Simple Manometer

advertisement

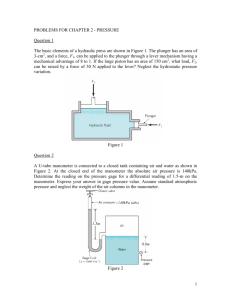

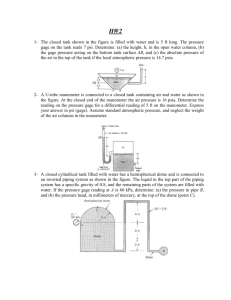

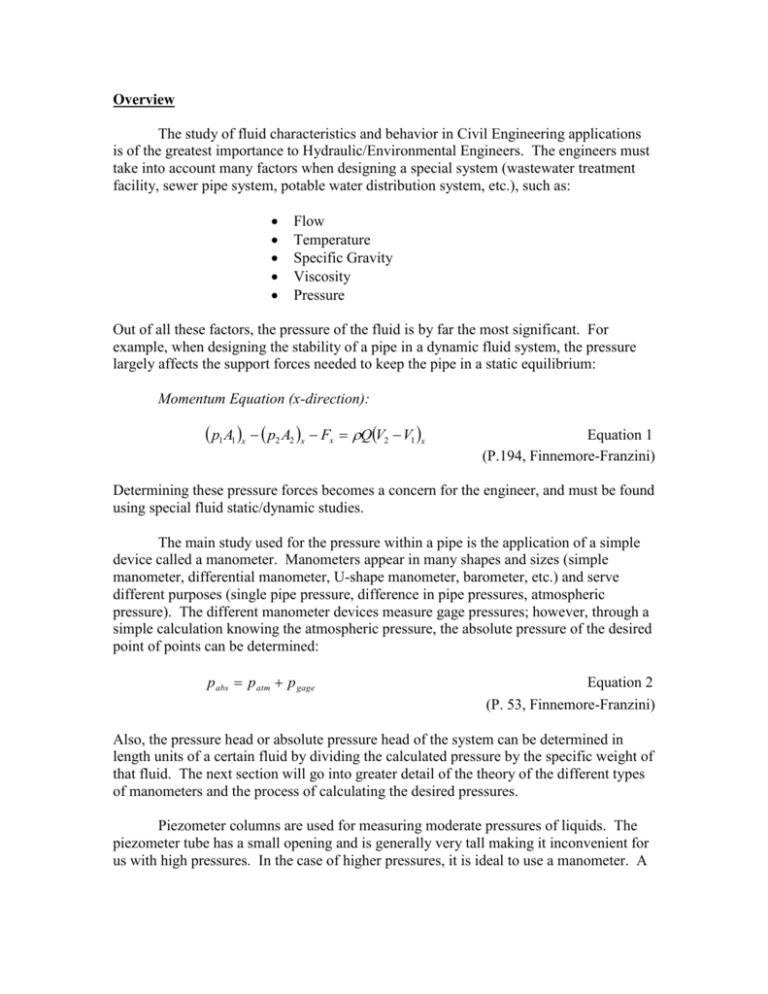

Overview The study of fluid characteristics and behavior in Civil Engineering applications is of the greatest importance to Hydraulic/Environmental Engineers. The engineers must take into account many factors when designing a special system (wastewater treatment facility, sewer pipe system, potable water distribution system, etc.), such as: Flow Temperature Specific Gravity Viscosity Pressure Out of all these factors, the pressure of the fluid is by far the most significant. For example, when designing the stability of a pipe in a dynamic fluid system, the pressure largely affects the support forces needed to keep the pipe in a static equilibrium: Momentum Equation (x-direction): p1 A1 x p2 A2 x Fx QV2 V1 x Equation 1 (P.194, Finnemore-Franzini) Determining these pressure forces becomes a concern for the engineer, and must be found using special fluid static/dynamic studies. The main study used for the pressure within a pipe is the application of a simple device called a manometer. Manometers appear in many shapes and sizes (simple manometer, differential manometer, U-shape manometer, barometer, etc.) and serve different purposes (single pipe pressure, difference in pipe pressures, atmospheric pressure). The different manometer devices measure gage pressures; however, through a simple calculation knowing the atmospheric pressure, the absolute pressure of the desired point of points can be determined: p abs p atm p gage Equation 2 (P. 53, Finnemore-Franzini) Also, the pressure head or absolute pressure head of the system can be determined in length units of a certain fluid by dividing the calculated pressure by the specific weight of that fluid. The next section will go into greater detail of the theory of the different types of manometers and the process of calculating the desired pressures. Piezometer columns are used for measuring moderate pressures of liquids. The piezometer tube has a small opening and is generally very tall making it inconvenient for us with high pressures. In the case of higher pressures, it is ideal to use a manometer. A manometer is a double-leg column gage that is used to measure the difference in pressure between two fluids. The various types of manometers have many similar characteristics: hollow tube, liquid partially filling the tube and a scale. The U-tube manometer consists of a hollow tube connecting two pressures sources. A differential manometer involves two enclosed pressure sources that are connected with the tube. On the other hand, a simple manometer involves a pressure source connected to atmospheric pressure through the tube. General Equations Simple Manometer The idea in solving for a simple manometer is to begin at the point of atmospheric pressure, then continue through the different fluids by calculating the pressure changes till the point of interest is reached. In Figure 1, a pipe with a steady flowing fluid, F, is connected with simple open-end manometer. The manometer fluid is indicated by M and is different from the pipe fluid. Also, the dimension, Rm, is the manometer reading, which is simply the height difference between the two surfaces of the manometer fluid. The dimension, h, is the difference in height of the pipe fluid/manometer fluid interface and the desired location in the pipe. The pressure is calculated using the specific weight and height dimension as shown below: Pressure: p h Pressure Head: h p Equation 3 (P. 50, Finnemore-Franzini) Equation 4 (P. 51, Finnemore-Franzini) The pressure difference is determined by the direction of calculation. For instance, the pressure increases when moving in the negative elevation direction and decrease when moving in the positive elevation direction. In the example of Figure 1, the calculations would start at the free surface (atmospheric pressure), travel through the fluid M and finally travel through fluid F to point A. The equation of the gage pressure would be as follows: 0 s M W Rm s F W h PA Equation 5 The pressure at A in this equation is the gage pressure. This pressure can be converted to either a pressure head in length units of a fluid (Equation 4) or an absolute pressure (Equation 2). Differential Manometer The same concepts of fluid statics are used in solving a differential manometer; however, the difference between the two types is that in a differential manometer the pressures are not always known. Therefore, the result will sometimes come out as a difference in pipe pressure. In Figure 2, the same concepts as used in the simple open-end manometer. The dimension, Rm, is the manometer reading, which is the height difference between the two surfaces of the manometer fluid, M. The dimensions, hA and hB, are the height differences between the pipe fluid/manometer fluid interface and respective pipe location (A or B). The equation for the difference in the pressure of A and B for this manometer is as follows: p A s F W hA s M W Rm s F W hB p B Equation 6 p A p B s F W hA s M W Rm s F W hB Equation 7 This equation can also be written as: pA s z B z A) 1 M sF pB Rm Equation 8 (P. 62, Finnemore-Franzini) p s z 1 M sF Rm Equation 9 (P. 62, Finnemore-Franzini) As in simple manometers, the pressure or pressure difference can be determined as a gage pressure (or pressure head), or as an absolute pressure (or pressure head). Sample Manometer Problems Simple Manometer Find the gage and absolute pressure at point A of the system. p atm 14.7 psia p gage A ? h 1.5 ft Rm 8in w 62.4lbs / ft pabs A ? 3 p gage A s M Rm s F h w 8 p gage A 13.6 (.83)(1.5)(62.4) 12 p gage A 488.1lbs / ft 2 3.39 psi pabs A patm p gage A pabs A 14.7 3.39 18.09 psi Differential Manometer Find pressure at B, and pressure head at B in length units of water. Rm 2 ft h 2.5 ft z 1 ft w 62.4lbs / ft 3 p A 7.21 psi pB ? p head , B ? p B p A s F ( Rm h 1) w s M Rm w s F h w p B (7.21)(144) (1)( 2 2.5 1)(62.4) (13.6)( 2)(62.4) (1)( 2.5)(62.4) p B 2548.32lbs / ft 2 17.7 psi p head , B pB w 40.8 ft