the 4 skill training in the practical session respectively. A certificate in Metal Scaffolding Training will be issued to the trainees upon satisfactory completion of the course. Fig. 2 - Lecture Session Fig. 3 - Practical Training Session Moreover, the method statement and the safety measures of the metal scaffolding will be introduced to the participants as well, so that they can realize the importance of risk assessment before carrying out any work 5. Conclusion The accident rate concerning the scaffolding work in construction industry is very high. In this respect, the Labour Department has recently amended Part VA of the Construction Site (Safety) Regulations for the purpose of reducing accident occurrence and improving safety record. The authors believe the amended regulations can achieve the said purpose. To support the legislation, the Industrial Centre developed a metal scaffolding training course for construction industry in 1995, and since then a total of 12 training courses for 300 participants has been successfully completed. The method statement and the safety measures of the metal scaffolding are emphasized in the training course. It stresses on the importance of risk assessment, safe working procedures, job instruction and safety monitoring. By emphasizing the safety measures to the trainees, their concept and awareness can be enhanced, and thus safety at work can be achieved. 6. References 1) Anton, Thomas J., 1979, "Occupational Safety and Health Management", McGraw Hill Book Co., New York. 2) Hong Kong Government, 1999 "Regulation of Factories and Industrial Undertakings Ordinance (Cap 59I), Construction Sites (Safety) Regulations", Hong Kong Government. 5 3) Petersen, Dan, 1978, "Techniques of Safety Management", Second edition, McGraw Hill Book Co., New York. 6