- Paradip Port

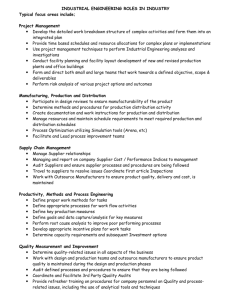

advertisement