MECH3300 COMPUTER TUTORIAL 2 – Modelling 2D

advertisement

MECH3300/3302 COMPUTER TUTORIAL 2 – Modelling 2D problems

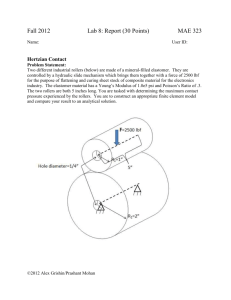

1. Plane strain crack model

This model will be constructed in STRAND7. The dimensions are those of the test

specimen used in the experiment in fracture mechanics. STRAND7 can import CAD

geometry, but cannot create geometry, hence for regular simple geometry, it is best to

create a coarse mesh that captures the geometry, that can then be refined (subdivided).

First enter x,y coordinates of the nodes of the coarse mesh below.

205 mm

148 mm

118 mm

88 mm

68 mm

48 mm

36 mm

26

mm

y

y fixed – beyond crack tip

x and y fixed

x

Pick Quad4 elements in Create, Element and join the nodes to create the coarse mesh.

The mesh can then be refined using Tools, Subdivide, to create a finer mesh, such as that

above. The mesh shown is too fine for the demonstration version of the program. Any

location to be treated as a crack tip is further refined using the mesh grading tool (Grade

Plates and Bricks) on the same tool menu. To replace an element by the subdivision

selected, click near the two sides of the element to be given the finer mesh – the sides

shown cross-hatched on the menu in STRAND7.

The mesh needs to be restrained to stop rigid body motion. First select Global, Load and

Freedom Cases and pick the 2D plane case under Freedom Cases – note that only x and y

displacements are used as unknowns. We wish to fix displacement normal to the plane of

symmetry ahead of the crack - the lower edge of the mesh, which is a half-model. This

will be revised to consider crack lengths from the load of 18, 30, 50, 70, 100 and 130 mm

– the shortest of these is not used in the practical. Use Attribute, Node, Restraint to

achieve this. Note one node must be fully fixed, to prevent sliding x-wards.

The load can be applied most simply to a single node. This is unrealistic locally, but

should still give a reasonable deflection. We need a unit load to find the compliance or

flexibility.

The Property setting is Plate property, then 2D Plane Strain. The properties of Perspex

are needed. Try Young’s modulus 2.6GPa and Poisson’s ratio 0.26. Solve and note the

displacement at the load for the various crack lengths, changing the restraints each time.

We will compare these values to the expectations of beam theory. Also plot the xdirection stress (Results, Contour, Stress). Use the global XX stress, as this is definitely

in the X direction. The local xx stress is in a direction determined from the first node

picked to the second node picked, when each element of the coarse mesh was created.

An advantage of the “combined” stresses, that are the principal stresses or functions of

them, are that they are independent of the choice of coordinates. Have a look at some of

these as well. Note that Von Mises stress, and Tresca stress – both numbers to compare

to yield strength - are always positive and do not distinguish tension from compression.

Examine the transverse shear stress. In theory for a cantilever, this is distributed

quadratically through the depth of the beam, peaking a mid-depth, the peak value being

Pc2/(2I), where c is half beam depth. Note, as the stress is really discontinuous at

element boundaries, the shear stress does not fall to zero at the surface, as it should.

To test the plane strain assumption, rerun the two longest longest crack lengths with the

actual 5.42 mm thickness of the specimen and a Plane Stress setting in the Property

menu.

To see how the accuracy is affected by an increase in the polynomial order in each

element (p-refinement), construct the mesh below with Quad8 elements. If in doubt

about the state of the model at any time, run Tools, Clean. This removes duplicate or free

nodes or duplicate elements, and checks the connections between elements. The hole is

created using the Tools, Grade Plates and Bricks menu, using the default setting of 0.5 on

radius to set the size of the hole. Note the unit load is now spread over three nodes for

greater realism. The mid-side nodes now present also need restraining ahead of the crack

tip.

Solve for the different crack lengths again.

To look at the effect of using more, smaller linear elements (h-refinement), construct a

mesh with six elements through the depth and appropriate numbers along the crack

specimen.

Estimating fracture mechanics parameters

The parameters G and KI both measure the severity of the stress conditions leading to

crack growth. G (strain energy released per crack surface area formed) can be estimated

from the change in compliance (or flexibility) with crack length a. Using Matlab or

some other tool, plot deflection at the unit load (twice that of this half model) versus

crack length, measured from the load. Do this for both linear meshes and the quadratic

one. Superimpose the deflection predicted by beam theory: (2PL3/(3EI)) for two

cantilevers. We could either think of P as unit load per width we applied, times the width

of 5.42 mm, or think of I here as the value for unit width, leaving P as unity, as that is the

assumption in a plane strain model. The former is more appropriate here. Also find the

deflection for the plane stress case of the coarser linear mesh for the two longest cracks,

and compare this to beam theory. It is worth looking at a log-log plot of the deflection v

crack length. Beam theory makes this a straight line with a slope of 3, due to the L3 term.

What are the finite element estimates of this slope from the plane stress and plane strain

data for the two longest crack lengths? This slope gives the change in compliance with

crack length d/da.

In the case of the shortest length, the depth of the beam is becoming comparable to its

length. In this situation, a correction of the deflection due to shear deformation is worth

considering. The extra deflection is 2Pc2L(1+)/(EI) where c is half the depth of the

beam, and is Poisson’s ratio.

Estimate G as a function of P

G = (P2/(2B)) d/da

B here is really 3 mm, not 5.42 mm, as there is a groove cut ahead of the crack to guide

its growth. Ignore this for the current computational exercise.

The mean stress ahead of the crack tip can be used to make an estimate of stress intensity

KI that should improve as the crack tip is approached. The quantity {(x+y)/2}(2x)

does in theory tend to KI, as x, the distance from the crack tip, ahead of the crack along

the plane of symmetry, tends to zero, as the stress components in polar coordinates all

depend on KI/(2r) f(), where r is radius from the crack tip, and f( is some function

of the angle. Setting 0 and r = x gives x = y = KI/(2x). The quantity KI

{(x+y)/2}(2x) can be estimated from the stresses in each element to the right of the

crack tip, along the plane of symmetry. Collect the data on these stresses and note it on

paper for the finer linear mesh. Then use (say) a spreadsheet to plot the above estimate of

KI, extrapolating to the crack tip.

The (crack opening) displacements at nodes prior to the crack tip (to the left of it) can

also be used to estimate KI by extrapolation. Again use the finer linear mesh. This time,

the quantity to be calculated at each node is

L

u

y

Eu y

2

KI

2

4(1 ) L(1 L )

2a

a

As L tends to zero, this estimate should again improve, the change being smoother than

that made from the stress, as displacement is the integral of strain.

For plane strain conditions, KI = (EG/(1-2)). How do the above two estimates of KI

compare to the estimate of G?

2. An axisymmetric model

This model will be created in the demonstration version of Nastran for windows, with a

300 node limit. Nastran can create a geometric (CAD) model itself, but one for the

purpose of meshing with finite elements. Loads and boundary conditions can be applied

to the geometry, as well as to the finite element model. There are many options in this

user interface. The F6 key brings up a menu that allows you to change the default

settings of what you see. In addition, on the top “View bar” there are options to change

the display (eg turning elements or geometry on or off, or switching from wireframe to

solid appearance of a mesh). Initially scales are visible, indicating the size of the model.

These can be switched off in “Tools and View Style”, “Workplane and Rulers”. Change

“Rulers” to “1. Skip Rulers”. The Quick Options

button is useful for turning

geometry on and off.

Examine the buttons on across the top of the screen and what they do. Loads, materials,

properties and restraints (constraints) in Nastran all have set numbers. Sets can lie

around in the data inactive, unless selected when solving. You can give a set a name to

help you remember what is in it (eg the type of loading).

An axisymmetric analysis involves modelling half a cross-section, each element

representing a ring of material. In Nastran, the choice of elements is limited for

axisymmetric analysis. We will use 6 node triangles to automatically mesh the halfsection below, because, if we do not, the elements will be changed to this type anyway.

In an axisymmetric analysis, it is assumed that the deflections are just in the plane

modelled (ie radial and axial), and the global X axis is taken as the radius, global Z being

the axis of symmetry – here the axis of the shaft on which the flywheel spins. Hence you

should rotate to the XZ plane before creating any geometry.

Axis Z

5R

Surface 1

7.5R

Dimensions in mm

Surface

3

Surface 2

30

X

50

5

Plane of symmetry

15

Note: top half

modelled.

10

20

80R

90R

To build the largest model possible within the 300 node limit, draw the boundary of the

part of the half-section of the flywheel above its plane of symmetry as a series of curves

(Geometry, Curve). Note there are many ways of constructing a circular arc (Geometry,

Curve, Arc). A simple way is to first place a point at the centre of the arc, and then use

the Center, Start, End option. You need to start at the end that makes the arc

anticlockwise. The arcs above can be approximated to 90 degrees. Having constructed

the boundary, we need to create surfaces to mesh. The mesh generation software needs

simpler surfaces to do a good job, than the entire cross-section. Hence the geometric

model is divided into three surfaces as indicated above. The surfaces are specified using

Geometry, Boundary Surface, From Curves. Pick each curve in turn in sequence around

the boundary, to define the boundary of each of the three surfaces, and hence the surface

enclosed by it.

As usual, it is necessary to specify a material – this time use a high strength alloy steel (in

SI units) – note that E does not vary much with the alloy content of steels. To find SI

units, you need to scroll down the list of materials available – the default is imperial

pound force inch units. A property must be specified with Elem/Property Type set to

Axisymmetric, and to Parabolic elements. Make the property list point to the material.

Note Nastran expects you to create the material data first, then the property data, and then

finally the elements with that property. The thickness data is redundant. Set the element

default size to 4 mm (Mesh, Mesh Control). Then mesh the surface with triangles (not

the default quadrilaterals) in Mesh, Geometry, Surface. The number of nodes created

should be below the demostration version limit of 300. To be more precise, in the

Automesh Surfaces window, set “All Triangles” and then “Midside Nodes on Geometry”.

This does not in fact force the midside nodes to be exactly on the boundary, as there is

also a tolerance on element distortion to be observed. It is important to check for

duplicate nodes on common edges of surfaces meshed. (Tools, Check, Coincident nodes).

The default tolerance needs increasing to pick them up.

Use Model, Constraint Set to create a set of restraints. Name the set for later reference.

Open the menu Model, Constraint, Nodal to add restraints to this set. Restraints are

displayed as numbers – 1,2,3 are x,y,z displacements and 4,5,6 are the corresponding

rotations. There is no need to constrain this model radially (X-wards), as radial motion is

not a rigid-body motion – it stretches each ring element circumferentially. Nodes on the

central plane of symmetry must be fixed in the axial (Z) direction, making axial

displacements relative to this plane. Only TX and TZ translations are needed at each node

to write the equations that are solved.

To load the model, we wish to apply inertia loading corresponding to spinning at 10000

rev min-1. First create a load set (Model, Load, Set), then apply a body force (Model,

Load, Body). Make Velocity active and set Wz, the angular velocity about the Z axis in

rev s-1. This will cause inertia forces to be found by integration over each element.

Check the model: Tools, Check, Coincident Nodes. If this is not done, the flywheel

model will remain in three separate sections – one for each surface meshed.

Run the analysis (File, Analyse). The right hand menu – an alternative to the top menu,

is most convenient for examining results. Click on the bottom icon to open the postprocessing menu – and to select the latest output. The deflected shape can be switched

on. The scale may need to be set in the View Options (F6) menu. The Post Data {} icon

is used to select what quantities to plot as contours. Of interest in the output, is the

maximum principal stress, to assess if fracture could occur, with an assumed flaw size

that would not be easily detected, and the maximum Von Mises stress to check for

yielding. Locate these maxima. Also find the maximum radial deflection at the hub.

This is of interest in assessing what shrink fit is needed to avoid the flywheel coming

loose on its shaft. Advise on the safety of the flywheel and on a suitable shrink fit. What

would be the effect on the stressing of the flywheel of a shrink fit?

In order to make a rough check the accuracy of the stressing of the flywheel, the rim can

be analysed as an unsupported spinning ring. This will exaggerate the stresses, as the

web acts to limit radial expansion in reality. The expression for circumferential (or

hoop) stress at radius r in a spinning ring of outside radius b and inside radius a is given

by

3

a 2 b 2 1 3 2

2 (b 2 a 2 2

r )

8

3

r

again is Poisson’s ratio. is density. is angular velocity (rad s-1).

V1

L1

C1

Y

X

Z

What to submit

(1) Crack specimens

Submit the plots used to estimate compliance.

Report the two estimates of stress intensity, and the comparison of these to the estimate

of G from change of compliance with crack length.

Report on the accuracy of beam theory in this problem, and on the difference between the

deflection results from the meshes of linear and quadratic elements. As well as

comparing deflections, for the longest crack size compare the most compressive stress on

the top surface of each of the models to that expected for a beam. Also compare the

maximum transverse shear stress to its value from beam theory. Show how the stresses

change with h or p-refinement.

(2) Axisymmetric problem

Submit the comparison of the hoop stress in the rim with that in an unsupported rim.

Show the locations and magnitudes of critical stresses as requested in the discussion

above. Suggest a suitable interference fit at the hub.