Waterous from Sampler

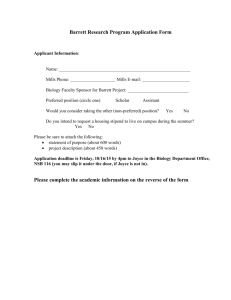

advertisement

From The Sampler, A Book About Brantford (A local initiatives and Wintario project), Moyer Printing Co. Ltd., 1979 WATEROUS LTD. Page 110 The "Waterous" name did not appear on Brantford’s early industrial scene until1848, although the foundations of the Waterous Engine Works Company had already been laid by P. C. Van Brocklin in 1844. When the rest of Canada West or old Ontario was very much the "Queen's Bush", Mr. Van Brocklin had located a foundry constructing stoves and plows on Dalhousie Street nearly opposite a livery stable (Baxter's). It remained a small business with little hint of changing for four years. In 1848 the family of Charles H. Waterous Sr. arrived in town, lately of Buffalo but originally from Burlington, Vermont. Charles Sr. was the son of two generations of iron workers. He had a natural talent for mechanics and had learned his trade well in Brandon Vermont. Prompted earlier by a fellow Vermonter who needed help, Charles Sr. had dabbled in the development of an electromagnetic invention in a New York workshop below that of one "Mr. Morse". This flirtation with fame was as short-lived as their invention and so Waterous returned to his previous occupation of engineer on the great lakes shipping systems. Page 111 It is not entirely clear why Charles Waterous became interested in the small Van Brocklin foundry in Brantford. Perhaps after the hectic life the family experienced previously, the appeal to settle somewhere permanently was strong. In any event, in 1848, barely a decade after the rebellious "troubles" of Upper and Lower Canada, Charles H. Waterous Sr. took a one-quarter interest partnership in the Van Brocklin foundry and his family took a temporary refuge around the corner in a solid red brick house on Queen Street. It wasn't long before Charles H. Waterous recognized what the looming importance of saw mills and equipment would be to the future of a young and heavily forested land soon slated for agricultural use. In 1849 there were 25 men employed in the foundry with an output of $30,000.. By 1895, after nearly 50 years of business the firm would employ 230 men and produce over $3,000,000. worth of goods. Detailed production information doesn't exist for the early decades, but it must have become obvious to Charles Waterous that the business was worth pursuing, for he had moved his family down to a proper homestead in "Eagle Place". This house gave its name to the whole area on the lower eastern river flats of the Grand River. By 1857-58 a new name for the firm reflected a change in partnership: "Gould, Ganson, Waterous and Co." Mr. Van Brocklin withdrew completely. This re-shuffled ownership could have been indirectly caused by the trying economy of the times. The prosperity of the Western world had been brought to an abrupt end by an economic slowdown. The Crimea debacle drew to a close and Canadian trade with the U.S. dropped 6.9 million dollars from 1857-58 (or 11 million dollars if you consider the peak of 50.3 million dollars in 1856).':. There was little hope of financial rescue from the Ottawa ministers. Apart from these international causes, the re-arranged ownership of a small foundry in the town of Brantford in 1858 left Charles H. Waterous Sr. in control. Early in 1861 Mr. Waterous could speak confidently at a banquet that after 12 years of his connection with the business, the company had turned out $750,000. in machinery with no law suits or disputes over imperfections or defects in the work executed. The firm had met, overcome, or waited out, the many diificulties arising from the commercial crises which had swept Upper Canada. 'One year ago the establishment of Gould, Ganson, Waterous and Co. had not one dollar's worth of work under contract and but little offering," declared Mr. Waterous. "Now they have $20,000 worth in course of construction. ..over $5,000. under actual contract with fresh orders coming in daily." 2 Three years later this enthusiasm and dedication was rewarded by another name change when the last of the old partners withdrew. A new partner, G. H. Wilkes, was added and for a decade the company was formally known as C. H. Waterous and Co. until 1874 when, 30 years after Van Brocklin's beginnings, incorporation created the Waterous Engine Works Co. Ltd., as it remained for a considerable time. The eighties were years of diversification into products with a future. By 1880, business capital had reached $750,000. and the company provided employment for 250 men. 3 It became increasingly obvious to the rapidly growing Waterous Company tliat saw-mills were about to be an industry of great importance. Accordingly, saw-mills and their accompanying equipment of maintenance tools were produced alongside the steam engines in the Waterous establishment. In the late fifties the company had begun manufacturing engines for oil wells in response to industry's increased requirements. 4 In the 1880's, Waterous introduced the first band mills into Page 112 Canada and “in order that the greatest efficiency might be obtained from these new mills, the company founded a school for filers at the factory during the winter". 5 The double-cutting bandmill was soon being produced, and the usual line of Waterous street fire engines were augmented by road rollers and other road building machinery. The distribution of these expanded lines spread into Western Canada and south of the border as offices in Winnipeg and St. Paul, Minnesota, were opened. This latter branch showed particular prosperity under the guidance of F. Waterous in its production of steam fire engines and pioneer grist mills, which caused the plant to double in size by 1888. 6 While the domestic market was opening up for Waterous Engine Works Co. Ltd., the period between !850 and into the 1880's saw an international market emerge. By deliberately aiming for the saw mill and forestry equipment and the demands of a growing world economy, the Waterous Engine Works began to build steady overseas sales in Commonwealth countries and throughout Europe. From the Chile coast, up the Amazon and Honduras over to New Zealand, Australia, India, Turkey, Russia, Central Europe, and Africa -Waterous equipment was spread all around the globe. Locally, waterworks equipment engineered by Waterous had been building up quite a reputation for its pressure capabilities in impressive demonstrations at fairs, prompting local orders from communities like Windsor; Orangeville; Longueit; Quebec; and Truro, Nova Scotia. 7 This tremendous expansion had its positive as well as negative results. While sales had increased to great heights, it became quite evident by 1890 that the company would have to think seriously about moving from its Dalhousie Street location. From the simple brick structure with its single horse-power-driven rotary motor that had run the machinery since 1844, the Waterous factory had spread up and down Dalhousie Street as the early stove and plow products gave way to threshing machines, saw-mills of many varieties, boilers, engines and heavy fire fighting apparatus. Despite some dullness in trade in the post confederation years, Waterous' prosperity had continued until the question of limited space could no longer be put off. New and greater premises would have to be found either in Brantford or elsewhere. The factory had been forced for many years to run a 15 to 17-hour day to meet order deadlines and employ 240 men where only 150 to 170 could work in comfort. Space was desperately needed. 8 A move from Dalhousie Street was absolutely necessary. The possibility of this successful company moving from Brantford to Woodstock or Hamilton Pg. 113 for example, was strong enough to prompt city co-operation in the form of By-Law 520. After much debate, planning and prediction, the city offered to purchase the old Dalhousie buildings while Waterous bought 25 acres on South Market Street just past the canal. There was some criticism over the city's indulgent behaviour towards Waterous but it cannot be denied that the arrangement allowed an established and prosperous company to remain in Brantford. 9 In early summer 1895, construction began on the new buildings amid much press ballyhoo. Throughout the year, weekly articles appeared reporting on the most recent progress of the building, doling out details about the expanse and capacity of the new premises. 10 Apart from the main building of some 300 by 120 feet (as reported in a company document) there were in addition, boiler, blacksmith, moulding ana other shops, equal again to the area already mentioned. Although these decorative details would come later, it was with a remarkable feat of efficiency that the building was completed by January 1896, barely 6 months after the widely reported ceremony of laying the cornerstone by Ignatius Cockshutt. 11 The Waterous Nail Works was also begun in 1896 by Julius Waterous to avoid the pressures of American combine monopolies. Before the year was out, extensions had to be made and a countrywide market responded. But this endeavour, as well as a new Brick Machinery Sales Division, took its toll in the over all company's performance. The General Manager's remarks of the 1893 performance in Brick Machinery could well have applied to the company as a whole. "While regretting that there is not a better showing, I think when we consider the state of business in the country and the fact that we are doing a great deal of work. ..which (is) a change upon the year's business, but should be useful for several years, that we may fairly congratulate ourselves on the result of the year's work.-C. M.Waterous." 12 In 1894 the net worth of Waterous Engine Works Co. Ltd. was $290,025, two-thirds of what 1890's $417,841 figure had been. In 1895 liabilities had slightly decreased and assets had slightly increased: an improving trend seemed to be settling in. By 1898 this pattern was clear when the liability figures remained at the 1894 and 1895 mark of $350,000, but the company's assets showed a marked increase of another $150,000 at $890,657. The last years of the old century indicated that a more optimistic economic picture might be in store and the Waterous Company with its new buildings and location was in an advantageous position. Around 1905 the firm was employing from 350 to 400 mechanics and the company's annual volume of business approached the $400,000 mark. Articles produced included heavy machinery, engines, boilers, saw mills, stone crushers, steam and road rollers, fire engines and ladders, hose wagons, hook and ladder trucks-a multitude of machinery styles, weights and functions. Generally, the company's performance in that first decade was steady with no grand leaps in production. There would be time enough for that in the fast approaching war years. On the brink of that second decade Waterous Engine Works was recorded as having "long held an enviable position in that' arena of the Province and its increased volume of business (was dependent upon its) excellent reputation for handling the very best quality of goods and for the fair and liberal manner with which the management (dealt) with their many employees." 14 Page 114 When a few years had passed Waterous found itself once again busily constructing a new foundry in 1912. The company's progress was followed closely by the press as illustrations and detailed descriptions of the new foundry's capacity hit national industry headlines. 15 The additional structure was fortunately planned as the heavy demands made upon Waterous during the first world war came quickly.. The Canadian Forestry-Corps steadily supplied the European Allies with timber for the miles of boarded trenches at the front, and with transportable equipment for the ever shifting service and communication installations. The company which supplied the saw mills and concrete machinery was Brantford's own Waterous. Speed was a significant factor in Waterous's favour, especially when the reality of a desperate need could be met with amazing efficiency. "Within 3 months from the date the British government sent its appeal to Ottawa, the battalion (Canadian Forestry Corps) had not only arrived in England, but its first mill was built and lumber was being delivered to the Imperial authorities". 16 Fast and high output were equated with the Waterous saw mills, originally designed to cut only 20,000 feet in a 10-hour shift, but actually producing closer to 55,400 board feet in those same 10 hours. The mills kept up that quota throughout the allies' counter attack against the German offensive in the spring of 1918. In fact, one Waterous mill in Surrey, England, was recorded as having processed to up 58,000 board feet in the 10-hour shift. 17 When America entered the Great War, Waterous had "supplied the U. S. Forestry Corps with drawings and their methods of packing their saw mill plants for transport of the most convenient kinds." 18 Waterous had certainly proved to be a significantly capable company unflappable in a crisis and cooly efficient under pressure. The American, European and further international markets began to sit up and take serious notice of the impressive first hand demonstrations furnished by Waterous-made machinery mills, boilers and engines. Not surprisingly, Waterous began to reorganize its production .lines (in post-war years) to exploit the distinction gained from their boiler and saw mills in" the Great War. By 1919 Waterous had a great deal in their favour: "three-quarters of a century of experience, the splendid reputation of its products, and the equally high reputation of its managing personnel."19 A year later the double-cutting board saw was gaining popularity (it had been tried before by many firms but without success) and it Page 115 was now displacing the circular and gang saw. A London, England representative agent had been appointed. 20 Waterous supplies were crossing the nation to British Columbia where exports were rapidly capturing the Japanese and Australian pulp and paper market.21 By the mid-1920's it was not an idle boast to declare that for Waterous Engine Works Co., “every civilized country in the world (was) their market." 22 In older days, Waterous boilers and engines were the backbone of every large city's fire department. But on into the 1920's there emerged five major product areas which reflected the changing requirements of the day. Power plant equipment (engines, high-speed or portable boilers. vertical and locomotive types etc.); saw mill equipment (band mills to chains); pulp mill quipment (with a variety able to I equip almost 8 complete mill); road construction equipment (rollers to tar distributors etc.); and steel.plate work (for pressure jobs in creating storage tanks etc.). With these "specialties" came a new name for the company -"Waterous Ltd." in 1928 – more suitable to the recent diversification and less restrictive than the old "Engine W orks" title. 23 Despite the common assumption that the 1920's were a madly bustling decade economically, many industries kept a more sedate but steady pace. Waterous Ltd. was deeply involved in great expenditures for new product lines and so the profits were ploughed back into the company's future. It is just as well this tactic was taken because once the Depression hit suddenly in 1929, it became quite evident that Waterous's diversification would save it from economic destruction. Nevertheless, the Brantford plant (an Edmonton one had been opened just in 1929) experienced wage cuts ( 10 per cent in June of 1931 and another 10 per cent in 1932) and regular two week 'turn-about' employment shifts in 1932. In that same year Waterous received favourable press comment when several road construction lines (crushing. screening and washing equipment) were introduced. The company's "steady and progressive development. in days gone by" made it a "worthwhile industrial development", unlike some fly-by-night plants that left only unpaid taxes, unemployment and bad feelings in their wake.24 By the mid 1930's, a full-year lay-off was a common occurrence. As late as 1939 the city as a whole experienced a general scramble for jobs, for it wasn't until shops were completely re-tooled for the second world war that the production slump was eradicated. Waterous had begun to re-vamp its equipment as early as 1939 and by late 1941 the whole company was completely adjusted to war production. Shells, generating engines for Corvettes, gun carriages, tank transmissions and anti-aircraft gun parts were all produced by Waterous during those years and many orders from the Ministry were completed in record times that even beat the World War I performances. Experienced Waterous employees were important enough to be recalled from overseas embarkation - their service to the war effort at home was more crucial that uniformed duty. Amidst the growing Allied strength in the European and South Pacific theatres of war, the Waterous Co. found time to arrange an elaborate 1OOth Anniversary celebration in 1944. It was an occasion for happy reminicences and renewing friendships, but also a time to recognize the sacrifice of company members killed overseas. Among the honour roll names that were displayed was one of Logan M. Waterous' sons, Charles III ("Chuck"), killed in action in Sicily in 1944. Activity in the post-war years was temporarily high, as replacement or repair material was demanded by a peace-time world that had been interrupted by the 6 years of war. Repair work alone brought in business of Page 116 one and a half million dollars. And once again the fortunate diversification in the Waterous foundry and boiler departments prevented a possible post-war slump. But soon the corporate age would catch up to the family business. Barely three years after Waterous had lavishly celebrated its lOOth birthday, the company succumbed to a brief take-over by the Toronto based Modern Tool Works Limited. It was promised that the name would remain and that Donald Waterous (as former President and General Manager) would continue as Vice-President and General Sales Manager. However, the five man group including Harold Fry and Lt. Col. L. M. Collin from Modern Tool would instead "represent management in its broadest sense"25 Despite the speculative plans. Modern Tool did not remain at the helm longer than 2 years. Adjusting to the modern world of economic consolidation, Waterous retained its family members in various department positions in purchasing. advertising and management. but gradually the family withdrew from active participation in the firm. Interest in keeping the family connection alive was simply no longer forthcoming. During these rather rudderless years it is not surprising to see that the union structure was voted into the engineering department as a first step towards organized labour relations. In 1953 the Koehring Company (a firm dealing in farm and plastic machinery manufacture, hydraulic excavations, back hoes etc.) from Milwaukee, Wisconsin, purchased control of Brantford's Waterous Limited. The economic times were not good and the temptation to survive through an amalgamation was too strong. Less than 10 years before the Cockshutt firm was to submit to similar American pressure, the Waterous take-over raised the normal apprehension within the offices and shop floor over dismissals that would inevitably result from plant re-organization. Appropriate declarations of sympathy were released to the press over the "job security" fears. An accommodating tone was kept whenever necessary over the American company's “sincere appreciation of the value of labour in industry “26 In fact, when American personnel were transplanted to the Brantford location, the odd result was that those same people became quite aggressively Canadian in their business attitudes, ever ready to defend and promote the Canadian pioneer firm within the parent company's hearing. Page 117 The 1960's and 1970's have been decades of careful expansion and exciting developments in technology and mechanical invention of Koehring-Waterous as it is now called. New offices were constructed, and concrete making equipment was phased out of operation as the company's emphasis on the timber field was reinforced. Some cutbacks had to be made, as when the two Alberta branches had to be sold after the merger in 1953. In 1964, Koehring-Waterous began to design and develop a harvester model that would take 7 years of correction and perfection before it would be marketed.27 Meanwhile the lumber fields in British Columbia had special problems in felling and shipping that were best solved by newly designed Feller-bunchers and mechanized lumber-jacks from the Koehring-Waterous Brantford plant. Gone were the days of Waterous Boilers and Engines (large and small) and the many varieties of mechanical aids that had eased the country's transition from a rural pioneer culture to an urban technological one. The big business of pulp and paper occupies most of the local plant's interest and produce. As undoubtedly as its World War I reputation for high efficiency and output, and pre-war boiler tradition were solidly established for years, so today the Koehring-Waterous Co. is adding to its international fame in the demanding world of pulp and paper equipment. No longer enjoying the benefits of a family-run business, Koehring-Waterous nevertheless has successfully made the transition and emerged as a modern international corporation.