SS_Man_Plan

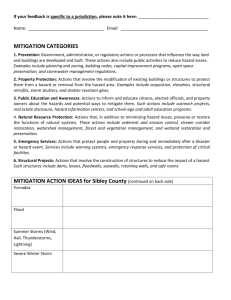

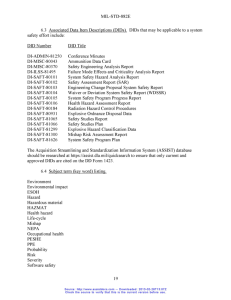

advertisement