Manufacturing Systems Review Assessment Checklist

advertisement

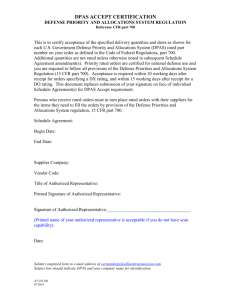

Kell Strom Tool Ref: FO 40-8000_14a00 Manufacturing Systems Review Assessment-Geographic Defense Contract Management Agency 130 Darlin Street East Hartford, CT 06108 860.291.7855 860.291.7855 Name Industrial Specialist Name Industrial Specialist Name Industrial Engineer Manufacturing Systems Review Assessment Checklist-Geographic Table of Contents Error! Reference source not found. Defense Priority Allocation System Chapters ..................................................................................................................................................3 Contract Review and Order Acceptance .............................................................................................................................................. 3 Requirements flow down..................................................................................................................................................................... 5 Delay Notification ................................................................................................................................................................................ 6 Preferential Scheduling ........................................................................................................................................................................ 7 Production Planning Chapters ...................................................................................................................................................................................... 8 Master Production Scheduling............................................................................................................................................................. 8 Rough Cut Capacity Planning ............................................................................................................................................................... 9 Material Requirements Planning ....................................................................................................................................................... 10 Capacity Requirements Planning ....................................................................................................................................................... 11 Shop Floor Control ............................................................................................................................................................................. 12 Summary ...................................................................................................................................................................................................................... 13 Glossary ....................................................................................................................................................................................................................... 17 1 Manufacturing Systems Review Assessment Checklist-Geographic Assessment Title: Contract Number: Assessment Number: Start Date: End Date: Location: Meeting Date: Assessor(s): Meeting Time: Contractor(s): Meeting Location: Continuous Improvement Opportunities: Program / Area Audited: RESULTS: 2 Manufacturing Systems Review Assessment Checklist-Geographic Defense Priority Allocation System Chapters Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. Contract Review and Order Acceptance - DPAS 1 Yes (Defense Priority Allocation System) contracts are reviewed and orders properly accepted. a. Do you have process for DPAS rated orders. Yes b. Do you know what the 15 CFR 700 is? No c. Have you been trained in DPAS? No 3 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic d. Do you have a CR&R process in place to insure all DPAS contracts/orders are identified? ? Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. e. Do you as a Company have a CR&R Checklist? ? f. Does it include checking for the FAR Clause 52.211-12 Defense Priority and Allocation Requirement Will Advise g. Are you familiar with the proper method of reviewing and accepting DPAS rated orders? Will Advise 4 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic No. Evaluation Criteria: System Adequacy Criteria: Comply Y/N Requirements flow down - DPAS requirements 2 are flowed down, both internally and externally, throughout the suppliers supply chain. a. Do you have a process of flowing down the DPAS 15 CFR 700 requirements to you sub-tier suppliers to include all outside process? b. How do you flow down the DPAS requirement to your sub-tier suppliers? Yes DFAS Rated clause on PO c. Does a statement in your purchase order read in substance: This is rated order certified for national defense use to follow all the provisions of the Defense Priority and Allocations System regulations (15 CFR 700) Yes 5 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic No. Evaluation Criteria: System Adequacy Criteria: Comply Y/N Delay Notification - Notification of delays on rated 3 Internal Process Document Finds / Action Item # or Evidence of Compliance Y orders, along with reason for delay, is provided in advance. a. Do you have a process to notify the Government when you are going to be delayed on a delivery in writing? Y b. Do you have any common processes for tracking deliverables and identifying if you are going to be late contract specific? Y c. What method is used to notify the customer in writing of the root cause of delay with an anticipated recovery date? Delay Notice d. Upon recognition of a delay, do you contact the PCO for a modification to extend the delivery date? Y 6 We notify DCMA and the PCO for date modification Manufacturing Systems Review Assessment Checklist-Geographic Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. 4 Preferential Scheduling - Preferential scheduling Internal Process Document Finds / Action Item # or Evidence of Compliance Y is used to ensure rated order scheduling over non-rated orders. a. Do you have a process to prioritize rated orders over un-rated orders? Y b. How do you identify rated vs. non-rated orders for scheduling purposes? We put this information on our in house open order reports c. Do you have a manufacturing plan in place to ensure rated orders are scheduled to the extent possible to ensure delivery by the required delivery date IAW 15 CFR 700.3 (c)? Y 7 Manufacturing Systems Review Assessment Checklist-Geographic Production Planning Chapters No. 5 Evaluation Criteria: Comply System Adequacy Criteria: Y/N Master Production Scheduling - Schedule for production by item, date, and quantity for the duration of the planning system is provided. a. Do you have a process for developing a master schedule for production by item, date due, and quantity required? Explain. b. Does the master schedule take into account all demands, including effective forecasting, contract delivery dates, customer orders, and frozen plan approvals? 8 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. 6 Rough Cut Capacity Planning - Capacity check of critical resources to ensure feasibility of the master production schedule. a. Do you have a process to perform a capacity check of critical resources to include materials requirements with long lead time items to ensure contract will meet the scheduled delivery times before accepting contract? b. When an order is accepted, do you ensure that all documentation is understood, material is available or will be available within the time stated in the manufacturing plan, and tooling required for processing an order are present? 9 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. Internal Process Document Finds / Action Item # or Evidence of Compliance Internal Process Finds / Action Item # or Evidence of Material Requirements Planning - Time phased 7 No. plans for all component parts, raw materials, subassembly and assembly activities required to produce all products on the master production schedule is determined. a. Do you have a time phased plan to ensure all component parts and raw materials, including sub-assemblies, are completed on time in order to meet delivery schedules? Evaluation Criteria: Comply 10 Manufacturing Systems Review Assessment Checklist-Geographic System Adequacy Criteria: 8 Y/N Capacity Requirements Planning - Capacity check of production plans generated from material requirements planning is provided. a. Do you perform a capacity check of material requirements including long lead time items to ensure contract will meet the scheduled delivery times before accepting contract? How is this accomplished? b. Do you perform a capacity check (manpower, tooling, machinery) of critical resources to ensure feasibility of a master production schedule) to meet contractually obligated delivery dates? How is this accomplished? 11 Document Compliance Manufacturing Systems Review Assessment Checklist-Geographic Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. Shop Floor Control - Documentation, material, and 9 tooling needed to process order are present. Orders are released as authorized by the material requirement plan. Priority control is exercised with respect to queues. Order performance is monitored and plans adjusted as necessary. a. Do you have processes in place for shop floor control? If so, what are they and how do they work? 1. Intent: Documentation, material, and tooling needed to process order are present. 2. Intent: Orders are released as authorized by the material requirement plan 3. Intent: Priority control is exercised with respect to queues. 4. Intent: Order performance is monitored and plans adjusted as necessary. 12 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic Evaluation Criteria: Comply System Adequacy Criteria: Y/N No. 10 Summary 13 Internal Process Document Finds / Action Item # or Evidence of Compliance Manufacturing Systems Review Assessment Checklist-Geographic Audit Meeting / Personnel Interviewed Close Out Meeting / Personnel Interviewed Findings are categorized as follows: Major Minor Observation A non-conformance that indicates a complete breakdown or absence of compliance. A non-conformance that indicates inconsistent compliance. A note documenting a recommendation for improvement or warning about potential non-compliances for which the internal audit team may have been unable to gather enough evidence to warrant a nonconformance. 14 Manufacturing Systems Review Assessment Checklist-Geographic Summary of Findings / Observations Description of Finding Number 1 No formal process documented for Solicitation or CR&R Review 2 Lack of communication a mongst departments – No database exists for effective parts tracking from other departments 3 Oracle entry process lacks written procedure# 4 Oracle currently used in lieu of formal ERP / MRP system 5 No Easy Identification of rated VS non-rated orders exist down to material managers/buyers 6 DPAS training not performed at contractor’s facility 7 Process for tracking deliver-ables by schedule and quantity extremely hard to follow 8 Increased IPT usage has led to many successful improvements 9 All demands are not taken into account or readily apparent in master production schedule 10 Production start dates not shown on Master Production Schedule 11 Contractor has no supplier risk rating system for sub tier suppliers 12 No documented process exists for frozen plan requirements 13 Capacity chart entry is not a documented process and a standard form 14 Lack communications from appropriate personnel concerning potential schedule delays not relayed to upper management/Government 15 Obs Min Maj Manufacturing Systems Review Assessment Checklist-Geographic Assessment Summary and Comments See Final Report Lead Auditor Date 16 Manufacturing Systems Review Assessment Checklist-Geographic Glossary Acronyms CFR Code of Federal Regulation CR&R Contract Receipt and Review DPAS Defense Priorities and Allocations System FAR Federal Acquisition Regulation IAW In Accordance With PCO Procurement Contracting Officer 17