Table of Contents - University of Colorado at Boulder

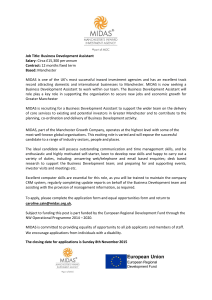

advertisement