Document

advertisement

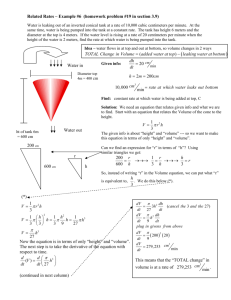

Aquaculture Magazine Mixed-Cell Raceway: combining the best characteristics of tanks and raceways James M. Ebeling Environmental Engineer Carla F. Welsh Research Associate Conservation Fund Freshwater Institute 1098 Turner Rd., Shepherdstown, WV 25443, USA j.ebeling@freshwaterinstitute.org Michael B. Timmons Professor Cornell University Biological and Environmental Engineering Department 302 Riley-Robb Hall Ithaca, NY 14853 Raceways have been used for years for the production of salmonids and other species by federal and state agencies for stocking purposes and commercial growers. Where there are large groundwater resources, such as the Thousand Springs area in Idaho, raceways are the most common production tank design, being used to grow the majority of rainbow trout produced in the USA. Two significant advantages of raceways is their better utilization of floor space and easier handling and sorting of fish as compared to traditional, circular tanks. Their primary disadvantages are the large volume of water required, high turnover rates, and limited selfcleaning ability. Even using lower exchange rates and lower velocities, their use has been severely limited due to the unavailability of large quantities of high quality water, increased concern about their environmental impacts on receiving waters, and the difficulty in treating large flows from effluent discharge. One solution to these problems is to convert the raceways into a series of counter-rotating mixed-cells that act as hydraulically separated round tanks, thus providing both the advantages of a raceway and the improved solids removal capability of circular tanks. This would allow the raceways to be managed either as partial reuse systems or as intensive recirculation systems. A prototype raceway was constructed to better understand the operations, management, and hydraulics of a large, mixed-cell raceway using a research greenhouse at the Conservation Funds Freshwater Institute. The basic design concept was to operate the raceway as a series of square/octagonal tanks (cells), each having a center drain for continuous removal of solids and sludge. Each cell received water from a vertical pipe section (downleg) extending to the tank floor and located in the corners of each cell through which water is pumped and discharged through several orifices (jets) to establish rotary circulation in the cells. The rotational velocity in the cells can then be controlled by the design of the orifice discharges, either by increasing the flow rate, the discharge velocity, or the total number of orifices. This was then combined with the concept of the ‘Cornell double drain system’, where 10% to 20% of the total flow into a tank 1 Aquaculture Magazine is removed from a center bottom drain and 80 to 90% of the flow is removed from the side drain. Settable wastes and sludge are then removed from the center drains and collected in a settling sump. Design and Construction The experimental raceway measured 16.3 m x 5.44 m x 1.22 m and was constructed of structural lumber with a HDPE liner. The floor of the raceway was covered with 5 cm of fine sand and graded to provide a slight slope to the three center drains. The walls and floor were insulated with 2.54 cm foam insulation board to minimize heat loss through the sidewalls. The tank was lined with a 20 ml high density cross laminated polyethylene (HDPE) raceway liner from Permalon, Reef Industries, Inc. A 15 cm drainline with three discharge drains (tee fittings) centered on each of the three cells was buried along the longitudinal axis of the tank. The three drains discharged into a 1.83 m x 1.83 m x 1.83 m fiberglass sump tank. The sump tank had both a standpipe for water level control and a drainline to empty the system. The sump tank was intended to fulfill several roles, including solids management by acting as a solids settling basin, maintaining desired water level by using a standpipe, and as a harvesting basin by draining the production tank through a screened harvesting cage. Eight 0.75 kW pumps were installed along the outside walls on platforms and discharged into a 10 cm schedule 40 PVC manifold that encircled the raceway. Two of the pumps were located at the sump collection tank, while the remaining six were placed equal distant along the length of the tank outside walls. The suction lines with check valves were located approximately one third below the water level in the tanks. The pump discharges were connected to the manifold with a 5cm flexible hose with a bronze gate valve to control flow and a clear plastic manometer to measure downleg back pressure. Four 5cm PVC vertical manifolds with seven orifices were placed in the four corners of the tank and four 8 cm PVC vertical manifolds were located along the sidewalls, dividing the tank into three equal cells. Two of the 8 cm vertical manifolds had 14 orifices; seven discharging along each edge of the wall in opposite directions and the other two vertical manifolds had 7 orifices each discharging perpendicular to the walls. The orifice opening were constructed by welding a threaded bushing 3.18 cm by 2.54 cm, which allowed a 2.54 cm threaded plug to be inserted. This allowed orifice sizes to be easily modified or plugging of unused orifice openings for research trials. Flow Measurement A SonTek Argonaut Acoustic Doppler Velocimeter from Yellow Springs Instruments was used to measure speed and direction within the hydraulically separated cells. The SonTek velocity meter is a single-point, 3D Doppler current meter designed for shallow water flow monitoring. Water velocity is measured via the Doppler shift in frequency of sound from a moving object, in this case small particulate matter in water current. The SonTek probe assembly was mounted on an aluminum beam supported above the width of the raceway, which allowed the probe to be moved across the tank width. 2 Aquaculture Magazine Hydraulic Characteristics The color contour plot for cell #3 (end cell farthest from sump) shows the velocity profile at intervals of 5 cm/sec using downleg discharge orifices of 15 mm. The discharge orifice pressure head was approximately 0.22 m. Research has shown that water velocities greater than 15 to 30 cm/sec (0.5 to 1.0 fps) are required to drive settable solids to the center of a tank for quick removal by the center drain. The outside perimeter of the cell exhibits these high scouring velocities and significantly lower velocities are seen near the center of the cell. The contour plot also shows the four discharge plumes at each corner. During a research production trial for marine shrimp, excellent solids removal was seen even at significantly lower cell velocities. Summary and Conclusions In order to better understand the hydraulics of a large, mixed-cell raceway, a prototype raceway was constructed in a research greenhouse at the Conservation Fund Freshwater Institute. Studies have been conducted on the velocity profiles for several different orifice discharge diameters and flow rates through the system. Results show excellent bottom velocities for scouring solids and transporting them towards the center drains in each cell. Further work will focus on determining the relationship between the orifice discharge velocities and the water rotational velocity, solids removal efficiency of the system, and management studies on how best to use the sump tank for solids collection and as a solids settling basin. In short, mixed-cell raceways show excellent potential for either retrofitting existing raceways or as a design for a new production system. This work was supported by the United States Department of Agriculture, Agricultural Research Service under Cooperative Agreement number 59-1930-1-130 and Magnolia Shrimp, LLC, Atlanta, Georgia. 3 Aquaculture Magazine Sludge Disposal Pump Pump Pump Sludge Tank Sump & Settling Basin 6” drain line Harvest by screen capture Pump Pump Pump 4” Manifold Schematic of Mixed-cell Production Tank showing the three counter rotating cells and settling and harvest sump. 4 Aquaculture Magazine 15 10 2.5 25 15 20 20 15 10 40 35 30 35 30 25 25 2.0 15 5 10 1.5 10 20 15 20 1510 35 30 25 20 10 5 35 20 20 5 15 25 20 15 20 1.0 25 10 10 20 25 20 0.5 15 20 0.0 20 10 15 25 15 5 5 35 10 -0.5 -1.0 20 10 10 5 20 3540 10 5 10 15 35 30 25 20 -1.5 40 25 30 5 15 15 15 25 20 15 20 25 25 10 -2.0 20 15 15 20 -2.5 20 25 15 10 -2.5 -2.0 -1.5 25 30 15 20 25 -1.0 35 -0.5 0.0 0.5 1.0 25 30 1.5 20 20 10 5 2.0 2.5 40 Cell #3: velocity contour plot, 5 cm/sec intervals 5 15 Aquaculture Magazine Overview of Mixed-cell Production Tank showing construction, pump manifold and pumps, and vertical manifolds. Mixed-cell raceway showing two vertical manifolds, pumps, and heat exchanger. 6