11 Cost Planning and Performance p68-74

advertisement

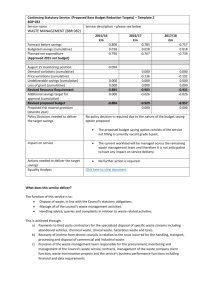

Unit 11 Cost Planning and Performance Why do Some Projects Overrun the Budgets? According to Arid Sigurdsen, a project management consultant in Norway who has more than 20 years of experience working with large development projects, poor cost control is what often puts a project in danger of exceeding the budget. Sigurdsen believes that we are still a long way to go before the largest pitfalls in cost control are removed. However, he offers the following insights into why these pitfalls occur: Many cost overruns stem from poor cost estimates. In many companies there is no standardization of rules for developing cost estimates and cost-control techniques, and neither is given much importance. Many people believe that because of the huge number of variables in a project, overruns are simple unavoidable —a devastating way of thinking, especially since it is not true. Project plans and controls often don’t take into account probabilistic measures. Project Cost Estimates It is during the development of the proposal by the contractor of project team that project costs are estimated. In some cases, the proposal will indicate only the total bottom-line cost for the proposed project. In other cases, the customer may request a detailed breakdown of various costs. The cost estimate may include the following elements: labor; materials; subcontractors and consultations; equipment and facilities rental; travel. In addition to the above terms, the contractor or project team may include an amount for contingencies, to cover unexpected situations that may come up during the project. It is good practice to have the person who will be responsible for the costs associated with the work make the cost estimates. This generates a commitment from the responsible person and prevents any bias that might result from having one person make all the cost estimates for the entire project. 68 Project Budgeting First, the project cost estimate is allocated to the various work packages in the project work breakdown structure. Second, the budget for each work package is distributed over the duration of the work package so that it’s possible to determine how much of its budget should have been spent at any point in time. There are two approaches to establishing the total budgeted cost, TBC, for each work package. One is top-down approach, in which total project budgets are reviewed in relation to the work scope for each work package. The other is a bottom-up approach, which is based on an estimate of the costs for the detailed activities associated with each work package. The project cost is usually estimated when the proposal for the project is prepared, but detailed plans are not usually prepared at that time. At the start of the project, however, detailed activities are defined and a network plan is developed. The TBC for each work package will be the sum of the costs of all the activities that make up that work package. Once a total cost has been established for each work package, the second step in the projecting process is to distribute each TBC over the duration of its work package. When the TBC for each work package is spread out by time period, it can be determined how much should have been spent at any point in time. This amount is calculated by adding up the budgeted costs for each time period up to that pointing time. This total amount, known as the cumulative budgeted cost (CBC), is the amount that was budgeted to accomplish the work that was scheduled to be performed up that point in time. The CBC is the baseline that will be used in analyzing the cost performance of the project. Determining the Actual Cost Once the project starts, it is necessary to keep track of actual cost and committed cost so that they can be compared to the CBC. To keep track of actual cost on a project, it is necessary to set up a system to collect, on a regular and timely basis, data on funds actually expended. In many projects, large dollar amounts are extended for materials or services that are used over a period of time longer than one cost reporting period. These committed costs need to be treated in a special way so that the system periodically assigns a portion of their total cost, rather than waiting until the materials ore services are finished to charge the total actual costs. 69 As data are collected on actual cost, including portions of any committed cost, they need to be totaled by work package so that they can be compared to the cumulative budgeted cost. For the packaging machine project, the following figure shows actual cost by time period for each work package through week 8. Also shown is the period-by-period actual cost for the entire project, as well as the cumulative actual cost (CAC). Actual Cost Period for the Packaging Machine Project (Amounts are in thousands of dollars) Period Week Element 1 2 3 4 5 Design 2 5 9 5 1 2 8 Build Total 6 7 8 Expended 22 10 14 12 Install & Test 46 0 Total 2 5 9 7 9 10 14 12 68 Cumulative 2 7 16 23 32 42 56 68 68 Determining the Value of Work Performed Earned value, the value of the work actually performed, is the key parameter that must be determined throughout the project. Comparing the cumulative actual cost to the cumulative budgeted cost tells only part of the story and can be wrong conclusions about the status of the project. The fact that half the budget was actually expended doesn’t necessary mean that half the work was performed. If the work performed isn’t keeping up with the actual cost, there is trouble, even if the actual cost is in line with the CBC. Determining the earned value involves collecting data on the percent complete for each work package and then converting this percentage to a dollar amount by multiplying the TBC of the work package by the percentage completed. The following table explains the cumulative percent completed by period with the Packaging Machine Project. In the table, we can see that design was 100 percent completed within 5 weeks, and build was 50 percent completed at the 8th week, and however, install and test have no work performance within 8 weeks. 70 Cumulative Percent Complete by period for the Packaging Machine Project (Amounts are cumulative percentages complete) Period Week Element 1 2 3 4 Design 10 25 80 90 100 100 100 100 Build 0 0 0 5 15 40 50 Install & Test 0 0 0 0 0 0 5 6 7 25 0 0 8 At the same time, the cumulative earned value (CEV) is also of great importance. In the following table, CEV is shown for each work package for the Packaging Machine Project. Cumulative Earned Value by period for the Packaging Machine Project (Amounts are in thousands of dollars) Period Week Element TBC 1 2 Design 24 2.4 6 Build 60 Install & Test 16 Cumulative 100 3 4 19.2 21.6 3 2.4 6 19.2 24.6 5 6 7 8 24 24 24 24 9 15 24 30 33 39 48 54 Cost Performance Analysis The following four cost-related measures are used to analyze project cost performance: TBC (total budget cost), CBC (cumulative budgeted cost), CAC (cumulative actual cost), CEV (cumulative earned value). They are used to determine whether the project is being performed within budget and whether the value of the work performed is in line with the actual cost. In analyzing the tables for the packaging machine project at the end of week 8, we see that $64,000 was budgeted through the end of the week 8 to perform all the work scheduled to be performed during the first 8 weeks. $68,000 was actually expended by the end of week 8. $54,000 was earned value of work actually performed by the end of week 8. 71 A quick analysis indicates that the actual cost is exceeding the budgeted cost. Aggravating the situation further is the fact that the value of the work performed isn’t keeping up with the actual cost. Cost Performance Index Another indicator of cost performance is the cost performance index (CPI), which is a measure of the cost efficiency with which the project is being performed. The formula for determining the CPI is CEV CPI = CAC In the packaging machine project, the CPI as of week 8 is given by CPI =$54,000/$68,000 =0.79 This ratio indicates that for every $1.00 actually expended, only $0.79 of earned value was received. Trend in the CPI should be watched carefully. When the CPI foes below 1.0 or gradually gets smaller, corrective action should be taken. Cost Variance Another indicator of cost performance is cost variance (CV), which is the difference between the cumulative earned value of the work performed and the cumulative actual cost. The formula for determining the cost variance is CV =CEV – CAC Like the CPI, this indicator shows the gap between the value of the work performed and the actual cost, but the CV is expressed in terms of dollars. In our project, the cost variance of week 8 is given by CV = $54,000 – $68,000 = –$14,000 This calculation indicates that the value of the work performed through week 8 is $14,000 less than the amount actually expended. It is another indication that the work performed is not keeping pace with the actual cost. 72 Cost Forecasting Based on analysis of actual cost performance throughout the project, it is possible to forecast what the total costs will be at the completion of the project or work package. There are three different methods for determining the forecast cost at completion (FCAC). The first method assumes that the work to be performed on the remaining portion of the project or work package will be done at the same rate of efficiency as the work performed so far. The formula for calculating the FCAC using the first method is TBC FCAC = CPI For the packaging machine project, the forecasted cost at completion is given by FCAC =$100,000/0.79 =$126,582 A second method for determining the forecasted cost at completion assumes that, regardless of the efficiency rate the project has experienced in the past, the work to be performed on the remaining portion of the project will be done according to the budget. The formula for calculating the FCAC using this method is FCAC = CAC + (TBC –CEV) For the packaging machine project, the forecasted cost at completion is given by FCAC = $68,000 + ($100,000 – $54,000) = $114,000 A third method for determining the forecasted cost at completion is to re-estimate the costs for all the remaining work to be performed and then add this re-estimate to the cumulative actual cost. The formula for determining the FCAC using this third method is FCAC = CAC + Re-estimate of remaining work to be performed This approach can be time consuming, but it may be necessary if the project experiences persistent deviations from the plan of if there are extensive changes. Cost Control The key to effective cost control is to analyze cost performance on a regular and timely basis. It is crucial that cost variances and inefficiencies be identified early so that corrective action can be taken before the situation gets worse. Once project costs get out of control, it may be very difficult to complete the project within budget. Cost control involves the following: 73 Analyzing cost performance to determine which work packages may require corrective action. Deciding what specific corrective action should be taken. Revising the project plan –including time and cost estimates –to incorporate the planned corrective action. When evaluating work package that have a negative cost variance, you should focus on taking corrective action to reduce the costs of two types of activities: Activities that will be performed in the near term. Don’t plan to reduce the costs of activities that are scheduled sometime in the distant future. You will get more timely feedback on the effects of corrective actions if they are done in the near term. As the project progresses, less and less time remains in which corrective actions can be taken. Activities that have a large cost estimate. Taking corrective measures that reduce the cost of a $20,000 activity by 10 percent will have a larger impact than totally eliminating a $300 activity. Usually, the larger the estimated cost for a activity, the greater the opportunity for a large cost reduction. There are various ways to reduce the costs of activities. One way is to substitute less expensive materials that meet the required specifications. May be another supplier can be found who can supply the same material but at a lower cost. Another approach is to assign a person with greater expertise or more experience to perform or help with the activity so as to get it done more efficiently. Reducing the scope or requirements for the work package or specific activities is another way to reduce cost. For example, a contractor might decide to put only one coat of paint on a room rather than two coats, as originally planned. Increasing productivity through improved methods or technology is yet another approach to reduce cost. For example, by renting automatic paint spraying equipment, a contractor may substantially reduce the cost and time of painting a room. Reference Jack Gido; James P. Clements: Successful Project Management, South-Western College Publishing, A Division of Thompson Learning, 1999; 机械工业出版社 2002 年。 74