Measurement Uncertainty

advertisement

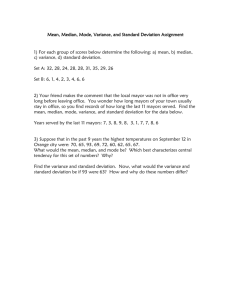

Measurement Uncertainty Objective In this lab we’ll look at the sources and results of measurement error. From this lab, you should learn to calculate and interpret mean, variance, and standard deviation, and identify component characteristics including tolerance, price, form factor, and de-rating. Concepts An error is defined as the difference between the measured value (xm) and the true value (xtrue). Error = xm - xtrue (1) This relationship begs several questions. What is the “true” value? If I measure very carefully, will my measurements still contain errors? Where do these errors come from and how can I minimize their impact on my design? System accuracy is the magnitude of the maximum expected error. This measure of system performance is usually specified for a piece of test equipment as a percentage of full-scale value. System precision is an estimate of repeatability. A precise system, making repeated measurements of the same thing, will consistently produce the same result. The more precise an instrument, the less random error affects the result. System resolution is the smallest possible discernible increment. The higher the resolution, the smaller the smallest increment is. --------------------------------------------------Types of Error---------------------------------------------Systematic errors occur in a repeatable way every time a measurement occurs under similar conditions. They are also known as ‘bias’ errors. If a measurement is consistently in error by a constant number, added or subtracted to the true value, it’s called an offset error. Offset Error: Xm = Xtrue ± Constant (2) When the true value can be determined by a ratio of the measured value and a constant (which can be greater or less than 1), it’s called a scale error. Scale Error: Xm = Xtrue x Constant (3) Nonlinear errors can result from poor design or from inappropriate system use. Many components and systems of components are designed to produce linear output from linear input. However, if those components are improperly used, either by the designer or the end user, nonlinear ( y= x 2, y = cos xt, or y = log x are examples of nonlinear functions) can result. 1 Over time, measurement conditions such as ambient temperature and humidity can change. Electronic components age, and their characteristic values can also change over time. This phenomenon is called drift. Random errors are different for every measurement event. The defining characteristic for random errors is that they have an average value of zero. As a result, it’s often possible to reduce random error in measurement by repeating the measurement and then averaging the outcomes. The National Institute of Standards and Technology, www.nist.gov, maintains many national and international standards of metrology, the science of measurement. Most sophisticated test equipment needs periodic calibration. For many design, maintenance, and test facilities, a current certificate of calibration that is “traceable” to NIST is mandatory. That means that the equipment has been calibrated by a facility that can credibly claim that the work was performed by someone who has been trained to calibrate that piece of test equipment and who used metrology standards that have been endorsed by NIST. ____________________Median, Mean, Variance, and Standard Deviation__________________ Suppose for a set of measurements on a small sample of 15 kΩ resistors we have the following data. 15.15 kΩ 14.81 kΩ 15.07 kΩ 14.98 kΩ 15.02 kΩ We can organize this data in several ways to help us understand the characteristics of the larger population of 15 kΩ resistors. First we can determine the sample median value of the sample. The sample median is just the middle value when the measurements are arranged from smallest to largest. If we know the sample median value, we can infer that there are as many measurements above the median as below. For our sample of 14.81, 14.98, 15.02, 15.07, and 15.15, the middle value is15.02. Another measure of the ‘center’ of a sample of data is the sample mean, also known as an ‘average’ value. The sample mean of a set of measurements is the sum of the measurements divided by the number of samples: Sample Mean: X n xi i 1 n (4) where Xi is the individual measurement and n is the total number of measurements. The sample mean for this set of data is 15.006K. How do you chose between the median and mean to determine the center of a sample? The median isn’t perturbed by a few very small or very large measurements. On the other hand, even one or two 2 extreme measurements will dramatically affect the sample mean. If we add one measurement of 10 kΩ and another of 12 kΩ, the median changes only slightly to 14.98 kΩ. The sample mean on the other hand changes from 15.006 kΩ to 13.86 kΩ. From a practical point of view, this is why it’s so hard to recover from even a single missed assignment or low test score when a sample mean is used. The variation on either side of the center or deviation is another important characteristic of our measurements. If we take the sample mean X as the center of our data, then the sample deviation is the difference between the measured value and the sample mean: Deviation = X - X (5) Because some deviations are positive and some are negative the deviation is not a good measure of the “spread” of the data. In fact it can be shown that the sum of the deviations for any data set is zero. So we calculate the sample variance by summing the square of the deviations and dividing by the number of measurements minus one. X 2 n Sample Variance: S2 = i 1 i X (6) n 1 In order to get an estimate of the variability of the sample in the same units as the data, take the positive square root of the sample variance. This quantity is known as the standard deviation and is the basic measure of variability. X 2 n Sample Standard Deviation: s i 1 i X n 1 (7) For “bell shaped” distributions you should expect approximately 68.3% of the measurements will fall between x s , 95.4% of all measurements will fall between x 2s , and 99.7% of all measurements will fall between x 3s . This bounded range is sometimes called the confidence interval. Consequences of Error Every system you design will use components that vary from their nominal value. Your job will be to create a system that is independent of these variations. This is called robust design. If you have to pick through the parts bin to find just the right inductor, your design is probably not very robust. A sensitivity analysis of your design will reveal which components contribute to the overall sensitivity of the design and which do not. Components that are manufactured to a very close tolerance, i.e. a very small standard deviation, cost more than components that are manufactured to a looser standard. Specifying a component as a ± 1% instead of a ±10% can significantly affect product profitability when that small difference in cost is multiplied over a production run of hundreds of thousands. In his book, “The Chip,” T. R. Reid describes the first engineering job held by Jack Kilby, co-inventor of the monolithic integrated circuit. “It was an intensely competitive business, where a cost differential of one dollar per thousand parts—a tenth of a penny per part—could win or lose huge 3 contracts. ‘It was sort of a crash course in sensitivity to cost,’ Kilby recalled later.” Your ability to create a clever design may make the difference in management decisions that affect many other people. Equipment and Components This experiment will require the use of the Fluke Digital Multimeter, several resistors with a nominal value of 15 k, Microsoft Excel, and Matlab. Prelab (25 points) – Due at the beginning of lab 1. Find the cost for 10 kΏ ± 1% and ±10% resistors in quantities of 1,000. Provide cost estimates from two vendors. 2. Write a paragraph identifying and describing three different ways to manufacture resistors. These variations can be the “form factor” or the technique used to establish the resistance. 3. Provide an example of a resistor derating curve from a manufacturer. Briefly explain the meaning the chart. Part 1: Measurement Analysis First we’ll take some measurements and do some statistical analysis to determine the type(s) of measurement errors involved. You’ll also be plotting a histogram, which is a chart that has the measured values on the horizontal axis and the number of times that value occurred on the vertical axis, as shown in Figure 1. Figure 1: A quick example histogram In this example histogram, there are 11 samples (total number of boxes). The number of resistors that fall between values of 15.2 kΏ and 15.3 kΏ, for example is 3. For the histogram you create the x-axis values shown here will probably not fit your data, since it is just for a hypothetical data set. When you make your own, choose x-axis values and increments that best allow you to express your data. Now on to the procedure proper: 4 1. As a class, measure and record the resistance of each of 40 resistors on your data sheet. 2. Using Excel, calculate the sample mean, the deviation for each value, the deviation squared for each value, as shown in the table on the data sheet. You can just turn in your Excel spreadsheet rather than writing all the values in. Also calculate the sample variance, and the sample standard deviation, and include it on both your spreadsheet and your data sheet. 3. Plot the result in a histogram either by hand or using Excel. Label the mean, and draw vertical lines indicating +/-s, +/-2s, and +/-3s. 4. On your data sheet, provide a brief description of why fitting data to statistics such as variance and standard deviation is important. 5. In terms of the types of error discussed in this lab, what type(s) of measurement error are evident in your resistor sample? Answer this on the data sheet. Part 2: A Simple Derating Simulator In your prelab assignment, you investigated derating curves. For this part of the lab, you’ll write a simple Matlab program that shows the output of the series circuit shown in Figure 2 in terms of resistor derating. R1 5.1k V1 24Vdc R2 13.8k - 15.2k Heater Figure 2: Circuit near a heater The input voltage is 24 V. R1 is 5.1 kΏ. R2, however, is affected by the heater. Its value varies between 13.8 kΏ and 15.2 kΏ. Write a Matlab program that plots the current through R1 for each value of R2, and plot the voltage across R1 for values of R2 between 13.8 kΏ and 15.2 kΏ. First, set the values for V1, R1, and R2. R2 will be an array. Calculate the voltage value across R1 for each value of R2 using a voltage divider (ratio of R1 to total resistance). Also calculate the current for each resistor value (total series voltage over total series resistance). These calculations are most easily done in a ‘for’ loop. Once you have the V and I values, plot V vs. R2 and I vs. R2. 5 Lab 4: Measurement Uncertainty Name_____________________________ Section________ Prelab (due at the beginning of lab) 1. Find the cost for 10 kΏ ± 1% and ±10% resistors in quantities of 1,000. Provide cost estimates from two vendors. 2. Include a paragraph identifying and describing three different ways to manufacture resistors. These variations can be the “form factor” or the technique used to establish the resistance. 3. Provide an example of a resistor de-rating curve from a manufacturer. Briefly explain the meaning the chart. Part 1: Measurement of Time Varying Signals 1. Measured data – calculate values in Excel and print out your spreadsheet to turn in. Measured Deviation Deviation2 Measured Deviation Deviation2 Value X Value X R1 R21 R2 R22 R3 R23 R4 R24 R5 R25 R6 R26 R7 R27 R8 R28 R9 R29 R10 R30 R11 R31 R12 R32 R13 R33 R14 R34 R15 R35 R16 R36 R17 R37 R18 R38 R19 R39 R20 R40 Total = Sum = Sum = Total = Sum = Sum = 2. Sample Mean:________ Sample Variance:_________ Sample Standard Deviation:_________ 6 3. Provide a brief description of why fitting data to statistics such as variance and standard deviation is important. 4. In terms of the types of error discussed in this lab, what type(s) of measurement error are evident in your resistor sample, and why? Part 2: A Simple Derating Simulator 1. Turn in your Matlab code and plots. 7