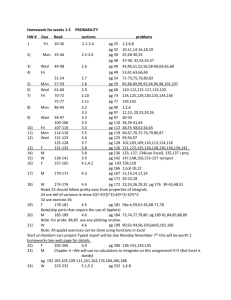

Turn-in: Skill Builder Exercise #1

advertisement

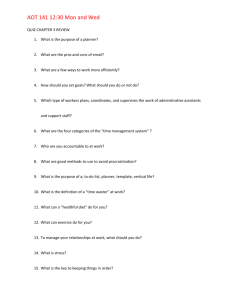

Weatherhead School of Management Case Western Reserve University OPERATIONS MANAGEMENT MBAC 425 (1,2,3) Spring 2003 Instructor: Telephone: Office: Professor Yunzeng Wang (216) 368-3811 Fax: (216) 368-6250 E-mail: yxw36@po.cwru.edu PBL 324 Office Hours: Thursday, 3:15-4:30 PM, or by appointment Teaching Assistants: Secretary: Vera Tilson tel: 368-2196; e-mail: vxt15; Amit Saharia e-mail: axs241 Antonis Printezis tel: 368-5009; e-mail: axp68; Susan Rischar Telephone: (216) 368-3845 Fax: (216) 368-4776 E-mail: sjr14@po.cwru.edu COURSE DESCRIPTION Operations Management deals with the part of an enterprise that creates value for its customers. It involves designing goods and services, producing goods and providing services, and the physical distribution of goods and services. As global competition in both goods and services increases, a firm's survival depends upon how well it integrates the operations function into the enterprise’s planning and strategy. Thus, it is essential for all business managers to acquire an understanding and appreciation of operations. The objective of this course is to provide you with an understanding of operations and the roles that they play in an organization. By the end of the course, you should appreciate the challenges in providing world-class products and services and you should be able to use some analytical tools and conceptual frameworks to guide your thinking about operations. In particular, you should leave this course with a better understanding of: The role of operations in supporting business strategy How to identify and define key business processes. How to define clear performance objectives and process measures. How to use data and analytical tools to improve the effectiveness of processes. The impact of an organization’s context upon process management and improvement. Key issues and techniques for managing an organization’s supply chain COURSE MATERIALS 1. Cases and readings: course pack at the campus bookstore. 2. The Goal by E. M. Goldratt and J. Cox, 2nd revised edition, North River Press, Great Barrington, Mass., 1992. We don not require a textbook. However, if you would like a reference, you might consider: Operations Management by L. J. Krajewski and L. P. Ritzman, 5th edition, Addison Wesley, Reading, Mass., 1999. 1 COURSE REQUIREMENTS The course involves a combination of lectures and class discussions of cases and readings that are contained in the course pack or to be distributed during classes. As described below, the workload consists of class participation, written assignments and two examinations. The course grade will be based on the weights shown in parenthesis. Class Participation (15%) Students are expected to come to class well prepared to be active participants in the learning process. So you should read before each class all the assigned materials and be fully prepared to participate case discussions. Your semester’s participation is evaluated based on the quality and quantity of your contributions, with a strong emphasis on quality. Skill Building Exercises (20%) During the semester there will be four (4) exercises assigned to help you practice particular techniques. These assignments should be written and handed in individually, although groups of students may discuss and work together on the problems. Report on The Goal (10%) The Goal is an entertaining, though deceivingly simple, business novel. It should help you to develop some basic problem solving skills that are useful not only in operations, but also in general management as well. It is recommended that you read it twice: once at the beginning of the semester to give you a taste for what is to come, and once at the end of the semester to tie everything together. On the last day of class, you are expected to turn in a report (at most three pages) on The Goal. In your report, be sure to answer the specific questions listed in a related homework assignment. Mid-Course (25%) and Final Examinations (30%) See Course Outline for scheduled dates of the two exams. COURSE POLICIES (These policies are meant to be enforced.) 1. Late submission of exercises will NOT be accepted and NOT be graded. 2. Submit your homework in hard copies and bind/staple them properly whenever you have multiple pages. Electronic submissions are NOT accepted, unless a special permission has been issued from the instructor. 3. DO NOT use your laptop computer during classes and exams. You will only need your computer to do your homework after class for this course. Bring a simple calculator for exams. 4. Turn off your cellular phones or pagers upon entering the classroom. 5. All students are expected to adhere to CWRU’s Honor Code. Each student is individually responsible for proper conduct in matters of coursework and assignments. Undue cooperation on individual assignments is not appropriate Student behavior deemed to be discreditable as determined by the instructor and the TA may result in a reduction of grade for the assignment/s involved or for the course as a whole or both. 2 COURSE OUTLINE Module I Operations Process Analysis, Capacity Management and Quality Control No. 1 Date Topics and Assignment 1/13, Mon. Course Overview, Introduction to OM Read: 2 1/15, Wed. Syllabus Process Analysis Fundamentals Read: 3 Process Fundamentals Lecture Notes (Slides) on Process Fundamentals 1/20, Mon. No Class (Martin Luther King Holiday) 1/22, Wed. Measuring Capacity Kristen’s Cookies Company (A) Read: Prepare the following questions for class discussions: 1. Draw a process flow diagram for cookies production at Kristen’s. 2. How quickly can Kristen fill an order for 1 dozen cookies? 2 dozens? 3 dozens? 3. What is the maximum rate at which Kristen can produce cookies if she makes batches of 1 dozen, 2 dozens and 3 dozens respectively? What assumptions do you have to make? 4 1/27, Mon. Align Process Design with Business Objectives Video: Read: Production Processes McDonalds Corporation (McD) Burger King Corporation (BK) Prepare the following questions for class discussions: 1. For each of the two cases (McD and BK), draw a process flow diagram. 2. What are the different competitive strategies adopted by McD and BK? How do they achieve their respective strategies through the design of their production processes? Turn-in: Skill Builder Exercise #1 3 5 1/29, wed. Bottleneck Analysis and Congestion Read: National Cranberry Cooperative Prepare the following questions: 1. Draw a process flow diagram showing the major process steps, inventories and flows for cranberry processing. Indicate the capacity at each of the process steps. 2. In Exhibit 2 of the case it is shown that, over the 20 days from 9/20/ to 10/9, an average of 16,400 barrels per day are delivered. Assume that on average each truck carries 75 barrels, and that trucks arrive uniformly over a 12 hour period. Also assume that during this period, the trucks carry 70% wet berries and 30% dry berries. a. Which operation(s) are bottlenecks? Note that both dry and wet berries can be run through the system at the same time. b. How much overtime is required? c. Why are the truck waiting times so high? 6 7 2/3, Mon. Capacity Planning for Services: Performance Measures and Analytical Tools Read: Lecture Notes (Slides) on Managing Customer Waiting Times A Note on the Management of Queues Turn-in: Skill Builder Exercise #2 2/5, Wed. Read: Managing a Capacity Constrained Service System The New York Police Department (NYPD) Patrol System Prepare the following questions: 1. Construct a queuing model for NYPD patrol system. Identify “customer” arrivals, the server, etc. in the system. 2. How do you measure service for systems? 3. Assuming that you have 18 patrol cars, how should you allocate them among the 6 precincts? (Each car can be assigned to only one precinct.) What is the objective that you are trying to achieve when you make your allocation decision? Are there alternative objectives that should be considered? Review for Midterm Exam 8 2/7, Fri. Midterm Exam 3:30 pm – 5:30 pm Room assignments to be specified before the exam. NO lap top computer is allowed. 4 9. 2/10, Mod. Read: 10. 2/12, Wed. Quality Management Lecture Notes (Slides) on Quality Management On Some Statistical Aids Towards Economic Production Constructing and Using Process Control Charts Quality Management (continued) Read: 11 Lecture Notes (Slides) on Quality Management On Some Statistical Aids Towards Economic Production Constructing and Using Process Control Charts 2/17, Mon. No Class (plant tour week) 2/19, Wed. No Class (plant tour week) 2/21, Fri. Plant Tour Read: (Detailed instruction and schedule will be provided later.) Why (and How) to Take a Plant Tour Module II Inventory and Supply Chain Management 12 Plant Tour Debriefing Performance Measures and Basic Trade-offs of Inventory Polices 13 2/24, Mon. Read: Lecture Notes (Slides) on Inventory Management Turn-in: Skill Builder Exercise #3 2/26, Wed. Read: 14 3/3, Mon. Read: Performance Measures and Basic Trade-offs of Inventory Polices (continued) Lecture Notes (Slides) on Inventory Management Identifying Opportunities for Improving Teradyne’s Service-Parts Logistics System Implementing a Control Policy for a Production and Inventory System Blanchard Importing and Distributing Company, Inc. Prepare Questions: 1. What is wrong with the way that the EOQ and ROP quantities have been determined for each of the five items mentioned in the case? Are the formulas used correctly? Are the values of parameters taken correctly? 2. Assuming that an EOQ/ROP system is an appropriate way to run this system, how would you correct the EOQ/ROP quantities for the five items? How do the corrected figures compare with the quantities calculated in 1969 and with production volumes scheduled for the June 1972 bottling run? 5 15 3/5, Wed. Inventory Pooling and Postponement Strategies in Supply Chain Management Read: Hewlett-Packard: DeskJet Printer Supply Chain (A) Acme Widget Company Prepare Questions for the Hewlett-Packard case: 1. What are the major problems facing H-P in its DeskJet printer supply chain? 2. What are the potential solutions? Turn-in: 16 3/10,Mon. No Class (Spring Break) 3/12, Wed. No Class (Spring Break) 3/17, Mon. No Class (Beer Game Week) 3/19, Wed. No Class (Beer Game Week) 3/21, Fri. The Beer Game In Room 103: Session I 9:00 am – 12:00 noon; Session II 1:00 pm – 4:00 pm Read: 17 3/24, Mon. The Beer Game: Board Version Supply Chain Coordination Video: Read: 18 Skill Builder Exercise #4 3/26, Wed. Aligning Supply and Demand: Creating the Right Supply Chain What Is the Right Supply Chain for Your Product? Discussion of “The Goal” Turn-in: Report on The Goal Course Review 19 4/4, Fri. Final Exam 2:00 pm – 4:30 pm Room Assignments to be specified later. NO lap top computer is allowed. 6 OPERATIONS MANAGEMENT MBAC 425, Spring 2003 Instructor: Professor Yunzeng Wang Course Pack Content 1. Process Fundamentals 2. Lecture Notes (Slides) on Process Fundamentals 3. Kristen’s Cookie Company (A) 4. McDonald's Corporation (Condensed) 5. Burger King Corporation 6. National Cranberry Cooperative 7. Lecture Notes (Slides) on Managing Customer Waiting Times 8. A Note on the Management of Queues 9. The New York City Police Department (NYPD) Patrol System 10. Lecture Notes (Slides) on Quality Management 11. On some Statistical Aids Towards Economic Production 12. Constructing and Using Process Control Charts 13. Why (and How) to Take a Plant Tour 14. Lecture Notes (Slides) on Inventory Management 15. Identifying Opportunities for Improving Teradyne’s Service-Parts Logistics System 16. Blanchard Importing and Distributing Company, Inc. 17. Hewlett-Packard: DeskJet Printer Supply Chain (A) 18. Acme Widget Company 19. The Beer Game: Board Version 20. What Is the Right Supply Chain for Your Product 7