Safety and Equipment Maintenance

G. SAFETY AND EQUIPMENT MAINTENANCE

POLICY #

G001

G002

Safety Program

Associate Safety Guidelines

G003

G004

G005

G006

G007

G008

G009

G010

G011

Right-to-Know Law Compliance

Chemical Accident

Equipment Maintenance Program

Preventive Maintenance Program Review Form

Equipment Inspection Program

Equipment Inspection Checklist

Repairs

Back-up Sources for Repairs

Work Requisition Form

Equipment Manual

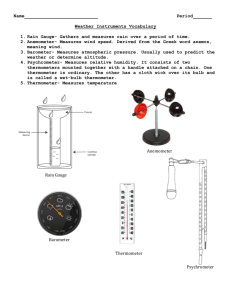

Thermometer Calibration (HACCP)

Thermometer Calibration Sheet

Vended Prepared Food Transport, Labeling and Sanitation

Interdisciplinary HACCP Committee

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: SAFETY PROGRAM

Policy #G001

Date Issued: 5/95

Date Revised: 12/17/12

POLICIES:

The Food and Nutrition Services Department/Dining Services shall be free from recognized hazards that are causing or are likely to cause physical harm or death to employees. Work habits conducive to safety are taught and expected of all employees. Safety rules will be followed or progressive disciplinary actions will be implemented.

PROCEDURES:

The components of the safety program are as follows:

The Director or a designated management appointee is a member of the Department and organization’s (if appropriate) safety committee. All safety problems and accidents are brought to the attention of this committee and management.

The Director utilizes the resources posted on the Safety & Loss page of Morrison Today, including: o

The Associate Safety Guide, available in both English and Spanish o Safety orientation for employees. The outline is in the Safety Manual. Each associate must sign a safety orientation acknowledgement form, which is placed in the associate’s personnel file. The form is posted on the Safety & Loss page. o Guidelines for establishing and maintaining a viable departmental safety committee, found in the Safety

Manual. The safety committee meets monthly. o

Key Safety Rules for an Injury-Free Workplace, found in the Associate Safety Guide. o Safety inspection forms and guidelines. See the Quarterly Safety Form, Safety Manual. o OSHA’s Hazard Communication standard is detailed in the Safety Manual – Part 1: Topic 4.9 - Hazard

Communication

In-service training (see Section E) includes, but not limited to, sessions about safety (specific to work area), food safety, departmental fire procedures, disaster/emergency preparedness and right-to-know.

(See Section G. Employees Safety Practices, Morrison In-service Training Manual and Training Resource

Library for reference materials. The In-service Training Manual is posted on Morrison Today. From the

Morrison Today homepage select: Training > Training & Talent Management Documents and Downloads >

MHFS Training Programs > In-service Training Manual. The catalogue for the Resource Library is also posted under MHFS Training Programs.)

Perform quarterly Safety Audit.

The Food and Nutrition Services Department/Dining Services participates with the Environmental

Services/Maintenance Department in a program of preventive and corrective maintenance.

On-the-job training as it relates to equipment operation and cleaning covers all required safety precautions. (See

G. Equipment Manual and F. Area and Equipment Cleaning Procedures.)

The Key Safety Rules for an Injury Free Workplace are posted and signed copies are in each employee’s personnel file.

Management is aware of crisis management procedures. The link to the Crisis Procedure Guide is posted on the

Home page on Morrison Today. The Crisis Hotline number is 1-877-710-6291.

OSHA standards are maintained

P & P CROSS-REFERENCE: Section H: Fire and Emergency Preparedness

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: ASSOCIATE SAFETY GUIDELINES

Policy #G002

Date Issued: 5/95

Date Revised: 2/17/12

POLICY:

Associates are expected to adopt work habits conducive to safety. The General Safety Rules are posted in an area accessible to all associates.

PROCEDURES:

General Safety

If unsafe conditions are seen in the kitchen, report them immediately to your supervisor so they can be corrected.

Promptly report to management all accidents that occur on the job, even if no serious injury is apparent.

[

Associates must disclose to their supervisor the use of any substances, legal or illegal, that create drowsiness, slowed reaction times, hallucinations, etc.

To control the amount of traffic in the department, only authorized personnel are allowed in the department.

Receiving and Storage

When opening boxes, cartons, barrels, crates, etc., remove any nails/staples that are protruding. Use box openers not knives.

In storing materials on shelves, always place the heavier and bulkier materials on the lower shelves. Anything 25 pounds or over should be located between the knees and the shoulders.

Stack layers of cases in a crisscross fashion to reduce the possibility of toppling. Avoid stacking cases too high.

Use adequate and safe ladders for obtaining materials from storage; avoid overreaching (or using a milk carton container). Never stand on a chair or table. Ladders should be equipped with non-skid feet.

Lift heavy items properly. A team should lift heavier items.

Food Preparation (Avoid Burns)

Use dry oven mitts when handling hot utensils.

Wear aprons when using the oven, grill, char-broiler, or fryer.

Cook in a minimum amount of water to avoid boiling over. This also reduces the handling problem when pouring off hot liquids.

Lift lids cautiously from hot pots or steamtable so that steam may escape without scalding hands or face.

Turn the handles of pots away from the edge of the stove so that the pots will not be knocked off, but take care that the handle is not too near an open flame.

When moving heavy containers of hot food, have adequate assistance and know where the container may be safely placed. Be sure that the work area is clear of fellow associates before moving hot containers, etc. If a cart is used put a towel under the hot pot to reduce the chance of it sliding off.

Control the splash when draining kettles. A plastic bucket with a hole in the bottom can help direct the hot liquids to a drain.

(Policy #G002: Page 1 of 4)

ASSOCIATE SAFETY GUIDELINES (Cont)

When drawing hot water or coffee from an urn, turn the spigot slowly so as to avoid splashing. Check carefully that all valves and spigots are in proper position before filling urn.

Keep oven doors closed when not in use.

Ventilate the oven for several minutes before lighting it. When striking a match to light an appliance, strike it in a direction away from your clothes or other flammable material; then place the match or wick at the gas jet before turning on the gas. Turn the gas gradually so as to avoid "blowing out" the match or wick.

Do not clean the oven, stove, grill, or fryer until it has cooled. Refer to the following Job Safety Analyses on

Morrison Today: Empty and Clean Deep Fryer, Filtering Fryer Oil, and Grill Plate Cleaning,

Do not use pan coating sprays near any flame; turn off range before using pan coating sprays near a range.

Knives and Food Preparation

Wear cut resistant gloves when cleaning and using knives and equipment with blades. Wear disposable gloves over the cut resistant gloves. Refer to Job Safety Analysis on Morrison Today: Cut Resistant Protective Glove.

When using knives, pay attention to what you are doing! Don't daydream!

Cut away from your body.

When drying a knife, keep the sharp edge away from you.

Keep all knives in their proper storage place when not in use. Do not store knives in a drawer.

Do not leave knives in the sink, or where they cannot be easily seen.

A sharp knife is safer than a dull knife since it will cut easier and will not require as much pressure with danger of slipping. The proper method of sharpening knives should be determined and demonstrated to you by your immediate supervisor.

Remove steel particles from knives after they are sharpened.

If a knife falls, don't grab it. Get out of the way! The floor can take it better than a hand or foot.

Use the proper knife for the procedure, i.e., boning knives, carving knives, paring knives, etc.

Knives are not can openers and should not be used as such.

Use a cutting board. A damp towel under the cutting board will keep it from slipping.

Machines Used for Food Preparation

Use machinery and tools, including knives and slicing equipment only for purposes in which they were intended.

Labor laws include restrictions on the use of machines such as slicers by minor-age associates.

Never use any machines until you are trained in their use. Be sure all guards and safety devices are in place.

Turn switch "off" and unplug before cleaning or adjusting any machine. Keep fingers, hands, utensils, etc., away from moving parts. Wait until machine stops before removing food/scraping the bowl. Refer to the following Job

Safety Analyses on Morrison Today: Hobart Mixer Operation and Cleaning Hobart Mixer.

(Policy #G002: Page 2 of 4)

ASSOCIATE SAFETY GUIDELINES (Cont)

All electrical appliances should be in the "Off" position before being plugged into the outlet.

Use “film wrap cutters” to cover the serrated blades on film wrap boxes.

Report to management any item or equipment that appears defective or in need of repair.

Take particular care when cleaning the slicer. Refer to the following Job Safety Analyses on Morrison Today:

Slicer Operation Automatic Type, Slicer Operation Manual Type , Cleaning Slicer and Vegetable Processing

Machine Operation .

-

-

-

-

-

-

Always wear safety gloves.

Turn slicer "off" and then unplug.

Turn the gauge to zero. This position closes the blade on most machines.

Do not touch the edge of the cutting blade.

Clean blade from center out.

Put safety guards over slicer after cleaning.

Mixers should not be started until the bowl or kettle is properly placed and the "beater" securely fastened.

Always use a tamper (plastic food stomper) to push food into the grinder.

At no time should you attempt to repair equipment. Notify your supervisor immediately of any equipment that is faulty or not functioning properly.

China and Glassware

Use care in handling glasses and dishes.

Use dust pan and brush or broom to sweep up pieces of broken glass or china. Use a dampened paper towel for cleaning up slivers of glass or china. Use a special garbage container for broken pieces. This container must be labeled "Broken Glass/China" and have a secured lid. Do not place broken glass in waste paper baskets or garbage or refuse cans.

Discard all food within the vicinity that may have received shards of broken glass or china.

Glass and metal pots don't mix, so keep glass and china articles out of the pot sink.

If you know or suspect that there is broken glass or dishware in soapy water, drain the water first. Then remove the broken pieces carefully.

Refuse Disposal

Place scraps of food and refuse in proper containers, as marked. Use as small a container as practical to limit the weight to be lifted.

Empty containers regularly so that refuse does not overflow onto the floor.

Promptly report any refuse containers that are broken or otherwise defective.

Keep lids on all outside refuse containers.

(Policy #G002: Page 3 of 4)

Use of Chemicals

Read and follow directions thoroughly before using any chemicals.

ASSOCIATE SAFETY GUIDELINES (Cont)

Never mix chemicals with anything but water.

Never allow chemicals to come into contact with food.

Wear protective goggles, gloves, aprons, etc., recommended by the manufacturer on the MSDS sheet.

Floors (Avoid falls)

Wear approved slip-resistant shoes.

Keep floors clean and dry! Clean up refuse, food, and water spills immediately.

Tile floors may be slippery when weather is humid and muggy. Be especially careful at such times to avoid slips and falls.

Use slip-resistant mats in areas that are likely to be wet.

Walk - do not run or slide across the floor. Look where you are going.

Use wet floor signs whenever this condition exists.

Self Protection

For your protection, use designated associate entrances, which are monitored and well lit.

Associates who work alone should be familiar with the emergency assistance procedures.

Always have two people make bank deposits.

Clean floors in a two-step fashion allowing for a dry path to walk.

(Policy #G002: Page 4 of 4)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: RIGHT-TO-KNOW LAW COMPLIANCE

Policy #G003

Date Issued: 5/95

Date Revised: 7/07

GENERAL SAFETY RULES

Each associate should sign the General Safety Rules form during orientation and have a signed copy in his/her personnel folder.

1) It is a requirement of the job for all food service associates to wear "approved" slip resistant shoes.

2) All associates using a knife or a slicer will wear a cut resistant glove and disposable glove on the opposite hand.

This is the receiving hand when using a slicer. Associates cleaning a slicer or chopper will wear cut resistant and disposable gloves on both hands.

3) Proper lifting techniques and team lifting will be followed.

4) Protective equipment and/or clothing must be worn as required. Oven mitts and apron when preparing oven, fryer or grill. Rubber gloves, apron and/or goggles when handling chemicals, hot grease or oven cleaner. Refer to the

MSDS of each chemical.

5) Report promptly to your manager any item of equipment that appears defective or in need of repair.

6) Keep floors dry, clean and free of grease residue. Clean up food, ice and liquid spills immediately. Use wet floor signs. Clean floors using approved chemicals and procedures, including daily cleaning with a deck brush.

7) High traffic areas must be cleaned in stages and in a fashion that provides a dry walk surface at all times. Use “wet floor” signs.

8) Report any hazardous condition or unsafe work habits immediately to your supervisor.

9) Promptly replace all safety guards after cleaning machinery. All equipment must be unplugged before cleaning.

10) Horseplay, running and practical jokes are not permitted.

11) Machinery and tools, including knives and slicing equipment, must be used only for the purposes for which they were intended.

12) Associates must disclose to their manager, the use of any substances, legal or illegal, that create drowsiness, slowed reaction time, hallucinations, etc.

13) Any "on the job" accident or injury must be reported immediately to the manager. Failure to do so may result in disciplinary action as well as the loss of workers compensation benefits.

Failure to follow General Safety Rules will result in progressive counseling up to and including termination.

_____________________________

Management

____________________________

Associate

POLICIES:

Policies and procedures regarding compliance with federal and state "Right-To-Know" laws are followed.

The Food and Nutrition Services Department/Dining Services will comply with all facility/community policies designed to ensure compliance with federal and state law.

Under this law, associates can refuse to work with hazardous substances ONLY if the employer has refused a request to show that associate a Material Safety Data Sheet or has not taken steps to obtain the sheets.

(Policy #G003: Page 1 of 2)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: RIGHT-TO-KNOW LAW COMPLIANCE

Policy #G003

Date Issued: 5/95

Date Revised: 7/07

PROCEDURES:

Director

Obtains (from facility/community) and reads a copy of the state law (if applicable). The state law includes a list of all chemicals in the state, to which the "Right To Know" law applies.

In general, departments will comply in the following manner: o At least annually, conduct an inventory of hazardous substances found in the workplace. Prepare a

Hazardous Chemical Inventory List (HCIL) of all chemicals in your workplace. o Obtain Material Safety Data Sheets (MSDSs) on all chemicals used or stored in the department. (ECOLAB makes available MSDSs on their products. Morrison units receive the applicable MSDS the first time a particular product is ordered. An ECOLAB Territory Manager can help units obtain any MSDSs not already on file.) o

Set up a "Right-To-Know" notebook and store it in a location accessible to all associates anytime they are on the job. Include:

-

- copy of facility/community policies and procedures

Hazardous Chemical Inventory List

- Material Safety Data Sheets o Clearly label all containers. ECOLAB provides transfer labels for spray bottles.

Post Right-To-Know notices (obtain state notices from facility/community) if applicable.

Ensure that each associate has signed a statement to the effect that he/she understands the Right-to-Know law.

This should be signed after the associate has viewed the HAZCOM presentation: Morrison Today > Safety &

Loss > Safety & Loss Documents and Forms > Training Modules > TM05.

Be aware that a request to review this notebook may be made by surveyors from The Joint Commission or licensing agencies or OSHA inspectors.

New associate safety orientation includes a discussion of toxic substances in the Department to which the associate might be exposed and the location and purpose of the Material Safety Data Sheets. (See Morrison

Today: Safety & Loss page > Documents and Forms > Safety Manual)

As new toxic substances are introduced into the workplace, all exposed associates are informed via in-service or on-the-job training.

An annual in-service is conducted on the Right-To-Know law and the toxic substances in the department.

(Policy #G003: Page 1 of 2)

RIGHT-TO-KNOW LAW COMPLIANCE (Cont)

Prepare Environmental Hazard Survey Forms - only if requested by the Department of Labor and Industry.

GLOSSARY

Right-To-Know Laws designed to make sure that all workers are informed about potential chemical hazards that may be encountered in the workplace and how to protect against them.

Toxic

MSDS - Material Safety

Data Sheet

A substance which has the potential to disrupt physical processes such as breathing, coordination, and other bodily functions (ex: glutaraldehyde, phenol, sodium hypochlorite).

A sheet of basic information for a specific hazardous chemical. It provides data related to health effects, how to clean up spills, what type of protection to use, handling, storage, transportation and information to counteract any undesirable effect of the chemical. The MSDS will also include multiple brand names of a chemical (ex.: glutaraldehyde = Cidex = Preserve).

(Policy #G003: Page 2 of 2)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: CHEMICAL ACCIDENT

Policy #G004

Date Issued: 5/95

Date Revised:

POLICY:

In the event of a chemical accident in the Food and Nutrition Services Department/Dining Services, immediate action shall be taken to address the incident.

PROCEDURES:

Employee must report accident to manager or supervisor on duty.

The MSDS for specific chemicals involved shall be pulled from the MSDS binder by the manager or supervisor on duty.

The MSDS will be sent to the Emergency Department/Occupational Health Department along with the employee.

The professionals in the Emergency Department/Occupational Health Department shall treat the employee.

The MSDS will be replaced in the MSDS binder.

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: EQUIPMENT MAINTENANCE PROGRAM

Policy #G005

Date Issued: 5/95

Date Revised: 3/06

POLICIES:

Proper maintenance of the physical plant and all equipment in the Department is the responsibility of the Director in cooperation with the Maintenance Department and subject to policies and procedures set forth by the facility's/community’s administration.

The Director is directed or has knowledge of all routine, periodic and critical maintenance work done to the physical plant or equipment in the Department.

PROCEDURES:

Director

Jointly with the Maintenance Department, plans in writing a program of preventive maintenance for all

Food/Nutrition equipment requiring regular maintenance. Cover:

-

- regular inspection/maintenance by maintenance department, periodic servicing by service companies contracted through the Maintenance Department.

Reviews the effectiveness of the Preventive Maintenance program annually with the Maintenance Department, and document meetings. (See Preventive Maintenance Program Review Form.)

For the equipment to be maintained by the Department, incorporates maintenance tasks into the Area and

Equipment Cleaning Frequency (see Section F.)

Trains Departmental employees to recognize the types of LOCKOUT/TAGOUT devices used by the facility/community maintenance staff.

REVIEW FORM

PREVENTIVE MAINTENANCE PROGRAM REVIEWED BY MAINTENANCE ENGINEER AND DIRECTOR .

REVIEWED (date)

REVIEW DATES NOTED BELOW:

DATE

PREVENTIVE MAINTENANCE PROGRAM

DEPARTMENT

DIRECTOR

MAINTENANCE

ENGINEER COMMENTS

(Policy #G005)

FYI

Policy #G005

SAMPLE EQUIPMENT MAINTENANCE SCHEDULES

On the following pages are two sample Equipment Maintenance Programs.

Use these pages as examples, from which you and the Maintenance Department can jointly, plan in writing, a preventive maintenance program for all Food/Nutrition equipment requiring regular maintenance.

Although it is important that the Maintenance Department (not Food and Nutrition Services/Dining Services) bear the responsibility for maintaining records of equipment maintenance completion, you should keep a copy of the record in the department.

EQUIPMENT

All Electrical

Wall Outlets

All Plumbing

Panel Box

Lower Distribution Panels

Microwave

Ovens

Stove

Grill

Char-Broiler

Water Coolers

Slicer

Mixer

EQUIPMENT MAINTENANCE SCHEDULE

DEPARTMENT OF FOOD AND NUTRITION SERVICES/DINING SERVICES

INSPECTION/MAINTENANCE

Visually inspect for defective cords and plugs.

Perform safety check with the model 250 electrical safety tester in accordance with the procedure in the monthly section of the master manual. If equipment rating exceeds tester capacity, use megger or ohmmeter. The term "portable" as used here means equipment that is not "hardwired" even though it is not normally moved around. All equipment must be provided with safety wire.

Safety check and tag. Replace as needed in hospital/community grade, spec. grade or twist lock receptacles.

Monthly

3

Months

6

Months

Annual

Check for leaks and low water pressure.

Adequate hot and cold water available from an approved source.

Backflow prevention or air breaks in place.

Inspect for loose connections, signs of heating.

Visually check for lint and dust.

Thermographic scan.

Check gaskets for leaks with detector.

Daily

Inspect for good working condition.

Check with oven thermometer for accuracy and calibrate.

Inspect burner orifices to ensure they are open and clear.

Check temperature with surface thermometer for accuracy and calibrate.

Inspect for good working condition. (Lava rock, replaced periodically as required.)

Check burner orifices to ensure good gas flow.

Clean condenser and compressor.

Ensure drain is clear.

Check fan and lubricate.

Inspect for good working condition.

Check blade for chips; replace as needed.

Sharpen blade.

Lubricate - USDA approved lubricant.

Ensure knobs and guards are intact.

Inspect for good working condition.

Lubricate.

Check and replace belts (if belt driven).

Date

Completed

& Initials

(Policy #G005)

EQUIPMENT

Cash Registers

Steamer

Valves

Hot Water/Booster Heater

Exhaust System

Ventilator Filters

Garbage Disposal

Refrigerators and Freezers

Soft Serve Machine

Grease Trap

Conveyors

Coffee Urn

Computers

Dishmachine

EQUIPMENT MAINTENANCE SCHEDULE

DEPARTMENT OF FOOD AND NUTRITION SERVICES/DINING SERVICES

INSPECTION/MAINTENANCE Monthly

3

Months

6

Months Annual

Service contract inspection.

Check timers and stream traps.

Check inspection plate/hand hole.

Check gaskets on doors and boiler.

Descale (frequency depends on water quality).

Lubricate all valves equipped with grease fittings.

Drain and flush. Inspect tank and heater coils for formation of rust, scale, sludge, etc.

Grease all supply and exhaust bearings.

Check motors for hot bearings, unusual noise, etc.

Change belts as required.

Wipe down and blow out motor winding.

Ventilator hood and interconnecting duct work to be cleaned professionally by member of the

International Kitchen and Equipment Cleaners Association (IKECA).

Check fire suppression system.

Check cutter rings, controls, timers and water solenoids.

Clean/vacuum condenser and compressor.

Clean and inspect door gaskets.

Check for proper operation and temperature.

Service call by manufacturer.

Check gaskets and lubricant.

Daily

Clean and dispense enzymes.

Professional company removes grease.

Check belt/slats for cracks, replace as necessary.

Check wash cycle and drain.

Check lubricant dispenser.

Check timer and controls.

Inspection by Superior Coffee.

Service contract inspection.

Date

Completed

& Initials

Inspection by Ecolab.

Service contract inspection by dishmachine manufacturer.

Check for leaks and low water pressure.

Daily

(Policy #G005)

EQUIPMENT

EQUIPMENT MAINTENANCE SCHEDULE

DEPARTMENT OF FOOD AND NUTRITION SERVICES/DINING SERVICES

INSPECTION/MAINTENANCE Monthly

3

Months

6

Months Annual

Toaster

Base Warmers

Plate Warmers

Lubricate chain and sprockets.

Check bases with surface thermometer to ensure 220°.

Check plate with surface thermometer to ensure 140°.

Check controls, calibrate thermostat.

NOTE:

Follow manufacturer's recommendations for cleaning and repair of equipment.

MSDS on all grease and lubricants on file.

Date

Completed

& Initials

(Policy #G005)

FYI

Policy #G005

EQUIPMENT MAINTENANCE SCHEDULE

FOOD AND NUTRITION SERVICES/DINING SERVICES DEPARTMENT

Sign and date each item upon completion of routine maintenance.

1. Hobart Dishwasher Model #C.R.S.6L a. Ecolab inspects working condition of dishwasher monthly. b. A form report is made of all inspection and work done on machine by Ecolab. c. Copy of report is given to Food and Nutrition Services Department/Dining Services and

Maintenance Department for possible additional work needed on dishwasher.

2.

3.

Hatco Water Heater a. Water heater will also be on Ecolab report (hot water only). b. Maintenance Department inspects heater periodically for good working condition.

Cecilware Coffee Urn a. Superior Coffee inspects working condition of coffee urn and recommends any major work to be done to coffee urn to Food and Nutrition Services Department/Dining Services and

Maintenance Department. Superior Coffee representatives will make minor repairs and replacement. b. Inspection report will be made quarterly - January, April, July, and October. Copies will be sent to the Food and Nutrition Services Department/Dining Services and Maintenance

Department.

4. Hot Point Grill a. Food and Nutrition Services Department/Dining Services is responsible for keeping grill clean and free of grease. Any bad cords or plugs are reported to Maintenance Department immediately. b. Maintenance inspects grill every 90 days for good working condition.

5. Retail Operation Thesco Two-Door Refrigerator Model 412SC a. b.

SAE - 20 oil is used in oiling each motor hole monthly.

Cafeteria employees check temperature daily and report any discrepancy in temperature or working condition of refrigerator.

6. Toastmaster - Model 102 a. Retail operation employees are responsible for cleaning and reporting to supervisor any malfunction of the toaster. b. Maintenance inspects toaster every 30 days for good working condition.

7. Gwen Steam Jacket Stock Pot - Model F-30 a. Cooks or persons using steam kettle are responsible for cleaning and reporting any malfunction to supervisor. b. Maintenance inspects steam jacket every 30 days for good working condition.

8. Market Forge Steam-It a. Food and Nutrition Services Department/Dining Services personnel using steam-it are responsible for cleaning and reporting any malfunction of market forge steam-it to their supervisor. b. Maintenance inspects steam-it every 90 days for proper working condition.

EQUIPMENT MAINTENANCE SCHEDULE (Cont)

9. Blodgett Bake Oven - Model # 931 a. Baker is responsible, with the assistance of porters, to clean Blodgett Bake Oven. Both are to report any malfunction of the oven to their supervisor. Cleaning is done daily. b. Maintenance Department inspects oven every 30 days for proper working condition.

10. Toledo Vegetable Peeler - Model A1-15 a. Person using vegetable peeler is responsible for cleaning the peeler and is also responsible for reporting any malfunction to the supervisor. b. Maintenance inspects vegetable peeler every 30 days.

11. Thesco 6-Door Refrigerator - Model 430 a. Tray and Salad employees inspect proper temperatures daily. They maintain cleanliness and report malfunction to their supervisor. b. Maintenance inspects refrigerator monthly for proper working condition.

12. Van 5 Well Steam Table a. Cooks are responsible for sanitation of the steam table. Cook will report leaks or any other malfunction of the steam table. b. Maintenance inspects steam table every 90 days for proper working condition.

13. Hobart Mixer - Model A-200 a. b.

Baker is responsible for the sanitation and sanitizing surface parts of mixer.

Maintenance inspects electrical and mechanical components every six (6) months.

14. Hobart Slicer - Model 410 a. Persons using slicer will be responsible for cleaning and sanitizing all moveable parts and report malfunction to immediate supervisor. b. Maintenance will inspect food slicer every six (6) months.

15. Schmidt Walk-In Refrigerators a. Food and Nutrition Services Department/Dining Services porters are responsible for the sanitation, storing, cleaning and sanitizing of these walk-in refrigerators and freezers. b. Maintenance Department inspects daily on proper temperature and good working condition of the walk-in refrigerators.

16. Ideal Hot & Cold Carts - Model 9118-UR a. Trayline employees are responsible for cleaning and sanitizing hot and cold carts. Any malfunction of hot and cold carts is to be reported to immediate food supervisor. b. Maintenance Department inspects carts every 90 days for proper working condition.

17. Ideal Hot & Cold Cart - Model 9118-VR a. Trayline employees are responsible for cleaning and sanitizing hot and cold carts. Any malfunction of hot and cold carts is to be reported to immediate food supervisor. b. Maintenance Department inspects carts every 90 days for proper working condition.

18. Jarvis Hot Cart - Model #1706 a. Trayline employees are responsible for cleaning and sanitizing hot carts. Any malfunction or hot cart is to be reported to food service supervisor. b. Maintenance Department inspects carts every 90 days for proper working condition.

EQUIPMENT MAINTENANCE SCHEDULE (Cont)

19. Philco Refrigerator a. Diet aide is responsible for cleaning and sanitizing. Temperature is checked daily and any discrepancies reported to supervisor. b. Maintenance will inspect refrigerator monthly for good and proper working condition.

20. Stoves a. Cooks are responsible for cleaning and sanitizing the tops and sides of the stoves. b. Porters are responsible for the interior of the stores. c. Cooks will notify their supervisor of any malfunctions of the stove. d. Maintenance Department will inspect stove every 90 days to insure good working condition.

21. Vulcan Fryer a. b.

Porters are responsible for sanitation of the fryer.

Maintenance Department inspects fryer every 90 days to insure good and proper working condition.

22. Spray With Insecticide a. Maintenance Department sprays appropriate surfaces with insecticide every 30 days to prevent infestation by insects.

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: EQUIPMENT INSPECTION PROGRAM

Policy #G006

Date Issued: 5/95

Date Revised:

POLICY:

To insure that all equipment is in safe operating condition, an equipment inspection program is followed.

PROCEDURES:

Director/Designee

Complete the Equipment Inspection Checklist monthly.

Perform the following checks of each item and any or all supporting parts or connections:

- Visual inspection to determine that the unit is in good condition, is not being used beyond its safe operating limits, and is effectively fulfilling its intended use.

-

-

-

-

Inspection for any loose brackets, nuts, screws, electrical connections, belts, pins, gears, etc.

Inspection of electric cords.

Examination of parts to discover wear which may cause failure if timely replacement is not made.

Inspection of all oil cups, grease fittings, and temperature gauges daily to insure proper unit operation.

Identify repairs needed.

Monitor completion of repairs.

( Policy #G006: Page 1 of 3)

EQUIPMENT INSPECTION CHECKLIST

CRITERIA Y/N/NA REPAIR NEEDS

Gas stock ovens operating properly.

Proof Box:

Temperature gauge operating

Cord and plug safe

3-compartment reach-in cooler:

Temperature gauge operating

Mixer:

Wiring and electrical box secure

Power control switch operational

Bowl lifter secure

Small fans:

Power control switch operational

Plugs and cords in good condition

Food delivery carts:

Power control switch operational

Plugs and cords in good condition

Floor buffer:

Power control switch operational

Plugs and cords in good condition

Buffalo chopper:

Power control switch operational

Plugs and cords in good condition

Sharp blade

Blade cover in good condition

Steam table:

Power control switch operational

Plugs and cords in good condition

Electric rotisserie toaster:

Power control switch operational

Plugs and cords in good condition

Conveyor chain free

Can opener:

Anchored

Blade sharp

Free moving handle

Floor drains:

Drain properly

Guards in place

Slicer:

Power control switch operational

Plugs and cords in good condition

Blade sharp

Blade cover in proper condition and position

Safety guard intact

No chips in blade

DATE/

COMPLETED BY

( Policy #G006: Page 2 of 3)

CRITERIA

Small mixer:

Power control switch operational

Plugs and cords in good condition

Bowl lifter secure

Automatic steamer:

Pop-off valve functional

Steam gauge accurate

Steam cut-off control operable

Steam kettle (large):

Steam cut off control operable

Drain valve functional

Lid fits securely

Handle on lid secure

Free of corrosion

Can be drained without getting liquid in walkways

Steam kettle (small):

Steam cut off control operable

Drain valve functional

Lid fits securely

Handle on lid secure

Free of corrosion

Can be drained without getting liquid in walkways

Gas range:

Gas jets clear

Flame well adjusted

Controls operable

Control knobs in place

Control knobs secure

Oven jet clear

Ventilation System

Walk-in:

No condensation or water on floor

Opens from inside

Hot water:

Proper temperature

Does not scald

Fuse box:

Extra fuses in box

Box is closed and unblocked

Outlets:

Not overloaded

Switch plates are in place

Step ladder:

Sturdy

Equipped with non-skid feet

Floor:

Non-slip strips/mats in place where needed

Lighting:

Adequate food candles

Y/N/NA REPAIR NEEDS DATE/

COMPLETED BY

( Policy #G006: Page 3 of 3)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: REPAIRS

Policy #G007

Date Issued: 5/95

Date Revised:

POLICIES:

The Food and Nutrition Services Department/Dining Services requests equipment repairs by an online maintenance request form.

Repairs to essential equipment are initiated by the Maintenance Department within 24 hours (may consist of a call to service company by Maintenance Department).

A list of backup sources of repairs exists for all equipment essential to patient food service. The list is jointly approved by the Food and Nutrition Services Department/Dining Services and Maintenance Department.

The Food and Nutrition Services Department/Dining Services has Administration's approval to contact these back-up sources for repairs in the event that Maintenance is unable to respond.

PROCEDURES:

Supervisor

Brings the need for repairs to the attention of the Director.

Director

Requests repairs online by using the Maintenance Department requisition form.

Files a copy of written request in the Engineering department.

Maintenance Department

Initiates repairs within 24 hours.

Director

Contacts back-up source of repairs for essential equipment if repairs not initiated by Maintenance within the established time frame. Contacts Maintenance first, to verify inability of Maintenance to respond, and to obtain go ahead to contact outside source.

BACK UP SOURCES FOR REPAIRS

The following vendors may be contacted for repairs in the event the Maintenance Department is unable to respond.

Maintenance assumes cost of repairs from the following vendors:

EQUIPMENT REPAIR SERVICE/PHONE

Dishmachine (repair & service) Hobart 229-436-7105 – 888-741-1455

Dishmachine Chemical

Coffee & Tea Equipment

Coffee Machine Trayline

Heat on Demand

Power Soak System

Refrigeration

Hood System

EcoLab 800-352-8649

Sara Lee 800-756-4357

Sara Lee 800-756-4357

Aladdin 800-888-5426

Power Soak 800-444-9624

Dalton 229-244-6190

Howze & Sons 229-244-9613

(Policy #G007)

INSERT COPY OF

MAINTENANCE DEPARTMENT

WORK REQUISITION FORM

(Policy #G007)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: EQUIPMENT MANUAL

Policy #G008

Date Issued: 5/95

Date Revised:

POLICY:

Manuals are maintained consisting of current operating instructions for all Food and Nutrition Services Department/

Dining Services equipment.

PROCEDURES:

Collect and organize manufacturers' equipment operating instructions, and/or write up instructions as necessary.

Include mention of all necessary safety precautions.

The Equipment Manual is located so that it is readily accessible to all employees.

The Equipment Manual is used as a basis for employee orientation, in-service, and on-the-job training, as pertinent to employee position(s).

NOTE: Orientation and in-service of employees, as appropriate, concerning safe equipment operation, is required by The Joint Commission.

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: THERMOMETER CALIBRATION (HACCP)

Policy #G009

Date Issued: 5/95

Date Revised: 11/09

POLICY:

Temperatures of food shall be monitored using accurate thermometers. Thermometers should be accurate to +/-2°F.

Pocket digital and thermocouple thermometers are the approved devices for temperature measurement. Bi-metal (dialtype) thermometers are not permitted because of their unreliability, need for frequent calibration and slow response time.

A thermocouple thermometer must be used to measure temperature of food less than two-inches thick.

PROCEDURES:

To verify accuracy of thermometers, use "ice proof" method (considered the most accurate [to 0.1°F]) method for calibration.

Fill container with ice, crushed, if possible. Add cold water to equal 75% ice to 25% water mixture. Stir mixture several times during a two-minute period to allow temperature to stabilize. Allow mixture to set for two additional minutes.

Turn thermometer on. Insert thermometer so that “notch” is fully submerged. Keep at least l inch from bottom and sides.

Let temperature reading on thermometer come down to 32°F (about l minute).

Complete Thermometer Calibration Sheet.

If pocket digital thermometer is not accurate within +/-2°F, of 32°F:

- Press and hold the D-H key for 8 seconds to begin calibration.

- CAL will be displayed for two seconds and calibration at 32°F is completed.

- Remove the thermometer from the ice water.

- Complete Corrective Actions and Initials columns on Thermometer Calibration Sheet.

Note: CAL will be displayed any time the D-H key is pressed for 8 seconds, but the thermometer will not be recalibrated unless the tip is inserted in ice water.

.

If thermocouple is not accurate within +/-2°F of 32°F, contact place of purchase for instructions on calibration.

Complete Corrective Actions and Initials columns on Thermometer Calibration Sheet.

DATE

THERMOMETER CALIBRATION SHEET

All thermometers will be calibrated weekly and documented on the calibration form. These forms will be kept on file for three months.

THERMOMETER

IDENTIFICATION

ACTUAL

TEMP

CORRECTIVE ACTION INITIALS

Calibration Procedure

1) Fill container with ice, crushed, if possible. Add cold water to equal 75% ice to 25% water mixture. Stir mixture several times during a two-minute period to allow temperature to stabilize. Allow mixture to set for two additional minutes

2) Turn thermometer on. Insert thermometer so that “notch” is fully submerged. Keep at least l inch from bottom and sides.

3) Thermometer should read 32

F, +/- 2

F.

4) If thermometer is within compliance, it can be used. Record temperature.

5) If pocket digital thermometer is out of compliance, press and hold the D-H key for 8 seconds to begin calibration.

CAL will be displayed for two seconds and calibration at 32°F is completed. Complete Corrective Actions and

Initials columns.

6) If thermocouple is out of compliance, contact place of purchase for instructions on thermocouple calibration.

Complete Corrective Actions and Signature columns.

*** Calibration of every thermometer is to take place once every week and form must be signed.

(Policy #G009)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: VENDED PREPARED FOOD TRANSPORT, LABELING

AND SANITATION

Policy #G010

Date Issued: 5/95

Date Revised: 1/06

POLICIES:

All foods for vending are properly prepared and labeled, transported and stored.

Vending machines are properly cleaned and sanitized.

PROCEDURES:

Designee

Transport food in portable carriers or permanent insulated boxes to maintain food temperature between 34°F and

41° F. Canned foods and soups are not included in this requirement.

Blue Ice is used to hold safe temperatures until the deliveries are complete. A thermometer is in each container to monitor the temperature during delivery. All carriers are pre-cooled, overnight, in walk-in refrigerators prior to loading with food items and Blue Ice.

Clean and sanitize portable carriers daily using hot water (not less than 170°F) and sanitizing solution.

Label food items with the following information:

-

- name, address and house code of the account name of the item

- list of ingredients in descending order of predominance by weight with all sub-ingredients also listed with a parenthesis around them. For example, sour cream would be listed as: sour cream

(cultured milk, cream, skim milk, whey, modified corn starch, gelatin, sodium tripolyphosphate,

- guar gum, carrageenan, calcium sulfate and locust bean gum, vitamin A palmitate, enzymes). major food allergens statement that states, “Contains …” and lists any of the eight major food allergens found in the food. Refer to Reading Food Labels document found in Food Safety section of MorrisonToday for ingredient names that correspond to the major allergens.

the following statement, “ Individuals with food allergies, be aware that we handle and prepare egg,

milk, wheat, shellfish, fish, soy, peanut and tree nut products and other potential allergens in the

food production areas of our facility”.

- net weight of item

- expiration date of item (pull date)

NOTE: Morrison prepared products are to be dated no more than two (2) days from the date of production.

Items are to be pulled from the machines no later than midnight of the posted date. As an example, an item produced on 3/2/06 will have an expiration date of 3/4/06.

In addition, potentially hazardous convenience foods that are loaded frozen into the machine must be used within seven (7) days when held at a temperature of 41°F or less.

Sanitize food machine as follows:

Daily:

-

-

-

-

-

-

-

-

Check the internal temperature of the machine to ensure it is between 34°F and 41°F. If the temperature is outside of the acceptable range, remove all items from the machine and notify a repair person. If temperature has been higher than 41°F for 2 hours or more or food temperature is above 41°F, discard food. Do not refill machine until it is operational within the temperature ranges noted. All Morrison cold food machines are equipped with health control devices.

Remove items past the expiration date from machine

Clean all liquid spills from shelves

Remove all loose debris from shelves

Wipe and dry all affected areas

Clean door glass inside and out

Wipe exterior of cabinet and dry thoroughly

Fill machine with fresh product

(Policy #G010: Page 1 of 2)

VENDED PREPARED FOOD TRANSPORT, LABELING AND SANITATION (Cont)

Weekly:

-

-

-

-

Follow daily routine

Remove and clean lint screen for condenser to insure proper operation of the refrigeration unit

Wash and sanitize food compartment and dry thoroughly

Fill machine with fresh product

(Policy #G010: Page 2 of 2)

Section: SAFETY AND EQUIPMENT MAINTENANCE

Subject: INTERDISCIPLINARY HACCP COMMITTEE

Policy #G011

Date Issued: 1/00

Date Revised:

POLICIES:

A hospital committee of interdisciplinary services is coordinated by Food and Nutrition Services to evaluate the handling of food, enteral tube feeding, and water. *

PROCEDURES:

Director of Food and Nutrition Services/Dining Services or Organization’s Designee

Coordinates a group of 3 to 7 facility/community personnel representing the various disciplines involved in handling food, enteral tube feeding products and water. The committee may have representation from management and hourly staff. Representatives must have authority for ensuring that policies are followed within their respective disciplines. Representatives must be trained in HACCP procedures or can be designated for training within one month of participating on the committee.

Coordinates HACCP training of committee participants. Coordinates activities of meeting, which will focus on proper handling of food, enteral tube feeding products and water, and issues related to implementing HACCP procedures throughout the organization to assure standards of regulatory and credentialing organizations are met.

Committee Participants

In the initial phase, meet weekly to review old procedures, establish new procedures, plan educational and training programs, establish record keeping and audit practices and develop an Action Plan for items that must be resolved external to the committee.

Once a program is established, the committee should meet monthly to resolve issues that present themselves as part of the implementation of a facility/community HACCP program and maintain an ongoing Action Plan in response to audit results or for other HACCP related items.

Director of Food and Nutrition Services/Dining Services or Organization’s Designee

Follows up on communicating the actions of the HACCP committee to appropriate Departments and

Administration.

*The HACCP Committee may be a special sub-committee of the organization’s Safety Committee, Pharmacy and

Therapeutic Committee, Standard Order Sets Committee, or any other appropriate hospital/community committee.