Seminar - NO

advertisement

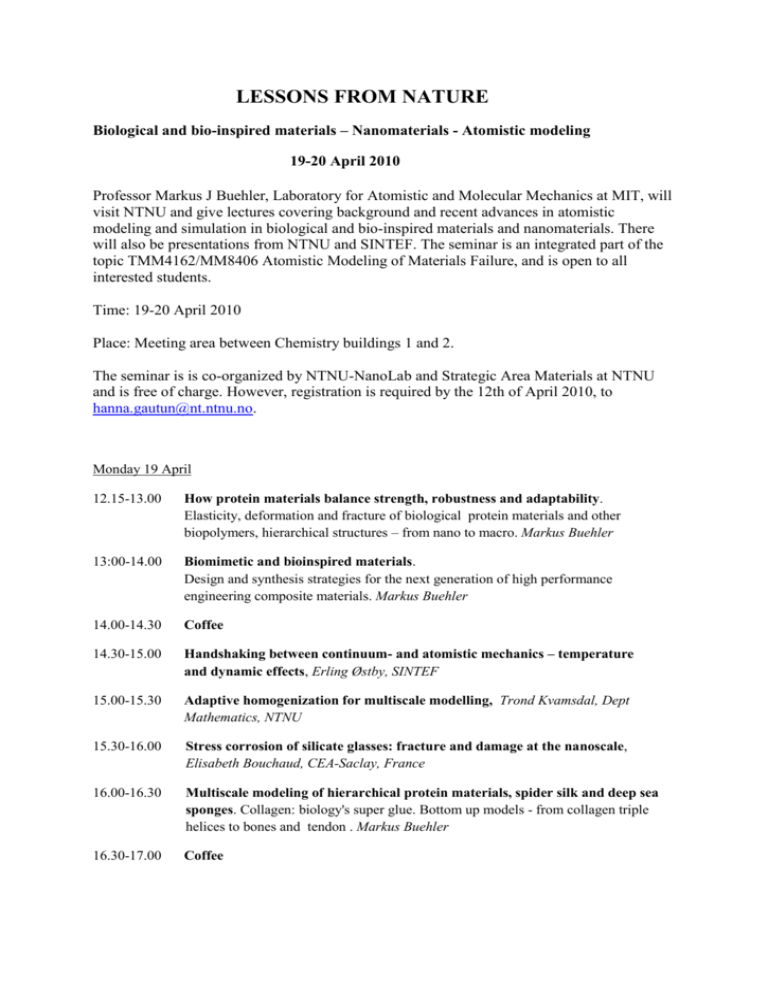

LESSONS FROM NATURE Biological and bio-inspired materials – Nanomaterials - Atomistic modeling 19-20 April 2010 Professor Markus J Buehler, Laboratory for Atomistic and Molecular Mechanics at MIT, will visit NTNU and give lectures covering background and recent advances in atomistic modeling and simulation in biological and bio-inspired materials and nanomaterials. There will also be presentations from NTNU and SINTEF. The seminar is an integrated part of the topic TMM4162/MM8406 Atomistic Modeling of Materials Failure, and is open to all interested students. Time: 19-20 April 2010 Place: Meeting area between Chemistry buildings 1 and 2. The seminar is is co-organized by NTNU-NanoLab and Strategic Area Materials at NTNU and is free of charge. However, registration is required by the 12th of April 2010, to hanna.gautun@nt.ntnu.no. Monday 19 April 12.15-13.00 How protein materials balance strength, robustness and adaptability. Elasticity, deformation and fracture of biological protein materials and other biopolymers, hierarchical structures – from nano to macro. Markus Buehler 13:00-14.00 Biomimetic and bioinspired materials. Design and synthesis strategies for the next generation of high performance engineering composite materials. Markus Buehler 14.00-14.30 Coffee 14.30-15.00 Handshaking between continuum- and atomistic mechanics – temperature and dynamic effects, Erling Østby, SINTEF 15.00-15.30 Adaptive homogenization for multiscale modelling, Trond Kvamsdal, Dept Mathematics, NTNU 15.30-16.00 Stress corrosion of silicate glasses: fracture and damage at the nanoscale, Elisabeth Bouchaud, CEA-Saclay, France 16.00-16.30 Multiscale modeling of hierarchical protein materials, spider silk and deep sea sponges. Collagen: biology's super glue. Bottom up models - from collagen triple helices to bones and tendon . Markus Buehler 16.30-17.00 Coffee 17.00-17.45 Recent developments in modeling and applications of carbon nanotubes and other nano-materials. Applications to mechanomutable materials. Markus Buehler 18.00 Dinner Tuesday 20 April 09.15-10.00 Fracture mechanics of proteins: Fundamentals and bottom-up modeling. Atomistic-level simulation approaches. Force field potentials for biological materials. Flaw tolerant protein networks. Markus Buehler 10.15-10.45 Novel spectroscopic tools for studies of amyloid protein states. Mikael Lindgren, Dept of Physics, NTNU 10.45-11.15 Nanoscale probing of the biopolymer energy landscape: selected examples, Marit Sletmoen and Bjørn Torger Stokke, Dept of Physics, NTNU 11.15-11.45 Molecular models of electrostatics in force fields. Per Olof Åstrand, Dept of Chemistry, NTNU 11.45-12.15 Mitral valve mechanics: using microstructural observations as basis for physiological modeling and numerical analysis. Bjørn Skallerud, Dep of Structural Engineering, NTNU 12.15-13.15 Lunch 1315-13.45 Towards Petascalecomputing@NTNU. Bjørn Lindi, Dept Information Technology, NTNU 13.45-1415 14.30-15.00 Effect of atomistic surface steps on the Brittle to Ductile Transition, Christian Thaulow, Dept Engineering Design and Materials, NTNU Case study on bioinspired hierarchical nanocomposites. Dipanjan Sen, Graduate student, MIT Brief biography – Markus Buehler Markus Buehler is the Esther and Harold E. Edgerton Associate Professor in the Department of Civil and Environmental Engineering at the Massachusetts Institute of Technology. Before joining MIT in 2005, he served as the Director of Multiscale Modeling and Software Integration at Caltech’s Materials and Process Simulation Center. After obtaining a M.S. in Engineering Mechanics from Michigan Tech, he received a Ph.D. in chemistry from the Max Planck Institute for Metals Research. Professor Buehler’s research focuses on bottom-up simulation of structural and mechanical properties of biological, bioinspired and synthetic materials across multiple scales, with a specific focus on materials failure from a nanoscale and molecular perspective. His recent work has focused on applying a computational materials science approach to study materials failure in biological systems, including the investigation of material breakdown in diseases. Professor Buehler has published more than 100 articles on computational modeling of materials using various types of simulation techniques. He was cited as one of the top engineers in the United States between the ages of 30-45 through invitation to the 2007 National Academy of Engineering-Frontiers in Engineering symposium of the National Academy of Engineering. Professor Buehler has also received the 2007 National Science Foundation CAREER award, the 2008 U.S. Air Force Young Investigator Award, the 2008 Navy Young Investigator Award, and the 2008 DARPA Young Faculty Award. In 2009, his work was recognized by the Presidential Early Career Award for Scientists and Engineers (PECASE). Dipanjan Sen (PhD student MIT) Atomistic and mesoscale modeling of mechanics of bio-inspired metal matrix composites Abstract: The nanostructural makeup and hierarchical assembly of natural composite materials such as bone or nacre are crucial for their superior mechanical properties over their constituent phases, providing high strength and toughness at high stiffness. However, the transfer of similar mechanical properties to functional metal-matrix composites remains challenging. Here we propose the design of a hierarchical biomimetic metal-matrix nanocomposite inspired by the structural motif found in biological materials. The deformation response to tensile loading of a biomimetic metal-matrix nanocomposite is firstly studied using molecular dynamics. Maximization of flow strength of the nanocomposite is observed through breakdown of dislocation-mediated plasticity at platelet dimensions of nanometers. The response to tensile loading, of the nanocomposite with two levels of structural hierarchy, is next probed through atomistically-informed mesoscale lattice-spring simulations. In particular, general design strategies to maximize material toughness and strength simultaneously through assembly at two or more levels of hierarchy are explored. We observe that geometric confinement at each structural level maximizes strength and toughness of the material. The discussion concludes with an illustration of how hierarchical designs can be used to optimize the material behavior at different levels in a material’s organization, leading to superior performance.