Indian Chemical Council

advertisement

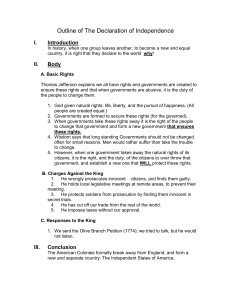

INDIAN CHEMICAL COUNCIL (FORMERLY: INDIAN CHEMICAL MANUFACTURERS ASSOCIATION) PRE-BUDGET MEMORANDUM FOR THE UNION BUDGET FOR THE YEAR 2011-12 1 The Indian Chemical Council (ICC) represents one of the major sectors of Indian economy i.e. Chemical Industry. The Council was founded by Acharya P.C. Ray & Dr. B.D. Amin. The Council has over 350 members representing all segments of Chemical Industry such as Inorganic and Organic Chemicals, Petroleum Refining Petrochemicals, Fertilizers, Agrochemicals Pesticides, Dyes, Pharmaceuticals, Paints, Specialty Chemicals etc. While the size of the global chemical industry is in the region of USD 3 Trillion, the Indian chemical industry has an output of around USD 80 Billion and ranks 12th in the world. While the overall industrialization and economic growth in India provides major opportunities for growth of chemical industry in India, there are some severe constraints and stumbling blocks like, Surge of imports from Asian and Middle East countries. Producers from Middle East (with feedstock cost advantage) and China aggressively pursuing Indian markets due to very low tariff levels. Growing menace of dumping High cost of Power, Energy, Finance and Capital Equipment Internal transaction costs being one of the highest in India Internal taxes – VAT rates substantially higher than other Asian countries. High logistics cost due to poor infrastructure State levies, entry taxes add to the local transaction cost 2 SECTION-I: GENERAL CONCERNS OF THE INDIAN CHEMICAL INDUSTRY ON INDIRECT TAXES Peak Import Duty on Chemicals: The Peak Import Duty on chemical products in India at 7.5% ad valorem level is at one of the lowest levels in the world. Last two decades have seen a major decline in Import Duty on chemicals in India from 300% in 1990 to current level of 7.5%. Besides this, the current Import Duty level is well below India’s bound rates under the WTO. Such low Import Duty level is against a scenario of rising costs of finance, fuels, power etc., which continue to be higher than in other parts of the world. The year 2010 has seen slow down in new investments in chemical industry in India. While we go into 2011-2012, the current trends in Rupee appreciation indicate further appreciation likely in the year 2011 as per the figures given below by the Financial Forecast Centre, Houston, Texas. Month Rupee/ USD Oct 2010 44.36 Nov 2010 44.9 Dec 2010 44.5 Jan 2011 44.3 Feb 2011 43.9 Mar 2011 43.5 Apr 2011 43.1 May 2011 42.8 Jun 2011 42.6 3 This will cause the landed cost of imported chemicals to drop by 5.12% in Rupee terms. This is in face of Rupee appreciation that has already happened so far since January 2009 of 8% as can be seen from Chart below: While this Rupee appreciation will bring the cost of imported chemicals down, the conversion costs of chemical industry (from raw materials to downstream chemicals) like cost of finance, fuels, power, manpower etc. have shown significant increases and these costs continue to rise further as can be seen from the figures, tables and charts below. The benchmark interest rate (reverse repo) in India was last reported at 5.25 percent. Interest rates are decided by the Reserve Bank of India's Central Board of Directors. These interest rates have shown an increase of 61.5% between January 2010 and November 2010. 4 Year Jan Feb Mar Apr May Jun Jul Aug Sep Nov 2010 3.25 3.25 3.38 3.63 3.75 3.75 4.08 4.50 5.00 5.25 INDIAN RLNG PRICE TREND - USD/MM BTU 9.00 RLNG PRICES-USD/MMBTU 8.80 8.60 8.40 8.20 8.00 7.80 7.60 7.40 7.20 7.00 Feb-10 Mar-10 Apr-10 May-10 Jun-10 Jul-10 Aug-10 Sep-10 Oct-10 Nov-10 MONTH AND YEAR 5 NATURAL GAS PRICES IN USA 220 NG PRICES- USD/ CBM 200 180 160 140 120 100 Dec-09 Jan-10 Feb-10 Mar-10 Apr-10 May-10 Jun-10 Jul-10 Aug-10 Sep-10 Oct-10 MONTH AND YEAR The inflation rate in India (of 9.7% as reported in October 2010) which has been a matter of concern all through the year has caused manpower costs to rise significantly in recent times and the trend is likely to continue unabated. Besides this, with the rising expectations of skilled manpower of Salary and Benefits in an era of globalization, the impact has got compounded and manpower costs of major corporates in manufacturing sector have been increasing at double digit rates (in some cases of over 15% per annum). In view of the hardship, we request the Government of India to increase the Peak Import Duty on Chemicals from 7.5% ad valorem to 12.5% ad valorem in the forthcoming Union Budget. 6 Need for Zero Import Duty on Feedstocks: For Indian chemical industry to be competitive, there is an imperative need for feedstocks and fuels to be available at international prices. We therefore request for Zero Import Duty on the following: Naphtha (Tariff Code 2710-1190) Hydrocarbons such as Ethane, Propane (Tariff Code 2901-1000, 2200) etc. which are feed stocks for manufacture of a wide range of Organic Chemicals and which currently attract Import Duty of 5% ad valorem. Change in Revenue if ID on Naphtha is eliminated 2009-10 Imports (MT) Naphtha S'pore ($/Mt) Value of Naphtha Import (Rs Crs) Revenue at 5% ID (Rs Crs) 949402 623 2796 140 10-11 11-12 (Estimate) 1009779 712 3328 166 1073996 800 3866 193 Total Revenue Loss in 2011-12 (Rs crores) 193 Note: Considering Naphtha imports by Haldia & Reliance. Naphtha Singapore Price is Platts average Need for Zero Import Duty on Ethanol (Tariff Code 2207 20 00): Ethanol is an important renewable feedstock for Indian chemical industry. There is a significant deficit in production of the same in India. Presently, this basic input attracts Import Duty of 7.5% ad valorem. We request the government levy Zero Import Duty on this basic input. Hon. Finance Minister 7 had also indicated that if the ethanol program for fuel blending was to commence, then the duty would be brought down to zero. Import Duty on Coal (2701 1100) and LNG (2711 1100): Manufacture of chemicals involves carrying out Unit Operations and Processes under very high pressures or very high vacuum, at very high or very low temperatures. These requirements impose high consumption of energy on the chemical industry. Besides this, chemical products need to be pumped or carried from one process or operation stage to the other mechanically, which also consumes a lot of energy. Chemical industry is therefore highly energy intensive. For Indian chemical industry to be globally competitive, it is necessary for fuels such as coal, natural gas and the liquid fuels from petroleum fractionation to be available to the Indian chemical industry at international prices. Coal is still a major source of energy for the Indian chemical industry. In line with our request for fuels to be made available to Indian industry at international prices, we request the Import Duty on Coal to be reduced from 5% ad valorem to zero. LNG is becoming increasingly important as an energy source. LNG currently attracts Import Duty of 5% ad valorem, which may kindly be reduced to Zero. COAL DEMAND AND SUPPLY PRODUCTION-MN TONS PER ANNUM 531 IMPORTS- MN TONS PER ANNUM 35 8 CONSUMPTION- MN TONS PER ANNUM 566 CURRENT PRICE OF AUSTRALIAN THERMAL COAL - USD/MT 117 NATURAL GAS- DEMAND SUPPLY IN INDIA MMSCMD MN TPA PRODUCTION 132 33 IMPORTS 35 9 CONSUMPTION 167 42 Import Duty on other Fuels: While fuels and basic inputs need to be made available to the industry ideally at international prices, Import Duty on Fuels [including Furnace Oil/ LSHS etc. (Tariff Code 2710 1950)] falling under Chapter 27 is 10% ad valorem, which is higher than the Import Duty on most of the chemical products (at 7.5%) ad valorem. While, ideally, fuels need to be made available to Indian industry at international prices and should ideally be eligible for import at Zero duty, we request at least for roll back of duty to 5% ad valorem. LSHS AND FURNACE OIL- MN TPA FO+LSHS ETC. PRODUCTION-2009-10 EST 17.54 IMPORTS-2009-10 EST 0.76 EXPORTS-2009-10 EST 5.17 Import Duty on Catalysts: Catalysts are an important input for manufacture of chemicals and decide the efficiency and cost of manufacture of chemicals produced in India. Usage of superior and selective catalysts leads to lowering of energy, power and capital costs. We have been requesting for Zero Import Duty on Catalysts. Certain precious metal Catalysts like Nickel or Nickel Compounds (Tariff Code 9 3815 1100) and Palladium (Tariff Code 3815 1200) Copper Chromite (Tariff Code 38159000) and others (tariff Code 3815 1290) attract Import Duty of 7.5%, which may kindly be reduced to Zero. Import Duty on Para-Xylene: This is a case of Inverted Duty Structure. The Import Duty on Naphtha which is a basic input is higher at 5% ad valorem, while the Import Duty on ParaXylene is Zero. We request the government to correct this anomaly and fix the Import Duty on Para-Xylene at 5% ad valorem. PARA XYLENE OVERALL SCENARIO QTY FIGURES IN '000 TONS DEMAND >2200 PRODUCTION-ESTIMATE-2009-10 2237 JAN-OCT-IMPORTS-ANNUALISED 395 IMPORT PRICE- AVG 2010-USD/MT 1011 REVENUE GAIN- RS. CRORES 92 Import Duty on Basic Building Blocks: o Olefins: Ethylene (2901 21 00), Propylene (2901 22 00) and other Olefinic monomers like Butene (2901 23 00), Octene (2901 29 00) are derived from Naphtha and currently attracts 5% duty. Since, these are primary building blocks, Import Duty on these may be reduced to 2.5% ad valorem. o Aromatics: 10 Benzene (2902 20 00), Toluene (2902 30 00), Ortho-Xylene (2902 41 00), Mix-Xylene (2902 44 00), Cumene ( 2902 70 00 ) and Ethyl Benzene (2902 60 00) are starting points for Organic Chemical Synthesis and presently attract 5% ad valorem Import Duty. We request that the Import Duty on these Basic Inputs be maintained at not more than 5% ad valorem. PRODUCT IMPORTS PRODUCTION AVG PRICE (CIF) ‘000 TONS ‘000 TONS OF IMPORTS JAN-OCT-2010 APR-DEC-09 ANNUALISED ANNUALISED BENZENE 64 821 46.14 991 5 5 - TOLUENE 187 136 41.85 902 5 5 - O-XYLENE 66 361 51.09 1098 5 5 - Rs./Kg IMPORT DUTY (%) PRESENT PROPOSED REVENUE GAIN/LOSS US$/MT Rs. Lakhs Inverted Import Duty Structure: There are various cases of Inverted Duty Structure (other than of Para-Xylene vs. Naphtha) which need to be corrected. We have come across two types of cases of Inverted Duty Structures: One related to the proposals in Union Budget The other arising out of the Free Trade and Regional Trade Agreements that India has entered into We are requesting correction of all these individual cases dealt with in detail in the next Section. Special Additional Duty (SAD) on Imports: SAD is a reflection of CST. However, the present rate of SAD is 4% ad valorem. We request that SAD rate be fixed in line with the prevalent CST rate of 2%. We also request that no exemption be granted from SAD on imported goods if locally manufactured goods are subject to CST/ VAT (except import against advance license). 11 Cess on Coal: In the last Union Budget, there is an additional levy in the form of Cess of Rs. 50/ Ton of Coal, which has led to increase in Power Generation cost by Paise 3.5 to 4 per KWH. Since this increase cannot be passed on to the domestic/ individual consumers, the load on industrial consumers is even higher. While the idea of the government to promote Clean Energy is commendable, the additional cost to the industry would be onerous. We request reconsideration of decision to impose Cess. In case Cess need to be continued it should atleast be made vatable. Duty on capital goods to be brought down to encourage investment Chemical industry is capital intensive. Besides this, competitiveness of Indian industry depends on operating at economic scales of operation and higher scales mean higher investment. The necessity for the industry to operate in environmentally friendly and safe manner necessitates even higher investments in plant and equipment and in instrumentation. We therefore request that Capital Goods be made Duty Free or the Import Duty on Capital Goods be brought down to a level not more than 5% ad valorem. Capital Goods and Fuels for Captive Power Plants: Energy is a vital input for Chemical industry. Availability of power both in terms of quantity and quality is deficient in most of the states compelling the industry to setup captive power plants. It is therefore recommended that inputs/equipment of captive power plants and their spares are allowed 12 duty free. Similarly, fuels required for captive power plants may also be allowed at zero rate of duty. 13 Inverted Excise Duty/ CENVAT structure: A. Molasses for Denatured Ethyl Alcohol and finally for Ethyl Acetate: The government has reduced the rate of Excise Duty (CENVAT) on most of the products including chemicals from 14% to 10% without any corresponding reduction in specific duty on Molasses. Excise duty on Denatured Ethyl Alcohol is effectively lower than Excise Duty on Molasses (Tariff Item 1703 10 00) at Rs. 772/ MT (equivalent to the rate of 16%) and this is an Inverted Duty Structure. Denatured Ethyl Alcohol is used by the chemical industry as substitute for petroleum feedstock and is also used for manufacture of Ethyl Acetate. It is therefore requested that Excise Duty on Molasses for use in the manufacture of Denatured Ethyl Alcohol (non-potable) be reduced to equivalent of 8% ad valorem or Rs. 386/PMT whichever is lower. B. Naphtha: CENVAT/ Excise Duty on chemicals is 10%, while CENVAT/ Excise Duty on Naphtha is higher at 16%. Naphtha is an input for the chemical industry. As a result, there is a distortion. It is requested that Excise Duty on Naphtha be brought down to 10%. C. Furnace Oil: Similarly, CENVAT/ Excise duty on Furnace Oil is 16% and needs to be reduced to general Excise Duty level of 10%. 14 SCETION-II: OUR CONCERNS ON SPECIFIC PRODUCTS/ INPUTS/ INTERMEDIATES INVERTED DUTY STRUCTURE ON LINEAR ALKYL BENZENE (LAB) VIS-À-VIS ITS RAW MATERIALS: The Import Duty on LAB is 7.5% ad valorem, while the Import Duty on inputs such as Normal Paraffin/ Kerosene is higher at 10%. We request that this Inverted Duty Structure be corrected. INVERTED CUSTOMS DUTY STRUCTURE ON NONYL PHENOL & DODECYL PHENOL (@ 7.5% AD VALOREM) VIS-À-VIS THEIR RAW MATERIALS PROPYLENE TRIMER (NONENE) & PROPYLENE TETRAMER (@ 10% AD VALOREM): Nonyl Phenol (Tariff Code: 2907 1300) is manufactured from Propylene Trimer (also called Nonene; Tariff: Code 2710 1990) and Phenol (Tariff Code: 2907.11). Dodecyl Phenol (Tariff Code: 2907 1950) is manufactured from Propylene Tetramer (Tariff Code: 2710 1990) and Phenol (Tariff Code 2907.11). Chemically, Propylene Trimer (Nonene) & Propylene Tetramer are Olefins like Ethylene, Propylene, Octene etc. They are Organic Chemical Building Blocks in slightly semi-pure form & come straight out of Petroleum Refineries. They are used as chemical raw materials (without further purification) directly for chemically reacting with Phenol to give Nonyl Phenol & Dodecyl Phenol. 15 The World Customs Organization classifies few Organic Chemical Building Blocks coming from Petroleum Refineries in slightly semi-pure form as a part of Chapter 27 (which primarily covers mineral fuels/ mineral oils) and this classification appears correct and is not being disputed. Both Propylene Trimer i.e. Nonene & Propylene Tetramer are completely imported into India as there is no domestic manufacturer. Since the Import Duty on Mineral Fuels falling under Chapter 27 is 10%, Propylene Trimer (Nonene) & Propylene Tetramer also attract 10% Import Duty. The Basic Customs Duty on Phenol is 7.5% ad valorem. Basic Customs Duty on their derivatives Nonyl Phenol & Dodecyl Phenol is also 7.5% ad valorem. This clear case of Inverted Duty Structure needs correction. Propylene Trimer (Nonene) & Propylene Tetramer being Olefins & Basic Building Blocks should attract Import Duty of not more than 5% ad valorem. We request the government to reduce Import Duty on Propylene Trimer i.e. Nonene and Propylene Tetramer (both falling under Tariff Code: 2710 1990) to a level not exceeding 5% ad valorem. PRODUCT DUTY PAID IMPORTS (KL) AVG PRICE (CIF) Rs./Kg US$/MT IMPORT DUTY (%) PRESENT PROPOSED OF IMPORTS REVENUE GAIN/LOSS Rs. Cr CURRENT IMPORT LEVELS PROP. TRIMER 4080 72.9 1.62 10 5 -1.49 PROP. TETRAMER 3850 67.5 1.50 10 5 -1.30 16 The negative impact on Customs revenue due to reduction in Import Duty will be compensated by spurt in demand for Nonyl Phenol and Dodecyl Phenol leading to increased imports of Propylene Trimer and Propylene Tetramer. This is besides increased revenue from CENVAT, Sales Tax and local levies due to spurt in domestic sales and production of Nonyl Phenol and Dodecyl Phenol. INVERTED DUTY STRUCTURE ON POLYMERS & CHEMICALS VIS-À-VIS ITS STARTING RAW MATERIAL NAPHTHA: Under the India-Singapore CECA, Polyolefin Imports are eligible for concessional 3.35% Import Duty, while Import Duty on Naphtha is higher at 5%. There is an immediate need for reduction in Import Duty on Naphtha to zero level. INVERTED DUTY STRUCTURE ON OLEOCHEMICALS: The Import Duty on the inputs Palm Fatty Acid Distillate and Palm Kernel Fatty Acid Distillate (both falling under Chapter 3823 1900) is 14% even under ASEAN-India FTA and Import Duty on another input Crude Glycerine (1520 0000) is 12.5% ad valorem. However, the Import Duty on their derivatives Stearic Acid (Ch. 3823 1190), Refined Glycerine (Ch 2905 4500) and Soap and Soap Noodles (Ch. 3401 2000) is lower at 7.5% ad valorem and on Fatty Alcohol (Ch. 3402 3709) also it is lower at 12% (than the duty on its inputs). We request that the Import Duty on all the Inputs mentioned herein be reduced to 7.5% ad valorem level. 17 IMPORT DUTY ON SODIUM NITRATE: The Import Duty on Sodium Nitrate is Zero based on the rationale that it is used as a Fertilizer. In India, Sodium Nitrate is not used as fertilizers. Actually, product used in the country is as an input in manufacture of Glass & Ceramics, Pharmaceuticals, in Water Treatment, Food Industry, Dyes & Pigments etc. We request that Import Duty on this product be fixed at 7.5% ad valorem level in line with Import Duty on most other chemicals. Item Sodium Nitrate should be covered under Chapter 28, and caption used should be Sodium Nitrate uses for other than as Fertilizers – Import Duty of 7.5 % should be applicable". PRODUCT IMPORTS (MT) AVG PRICE (CIF) Rs./Kg US$/MT IMPORT DUTY (%) PRESENT PROPOSED OF IMPORTS SODIUM NITRATE 3160 21.17 451.83 REVENUE GAIN/LOSS Rs. Lakhs 0 7.5 50.17 CENVAT RATE ON PRECIPITATED SILICA: This product is manufactured in India with total capacity of 40,000 TPA. This product is consumed in manufacture of tyres and toothpastes. The small scale manufacturers of toothpastes are not able to avail CENVAT credit, while the CENVAT rate is 10% ad valorem. It is requested that the CENVAT rate is brought down to lowest level possible. 18 SECTION-III- OTHER ISSSUES Depreciation Rate for Chemical Industry: The industry employs processes involving the use of highly corrosive materials. The structures (on which equipment is installed) are also made of steel, which is also prone to corrosion. Some of the chemicals like Brine/ Chlorides corrode even Stainless Steel. Reactions and separation processes involve tough conditions in terms of temperature and pressures from extremely high pressures and temperatures to sub zero temperatures and sub-atmospheric pressures/ extreme vacuum levels. All this takes toll on the equipment used in chemical industry. The wear and tear of plant & machinery in the chemical industry is relatively much higher as compared to other industries. The depreciation allowed for the purpose of income tax was earlier @ 25% which was brought down 15%. It is requested that same may be restored to 25%. Additional concessions required to boost R&D in chemical sector: For Indian chemical industry to become globally competitive there has to be greater emphasis on innovation and R&D. Establishment of R&D facilities is very capital intensive. Though India has acquired significant position in Specialty Chemicals sector especially in Pharmaceuticals, Fine Chemicals and Agrochemicals, industry’s expenditure on R&D is hardly 1% of its turnover. This is very low compared to other major countries where it ranges from 3% to 7% depending on specific sectors. To be globally competitive, Indian chemical industry has to invest in R&D and continuously develop new products and new technologies. This will 19 require considerable investment. Indian chemical industry therefore needs financial incentives to pursue the course of innovation in the form of: Soft loans at reduced interest rates with longer moratorium repayment periods Zero Import Duty on capital goods imports for R&D activities To encourage R&D, Government should extend income tax exemption of 200% of expenditure in R&D beyond 2012 by additional 10 Yrs. Companies spending on R&D get benefit under Section 35. However, no benefits are available upon launching of the product. In order to give boost to R&D spent, it is necessary that profits on new products launched are given some Tax benefits, at least initially for 3 years. Reimbursement of REACH Registration Costs: The costs of data generation and registration fees in this context are extremely high and for companies exporting 7-8 products to Europe, the costs could run into crores of Rupees. We request the government of India to constitute a fund of substantial amount for reimbursement of REACH registration expenses and evolve a mechanism for granting reimbursement of REACH expenses to incentivize chemical exports to European Union countries. Membrane in Caustic industry should be considered as capital equipment and not spare: 20 The membrane is an integral part and the main member of the Membrane Cell in which electrolysis of Common Salt is carried out to give Caustic Soda and Hydrogen. It is certainly not a spare and is the heart of the Membrane Cell. It therefore deserves the same treatment while importation that is accorded to Capital Equipment and should be eligible for all the concessions that are applicable to Capital Goods. Misuse of Duty Free Import Authorisations (DFIAs): There is an Anti-Dumping Duty on Sodium Hydrosulfite. However, imports against transferrable DFIAs is permissible without payment of any Import Duty or Anti-Dumping Duty. Since these licenses/ authorizations are transferrable, there is misuse of the DFIAs granted under the Foreign Trade Policy. It is therefore recommended that imports against DFIAs should attract Anti-Dumping Duty or alternatively an Actual User condition be imposed. De-canalization of Petroleum Solvents: Imports of certain solvents, which fall under Chapter 27 of Customs Tariff Classification attracting codes nos. 2710 11 11, 12, 13, 19 are canalized through Indian Oil Corporation. The purpose of canalization is to prevent import of petroleum solvents which could be used as admixtures with any substance suitable for use as a fuel in spark ignition engines, which might result in adulteration of transportation fuels. These solvents are used in manufacture/ extraction of Pharmaceuticals and Essential Oils. Indian solvents are not free from undesirable impurities and cannot be used making imports necessary. 21 We request that imports of these solvents be de-canalized. Investment Allowance The global recession has affected many Companies plans for investments and the sentiments are very week on capital investments. In order to bring back the economy in growth mode, it is necessary that some incentives, like Investment Allowance, given earlier be re-introduced as a part of stimulus package. 22

![(NPD-60) []](http://s3.studylib.net/store/data/007320126_1-47edb89d349f9ff8a65b0041b44e01a8-300x300.png)