guide

advertisement

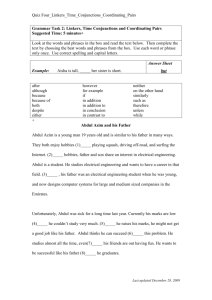

Prepared by P T. Abdul Sakkur B. Tech. Mechanical Engineering MBA Utility Qatar Steel Company Ltd 2 Useful Guideline on Water Preface My career with the process cooling system in QASCO inspired me to begin with a concentrated study on water. The study notes when put altogether in an Ms. Word file ended with a useful guide to both the beginners and the professionals. Here are discussed many factors related to water, such as water physics, water chemistry, water treatment, R O System, water supply engineering, System Designing and analytical method to maintain the Quality. Some relevant data are put in tables. So a collection of knowledge on a single topic is available at a place. A number of References of famous authors on Mechanical and Chemical Engineering are utilized to prepare this Guide. The authors’ efforts are gratefully acknowledged. You may find some unfamiliar notations in some of the equations, like those in the blow down quantity of water. In fact, such equations are derived by myself as I could not find any materials on this regard when I was essential such relations. I am grateful to Mr. C. Imthiyas, M. Sc. Chemistry, PhD (Undergoing) on advising and clarifying the matters related to water chemistry. QASCO is blessed with his presence as a chemist in its QA/QC laboratory. As he has exposure on industrial, teaching and research, his advice, no doubt is worth. Further suggestions will be greatly appreciated. With Regards and Thanks P T Abdul Sakkur B Tech. Mechanical Engineering MBA QASCO, Utility Date: 23.11.2006 Prepared: Abdul Sakkur P T 3 Useful Guideline on Water WATER Planetary significance Water constitutes one third part of the earth. In terms of number and variety of organisms, water is the first to mention. Water is one of the most important substances in human life. It makes up over 65% of the human body. It is said that the human body is the replica of the earth where blood and the body fluids take the part of water. It is no surprising if one accepts the premise that life emerged from water. All forms of life, even in the desert, require a reliable intake of water and most of the nutritional and excretory functions are water based. Some organism such as jellyfish is about 98% water, while trees may be only about 50% water. It is the most abundant and universal solvent. Water as oxygen provider For plants, water is required along with carbon dioxide in photosynthesis. Oxygen is liberated during this process. The process can be approximately represented by the equation: CO2 + 2H2O* h 1/n (CH2O) n + H2O + O2* The Oxygen molecule (O2) in the product side comes from water, not from carbon dioxide. It is experimentally proved through radio active labeling (*) studies. Another way for the natural production of oxygen is photodecomposition of water in the atmosphere under the influence of ultraviolet radiation from the sun, according to the formula; 2H2O h 2H2 + 2O 2H2 + O2 Water as steadying media of climate: Water has capacity to absorb large quantities of heat and the reverse, with small change in temperature owing to the high heat capacity and high latent heat of fusion and vaporization. Water has the highest heat capacity of all liquids and solids, except NH3. Water as both acid and base Water can function as both acids and bases. Such compounds are called Amphoteric or ampheprotic compounds. See the reactions: HCl (aq) + H2O (l) H3O+(aq) + Cl-(aq) acid base acid base NH3 (aq) + H2O(l) NH4+(aq) + OH-(aq) base acid acid base Prepared: Abdul Sakkur P T 4 Useful Guideline on Water Water as Energy Source The energy of flowing water can be converted to electric energy by means of Turbines, which is commonly termed as ‘hydro’ power. The imparted energy to the impeller rotates the shaft connected with it kept in between two opposite poles of magnetic field causes to generate an electric flux. It can be taken out as useful energy. Moving water Hydro Turbine Work Output Shaft Electric energy Generator WATER PHYSICS Water is colorless, it freely occurs in all the three phases of matter. The melting point of water is 273K and boiling point is 373K. (1oC =273K) It means that it has a convenient liquid range at these two temperature ranges. Water contains two hydrogen atoms and an oxygen atom (H2O). Due to higher electro negativity, oxygen atom attracts the bonding electrons towards itself. So it acquires a partial negative charge and, the hydrogen atom a partial positive charge. On account of this, water molecule becomes polar. The positively charged hydrogen atom attracts the negatively charged oxygen atom of a second molecule by electrostatic force of attraction. The attractive force which binds hydrogen of one molecule with a highly electronegative atom of another or different part of the same substance is known as hydrogen bonding. A number of water molecules associate together to form a larger cluster of molecules (H2O) n. As it is clear in the picture, in water the hydrogen atom is attached to two oxygen atoms, one through covalent bond and the other through the hydrogen bond. A number of water properties are explained on the basis of hydrogen bonding. Example is the lighter density of ice. In ice, each oxygen atom is surrounded by four other oxygen atoms located at the corners of a regular tetrahedron. There is one hydrogen atom between any two oxygen atoms; vacant spaces are created and as a result the volume of ice gets increased than water, and so the density gets decreased. Prepared: Abdul Sakkur P T 5 Useful Guideline on Water When ice melts, the hydrogen bonds start to break and the tetrahedral structure starts to destroy. The molecules are packed closely together to cause a greater density at its melting point (273K). As the temperature rises above 273K, a gradual increase in density occurs since the increase in kinetic energy of the molecules breaks down more hydrogen bonds. Upto 277K, this effect is more significant, and so the maximum density of water is at 4 0C. Further, the increasing vibration of molecules becomes significant and overcomes the compacting effect due to breaking of hydrogen bonds. Physical Property of water specific heat capacity of water (20oC) surface tension (20oC) Heat of fusion (0oC) Heat of vaporization Heat conductivity (at 20oC) 4.18JK-1g-1 72.8 x 10-3 Jm-2 0.333kJg-1 2.257kJg-1 59.8Js-1m-2 Pascal’s Law When a certain pressure is applied at any point on a fluid in a closed vessel at rest, the pressure is equally transmitted in all the directions and to every other point in the fluid. Principle of flotation The weight of a body floating in a fluid is equal to the buoyant force which in turn is equal to the weight of the fluid displaced by the body. Capillarity of water Weight of the water column in the tube above the water surface acting downwards = hd2 4 Vertical component of the force of surface tension = dcos Equating these two equations dcos = hd2 4 The capillarity rise, h = 4cos d specific weight a = angle of contact of water surface Prepared: Abdul Sakkur P T 6 Useful Guideline on Water Bernoulli’s Theorm If a fluid flows at a constant rate through a pipe, it pressure will be constant unless the diameter changes. When the diameter reduces, fluid velocity increases, the fluid pressure reduces. The height to which the fluid rises in each vertical pipe is proportional to the fluid pressure in the main pipe. The figure illustrates the theorm neglecting the frictional loss. CHEMISTRY OF WATER The basic equation of formation of water, as all know, is given below. H2 + O2 H2O On studying the stoichiometry of the reaction, since an atom of oxygen disappears, a balanced equation is formed. 2H2 + O2 2H2O It means that, for every mole of molecular water to form one mole of hydrogen undergoes reaction with half a mole of oxygen. (H2 + ½O2 H2O) The atomic number of central oxygen is 8 and its electronic configuration is 1s2, 2s2, 2px2, 2py1, 2pz1. The oxygen in water is sp3 hybridized. Out of the four hybridized orbitals, two form bonds with 1s orbitals of hydrogen atoms. The electron present in the other two hybrid orbitals are not involved in the bond formation. They constitute two lone pairs. The structure of H2O molecule is a bent triatomic, with the H-O-H angle of and the two interatomic O-H distances the same, 0.096 nm. The bond energy for these covalent O-H bonds is 463kJ 104.5o, Prepared: Abdul Sakkur P T 7 Useful Guideline on Water CHARACTERISTICS OF WATER COMPOSITION Common Impurities in Water are as follows 1) Suspended impurities 2) Dissolved impurities 3) Colloidal impurities According to O.A. Alekin, the chemical composition of natural waters, which is understood as a complex of mineral and organic substances present in various forms of ionic, molecular or colloidal state, may be thought to consist of five principal groups: 1. Main ions which are present in appreciable concentrations (Na+, K+, Ca2+, Mg2+, SO42-, CO32-, Cl-, HCO3) 2. Dissolved gases (N2, O2, CO2, H2S) 3. Biogenic elements (compounds of phosphorus, nitrogen and silicon) 4. Microelements (compounds of all other chemical elements) 5. Organic substances. Suspended matter in water may contain particles of different size; from colloidal to coarse disperse as may be seen in the following table. Suspended matter in water Suspended matter Colloidal particles Grain size, mm 2x10-4 -- 1x10-6 Fall velocity mm/s 7x10-6 Time of settling to depth of 1m 4years Fine clay 1x10-3 -- 5x10-4 7x10-4 -- 17x10-5 0.5 – 2 months Clay 27x10-4 5x10-3 2 days Fine sludge 1x10-2 -- 5x10-3 7x10-2 -- 17x10-3 4-18 h Sludge 5x10-2 -- 27x10-3 1.7—0.5 10-30 min Fine sand 0.1 7 2.5 min Medium sand 0.5 50 20 s Coarse sand 1.0 100 10 s L.A.kulsky has proposed to classify water impurities by their phase state and dispersity. Accordingly all water impurities can be divided into four groups. The property and the quality of water is determined by the concentrations of particular impurities the quality of water can be determined in terms of physical indices (temperature, suspended matter, coloration, odour, flavor), chemical (hardness, alkalinity, oxidation susceptibility, dry residue), biological (hydrobionts), and bacteriological (total concentration of bacteria, Coli index) Prepared: Abdul Sakkur P T 8 Useful Guideline on Water pH value pH is a term used to express the intensity of the acid or alkaline condition of a solution. Even if no acid or base is added, there is some hydronium (H3O+) and hydroxyl (OH-) present in pure water. Some of the water molecules react with each other, one molecule of water acting as an acid, another as a base, to produce the ions. H2O(l) + H2O(l) H3O+(aq) + (OH-)(aq) ACID BASE ACID BASE The equilibrium constant for this reaction is, With our usual convension, K = [H3O+][OH-] [H2O] 2 [H2O] = 1 K[H2O]2 = KW = [H3O+][OH-] The ionic product of water at 298K is given by, kW = 1.0x10-14mol2/l2 For pure water, [H3O+] = [OH-] = 1x10-7 mol/l pH value of a liquid is the negative logarithm of the concentration of hydronium (H3O+) ions. pH value = -log [H3O+] ] From the above definition, it is clear that the pH value of the neutral water = 7 There fore, if the pH value > 7, water has alkaline quality. Since acidic water has more tendency to react with metals, it is recommended to keep the pH value of circulating water more than 7. pH meter pH value can be directly measured using pH meter. pH meter comprised with a glass electrode with a saturated potassium chloride-calomel reference electrode. A glass electrode in contact with H+ in solution measures the pH potentiometrically against calomel electrode as reference. The potential difference between glass electrode and calomel electrode is expressed as pH. Total Dissolved Solids (TDS) It denotes the various types of minerals present in water in the dissolved form. In natural waters, dissolved solids are composed of mainly carbonates, bicarbonates, chlorides, sulphate, phosphate, silica, calcium, magnesium, sodium, and potassium. Prepared: Abdul Sakkur P T 9 Useful Guideline on Water Hardness Hardness is caused by the presence of the salts of calcium and magnesium. Mg2+). Hard water possesses problems when used in industrial cooling purposes because it causes chocking and clogging troubles of plumbing due to precipitation of salts causing hardness, and formation of scales on the hot water systems which affects the heat transfer efficiency. (Ca2+, Classification of hardness Classification 1. Soft 2. Moderately hard 3. Hard 4. Very Hard Total hardness as mg/l of CaCO3 50 50-150 150-300 300 Hardness is usually expressed in terms of the dissolved calcium and magnesium salts calculated as calcium carbonate equivalent. It can be divided into two classes temporary and permanent. The temporary hardness is caused by the presence of dissolved bicarbonates. It can be reduced by heating or by the addition of a calculated amount of lime whereupon Mg/Ca carbonate is precipitated. Reaction on heating Heating Ca (HCO3)2 → Mg (HCO3)2 → Bicarbonate hardness CaCO3 + CO2 + H2O MgCO3 + CO2 + H2O Ca/Mg carbonate get precipitated Reaction on addition of lime Ca (HCO3)2 + Ca(OH)2 → 2CaCO3 + 2H2O Mg (HCO3)2 + Ca(OH)2 → MgCO3 + CaCO3 + 2H2O Bicarbonate hardness Ca/Mg carbonate get precipitated The Ca/Mg Carbonate so formed can be removed in the sedimentation tanks since these are insoluble in water. Hardness Compound Causing temporary hardness 1.Calcium bicarbonate Ca(HCO3)2 2. magnesium bicarbonate Mg(HCO3)2 Causing Permanent hardness 1. Calcium Sulfate (CaSO4) 2. Magnesium Sulfate(MgSO4) 3. Calcium Chloride (CaCl2) 4. Magnesium Chloride( MgCl2) Prepared: Abdul Sakkur P T 10 Useful Guideline on Water Removal of Permanent hardness The permanent hardness is due to the presence of sulfates and chlorides of calcium and magnesium. It can be removed by one of the following methods. 1. Lime-soda process 2. Zeolite process 3. Demineralization or de-ionization process. 1. Lime-soda process This process is commonly known as Clark’s’ system. The addition of lime [Ca(OH) 2] and soda ash (Na2CO3) into the raw water is known as lime soda process. Both the temporary and permanent hardness can be removed by this method. The process involves the thorough mixing of the chemicals with water, followed by slow agitation for 30 to 60 min. to allow completion of chemical reaction. Precipitated cahemicals are removed by sedimentation or filtration or both. In the following process indicates the precipitation. CO2 + Ca(OH)2 CaCO3 + H2O Ca(HCO3)2 + Ca(OH)2 2CaCO3 + 2H2O Mg(HCO3)2 + Ca(OH)2 CaCO3 + MgCO3 2H2O MgCO3+ Ca(OH)2 Mg(OH)2 + CaCO3 MgSO4 + Ca(OH)2 Mg(OH)2 + CaSO4 CaSO4 + Na2CO3 CaCO3 + Na2SO4 CaCl2 + Na2CO3 CaCO3 + 2NaCl MgCl2 + Na2CO3 Mg(OH)2 + CaCl2 Summary of Chemical used Type of hardness Chemical required CaCO3 alkalinity (as bicarbonate) Lime Ca(HCO3)2 Lime Ma(HCO3)2 Lime (2 units) MgSO4 (i) Lime, (ii) Soda ash CaSO4 Soda ash CaCl2 Soda ash MgCl2 (i) Lime (ii) Soda ash This method is essentially a precipitation method of water softening. A lot of arrangements are required to get out of the product water. So, in industrial cooling purposes it is not used. Prepared: Abdul Sakkur P T 11 Useful Guideline on Water 2. Zeolite process – water softening Removal of dissolved salts of calcium and magnesium is called water softening. Water softeners containing zeolite are used for the industrial purposes. The zeolites exchange the positively charged sodium cations (Na+) for the cations of calcium (Ca+) and magnesium (Mg+). So softening is essentially a cation-exchange process and the process is also known as Base Exchange or ion-exchange process. It is most commonly used for the softening of water for industrial purposes. The zeolites are complex compound of aluminium, silica, and soda. Some forms of which are synthetic and others are naturally occurring. Natural zeolites are mainly processed from Green Sand. (Glauconite). It is green in colour and has an exchange value of 6500 to 9000gm of hardness per m 3. The common artificial zeolite is permutit. It has larger grains and has high exchange value of 35000 to 40000gm of hardness per m 3. Its chemical formula is SiO2Al2O3Na2O. Since it absorbs moisture from atmosphere it should be stored in a dry place. When hard water passes through a bed of permutit, the following reactions take place: 2SiO2Al2O3Na2O + Ca(HCO3)2 2SiO2Al2O3CaO + 2NaHCO3 2SiO2Al2O3Na2O + CaSO4 → 2SiO2Al2O3CaO + Na2SO4 2SiO2Al2O3Na2O + CaCl2 → 2SiO2Al2O3CaO + 2 NaCl Considering the permutit resin as an activated ion, ‘A’, the above process can be rewritten as follows: CaCl2 MgCl2 + + Non-Carbonate hardness → → + + Na2 . A. Na2 . A. Ca . A Mg . A + + 2 NaCl 2 NaCl Sodium hydrogen carbonate (remains in soft water) Exhausted ion exchange resin Active ion exchange resin Carbonate hardness Ca SO4 Mg SO4 Na2. A Na2 . A → → Active ion exchange resin Ca . A Mg . A + + Na2SO4 Na2SO4 Sodium sulphite carbonate (remains in soft water) Exhausted ion exchange resin Where, ‘A’ stands in place of SiO2Al2O3Na2O Regeneration of softeners Due to continuous use of zeolite, the sodium present in it is exhausted. At this stage, zeolite is regenerated by passing brine solution (Aqueous NaCl) through it. The sodium in the brine replaces the calcium and magnesium in the exhausted zeolite. The following reactions take place during regeneration: 2SiO2Al2O3CaO + 2NaCl → 2SiO2Al2O3Na2O + CaCl2 2SiO2Al2O3MgO + 2NaCl → 2SiO2Al2O3Na2O + MgCl2 Prepared: Abdul Sakkur P T 12 Useful Guideline on Water Steps in regeneration 1. Backwashing: It loosens the resin bed and removes the debris and suspended solids 2. Brine injection: This is the actual regeneration stage where the ion replacement as takes place. 3. Slow/rapid rinse: It rinses away the residual brine and calcium/magnesium salts removed from the resin. Notes: 1. The process is unsuitable for acidic water which irreversibly substitutes hydrogen for sodium in the zeolite. The acidic water may aggressively attack the zeolite by the dissolving alumina or silica from it. 2. The process is not suitable for water containing iron and manganese. Iron or manganese bearing water either deposit hydroxides on the surface of zeolite or irreversibly react with the zeolite. 3. There is likelihood of growth of bacteria on the bed of zeolite. It should therefore be flushed annually with chlorinated water. 3. Demineralization or de-ionization process. In this process both anionic and cationic exchanges are taking place. A typical ion exchange plant comprises two groups of ion exchange softeners one of them operates by the cycle of H-cations from water and the other removes the anions. The regeneration is made by H2SO4 (concentration 2-4%) of HCl (conc. 3-5%) on the cationic exchanger and NaOH (conc. 2-4%) on the anionic exchanger) Cations Anions () Na+, K+, Ca2+, Fe3+ SO42-, Cl-, Prepared: Abdul Sakkur P T 13 Useful Guideline on Water 1. Cationic Exchanger: The cationic resin takes 4 calcium ions (Ca++) and gives out 4 hydrogen ions (H+). Pictorially it can be shown as given below: Before Normal usage After Cationic Resin Cationic Resin H+ ClClClCl- Ca++ Ca++ Ca++ Ca++ H+ semi demi water Ca++ H+ Ca++ H+ H+ H+ H+ H+ Ca++ Ca++ ClClClCl- Regeneration of Cationic exchanger is shown below: HCl H+ + ClH2SO4 2H+ + SO42- cationic resin cationic resin H+ Ca++ Ca++ Ca++ + HCl H+ H+ + Cacl2 H+ Ca++ 2. Anionic Exchanger: The cationic resin takes 4 chlorine ions (Cl-) and gives out 4 hydroxyl ions (OH-). Pictorially it can be shown as given below: Before Normal usage H+ H+ H+ H+ ClClClCl- After anionic resin anionic Resin OH- ClOH- OHOH- Cl- ClCl- semi demi water H+ H+ H+ H+ OHOHOHOH- Prepared: Abdul Sakkur P T 14 Useful Guideline on Water Regeneration of anionic exchanger is shown below: NaOH Na+ +OH- ( - ) anionic resin OH- ClCl- Cl- + NaOH OH- OH- + NaCl OH- ClElectrical Conductivity (E C) It is a term in electrochemistry. When a voltage is applied to electrodes immersed into an electrolyte solution, ions of electrolyte move and the electric current thus flows through the electrolytic solution obeying the Ohm’s law. The reciprocal of resistance is called conductance and its unit is siemens (ie.1S = -1). Conductivity is the reciprocal of resistivity (). The usual symbol of conductivity is (kappa) and its unit is -1cm-1 or Scm-1. Very pure water has a conductivity of 6.0 x 10-5 Scm-1. The conductivity of water increases with temperature. The temperature dependence of conductivity reflects the speed of the ions as well as degree of dissociation and an abnormal transport mechanism. It can be measured directly by conductivity meter. An empirical relation exists between Specific Conductance and TDS. The conversion factor is given in the table: Multiplication Factors between TDS and Electric Conductance 1 2 3 4 TDS 0 - 700 Conductance 0.55 700 - 1200 1200 – 2000 Above 2000 0.6 0.65 0.70 Alkalinity Alkalinity is determined as the sum of the hydroxyl ions and anions of weak acids. It results from the presence of the hydroxides [OH-], carbonates [CO32+] and bicarbonates [HCO3-] of elements such as calcium, magnesium, sodium, potassium and ammonia. Of these, calcium and magnesium bicarbonates are most common. Borates, silicates, phosphates, and similar compounds can also contribute to the alkalinity. It is distinguished between bicarbonates, carbonate and hydrate alkalinity. Their values can be found by reference to nomograms. Their sum makes what is called the total Alkalinity. Alkalinity is the capacity of a system to neutralize acid. The alkalinity in water helps to resist changes in pH. The components of Alkalinity that can form during water treatment are given below Prepared: Abdul Sakkur P T 15 Useful Guideline on Water Method of water treatment Components in total alkalinity Lime treatment Lime treatment followed by Na-cation exchange softening Na-cation exchange softening CaCO3, Ca(OH)2, Ca(HCO3)2 Na2CO3, CaCO3, NaOH, Ca(OH)2 NaHCO3 The general method for measuring alkalinity is the potentiometric titration technique. This method involves continuously adding volumes of acid with a certain concentration to a water sample until the pH of the water reaches a specified endpoint. "Potentiometric" refers to the use of a pH meter to identify when the desired pH has been reached. The amount of acid added is converted to equivalent mg CaCO3/L and reported along with the titrated pH endpoint. CORROSION Corrosion is the deterioration of a material as a result of an unintentional chemical or electrochemical reaction that occurs between the environment and the surface of the material in question. The basic cause of corrosion of metals is their inherent instability in their refined forms. Thus corrosion can be regarded as the tendency of metals to go back to their more stable chemical forms such as oxides and sulphides in which they occur in nature. In water pipelines, the direct corrosion is taking place. It is a chemical attack as a result of chemical reaction between the pipe inner surface and the water of acidic nature. The chemical attack will be uniform and continuous at an almost constant rate that can be measured in standard units, e.g., milligrams per square decimeter per day (mdd) and mills (1/1000”) per year (mpy). One means of controlling the direct corrosion is the addition of certain inhibiting chemicals into corrosive solution. They act as barriers between the metal involved and the environment. Mechanism of Corrosion A metal in contact with an aqueous solution functions as an electrode. The potential of this electrode is a measure of the tendency of the metal to act as an anode and become oxidized when coupled with some other material or with localized portions of the same metal which can act as cathodes. The anodic or corrosive half reaction can be represented as Ml → Ml2++ 2e Where, Ml is metal corroded. The e.m.f of the galvanic corrosion cell formed is given by; Ecell = cathode-anode Prepared: Abdul Sakkur P T 16 Useful Guideline on Water This gives a driving force behind the process under equilibrium conditions. The values of in the above expression for both anode and cathode are considered as reduction potentials which explain the negative sign for anode. Cooling water systems provide an ideal environment for corrosion of the material of supply pipe and equipment, by which the metal returns to its natural state. Water acts as a galvanic corrosion cell unit in which one part of the system acts as an anode and becomes corroded, while another part of the system functions as a cathode. The rate of corrosion is proportional to the current density and this in turn is proportional to the cell potential. Metal ions dissolve into water (electrolyte) at anode and electrically charged particles are left behind. These electrons flow through the metal to other points (cathode) where electron consuming reactions occur. As a result of this, metal losses and often deposit forms. The half reactions of the unit are partially shown below: Anodic reaction: Feo Fe2+ + 2e- Cathodic reaction 2e- + ½O2 + H2O 2(OH-) Method to avoid corrosion 1. Cathodic Protection, 2. Proper selection of Pipe material, 3. Protective linings and coatings, 4. Treatment of water The treatment of water includes (i) pH adjustment (ii) Control of Calcium carbonate (iii) Removal of dissolved oxygen (iv) Removal of CO2 (v) Addition of corrosion inhibitors like Sodium Silicate, sodium molybdate and sodium phosphate. A calculated amount of Chemical inhibitors are dosed in the supply water in order to reduce or stop corrosion by interfering with the corrosion mechanism. Usually it affects either anode or cathode such that it creates a protective film in Prepared: Abdul Sakkur P T 17 Useful Guideline on Water between the metal and water. Caution should be taken when the inhibitors are being dosed. For example, if inhibitors dosed less than required, the entire corrosion potential occurs at the unprotected sites. This causes severe localized (pitting) attack. Pitting is the most serious form of corrosion because the action is concentrated in a small area; it may perforate the metal in a short time. At the same time, if inhibitors dosed more than the required, film produced will be more and it may cause to reduce the heat exchange, or the cooling efficiency will be affected. OSMOSIS Osmosis occurs when pure water flows from a dilute saline solution through a membrane into a high concentrated saline solution. The phenomenon is illustrated in the figure. A semi permeable membrane is placed between two compartments. Semi-Permeable means that the membrane is permeable to some species and not permeable to others. Assume that the membrane is permeable to water and not to salt. Place a salt solution in one of the compartments and pure water in other. The membrane will allow water to permeate through to either side, but salt cannot pass through. As a fundamental rule of the nature, the system will try to reach equilibrium, i.e., it will try to reach the same concentration on both sides of the membrane. More specifically, the vapour pressures of liquids at both the sides will play on the liquids to reach the concentrations the same. The only possible way to reach the same concentration for water is to pass pure water compartment to salt containing compartment, to dilute the salt solution, consequently the level of the salt solution increases as shown in figure. The level will increase until the pressure of the column of water (salt solution) is so high that the weight of this water column stops the water flow. The equilibrium point of this water column height in terms of water pressure against the membrane is called Osmotic Pressure. Reverse Osmosis: As the term indicates, it is the reverse of osmosis process, externally made by applying pressure. When the applied pressure exceeds the osmotic pressure, the flow water occurs in reverse direction as shown in the figure. The process can produce pure water from salt water since the membrane is permeable to salt. Seawater Brackish water Osmotic Pressure 23.8 ~27.7 bar (350 ~400psi) 0.7 ~ 3.4bar (10 ~ 50psi) Prepared: Abdul Sakkur P T 18 Useful Guideline on Water Reverse Osmosis Plant Shown is an R.O Plant Schematically. Here the feed water is taken from a beach well. The Water is pumped from the Beach well is first filtered through a dual media sand filter and passed through a cartridge filter by means of a pump. Using a High Pressure Pump (HPP) it is allowed to pass through the Seawater membrane (Polyamide). The product water from the membrane is collected into an intermediate suck tank. The remaining water is thrown out through an Energy Recovery Turbine (ERT), the work output of the turbine is used as an input energy to the HPP as shown in the figure. Water from the Intermediate Suck Tank is passed through the brackish water membrane by means of a booster pump. The product water is collected in the surge tank, among with the overflow of the Intermediate tank, and is pumped into the Over Head Tank, from where; it is supplied to the necessary areas. Necessary chemical treatments are given at different points as it is shown in the figure. Chloride Content in water Chlorides are mineral salts. The solubility of common salt is 360g/l and that of magnesium chloride is 546g/l. when present in substantial concentration, chloride makes the water aggressive relative to concrete. The chlorides of calcium lead to the formation of non-carbonate hardness of water. The traditional method of reducing chloride ion concentration from a water system is to blow down. The exact amount of blow down water could be calculated. The chloride concentration can be found out by titrating the sample of water with a standard silver nitrate solution, using potassium chromate as indicator. Such method is called Mohr’s method. Normally a sheet of calculated value is kept in laboratories. The chloride ions react with standard silver nitrate solution to form the white silver chloride precipitate: Prepared: Abdul Sakkur P T 19 Useful Guideline on Water ACl + AgNO3 AgCl + ANO3 (where A can be any cations) As all the Cl- ions react with AgNO3, the silver ions will react with Chromate ions present in the indicator to give an orange red coluor. The red colour is an indication of absence of chloride ions other than that of silver, and it is taken as the endpoint. The reaction of AgNO3 is given below. 2AgNO3 + K2CrO4 Ag2CrO4+ 2KNO3 Seawater and brine water The chloride concentration of seawater is of the order of 200, 000mg/l whereas brine may contain as much as 10 times that amount. Chlorination of water According to ‘Enzymatic Hypothesis’, chlorine compounds formed when chlorine is added to water, interfere with certain enzymes in the bacterial cells which are vital for the support of life. Chlorine water is an effective bleaching and sterilizing agent. That ability is used in the treatment of water supplies to reduce bacterial contamination. When chlorine in the form of Cl2 gas is added to water, two reactions take place; hydrolysis and ionization. Hydrolysis may be defined as the reaction in which chlorine gas combines with water to form hypochlorous acid (HOCl) Cl2 + H2O HOCl + H+ + Cl- (hydrolysis) The equilibrium constatnt KH for this reaction is KH = [HOCl] [H+][Cl-] = 4.5 x 10-4 (mole/L)2 at 25oC [Cl2] Because of the magnitude of the equilibrium constant, large quantities of chlorine can be dissolved in water. (2.2 liters in 1 liter of water at 20 0 C) Ionization of hypochlorous acid to hypochlorite ion (OCl-) may be defined as HOCl H+ + OCl- (ionization) The ionization constant Ki for this reaction is Ki = [H+][OCl-] = 3 x 10-8 mole/L at 25oC [HOCl] The total quantity of HOCl and OCl- present in water is called ‘free available chlorine’. It is hypochlorous acid and hypchlorite ions which accomplish disinfection. The killing efficiency of HOCl is 40 to 80 times that of OCl-. When chlorine is added to water, all the three (HCl, HOCl, OCl-) are formed and they remain the equilibrium at different concentrations depending upon the pH of water which controls the amount of dissociation. Prepared: Abdul Sakkur P T 20 Useful Guideline on Water Hypochlorite reaction with water The hypochlorite salts ionize in water and yield hypochlorite ions, which establish equilibrium with hydrogen ions: Ca(OCl)2 + 2H2O 2HOCl + Ca(OH)2 NaOCl + H2O HOCl + NaOH The process of chlorination with hypochlorites is known as hypochlorinaiton. Factors affecting bactericidal efficiency of chlorine Turbidity, presence of metallic compounds, ammonia compounds, pH, temperature, time of contact, number of concentration of bacteria are those factors affecting the bactericidal efficiency of chlorine. 1. Turbidity: it makes difficulty to obtain free residual chlorine, the penetration of chlorine so the destruction of bacteria in particles of suspended matter of turbid water is uncertain. 2. Presence of metallic particles: metallic particles utilize chlorine to convert into their higher stages of oxidation which are insoluble in water. Since the shop return water of a steel industry will be both turbid and full of iron particles, chlorination is preferred after doing all kind of physical treatment including filtration. 3. Ammonia compounds: it may form combined available chlorine, which is not so effective a bactericide as free available chlorine. If similar doses of free and combined chlorines are used, then the combined chlorine will take 100 times as long as the free chlorine to achieve the same degree of kill. 4. pH of water: Increasing the pH reduces the effectiveness of chlorine. The effective sterlising compound, hypochlorous acid, is formed in greater quatities at low pH than at high pH values as is clear from table below: pH Value Amount of hypochlorous acid Upto 6.7 95% of total free chlorine 7.0 80% of total free chlorine 8.0 30% of total free chlorine 9.0 5% of total free chlorine 5. Temperature of water: As temperature increases the killing power of chlorine increases. The relationship between time and temperature, to effect a given percentage of kill can be expressed as: Log10 t1 = . E (T2-T1) . t2 2.303RT1T2 t1, t2 = time for given % of kill at temperature T1, T2 (K) respectively E = activation energy, J/mol K, R = gas constant, = 8.314 J/mol K = 1.99 Cal/mol K Prepared: Abdul Sakkur P T 21 Useful Guideline on Water Electrolysis of salt solution In the solution of NaCl there will be Na+, Cl-, H3O+, OH- ions present. When circuit is closed, chlorine appears as a gas at the anode and hydrogen at the cathode, whereas NaOH is formed in the solution. This is due to the secondary reaction taking place at the cathodes. Following reactions take place at the electrodes: At anode, 2Cl-(aq) Cl2(g) + 2e- (oxidation) At cathode, 2H2O + 2e- 2OH-(aq) + H2 (g) (reduction) Net reaction 2Cl-(aq) + 2H2O 2OH-(aq) + H2(g) + Cl2(g) The OH- ions migrate from the cathode area and react with Na+ to produce NaOH. Na+ + OH- NaOH The liberated chlorine at anode is dissolved in water and reacts with NaOH to form NaOCl which acts as the bleaching agent ie., 2NaOH + Cl2 NaOCl + H2O + NaCl ELECTRO-CHLORINATOR Electro-chlorinator is an equipment to produce nascent chlorine in the form of NaOCl from seawater. It works on the same theory as explained above. Since seawater Prepared: Abdul Sakkur P T 22 Useful Guideline on Water contains the ions of Mg and Ca, there will be formation of their hydroxides and carbonates, thus the efficiency gets reduced. So after a long operation the chlorinator should be cleaned by diluted HCl (3 – 5% concentration). Hydrogen is highly flammable with an ignition temperature of 530 oC. A spark will ignite the explosion if the air/hydrogen is in explosive range. So, care must be taken, especially during the maintenance activities like arc welding inside the plant. Reaction of Chlorine with Hydrogen Hydrogen gas readily reacts with chlorine gas very aggressively to give Hydrogen Chloride. Cl2 + H2 2HCl But, it is purely a photochemical reaction. In the dark, no reaction occurs. So a degassing tank should be provided with proper design in order to keep it away from photons (sunlight). Calculations of Electrolysis The amount of chemical change which occurs at any electrode or the amount of substance liberated or deposited on the electrode is directly proportional to the quantity of the electricity passed. Suppose, W grams of a substance is deposited at an electrode and Q coulombs of electricity are passed, Then, W Q. If a current of I ampere is passed for t seconds, then the quantity of electricity is give current strength x time, i.e., ct coulombs. W It = ZIt. Where, Z = electrochemical equivalent. The quantity of electricity which can liberate or deposit 1g equivalent of any substance is called 1 Faraday, F and its value is 96500 coulombs/eqv. Sedimentation Plain Sedimentation and coagulation: When the impurities are separated by the action of gravity force only, it is called the plain sedimentation When it is with the addition of chemicals or other substances, it called sedimentation with coagulation or simply clarification. Prepared: Abdul Sakkur P T 23 Useful Guideline on Water Types of Sedimentation 1. Discrete Settling (1) (free settling): Corresponds to the sedimentation of discrete particles in a suspension of low solids concentration. 2. Type (2) Hindered settling: refers to rather dilute suspension of particles that coalesce or flocculate during sedimentation process. 3. Types (3) Zone Settling: Refers to flocculent suspension of intermediate concentration. 4. Types (4) Compression settling: Refers to flocculent suspension of high concentration that particles actually come in contact with each other resulting in the formation of a structure. Settling of discrete particles Settlement Velocity (Vs) The settling velocity of particles in water can be calculated by the formula: Vs = 4 g (Ss – 1) d 3 CD Vs = Settling velocity (mm/sec) Ss = specific gravity of particle d = Dia. Of particle, in mm CD = Drag Coefficient which is related to Reynolds’s number Re. 1. For Re between 0.5 to 104, 2. For Re > 103 to 104, 3. For Re < 0.5, CD = 24/Re + 3/Re + 0.34 CD = 0.4 CD = 24/R Sedimentation with coagulation (clarification) The chemically assisted sedimentation is called the clarification or sedimentation with coagulation. The flocculent should be dosed at a point of high turbulence. Flocculation refers to the building up of the particles of floc to a larger size which can be removed by sedimentation. When coagulant is dissolved in water and thoroughly mixed in it, a thick gelatinous precipitate, known as floc is formed. Prepared: Abdul Sakkur P T 24 Useful Guideline on Water Common coagulants Depending upon the impurities the coagulant differs. In steel industries the return water will contain positively charged ferric ions, and so they attract the negatively charged particles. Anionic flocculent is advised in such places. The Cationic flocculent is recommended for using in oily waste water clarification Aluminium sulphate or Alum, Chlorinated copperas, ferrous sulphate and lime, Magnesium carbonate, Polyelectrolyte and Sodium aluminate are the common coagulants Blow down quantity (self derived) Suppose that, Q = Total Quantity of system water and, P1 = Cl- amount in ppm (mg/l) for the system water, P2 = Cl- (say)a mount in ppm for make up water, P3 = required ppm of the system water. Take 1 liter of supply water and remove x liters out and add same quantity of make up Ie, P3 = (1-x) P1 + xP2 Solve for x P3 = P1 – xP1 + xP2 (P3 – P1) = x (P2 – P1) X = (P2 – P1) (P3 – P1) Total amount of water to be blow down q, to normalize the Cl- is q = xQ Note: P3 is available from the manual, and P1, P2 are getting on analysis. Water Supply Engineering Pump Centrifugal pumps are the common supply pumps. The pump will be primed before starting because the pressure generated in a centrifugal pump impeller is directly proportional to the density of the fluid that is in contact with it. Hence, if an impeller is made to rotate in the presence of air, only a negligible pressure would be produced with the result no liquid will be lifted up by the pump. To produce pressure centrifugal pumps depend on the basic law of inertia, the Newton’s first law of motion. Negative pressure Atmospheric pressure Water to impeller Prepared: Abdul Sakkur P T 25 Useful Guideline on Water The increase of pressure at any point is proportional to the square of the angular velocity and the distance of the point from the axis of rotation. As the delivery valve is opened, the flow causes creating a partial vacuum at the eye of the impeller, to which water is rushed up due to the pressure exerted by the atmosphere on the liquid surface. Since the atmospheric pressure is the real cause to lift up the water in a centrifugal pump, the suction line should not be exceeded more than the atmospheric pressure in terms of water head. Practically it is 7.5m. Pump Symbols Power required for pumping Power in kW = HQ 3.67 x 105 is the mass density kg/m3, H = Head of pump in terms of metes of water, Q = flow in m3/sec Power in HP = HQ 3960 specific weight of water Performance Curve of a Centrifugal Pump Vibration Check Points of the pump 1. Left bearing 3. Right Bearing (inboard bearing) 5. Motor bearing 7. Motor base bolt 2. Pump case 4. Base bolt (pump side) 6. Motor Middle Prepared: Abdul Sakkur P T 26 Useful Guideline on Water Method to check vibration Keep the vibrometer tip on the points mention as follows (see the figure) 1. vertical 2. horizontal 3. longitudinal Practical Significance of vibration Comparison of vibrations of same pump during foreign materials inside impeller and after removal Vibr. While material inside Vibr. After Removal materials Points 1 2 3 4 5 6 7 1 2 3 4 5 6 7 vertical 25 15 20 16 6 6 8 2 5 10 3 7 3 4 horizontal 14 16 21 10 6 7 7 7 9 17 2 6 5 3 longitudinal 70 35 20 16 9 8 6 12 8 5 2 6 4 2 Delivery pressure of Pump 2.0kg/cm2 Delivery pressure 2.8Kg/cm2 Motor Current of pump 12.5A Motor Current 13.5A Experiment date: 10.11.2006, QASCO, Water Treatment plant for CC # 3 Minimum starting speed: [(N/60)2 (D12 –D2)] = (2gHm) Where: N = rpm, D1= outer diameter of the impeller, D = inner diameter, Hm = the manometric Head. Variable Speed Q2 = Q1 (N2/N1), or H2 = H1 (N2/N1)2 Specific Speed (Ns) It is the speed in rpm of a geometrically similar pump of such a size that under corresponding conditions it would deliver 1 litre of liquid per secd against a head of 1 metre. Ns = NQ Hm3/4 NPSH: Net Positive Suction Head NPSH is defined as the absolute pressure head at the inlet to the pump minus vapour pressure head (in the absolute units) corresponding to the temperature of the liquid pumped, plus the velocity head at this point. Prepared: Abdul Sakkur P T 27 Useful Guideline on Water NPSH = (pa/w + ps/w) – pv/w + Vs2 /2g = pa/w - pv/w – hs - hfs pa = ambient pressure, pv = vapour pressure, ps = pressure at inlet, vs = suction velocity, hs = static suction lift, hfs = frictional loss in suction pipe Criterion for NPSH in installation of pumps: NPSH available should be greater than the required. Or, (NPSH)a > (NPSH)req Cavitation When a liquid flows into a region where its pressure is reduced to vapour pressure, it stars vaporizing and vapour pockets or bubbles are formed in the liquid. These vapour bubbles are carried along with the flowing liquid until a region of higher pressure is reached, where they suddenly collapse as the vapor condenses to liquid again. When a vapour bubble collapses a cavity is formed and the surrounding liquid rushed in to fill it. This process of formation of bubbles and their collapsing is called cavitation. This becomes problem in water flow in certain cases. 1. Pump suction: the centrifugal pumps are creating negative pressure to raise the water. if the fluid pressure inside the impeller equals the then vapour pressure of the fluid, vapour pockets will loss the priming. 2. the heat generated by the rotation of impeller is carried away by the supply water. so if the delivery valve is throttled more than a certain limit (40%), its temperature increases, resulting to generate the cavities to loss the prime. 3. When the velocity of flow is high, the pressure will be less at that region. if the vapour pressure and fluid pressure are same at one region and differ at another, cavitation occurs. The pressure waves propagate to the inner surfaces of the pipes resulting in erosion, which is known as pitting. Cavitatiion reduces the efficiency of the system. Cavitation in pumps Thomas cavitation factor for pumps [(pa – pv)/w] – (hs + hfs) Hm It can be proved that [(pa – pv)/w] – (hs + hfs) = NPSH (1) NPSH Hm Cavitation will occur if the value of is less than the critical value c at which the cavitation just begins. The c can be found out from the formula: c = 0.103(Ns/1000)4/3 Prepared: Abdul Sakkur P T 28 Useful Guideline on Water The relation [(pa – pv)/w] – (hs + hfs) = NPSH indicates that the value of can be increased by reducing the suction lift. In some cases especially hot liquids are to be handled, the pump my to be installed either at the liquid surface or even below the liquid surface. Vapour pressure of water at operating temperature of water (2) Possible Operating temperature of water Temperature o C Vap. pressure kg/cm2 15 20 25 30 35 40 45 50 55 1.734 2.549 3.263 4.385 5.812 7.648 9.789 12.644 16.112 Water hammer When the water flow in a long pipe is suddenly brought to rest, a sudden rise in pressure will occur due to the momentum of the moving water being destroyed. This causes a wave of high pressure to be transmitted along the pipe, the phenomenon of sudden rise in pressure is known as water hammer or water blow. It creates a noise known as knocking and even the pipe may burst on water hammer. So care should be taken while closing a valve on the supply line. Water hammer pressure pi = V a (g/w (1/K + D/(TE)(1-1/(2m))) V = velocity of water, E = Young’s modulus of the material of the pipe, K = bulk modulus of water, T = wall thickness of pipe, 1/m = Poisson’s ratio, D = diameter of pipe. Valves Needle valve owing to the pointed stem needle valve can control accurately the rate of fluid flow. It is used both as throttle and shut off valve. Globe valve Since the flow area of a globe valve is larger, it has larger flow capacity at low pressure drop than a needle valve of the same size. Globe valves are not suitable for throttling service. Gate valve Mostly used as either shut off valve or open the line to full flow. It gives large opening with minimum pressure drop. Prepared: Abdul Sakkur P T 29 Useful Guideline on Water Pipes and Network components Pipe Network Diagram A group of interconnected pipes forming several loops or circuits is called a network. According to the principle of continuity, the flow into each junction must be equal to the flow out of the junction. The Darcy – Weisbach equation must be satisfied for flow in each pipe. According to it, the loss of head hf through any pipe discharging at the rate of Q is hf = rQn Where, r = proportionality factor, which can be determined by means of the below equation for each pipe knowing the friction factors f, the length L and the diameter D of the pipe. r= fL .= fL . ; n is a an exponent having a numerical value 2 5 2gH(/4) D 12.D5 Ranging form 1.2 to 2.00 Prepared: Abdul Sakkur P T 30 Useful Guideline on Water Water System Designing When designing a water system, two things are considered, 1. Physical characteristics and, 2. chemical characteristics. Physical characteristics include Pressure, flow, temperature etc. Chemical characteristics include corrosion etc. The battery point is the first one to be considered. As per it all the other parameters are decided. The technology suppliers provide all the necessary utility requirements and the project engineers need to decide as per that only. Pump Selection From the battery point requirements, Find out the T.D.H, (total developed head). From the performance curves of pump manufactures select the required pumps that satisfy the battery point requirements. Analyze the isometric drawing of the pipe lines to study the possible pressure drop of supply water from the supply station. Lubricants A number of lubricants are used in various parts of the equipment. SAE (Society of Automotive Engineers) relates viscosity range to a number. SAE20 oil has a viscosity of 120 to 185 SSU at 130 oF, SAE30 oil has a viscosity of 185 to 255 SSU at the same temperature. SSU refers to Seconds Saybolt Universal. The saybolt viscometer/viscous meter measures the number of seconds it takes for a fixed quantity of liquid (6)cm3) to flow through a small orifice of standard length and diameter at a specified temperature. The time taken to fill the container is considered as a measure of the viscosity and represents with SSU. Viscosity Index (VI) This value shows how temperature affects the viscosity of an oil. Parrafinic (Pennsylvania) oil vary comparatively little in viscosity. While naphathenic (Gulf cost) vary considerably. The change in viscosity of Pennsylvania crudes between 100 and 210F is rated as 100 and of Gulf cost is rated as 0. Other oils are then assigned a viscosity index in terms of the degree to which this viscosity changes over the range as compared with these standard oils. So, the lower the V.I the greater the variations in viscosity with changes in temperarutre. V.I figures may range above 100 or below 0 if the viscosity of the oils being measured varies less or more than the standard oils. IMPORTANT TERMS AND DEFINITIONS ppm The quantity of constitutes of water is measured in ppm. The treatment chemical agent is dosed in water at a rate of ppm. It means the parts of chemical Prepared: Abdul Sakkur P T 31 Useful Guideline on Water agent per million of water. In pure water it is equivalent to 1mg/l, or 10 -6/l. This relation may not be correct in the case of contaminated water. Since the supply water is free from contaminations, its quality could be approximated to that of pure water. The amount of constituents in pure water can simply calculated in ppm as follows. If ‘p’ is the amount of chemical recommended to be added in ppm, , ‘q’ the volume of water added in the water basin, then the amount of chemical ‘w’ in kg is given by, w in kg = p . q /1000 The same formula can be used for the purpose of calculations in the case of cooling supply water also. Specific gravity The specific gravity is the ratio of specific weight of a fluid to the specific weight of pure water at 40C. on the basis of this definition we can derive a relation for the weight of chemical delivered as follows. Weight of chemical delivered = Volume in liter of the chemical Specific gravity of the chemical Chlorine demand It is the difference between the amount of chlorine added to water and the quantity of free available chlorine remaining at the end of a specified contact period. Electrochemical equivalent It is the amount of substance (in gram) liberated or deposited on the electrode, on passing a current of 1 ampere for 1 sec, or on passing 1 coulomb of electricity. Electrolytic conduction The electrolytes are termed as ionic conductors. The acids, bases or salts in their fused state or in aquies solution will function as electrolytes. It consists of the movement of ions in the electrolyte. The resistance of the flow decreases with increase in temperature. Conductivity of solution According to ohm’s law, the current 1A flowing through a conductor of resistance R ohms is related to the potential difference E volts, through the equation, I = E/R. The reciprocal of R is called the conductance C. Prepared: Abdul Sakkur P T 32 Useful Guideline on Water Specific resistance The resistance R of any uniform conductor is directly proportional to its length, l and is inversely proportional to its area of cross section a. Mathematically, R l/a = xl/a An electrolyte specific resistance () may be defined as the resistance of a column of a solution of unit length and unit area of cross section , i.e., it is the resistance of a unit cube of the solution. Specific conductance From the above equation, 1/R =C= 1/x a/l = K a/l, where K = 1/ the reciprocal of specific resistance is called specific conductance, K and is expressed in m. thus K = C x l/a. the specific conductance is defined as the conductivity of the electrolytic solution, a unit cube of which offers to the passage of electricity. Variation of specific conductance with dilution The specific conductance will reduce with the decreasing concentration of the current conducting particles. Bond energy: Average bond dissociation energy of the entire bonds is called as bond energy Cell constant It is the ratio between length of the cell to the cross sectional area Cell constant = l/a = Resistance x specific conductance. Detention time: It is the theoretical time taken by a particle of water to pass between entry and exit of a settling basin. Dielectric constant: It is a measure of the ability of a medium to reduce the force of attraction between oppositely charged particles. OR It is the ability to break a molecule into its constituent ions. Electro negativity: It the tendency of an atom to attract the bond pair electron in a covalent bond Hybridization: The mixing up of various atomic orbitals to give equal number of new orbitals having equality in all respects. Recycle rate: It is the ratio of gross water use to intake. Prepared: Abdul Sakkur P T 33 Useful Guideline on Water Stoichiometry The study of chemical reactions and the mass relationships implied by them is called stoichiometry Pipe & Tube Tube is specified by outside dia and wall thickness expressed either BWG (Birmingham Wire Gauge) or thousands of an inch. Pipe is identified by norminal size with wall thickness defined by schedule number. bond: It is a bond formed by axial overlapping of atomic orbitals. EDTA: ethylene di-amine tetra acetic Acid Instrumentation Pressure, temperature and flow are the most important parameters in a process flow. Calibrated instruments are available to measure these parameters. The basic theory of the instruments is given in short. Pressure Gauges Mostly the elastic property of material is utilized to measure the pressure. The pressure above or below the atmospheric can be measured by a Bourdon’s Tube pressure gauge as well as the diaphragm pressure gauge. Since the tube of a Bourdon’s pressure gauge is encased in a circular cover, it tends to become circular instead of straight, and the calibrated scale gives the pressure. The diaphragm gauges utilizes the expansion of a diaphragm for measuring pressure. Temperature measurement The temperature at which a sample is collected is important for data correlation and interpretation purposes, like in tests on pH, specific conductance,, salinity and forms of alkalinity. Temperature affects the stability of salts. It influences the bioproductivity in the aquatic environment determines the degree of dissociation of dissolved salts, and controls to some extent the rate of oxidation of the organic matter. Thermometric property of materials such as, the thermal expansion and the change in resistance is utilized for the measurement of temperature like in Mercury thermometer and thermocouple. The zeroth law of thermodynamics is applied in any kind of thermal gauges. The zeroth law of thermodynamics states that, when a body A is in thermal equilibrium with a body B, and also separately with a body C, then B and C will be in thermal equilibrium with each other. Prepared: Abdul Sakkur P T 34 Useful Guideline on Water Flow of water The basic equation of flow measurement is the velocity of the fluid x cross sectional area of the pipe Q = AV For a circular pipe, A = r2, Where, r = the radius of the cross section. The cross sectional area of other shapes can be found out the relevant equations. And the velocity of moving water is found out by the relation V = (2gH) g = acceleration due to gravity, H = head in meters of water Instrument such as Orifice meters are used for the measurement of flow. The differential pressures between the inlet and the throat is utilized for deriving an equation, from the basic equation of flow. Q = C a0a1(2gH) (a12 – a02) A variety of methods are available to get the direct measurement of flow either by calibrating or using transducers. Thermal Calculation Thermal energy is carried away by the cooling water. It is further dissipated by the secondary cooling media. the amount of heat carried away is calculated using the following formula: Q = mCpΔT Where, m = quantity of water flow in m3/sec, Cp = the specific heat at constant pressure, ΔT = the differential temperature. Water balance Suppose Q amount of water supplies to 3 utility points as shown in figure from water storage. Suppose A, B, C are the amount of water supplied to various utility Prepared: Abdul Sakkur P T 35 Useful Guideline on Water points respectively, and an amount of x, y, z water evaporates from each utility points. Suppose E is the total amount of water evaporated, Then, supply water Return water Where Q = A + B + C. R=Q–E E = x + y + z, the total evaporation loss Make up water, M = E Water Equivalent Water equivalent of a substance may be defined as the quantity of water which requires the same quantity of heat as the substance to raise its temperature through one degree. Mathematically, Water Equivalent of substance = mc m = mass of substance in kg, c = specific heat of the substance in kJ/kg.K Note: The numerical value of the thermal capacity and the water equivalent of the substance are the same, but they are expressed in different units. Heat Exchanger Calculation for conduction (Fourier’s Law) Q = kA (T0 – TL) = 1 (To –TL) L L/KA K = thermal conductivity (W/m0C) Prepared: Abdul Sakkur P T 36 Useful Guideline on Water Reynolds number and Turbulent flow of water Reynold’s Number = Inertia force/viscous force Re = Fi/Fv On substituting, Re = VL/ = mass density, V = velocity of flow, L = characteristic linear dimension = viscosity of water. In circular pipes, the flow will be laminar if Re is less than 2000 and turbulent if it is greater than 4000. Between Reynold’s numbers 2000 and 4000 the transition region occurs. W H O Std. Of Drinking water Physical And Chemical Standards of Drinking Water (WHO) No Characteristic 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Highest Desirable level Max. Permissible Turbidity on Jackson Scale Colour on Platinum Cobalt Scale Taste and colour pH Total Solids 5 5 Unobjectionable 7- 8.5 500 10 50 Unobjectionable 6.5 -9.2 600 Chloride Sulphates Total Hardness (as CaCO3) Nitrates Flurides 200 200 200 45 1.0 400 600 600 45 1.5 Iron Manganese Copper Zinc Calcium Magnesium Phenol Anionic Detergent Arsenic Cadmium Hexavalent Chromium Cynades Lead Selenium Mercury Gross alpha activity (pc/L) Gross beta activity (pc/L) 0.1 0.05 0.05 5 75 30 0.001 0.02 0.05 0.01 0.05 0.05 0.1 0.01 0.001 3 30 1.0 0.5 1.5 15 200 150 0.002 1.0 0.05 0.01 0.05 0.05 0.1 0.01 0.001 3 30 Prepared: Abdul Sakkur P T 37 Useful Guideline on Water Quantitative analysis for Quality Control of Water Total Hardness Total Hardness is estimated by complexometric titration with standard EDTA solution using Dotite BT as indicator Procedure Pipette out 50ml water sample into a conical flask. Add 10ml of buffer solution and wait for 5 minutes. Titrate with standard M/100 EDTA solution taken in the burette using Dotite BT as Indicator. End point is sharp color change from Wine red to blue. Total Hardness is calculated as follows. Total Harness = V x 1000/50 mg/litre Ca Hardness Ca Hardness is estimated by complexometric titration with standard EDTA solution using Dotite NN as indicator. Procedure Pipette out 50ml water sample into a conical flask. Add 5ml of 10% KOH solution and wait for 5 minutes. Add 0.5ml NH2OH.HCl. Titrate with standard solution of M/100 EDTA taken in the burette using Dotite N’N’ Indicator. End point is sharp color change from Wine red to blue. Ca Hardness is calculated as follows. Ca2+ = V x 0.4008 x 1000/50 In terms of CaCO3 = Ca2+ x 2.495 mg/litre Chloride in Water Chloride content in water is estimated by Argentometric titration with standard AgNO3 using K2CrO4 as indicator. Procedure Pipette out 50 ml water sample into a clean conical flask. Add I ml of K2CrO4 indicator solution into to the sample. Titrate with standard 0.1N AgNO3 solution. Endpoint is sharp color change to Orange red. Chloride ion is estimated as Chloride (mg/l) = A x N x 35.45 x 1000 Vol. of sample mg/litre Where, A = Vol. of AgNO3 required for sample N = Normality of AgNO3 Prepared: Abdul Sakkur P T 38 Useful Guideline on Water Total Alkalinity Total alkalinity in water sample can be determined by titrating a known volume of sample against standard sulphuric acid solution using methyl red indicator. Procedure Pipette out 50 ml water sample into a clean conical flask. Add 2-3 drops of methyl red indicator. Titrate with standard N/50 H2SO4 solution taken in the burette. Endpoint is sharp color change from blue to white. Alkalinity is calculated as Total alkalinity = VX 1000/50 ppm Total Dissolved Solids (TDS) At present Conductivity/TDS meter is used to find the both parameters. The following chemical analysis can also be used. 1. Take 100ml of water into a pre-weighed clean, dry porcelain dish. 2. Evaporate the water in the basin to dryness over a water bath 3. Clean the outside of the dish, dry it in an air oven at 105oC for an hour to remove moisture, cool and weigh. 4. the difference between the weights is the weight of total soluble salts. Calculation Volume of water taken = 100ml Weight of empty dish = Agrams Weight of dish + residue = B grams Weight of TDS in 100ml sample = (B – A) grams TDS (mg/l) = (B – A) x 106 100 Total Suspended Solids TSS in water sample is determined by filtering the sample through filters with nominal pore sizes varying from 0.45m to about 2.0m. TSS test is somewhat arbitrary because it depends on the pore size of the filter paper. Procedure Accurately weigh a GS 25 filter paper. Shake the given water sample vigorously and Filter 500ml sample through the filter paper using a filtration a pump. Dry at 100 oC for 2 hr. Cool and weight is noted .TSS is calculated as TSS = (W2-W1) /Vx 106 mg/litre W1= Weight of filter paper W2 = Weight of filter paper with sample V= volume of sample taken Prepared: Abdul Sakkur P T 39 Useful Guideline on Water Total Phosphate in Circulating water The estimation is based on the reaction of the phosphate ions with acidified molybdate reagent to give phosphor-molybdate complex which is then reduced to a blue compound by SnCl2 or by suitable reducing agent. The absorbance of the compound is measured by spectrophotometry. Procedure Pipette out 10 ml water sample into a clean graduated test tube. Add 1ml H2SO4 and 10 ml potassium per sulphate solution. Cover with aluminum foil, autoclave for 1 hr. Cool, add 2-3 drops phenolphthalein and add NaOH drop wise to pink colour. Add 5ml ammonium Molybdate solution. Mix well and add 0.25ml SnCl2. Make up to 50ml. Mix well and allow t stand 15mts. Measure absorption rate at 700nm using spectrophometer. Prepare a blank solution with distilled water and follow same procedure. HCl Concentration (for acid washing of Chlorinator) Before circulating the HCl in the hypo-chlorinator, its concentration will be analyzed. Concentration of HCl can be estimated by potentiometric titration using standard NaOH solution. Procedure Pipette out 10ml acid in to a 100ml beaker. Add 50ml Distilled Water and keep a magnetic stirrer in it. Dip pH meter electrode and slowly add standard NaOH (1N) from burette with stirring. When pH increases to 3 minimize addition of NaOH. Continue addition slowly with stirring till pH increases to 8. Note volume of NaOH. Then HCl percentage is calculated as % HCl = (V1 x N1 x 0.3646)/sp. Gravity of HCl Where V1 = Volume of NaOH N1 = Normality of NaOH Sp. Gravity is measured using a hydrometer T Fe of water (Soluble Fe) Total Iron in circulation water is estimated by absorption photometric method. Procedure Pipette out 50ml sample in to a conical flask. Add 5ml 3N HCl. Boil and reduce the volume to 25%. Cool and transfer in to a 50ml standard flask. Add 1ml NH2OH.HCl and 2.5ml O-phenanthrolein hydrochloride. Put a small piece of Congo red paper. Add 6N NH4OH drop by drop till color turns red. Add 2.5ml buffer solution and make up to volume 50ml. Wait for 30mts and take spectrophotometer reading at = 510nm Prepared: Abdul Sakkur P T 40 Useful Guideline on Water HISTORICAL DEVELOPMENT OF WATER TREATMENT Ancient civilizations established themselves around water sources. It took thousands of years for people to recognize that their senses alone were not accurate judges of water quality. Water treatment originally focused on improving the aesthetic qualities of drinking water. Methods to improve the taste and odor of drinking water were recorded as early as 4000 B.C. Turbidity was the main driving force behind the earliest water treatments. Ancient Sanskrit and Greek writings recommended methods such as filtering through charcoal, exposing to sunlight, boiling, and straining. To clarify water, the Egyptians used the chemical alum as early as 1500 B.C. to settle down the suspended particles. By the early 1800s, slow sand filtration began to use in Europe. During 1800s, scientists understood the sources and effects of drinking water contaminants. In 1855, Dr. John Snow proved that cholera was a waterborne disease. In the late 1880s, Louis Pasteur demonstrated the “germ theory” of disease, which explained how microbes could transmit disease through water. During the late nineteenth and early twentieth centuries, concerns regarding drinking water quality continued to focus on disease-causing microbes (pathogens) in public water supplies. It was disinfectants like chlorine that played the largest role in reducing the number of waterborne disease outbreaks in the early 1900s. In 1908, chlorine was used for the first time as a primary disinfectant of drinking water in Jersey Citty. The use of other disinfectants such as ozone also began in Europe around this time. By the late 1960s it became apparent that industrial and agricultural advances and the creation of new man-made chemicals also had negative impacts on the environment and public health. Many of these new chemicals were finding their way into water supplies. Treatment techniques such as aeration, flocculation, and granular activated carbon adsorption at this time were ineffective at removing some new contaminants. A study in 1972 found 36 chemicals in treated water taken from treatment plants that drew water from the Mississippi River in Louisiana. Scientist continued their effort on the quality of water. Ancient treatment techniques are still in use. However, techniques like reverse osmosis and granular activated carbon are newer. Since water is a raw material in a variety of industries, and it being the best and cheap cooling medium, a variety of treatment program was designed to make it suitable for industrial purposes and eco-friendly manner. Prepared: Abdul Sakkur P T 41 Useful Guideline on Water Foot Notes 1. Hydraulics and fluid mechanics, P.N.Modi P: 1168 2. Hydraulics and Fluid Mechanics, P N Modi - Page: 35 References 1. George T. Austin, Shreve’s Chemical Process Industries. 2. David R Sherwood, The piping Guide; For Design & Industrial Piping systems 3. P N Modi, S M Seth, Hydraulics and Fluid Mechanics 4. John J Pippenger, Industrial Hydraulilcs 5. R S Khurmi, Hydraulics 6. B C Punmia, Ashok Jain, et-al Water Supply Engineering 7. P K Nag, Engineering Thermodynamics 8. Breck, Brown, McCowan, Chemistry For science and Engineering 9. MetCalf & Reddy, Waste water Engineering; Treatment & Reuses 10. B C Punmia, Ashok Jain, Wastewater Engineering 11. A.O Thomas, Modern chemistry vol - I 12. R S Khurmi, J K Gupta, Thermal Engineering 13. G. Nikolandze, D. Mints et-al, Water treatment for Public & Industrial supply 14. A O Thomas, Practical Chemistry (BSc Main) 15. R Ramesh & M Anbu, Chemical Methods for Environmental Analysis: Water & Sediment 16. Hoffman, Heat and Mass Transfer Prepared: Abdul Sakkur P T