RoshanMathewGeorge_FYP

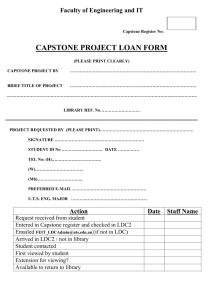

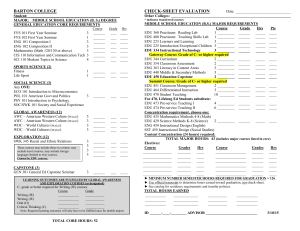

advertisement