Discussion

advertisement

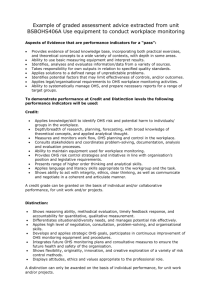

Chapter 7 - Discussion CHAPTER 7 – DISCUSSION Scope of Discussion 7.1 Upon review of the results of the survey, discussion is focused on the elements related to the deficiencies in planning and implementation of OHSMS of the XYZ Company with an aim to substantiate the hypothesis on the factors affecting the planning and implementation of OHSMS. The scopes of discussion include the following areas: Management strategy, policy and commitment Management structure and responsibilities Participation, consultation and communication Training and technical competence Integrated management and operations Performance benchmarking and Objectives Best practice and safety culture Planning for implementation Management Strategy, Policy and Commitment 7.2 In the case study, the XYZ Company did set up their safety policy with the policy statement endorsed by the CEO. However, numbers of defects were identified in the XYZ’s policy statement, like health aspects, integration, commitment to compliance of statutory requirements and OHS of contractor and visitors. Inconsistence was also found in their incident-free policy while they tolerated risk to a certain degree under the ALARP principle of their Risk-based safety management system. Obviously, it was found that the health surveillance programs and the contractor safety control program of the XYZ Company have not been properly set up in the - 89 - Chapter 7 - Discussion organization. Coincidently, they are the missed concerns in the policy statement. A policy statement is a vehicle to convey management strategy to all staff. It provides directions and guidelines for line management to plan and execute their OHS programs. It proves that effective planning and implementation of OHSMS relies very much on the policy setup which is one of the essential inputs for formulation and implementation of OHS processes. As highlighted in ILO Universal OHSMS model in Figure 3.6, outputs are generated corresponding to necessary inputs. We cannot expect to produce any output without provision of required input. Policy deficiencies provide uncompleted management objectives and directions for effective planning and implementation of OHSMS. 7.3 It has been identified that top management commitment to adequate resources is significant for implementation of OHSMS. However, the XYZ Company only demonstrated top-management commitment on paper instead of physical commitment on resources allocation. In the questionnaire analysis, it was identified that 4 out of 7 sections had linked up the OHS management problems with inadequate resources or uncertain resource support. XYZ management commitment did not equate with planned resources. Inadequate resources identified on various areas. Unclear functions and roles between line management and the Safety Section also led to confusion in budget and funding preparation which could be another reason for inadequacy of resources. Staff had expressed their serious concern on the inadequate resources for execution of their OHS responsibilities. Obviously, superficial management commitment - 90 - Chapter 7 - Discussion without proper resources allocation cannot put OHSMS into effective operation. 7.4 Funding for safety is always found to be a financial burden to the management. Some companies resist treating it as part of their operational overhead. Situations will become more critical under economic recession since the management will concentrate their economic interest on the improvement of economic opportunities rather than OHS. Market used to trim down their safety standard and tolerate certain risk so as to provide low costing environment for attraction of investment. Investors also take such an opportunity for adjustment of their investment proportion on their safety management. Cathay Pacific Airline is a typical case, which cut down their running costs by eliminating the whole risk management department in 1998 and only keeping three safety officers to look after the safety of their worldwide business. 7.5 It is considered that resource allocation for safety is difficult to be secured unless the top management realizes that safety funding forms part of required overheads for company operations and commits to provision of fixed percentage of operation cost as the baseline for funding to safety. It would be more effective if it can be worked under a centralized safety funding system for proper resource allocation and prioritization of safety improvement initiatives. It can also release the financial burden of line management in the modern cost-centered financial management approach since it is treated as part of the corporate management overheads instead of line operation overheads. Resource allocation forms the greatest barrier on the planning implementation of OHSMS. It is not only on funding but also - 91 - Chapter 7 - Discussion on adequacy and competence of safety professions in supporting the planning and operation of OHSMS. 7.6 Another essential element that would serious affect the planning and implementation of OHSMS is the appropriateness of management strategy being adopted by the organization. The XYZ Company initially set up the OHSMS on risk-based approach which came to dominate the entire safety management establishment. However it is obvious that risk management cannot cover all aspects of OHSMS. From the findings of the survey, it has identified certain deficiencies of risk-based safety management approach. Risk-based safety management strategy is an advanced safety management concept that takes proactive approach for eliminating and controlling hazard. However it concentrates on preventive measures and sometimes overlooks certain reactive and general safety management elements, like emergency handling and accident investigation and safety promotion. Obviously, the OHSMS setup of The XYZ Company described in Chapter 2 has not mentioned a reactive approach on accident investigation and root cause analysis. 7.7 Risk management concentrates the consequence of hazard on injuries, fatalities and damages. It cannot be applied for the risk of occupational diseases which cause long-term ill health. There is no value justification for long-term ill health in the cost-benefit analysis. It is also difficult to define the likelihood of the risk as most of occupational diseases depend on the length and frequency of exposure as well as cumulative damage. It could be one of reasons why health surveillance was not included in the XYZ’s policy. - 92 - Chapter 7 - Discussion 7.8 The risk management approach aims to justify cost-effective ways to control and eliminate the identified hazards. However, it may not be cost effective to conduct a full risk assessment including cost-benefit analysis for a simple risk which can be easily identified by other means and eliminated with minimal cost. Especially as the assessment is so complicated and is required to be carried out by a group of well-trained staff. In addition to the significant staff cost in assessment, it requires expensive investment in training up certain number of staff in each line department before adequate competent staff are available for carrying out such complicated risk assessment. It may need further review to justify the staff cost in this regard. Indeed, this can explain the reasons for the inadequacy of resources for training and shortage of competent hazard controllers for carrying out PHA in the XYZ Company. The survey found that line management resisted to take up their responsibilities on PHA and shifted them to the Safety Section. The resources for conducting PHA were inadequate to cover all operation areas. 7.9 There are also certain limitations in risk assessment with cost-benefit analysis approach. Value of life as well as injuries is difficult to be quantified in monetary value. The XYZ Company as recommended by their consultant adopted a “Value of Preventing a Fatality” up to HK$30 million per head which was originated from a railway safety plan (Railway Group Safety Plan 1996/97, Railtrack PLC, London) in UK some years ago. Obviously there is a great variation on this value from one country to another and from time to time. It is due to different social perception of different countries, which continuously change with time upon change of - 93 - Chapter 7 - Discussion environment including economic and cultural. In the recent Corporate Safety Committee Meeting, The XYZ Company ruled out the application of cost-benefit analysis on the ground of uncertainty in the validity of the value of preventing a fatality. Employee and trade union may also resist accepting the justification of risk control by means of cost benefit analysis as it only goes for employer rather than employees. Certain risk control may be of great benefit to employees but is outweighed by cost benefit. It will cause grievances on prioritization of risk control and toleration of risk between the employer and the employee. Therefore toleration of risk is most critical and may require extensive consultation to gain the acceptance from the authority, the staff and the public. Yet the effort may be in vain as different people have different perception of risk and different risk acceptance level. 7.10 Indeed, a risk management approach was initially developed for hazardous trade while it was recognized that risk could never be completely eliminated. In hazardous trade, the tolerability of calculated risk is required to go through an approval process by the local government with public consultation. The toleration of risks deems to have public acceptance of the community to a certain extent. However, the risk-based safety management approach adopted by the XYZ Company was an indoor process and the identified tolerable risks were not required to go through any approval process of the local government. It is so risky that toleration of the identified risk may not be agreeable by the authority as well as the public or the staff. The company could face a serious liability on negligence in duty of care when an accident occurred. Therefore, the - 94 - Chapter 7 - Discussion Safety Maxim suggested by Kinney and Wiruth (1976) should be carefully considered when it is applied for general risk issues. The XYZ Company may have adopted an improper management strategy, which causes the OHSMS to be ineffective and vulnerable. The management had relied too much on the consultant and did not have adequate understanding of the management principles of a proper OHSMS. This can be evidenced by their revised Safety Policy Statement, in which the incident free policy is contradictory to the toleration of risk. They may have misinterpreted the risk-based safety management concept. 7.11 The application of a proactive approach in management strategy of OHS is fully supported but it should not only concentrate on the risk management, especially on the tolerability of risk, which may involve uncertainty in legal liabilities. However important the determination of risk may be, it is only one component of a safety management system. Other strategies, such as training and performance monitoring through audits, will complement the effective implementation of the OHSMS as a whole. Management Structure and Responsibilities 7.12 Establishment of management structure coupled with clear responsibility and accountability is one of the fundamental elements of generic management. However, the XYZ company has demonstrated a serious deficiency in this area.. For successful implementation of safety management and achieving continual improvements in safety performance, the senior management of The Company shall require strengthening of the safety management structure and the organizational culture to ensure understanding, acceptance, effective delegation of safety and health - 95 - Chapter 7 - Discussion responsibilities and sustained implementation at every level of the organization. 7.13 The study found that the XYZ Company intended to establish a two-tier approach in their safety management structure. Such a management approach is considered appropriate for such a complex organization as corporate management can ensure integration of safety essences into management while line management can ensure integration of safety requirements into operations. Line departments can own their safety management plans to ensure appropriateness to their operations while corporate management issue corporate safety management plan as a policy guidelines to line management for ensuring consistency. However, there was no clear documentation available in The XYZ Company for such amanagement approach. Notwithstanding the situation that the corporate safety management plan was still under preparation, line departments already issued their own safety management plans. There were serious inconsistencies on the functions and roles between the Safety Section and line management amongst individual safety plans of line management. This can well explain the management problems of the XYZ Company on implementation of OHSMS. 7.14 Indeed, confusion in responsibilities may lead to inadequacy in resource allocation and ineffectiveness in utilization of resource since line managers were unable to justify their funding application and budget while they could not explain whether their safety initiatives fell within the areas of their responsibilities. Unclear management structure and responsibilities caused chaotic planning and implementation of OHSMS. On one side, - 96 - Chapter 7 - Discussion resources could have been wasted by duplicated effort on similar tasks carried out by different line departments. On the other side, safety legislation could have been violated due to overlooking of essential safety issues in grey areas of responsibilities by line departments. 7.15 Line management participation is vital for the successful implementation of OHSMS. Line management should take up a major function in planning and execution of OHSMS as it can ensure appropriateness of OHSMS for their operation environment and proper integration. The unexpected high response rate from the target group has demonstrated the enthusiasm of the line management of The XYZ Company in participation of OHS matters, but it could also imply their eagerness for improvement in certain areas with serious OHS deficiencies. The availability of departmental safety management plans further proved the line management participation. However, the inconsistency of the plans showed that the safety management structure was not strong enough to support horizontal integration. The integration links amongst line departments are very weak. In certain specialized safety areas, like risk assessment, the line management have demonstrated their reservations in taking up their responsibilities and shifted them to the Safety Section. Some even admitted to full reliance on the Safety Section for OHS matters. The safety responsibilities of the majority of the line department rested on one person. It meant that the implementation of OHSMS was limited to line management level and had not been extended to the frontline operation staff. It was further substantiated by the failure of the line management in ensuring the organization objectives and policy in OHS to be well - 97 - Chapter 7 - Discussion understood by their staff. In fact, the most critical issue was the inadequate resources for execution of duty. That was why the line management demonstrated their positive attitude in participation of OHS management on one side but resistance to take up OHS responsibilities on the other side. These confusions and deficiencies were caused by the weak management commitment and absence of proper management structure and clear responsibilities and accountabilities. 7.16 For complex and dynamic organization, it may be an effective way to provide a safety team at corporate level to assist senior management in execution of their OHS policies and monitoring safety performance so as to ensure consistency in planning and implementation amongst line departments. Yet the safety management structure of the XYZ Company displayed in Figure 2.5 showed that the Safety Section only took up the supporting roles to the line management and did not necessarily to provide support to the corporate management. It turned out that the Safety Section was extensively involved in supporting OHS activities of line management. The administration of the corporate safety management became rather weak. The Corporate Safety Management Plan was still not yet completed for safety manuals and guidelines. Therefore, the Safety Section should be empowered with corporate safety function. However, safety executives should only act as safety mentors rather than safety police so as to prevent any resistance from the line management. The corporate safety function should focus on: Providing support and policy advice to senior management Providing strategic or technical support to line management - 98 - Chapter 7 - Discussion Interpreting legislations and standards and developing user-friendly tools for corporate-wide use Lobbying external related-parties and the authority on behalf of the company Performing internal and external benchmarking Providing safety training and arrange safety promotion Administering safety performance. 7.17 For line management approach, each employee should be accountable to a supervisor who is a member of the line management. Each member of line management should be accountable to the next higher level of management in their respective division/section. Ultimately, the head of each division/section should be accountable to the Director. The Director sets OHS policy, and provides direction on implementation strategies and budgets. Line supervisors should be responsible for planning and conducting work safely; consistent with established policy and direction; and assuring that worker training and qualifications are appropriate. Line managers should have landlord responsibility for providing a safe infrastructure to perform work. Line workers are responsible for the safe performance of work. 7.18 It should be noted that it is generally accepted on a worldwide basis that the CEO of any organization has the ultimate responsibility for safety and health of all persons under his control. This does not absolve corporate or line management from responsibility and accountability to the CEO. The distance of the CEO from the decision making process that caused the accident and the doctrine of due diligence and the extent to which he had - 99 - Chapter 7 - Discussion control are factors to be determined by legal opinion. Notwithstanding that, the responsibility and accountability in certain circumstances passes down the management hierarchy through corporate management to line management. 7.19 Other than responsibility and accountability, it is also important to delegate staff with suitable authority. For avoidance of violation to safety, it should be considered to empower all level of staff with appropriate stop work authority. Every individual should have the authority and responsibility to stop any work, which they feel is not safe. Every level of supervision should be responsible to stop work for which they are responsible that is not safe. Full stop work authority should rest with all safety executives. Yet such authority had not been mentioned in the OHSMS of the XYZ Company 7.20 Regarding the responsibility of contractors, the case study found that the XYZ Company can contract away OSH responsibilities and potential liabilities for specific work to a general contractor, but this applies only as long as the general contractor undertakes the work fully, properly and completely on behalf of the owner / occupier. However, there is a potential financial loss arising from departmental prosecutions and as such this loss could not be transferred to the insurer. The potential for common law liability exists where injuries to contractor’s employees are involved. The XYZ Company must be safeguarded against this loss by making sure that all workers are in fact insured. This requires that their insurance documents be checked and procedural documentation be provided to ensure this is done. This is an important caveat: If the owner exercises any - 100 - Chapter 7 - Discussion control and responsibility along with the prime contractor, then the owner / occupier remains liable for the proportion of the loss, no matter what the contract between the owner and general contractor states. 7.21 Management should commit to implementing OHS requirements for activities involving subcontractors, participating guests and visitors, while maintaining an appropriate business relationship that does not result in unnecessary assumption of liability for contractor operations. An accident prevention clause should be inserted into subcontracts for service, engineering and construction labour. It should specify that contractors must have integrated safety into their business activities and follow all applicable OHS requirements. All subcontracts contain provisions for stopping work and terminating contracts for lack of OHS performance. Certain subcontractor individuals may be excluded from the site for failure to follow OHS requirements. A policy should be established to exclude subcontractors from bidding if they have a record of poor OHS performance. Participation, Consultation and Communication 7.22 It is understood that safety cannot be imposed from above. The work will be safe only if staff are involved in the process of developing safe work procedures. Staff participation was critical to the success of all the initiatives. On the other hand, management should provide support to the participatory approach. Lack of necessary support from management or staff will cause system breakdown in OHSMS and all people will be exposed to unnecessary risk. It has been proven that the majority of line departments of the XYZ Company rested their OHS responsibilities on - 101 - Chapter 7 - Discussion only one person and OHS participation was limited to line management level. Frontline operations staff have not been encouraged to take part in OHS management. Therefore it was unable to ensure full integration of OHSMS to line operations. It showed that inadequate participation of all staff in OHS would render ineffectiveness in planning and implementation. 7.23 We need staff participation in joint employee effort to implement an effective OHS policy. In the principles of participatory approach, the people who do the work also participate in the planning for the work--i.e., analyzing the hazards, determining the controls and implementing the controls. This avoids disconnection between those planning and implementing controls and those doing the work. It also makes good use of worker knowledge in the planning process. The key issue on this approach is the competence of workers. An incentive scheme may be used to attract participation like an employee improvement scheme. 7.24 Communication is another essential elements for implementation of OHS management system and development of safety culture. The extent to which management genuinely wants to consult with employees and to collaboratively manage OHS risks using a participative style of management will greatly affect the effectiveness of the OHS management. The XYZ Company demonstrated a serious deficiency in this area. Communication breakdown was not only between corporate and line management but also between line management and staff as well as amongst line departments. Senior management has not provided proper mechanism for dissemination of their safety policy and performance standards while line management have not ensured the safety management - 102 - Chapter 7 - Discussion policy and standards were well understood by their staff. The safety management structure together with roles and responsibilities were not made known to all personnel. The management system was not open enough to ensure effective communication. Mechanisms on feedback and resolving disputes in OHS issues need to be enhanced. 7.25 One of the deficiencies in the XYZ policy statement was the absence of consultative mechanism between management and employees for of exchange their concerns on the occupational health and safety issues. Besides, it also found that procedures and the manual of the XYZ Company were not readily accessible by all staff. The communication barrier greatly hindered the effectiveness in planning and implementation of OHSMS in The XYZ Company. Ineffective communication will cause misunderstanding and grievances between management and staff. An effective communication system should be provided with suitable channel to receive feedback from each other as well as from the external environment together with a function to secure the information to be received by the targeted recipient within the prescribed time frame. Training and Technical Competence 7.26 It is recognized that training is essential to ensure competence of staff in execution of OHS responsibilities. It is also an indicator of the top management commitment to OHS. OHS training used to be a mandatory requirement for staff under various OHS and Factory and Industry Undertaking Legislations. However, there are common deficiencies in identification of training needs for safety executives and senior management. The situation was obvious in the XYZ Company where it - 103 - Chapter 7 - Discussion was identified that the competence of senior management and safety executives in certain safety areas was in doubt. 7.27 OHS practice in some area of operation in specialized industry required specific expertise backed up by professional training in order to allow problems to be measured and suggestions to be made. For the same reasons, safety executives from the general safety field are facing difficulties in execution of their duties, as they do not possess the required knowledge in the operation as well as related engineering aspects of such specialized industry, like aviation, marine and railway. The safety officers of the XYZ Company were found have a lack of adequate knowledge on the specialized operation of the carrier field. However, training still had not been provided for enhancement of their competence in this area. 7.28 The policy defects on the XYZ Safety Policy Statement, especially on the contradiction between incident-free policy and toleration of risk, has proved that the perception of senior management in general management principles of the safety system was not adequate enough for formulation of a proper safety policy and setting up an appropriate management strategy for safety. For effective planning and implementation of OHSMS, managerial staff shall be trained up with adequate safety consciousness and competence, especially for senior management, as they are the ones taking the lead to establish positive safety culture. However, it is a common problem on how to attract these busy managers to attend safety training. 7.29 The competence problem was more serious for the Hazard Controllers of the XYZ Company. They were not trained up to fully extend their - 104 - Chapter 7 - Discussion capability to conduct a PHA. As a deviation from the original intents, the PHA was conducted by the Safety Section instead of by the line management. Therefor the Safety Section tied up their limited resources in PHA and updating the HRS. Hence their efficiency and performance in setting up OHS policy and procedures was greatly affected, which was more important for the planning and implementation of the overall OHSMS. 7.30 The case study identified that resource constraints were again experienced in the XYZ Company in this area. The Safety Section was faced with a shortage of resources for the provision of safety training. Line management were also faced with serious staff constraints under shift operations and resisted the release of their duty staff for safety training. Discouraging effects were identified on operations staff since they were nominated to attend training during their off-duty time. The organization establishment was not provided with training reserve to relieve staff on training. Therefore, outsourcing of training could not solve the problem. In fact, an external safety course could not provide tailored made training to meet their training needs and was unable to cultivate tailored made safety culture. It also reduced the means for safety executives to have face-to– face feedback from frontline operation staff. The deterrent effects of resources constraints on safety training adversely affected the competence of staff in safety performance and in turn adversely affected the quality of OHSMS management. Therefore, it can be concluded that staff incompetence can fully defeat the effectiveness and efficiency in planning and implementation of OHSMS. - 105 - Chapter 7 - Discussion Integrated Management and Operations 7.31 It is widely accepted that effective implementation of OHSMS required full integration of the system into both management and operations. The policy of the XYZ Company did not support this function. Obviously it treated safety as a stand-alone adjunct. Communication between divisions/departments was rather weak and cause a deficiency in sharing information. Inconsistency of safety plans proved weakness in horizontal integration. That was why the safety culture of the organization was not strong enough for sustaining continual improvement and supporting effective implementation of OHSMS. 7.32 Safety policies and programs should be designed to systematically integrate OHS into the management and work practices at all levels so that corporate mission is accomplished while protecting the public, the worker, and the environment. In other words, the overall management of safety functions and activities become an integral part of corporate mission accomplishment. However, the line management approach in neglecting the participation of frontline operation staff in OHS management of the XYZ Company has refrained the OHSMS from proper integration into operations. Obviously, the OHSMS of the XYZ Company was not unable to be effectively integrated into management and operations both vertically and horizontally. This proves the significance of proper integration for effective planning and implementation of OHSMS. 7.33 Line management should implement the OHS program within their divisions/sections in a way that makes the most sense for their operations. In practice, there should be greater divisions/sections participation in the - 106 - Chapter 7 - Discussion development of corporate safety programs and considerable effort should be made to obtain consistency amongst different safety programs of line departments, so implementation variations are few. Uniformity should only be imposed where implementation by one division/section may have a negative impact on another. Therefore, in nearly all cases, there would be distinct variations in implementation at the division/section level or activity level only when there is a need because of the nature of the operations. 7.34 Vertical integration of the OHS program is facilitated by the downward flow of information regarding expectations for OHS program implementation, from the top down through the organizational lines. At the same time, vertical integration provides a mechanism for the upward flow of information about problems in implementing the OHS program including the need for support and resources from the worker and through the organization to supervisors, and/or upper management, as appropriate. 7.35 Horizontal integration is needed to provide for normality and compatibility. It can ensure similar controls for similar hazards and similar work within an organization and avoid conflicting requirements among organizations and technical disciplines. Horizontal integration of the OHS program provides assurance that: Peer organizations exchange ideas e.g. lessons learned & success stories, OHS processes are similar in similar organizations 7.36 Integration into management need top management commitment while integration into operations needs line management support and staff participation. For broader vision in management, efficiency, productivity, - 107 - Chapter 7 - Discussion quality, safety and environment should be integrated all together as the key performance functions in the operation process. Performance Benchmarking and Objectives 7.37 A performance monitoring system does not form one of the implementation processes. However, performance indicators and benchmarking are essentials for planning and implementation of OHSMS. Without these essentials performance targets cannot be established - hence safety workplans cannot be properly prepared. However, it is a quite common deficient item in the worldwide-recognized safety standards and models. As observed in Table 3.1, nine out of twenty-four OHSMS do not include a performance measures element. These almost match with another related deficiency of these systems on the coverage of goals and objectives. Seven of them also do not provide a goals and objectives element, which is highlighted in the modern management theories of “Management By Objective”. 7.38 Benchmarking was one of the deficiencies identified in the OHSMS of the XYZ Company. In the absence of performance benchmarking and proper performance indicators, XYZ faced difficulties in setting up proper performance targets and goals for further improvement. Management could not assess their safety performance level and was at a loss to make management decisions on their way forward regarding safety management. OHS benchmarking can help management to establish best-practice safety culture in their organization. On one side, it provides a yardstick for line management in their OHS performance. On the other side, it gives - 108 - Chapter 7 - Discussion confidence to the senior management for continual improvement in OHS management. 7.39 Managers often regard OHS as a barrier to their performance. To rectify this concept, OHS should be integrated into their management and form part of their performance appraisal. OHS should be regarded as part of operation efficiency instead of the traditional consideration of taking priority from operation efficiency, which would deter full integration. To secure effective implementation of OHSMS, performance appraisal could be one way to enhance the positive attitude of line management in execution of their OHS responsibilities for meeting their agreed performance targets. Best Practice and Safety Culture 7.40 As mentioned before, one of the deficiencies of the XYZ Company in implementation of OHSMS was failure in the establishment of a positive safety culture throughout their organization. The negative attitude of line management in promotion of staff participation had a discouraging effect in the establishment of safety culture. Culture is the total way of life. It represents people’s attitudes, thoughts, expectations, goals and values. OHS culture is the system of shared values and beliefs about OHS, which creates behavioural norms which guide OHS activities in the organization. It directly relates to the effectiveness of the integration of OHS into the organization. 7.41 There are two major types of safety sub-culture and they are the operationoriented culture and safety management oriented culture. The former believes that safety culture is top-down approach, whereas the latter is - 109 - Chapter 7 - Discussion work done through an effective communication network. In the XYZ Company, many employees were transferred from government departments and were old government officials. Some of them still maintained certain bureaucratic attitudes and adopted the operationoriented approach. Furthermore, some of them, especially the senior employees, were still adapting the traditional paternative management approach. Staff were not allowed to gain free access to and participate in formulation of the policy and procedures. To change the culture and the behaviour of senior employees is not easy and is also time consuming, still we should keep on educating them by introducing the new idea of OHS policies and explaining the pros and cons of a safety management system. There were many employees from different foreign countries working in the XYZ Company and their business-related partners. This introduced the problems of adaptation, communication and co-operation. In terms of OSH, these were differences in the paces of work as compared to their own countries; variation in OSH practice and standards; language ability relating to daily operations and safety training; and the willingness to report unsafe conditions or unsafe acts. 7.42 Positive OHS culture can promote employee participation and involvement at all levels. It is far better to incorporate the OHS culture with corporate management culture. Since everybody shares a common goal and objective, OHS policy can be carried out smoothly and cost-effectively. To secure excellence in planning and implementation of OHSMS and continual improvement, it could be better to taking best-practice philosophy instead of compliance base approach, which only provides minimum standards for - 110 - Chapter 7 - Discussion safety. Obeying the law is regarded as a duty for which one receives little recognition or credit. Planning for Implementation 7.43 It is recognized that OHSMS concentrates on safety elements but is used to overlook a key element on how to plan and manage the implementation of OHSMS. Indeed, it comes to be a management issue rather a safety issue, which may not be clearly realized by safety executives. It is quite a common problem that certain organizations run “Safety” without “Management”. The XYZ Company is one of the typical examples. They concentrated on risk identification but were unable to manage the identified problems with no prioritization of works. Their OHSMS only highlighted the planning for various safety functions but missed one of the major management functions on how to plan for implementation. A corporate safety plan had not been well prepared. Procedures and manuals were not made available to all staff. No structured mechanism had been established for the implementation of OHSMS. Safety functions were implemented without properly integration to management and operations. In over two years of business operation, there were only two Executive Committee papers endorsed for OHSMS; one for the RBSMS approach and other for the Safety Policy Statement. Obviously, it had not full utilized these mechanisms to gain policy support from the top management for securing the management structure and resource allocation for various safety initiatives. 7.44 This study has identified that planning is not only required for OHSMS but also needed to establish a structured management approach for its - 111 - Chapter 7 - Discussion implementation. For assurance of proper implementation, an OHS Implementation Plan is basically required in support of the integrated safety management plan, including specific performance commitments. The Plan should be updated annually to reflect progress made, changes in mission and site budgets, and feedbacks aim at improved performance objectives and measures. The OHS Implementation Plan shall include the follow functions: To identify the resources needed to fulfill OHS commitments and meet OHS objectives, and to assure that adequate OHS skill levels and mixtures are available to support the accomplishment of the corporate mission. To set OHS performance objectives and commitments, responsive to the safety expectations, consistent with mission, budget direction, and program guidance and direction. Appropriate priority, key milestones and schedules tied to commitments are identified. For an on-going annual report, the Plan shall also report the performance results compared against the previous year's Plan commitments, performance objectives and measures, including the measures and commitments negotiated for the previous year; and include specific description of how risks were actually reduced. The Plan shall be endorsed by the Executive Board so to secure proper allocation of resources for implementation. Then the Plan shall be disseminated to all working levels of the organization for full implementation. - 112 -