Ricercaforestale

advertisement

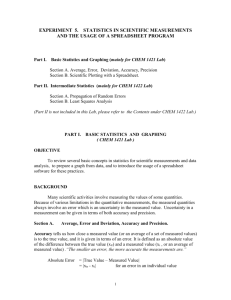

Ri.Selv.Italia SubTask 2.2 Wood production outside forest – Wood production arboriculture with fast-growing species (poplar cultivation) Scientific referent dr. Achille Giorcelli (C.R.A. – Unità di Ricerca per le Produzioni legnose fuori foresta, Casale Monferrato – AL) Final Report Title: 2.2.1 – Technical and economic evaluationof of poplar logging. Working Unit (W.U.): C.R.A. – Unità di Ricerca per le Produzioni legnose fuori foresta, sede distaccata per le colture da legno in ambiente mediterraneo, Via Valle della Quistione 27 – 00100 ROMA Head of W.U.: dr. Stefano Verani stefano.verani@entecra.it; verani.s@inwind.it 1) Object of the research In the forest logging operation, the use of the high mechanization (harvester especially), in comparison to other European countries, in Italy is limited. Traditional mechanization ( using chain-saw for felling and processing and agricultural tractor for extraction ) is mostly employed. Even in the poplar plantations, despite their peculiar technical characteristics, the advanced mechanization is not very employed. In fact, if we consider the technical point of view, the use of a harvester on these plantations, generally consisting of regulated stem and rather contained branches plants, is particularly suitable emphasizing the machine productive abilities. In our country today about 50 harvesters are in working, with different settings (on agricultural tractor, on excavator and specialized engine) and some wood enterprises are endowed with forwarder, for lumber extraction, and with chipper, for chips production. Certainly, the problematic tied to the elevated price of purchase of these vehicles (at least 200.000 Euro) and the high specialization of the operators required as well as the excessive private ownership splitting up that hinders the use on ample surfaces, remain as negative elements. It’s necessary remember that from an economic point of view, the poplar assortments (particularly the veneer log) obtain excellent prices on average, and they guarantee the company a possible increase of amortization and the invested capital for the new machines purchase recovery. In this context, the main objective of research has been to verify if the technical-economic conditions for a further diffusion of this specialized machines are available in our country. The technical performances and the operating costs of the specialized machines, for single logging operations, are calculated. These data, with those recorded for the machines in the traditional mechanization using, are compared. 2) Materials, methods and working plans In a first phase the research has foreseen with the location of different work sites: among these nine have been selected in connection with the level of mechanization employed. The work sites are situated in center-northern Italy. Three degrees of mechanization are individuated: the traditional mechanization; the traditional advanced mechanization and the high mechanization. In traditional mechanization, for the felling and trees processing the chain-saw is used; for the extraction, in the case of limbed stems, the agricultural tractor partially suited for the forest use, or, in the case of logs, the trailed pulled by tractor, are used. Using the mechanization the type traditional advanced a machine (generally an excavator), moving the stems or the logs, is employed. Using the high mechanization, all the harvesting operations are mechanized: harvester, for felling and trees processing is used; forwarder for logs loading and extraction is used. In some work site the chipper, for chipping the tops and limbs, is used. The work sites with a traditional mechanization were three and all situated in Lazio region; that one with a traditional advance mechanization is situated in Toscana region. Those with 1 Cost (euro/t) high mechanization are five and situated in the Lombardia region (two), in the Emilia Romagna region (one) and in the Toscana region (two). Before dealing with poplar plantation logging, stands in every single work site are characterized for many Traditional mechanization Advanced mechanization parameters (age, planting scheme, clone) as well as the average volume of the 4,078 4,500 trees and the the different final assortments (veneer 2,842 2,207 logs, sawlogs, pulpwood) 3,000 are determined. This 1,216 parameter, compared to the 1,000 1,000 1,500 480 390 execution’s times 295 331 operations, has allowed a 0 calculation of work Felling and Extraction Chipping Loading Total logging processing productivities for each operation. Figure 1-Comparison of the average costs per hectare of the poplar Comparing the plantation logging for the different degree of mechanization adopted. productivities of work to the operating cost of the machines, the unitary production cost of every assortment is determined. The work productivities, on the basis of the execution times recorded in every operation (felling, limbing, bucking, extraction, load of the logs and chipping), are calculated. Only in the two work sites the chipping time are recorded, and consequently therefore the unitary production cost is calculated. The work times are recorded, according to the logical sequence, of the logging operation. 3) Scientific results and innovation. The productivity and costs of every operation (felling and processing, extraction and chipping) in the examined work sites are determinated. The whole productivity of work sites is determinate too. The results got, degree of mechanization Parameters Traditional Advanced from the examined work sites, in -1 connection with employed 200 200 Wood harvested (t ha ) mechanization degree, are gathered Average tree weigth (t) 0.72 0.72 in two principal typologies: Operator (N.) 2 1 traditional work sites, which are -1 73.57 12.16 Gross working time (h ha ) work sites with traditional -1 2.72 16.45 Productivity (t h ) mechanization and those with traditional advance mechanization, Table 1 – Gross times and average productivity of the felling and processing operation. and advanced work sites, characterized by an high mechanization employed. The values, for the two typologies showed, represent the average of the results of the work sites and they are related to four assortments: veneer logs, sawlogs, pulp wood and chips. In table 1, the gross times and degree of mechanization Parameters Traditional Advanced the gross average productivities of the felling and 160 160 Average extracted load (t ha-1) processing operation, in Average extraction distance (m) 184 184 reference to a poplar Operator (N.) 1 1 plantation with 277 trees per Average Transported load (t) 1.60 14.60 hectare and an average stand -1 11.48 6.03 Gross working time (h ha ) production hypothesized of -1 13.93 26.63 Productivity (t h ) 200 t per hectare, are reported. In the advanced Table 2 – Gross times and average productivity of the extraction system the gross times of work operation. per hectare are middly reduced of about six times in comparison to the traditional system and realizing hourly productivity of about six times higher. 2 In the extraction, the gross average productivities of the advanced system increases to 90% in comparison to the traditional system (table 2); the work times per hectare in the advanced system reduce it of around the half. Of the total wood manufacture, middly 40% are Average value destined to veneer production, while for the Assortments euro/t sawmill, paper mill and chips production, the Veneer log 135.00 same 20% are esteemed. Therefore, limbs and Sawlog 70.00 top excluded, timber represents the 80% of the Paper wood 45.00 commission. Various assortments average market prices hypothesized and stumpage are Chips 40.00 reported in table 3. Chips production cost, for Stumpage 50.00 both work sites typologies, is considered equal, Table 3 - Hypothesis of market’s prices of the assortments and stumpage. supposing that the operation is submitted to a outside contractor with a cost of 25 Euro/t wood, load on truck included. The economic evaluation is finalized to the calculation of the production cost and budget of the two typologies of enterprises. The economic elements and manpower rates are referred to a year 2005. The hourly rate imputed to manpower, is of 20 Euro for the harvester’s operator, and 12 Euro for all the other operators. The average investment of capital for purchasing machines is considered of 50.000 and 370.000 Euro respectively for the traditional and advanced system. In this last case is considered the hypothesis of machines on the secondhand market purchase. Considering economic elements above suitable and average productivities, in figure 1 the unit average costs of the single effected operations and the whole poplar plantation logging, for the two systems, are reported. Proceeds are calculated in reference to the average market’s prices of the assortments and the quantities obtained, on the basis of the percentages above reported. The elements and the calculation of the economic budget and the profitability, for the two typologies of enterprises, are showed in table 4. 4) Conclusions, general comments and possible further investigations The analysis shows a smaller average cost of production in the advanced work system. The production cost is reduced of 30% (2.842 against 4.078 Euro). Work times, for unit of surface, results four times lower: theoretically using advanced work system, 68 hectares per year are harvested forehead. On the other hand, using the traditional work system, 17 hectares per year are harvested. Traditional Advanced ratio (b)/(a) The annual capital Technical-economic parameters mecanization (a) mecanization (b) % invested in -1 200.00 200.00 100.0% Stand production (t ha ) mechanization 160.00 160.00 100.0% profitability in the Timber production (t ha-1) -1 advanced system 95.72 23.62 24.7% Gross time of extraction (h ha ) -1 results equal 32%, 200 200 100.0% Average working period (day year ) against few more than 16.71 67.75 405.4% Average surface harvested (ha year-1) the 17% of the -1 10,000.00 10,000.00 100.0% Stumpage (euro ha ) traditional system. In -1 4,077.62 2,842.39 69.7% Average cost of extraction (euro ha ) synthesis, in reference -1 2,400.00 2,400.00 100.0% Average cost of transport (euro ha ) to the technical-1 16,477.62 15,242.39 92.5% Total production cost (euro ha ) economic parameters -1 17,000.00 17,000.00 100.0% Average proceeds (euro ha ) and to the economic results, can be 522.38 1,757.61 336.5% Net income (euro ha-1) affirmed that the 8,728.97 119,078.08 1364.2% Annual net income (euro year-1) conditions for a Purchase machines cost (euro) 50,000.00 370,000.00 740.0% greater diffusion of the Return on investment 17.46% 32.18% 184.3% advanced Time of return of the capital (years) 5.73 3.11 54.2% mechanization subsist. Table 4 - Elements of the economic budget in the two typologies of enterprise. The values of obtainable profitability from the work site to smaller mechanization, also considering the actual contingency of the poplar market, are satisfactory. 3 The possible expansion of an advanced mechanization is subordinate to the availability of operators with high professionalism, able to exploit to full the potentialities of the machines, and to the good organizational and administrative enterprises ability in quickly reacting to any sudden poplar wood market variation. Participants Dott. Giulio Sperandio –Ricercatore, CRA-Unità di Ricerca per l’ingegneria agraria di Monterotondo (Roma) Tel.+390690675218 Fax +390690625591 e-mail: giulio.sperandio@entecra.it; g.sperandio@ingegneriaagraria.it Dott. Giuseppe Pignatti- Ricercatore, CRA- Unità di Ricerca per le produzioni legnose fuori foresta sede distaccata di Roma. Tel. +390661571034 Fax+390661571030 e-mail: giuseppe.pignatti@entecra.it Total funds 1st year: 2nd year: 3rd year: TOTAL: € 11.104,00 € 16.500,00 € 8.000,00 € 35.604,00 Publications Verani S., Sperandio G., 2003. Utilizzazione del pioppeto. Sherwood n. 88: 37-44. Verani S., Sperandio G., 2003. Meccanizzazione spinta per la raccolta di biomassa lungo alvei fluviali. Mondo Macchina 12(4):56-59. Verani S., Sperandio G., 2004. Valutazione tecnico-economica dell’impiego della meccanizzazione nell’utilizzazione del pioppeto. In: Convegno “Presentazione e discussione dei primi risultati di Ri.Selv.Italia”. Sessione Poster. Milano,16 settembre. Pubblicato sul sito www.ricercaforestale.it/riselvitalia/poster. Verani S., Sperandio G., 2004. Valutazione tecnico-economica dell’impiego meccanizzazione nell’utilizzazione del pioppeto. EM-Linea Ecologica 36 (6): 61-64. della Verani S., Sperandio G., 2004. Technical economic evaluation of the use of mechanization in poplar plantation logging. In: 22 nd session International Poplar Commission. Santiago, Chile November 28- December 2. Verani S., Sperandio G., 2005. Potatura meccanizzata di un giovane pioppeto. Alberi e Territorio 2 (4/5): 50-53. Verani S., Sperandio G., 2005 - Valutazione tecnica ed economica delle macchine per l’abbattimento e l’allestimento del pioppeto ---Poster n. 1/2/3/4/5 – In: Giornata dimostrativa sull’utilizzazione del pioppeto con meccanizzazione spinta. CRA ISMA Monterotondo Verani S., Sperandio G., 2006. Meccanizzazione avanzata nella raccolta del pioppeto. Quali margini di convenienza economica? Sherwood n. 122: 31-35. Verani S., Sperandio G., 2006. La meccanizzazione avanzata nel taglio del pioppeto: analisi di convenienza. In: Convegno “Gestione forestale sostenibile tra bioenergie, utilizzo energetico delle acque e impatti socio-economici ambientali nelle aree protette”Sessione Poster. XIV D.I.M.A.F., San Severino Lucano (PZ), 6-7 ottobre 2006. 4 Publications in press Verani S., Sperandio G. - Meccanizzazione spinta nel taglio del pioppeto: analisi di un cantiere. Sherwood Title: Use of high mechanization in poplar plantation logging: work site analysis. Abstract The paper deals with logging poplar 14 years old poplar plantation in Tuscany in the Pisa district. The degree of, harvester for cutting and processing, forwarder for hauling and large chopper for chipping, was employed. The average daily production was 120 ton for sawlogs. The economic point wiew the high mechanization it guarantee a 13,9% profitability. The results suggest the possibility of high mechanization diffusion in poplar plantation logging. 5