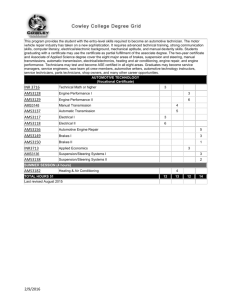

Automotive Service Technology

advertisement

Automotive Service Technology Program Syllabus Frederick County Career & Technology Center 7922 Opossumtown Pike Frederick, Maryland 21702 Phone: 240-236-8500 Fax: 240-236-8501 Website: http://education.fcps.org/ctc/ Instructors: Richard C. Smith Jr. Phone: 240-236-8507 Email: richard.smith@fcps.org Gary R. Wilfong Phone: 240-236-8534 Email: gary.wilfong@fcps.org Program Description This program prepares students for careers as entry-level automotive technicians. It is a NATEF (National Automotive Technicians Education Foundation) http://www.natef.org accredited training program in engine repair, automatic transmission and transaxle, manual drive train and axles, suspension and steering, brakes, electrical/electronic systems, heating and air conditioning, and engine performance. Mathematics, (including algebra/geometry) and a strong science background including basic electricity/electronics are recommended for success in this program. The program is supported by the Automotive Youth Educational Systems (AYES) http://ayes.org program. Students selected for AYES must successfully complete their junior year of the Automotive Service Technology program. During the summer between their junior and senior year, qualified students have the opportunity to work as paid interns at participating dealerships and independent repair facilities in a guided mentorship with an experienced automotive technician. A tool scholarship (sponsored by Snap-on Tools) is also included with the AYES Internship. Graduates of this program are encouraged to go on to post-secondary education at technical colleges. Career Experiences Work-based learning and job shadow career related employers. School to Work Cooperative Opportunities. Internships/Apprenticeships for AYES Students. Program Objectives The focus of the course is more than learning how to repair a vehicle. Although it's important to be able to read and follow instructions in a repair, procedures are more important in automotive repair where proper repairs are necessary. In a fast paced commercial repair facility you may not always have time to stop and read every procedure before repairing the vehicle. In all cases, it's important to know as much as possible about the automotive systems used in vehicles and the basic methods and procedures in repairs. Developing problem-solving skills are necessary in solving customer concerns. Automotive students will be responsible for NATEF classroom theory, and will have the opportunity to complete over 190 NATEF Maintenance and Light Repair tasks within nine areas: Automotive Fundamentals; Engine Repair, Automatic Transmission and Transaxle, Manual Drive Train and Axles, Suspension and Steering, Brakes, Electrical/Electronic Systems, Heating and Air Conditioning, and Engine Performance. Some labs may be performed at local repair facilities during offered paid internships. Students are responsible for professional NATEF work ethics and safety procedures at all times while enrolled in the Automotive Service Technology program. SkillsUSA is the leadership organization that students at The Career and Technology Center are members of while enrolled at the center. Program Content & Course of Study I. Level 1-Term 1: Automotive Fundamentals A. Automotive Technician 1. Explain how to become an ASE Certified Automotive Technician. 2. Identify the purposes and explain the importance of ASE, NATEF, and STS to the Automotive Technician Career. 3. Define the educational requirements for an automotive technician. B. Working in the Automotive Technology Field 1. Identify career opportunities in the automotive industry. 2. Describe the main differences between dealerships, independents, and franchise repair facilities. 3. Explain the basic duties of automotive shop personnel. C. Automotive Shop Operation/Communication Skills 1. Demonstrate understanding of the role of a professional automotive technician and other dealership personnel, and how effective communication contributes to the whole organization. 2. Use computers to acquire, organize, analyze, and communicate information. D. Automotive Shop Safety 1. Explain the purposes of the Occupational Safety and Health Act. 2. Achieve certified status in Hazard Recognition and Hazard Prevention. E. Vehicle Maintenance 1. Perform tasks associated with maintaining vehicle systems; such as servicing of all fluids, under hood and underbody inspections. 2. Engine repair: Cooling system service. Level 1-Term 2 II. STEERING and SUSPENSION A. Steering systems diagnosis and repair. B. Suspension systems diagnosis and repair. C. Wheel alignment diagnosis, adjustment, and repair. D. Wheel and tire diagnosis and repair. Level 1-Term 3 III. BRAKES A. Hydraulic systems diagnosis and repair. B. Drum brake diagnosis and repair. C. Disc brake diagnosis and repair. D. Power-assist unit diagnosis and repair. E. Miscellaneous: wheel bearings, parking brakes, electrical, diagnosis & repair. F. Anti-lock brake system diagnosis and repair. Level 1-Term 4 IV. Heating, Ventilation, and Air Conditioning A. Identify and Inspect Refrigerant System Components B. Inspect HVAC and Engine Cooling systems, determine needed service. C. Identify and Inspect HVAC Operating Systems and Related Controls. Level 2-Term 1 V. ELECTRICAL/ELECTRONIC SYSTEMS A. General electrical systems diagnosis. B. Battery diagnosis and service. C. Starting system diagnosis and repair. D. Charging system diagnosis and repair. E. Lighting system diagnosis and repair. F. Gauges, warning devices, driver information systems diagnosis and repair. G. Horn and wiper/washer diagnosis and repair. H. Accessories diagnosis and repair. I. Use wiring diagrams during diagnosis and repair. Level 2-Term 2 VI. ENGINE PERFORMNACE A. General engine diagnosis and repair. B. Computerized engine controls diagnosis and repair. C. Ignition system diagnosis and repair. D. Fuel, air induction, and exhaust systems diagnosis and repair. E. Emissions control systems diagnosis and repair. F. Engine related services. Level 2-Term 3 VII. ENGINE REPAIR A.General Engine Service B. Cylinder Head and Valve Train C. Lubrication and Cooling Systems Level 2-Term 3 Continued VIII. AUTOMATIC TRANSMISSION and TRANSAXLE A. In-Vehicle Transmission/Transaxle Service B. Off-Vehicle Transmission/Transaxle Service. Level 2-Term 4 IX. MANUAL DRIVE TRAIN and AXLES A. General Service Procedures B. Clutch System C. Transmission/Transaxle Manual Control D. Drive Shaft, Half Shafts, Universal and Constant Velocity Joints E. Differential Case Assembly F. Drive Axles Evaluation/Grading Methods This grading policy will be used this school year in the Automotive Service Technology program. The policy is subject to change. Parents and students will be notified prior to the changes being implemented. Although this policy is written and prepared by the instructor, it reflects the Frederick County Public Schools’ regulations and industry standards. Grading in this program will be based upon demonstrated student mastery of specific proficiency skill objectives. Student mastery level is determined through a sense of performance-based assessments after the necessary skills are taught. Students will receive an incomplete grade, which carries the same weight as a zero, for an incomplete assignment Instruction methods include classroom theory and practical theory. Student’s professional skills are scored using a point system. Please refer to the CTC Student Handbook for point indicators and values. In the event of an absence, students are required to request missed assignments from the instructor. The principal is the final authority in all appeals and disputes concerning grades for all students at the Frederick County Career & Technology Center. Grading Categories Classroom/Lab Assignments Work Maturity Skills Tests and Quizzes Homework Total 40% 25% 25% 10% 100% Grade Calculation Percentage Grade 90% – 100% 80% - 89% 70% - 79 A B C 60% - 69% D 0% - 59% F Description Excellent Work, Professional Standards Good Work, Above Average Quality Average Work, Acceptable, Needs Improvement. Below Average-Improvement necessary to meet industry standards. Poor Work, Unacceptable, Does not meet industry standards. Grading Category Description Classroom/Lab Assignments (40%) – Students will be assessed in both lab assignments and classroom activities or projects using a point system. Students must complete daily activities in order to obtain a passing grade in this category. Incompletes are entered as zeros for student’s grade. Late assignments and/or projects may be penalized. Grading of tasks and lab assignments will be assessed as outlined in the Modern Automotive Technology and AYES curriculum. At the completion of each job sheet the student will be given a grade based on the rubric on the last page of each job sheet. The grade percentages will be assigned as follows: 1 – Demonstrated exposure/observation of the competency = 20% = F 2 – Applies the competency but only mastered a few essential attributes of the competency = 40% = F 3 – Capable of the competency but needs further practice = 70% = C 4 – Performs the competency satisfactorily = 80% = B 5 – MASTERED the competency = 100% = A Professional Skills (25%) – One of the primary objectives of the automotive technology program is to teach students excellent work habits. These skills are essential in our every day lives and in the workforce. The point system used is described in the Professional Skills Guidelines. Students are given copies of this rating scale in their handbooks and a copy of this guideline is posted in the classroom. Tests and Quizzes (25%) – Students will be given a quiz weekly, a mid-term exam, and a final exam after each unit is completed. Students are encouraged to take notes during class to aid in studying for tests and quizzes. Homework (10%) – Students will be given very little homework in the automotive program. Due to the fact that the textbooks cannot be removed from the classroom, and tools, equipment, and projects normally cannot be carried, the students are limited in homework assignments. However, occasionally students will be required to complete a small activity outside of school. Instructional Resources Modern Automotive Technology /GoodheartWilcox AYES Curriculum MSDE Curriculum Materials 1st Year/Level I Uniforms $50.00 per set-Minimum 2 set purchase Leather Work Boots -Oil and slip resistant soles Automotive Student Workbook - $25.00 Tire Pressure Gauge Flash Light ASE Testing Fees - $30.00 Digital Multimeter -Approx. $50.00 2nd Year/Level II ASE Testing Fees $30.00 Business Partners *DARCARS Toyota *Fitzgerald Auto Mall *Tate Chrysler *Dynamic Automotive *Shockley Honda *Superior Automotive *Ideal Buick GMC Hyundai *R&R Garage *Frederick Equipment Company *Krietz’s Auto Service *Triangle Motors *Hagerstown Honda *Grimes Truck Center *Frederick Motor Company *Justice Racing Engines Just to name a few……….