AUTOMOTIVE ELECTRONIC-unit-4 - E

advertisement

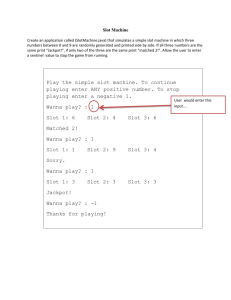

AUTOMOTIVE ELECTRONICS UNIT-4 Section-A 1. What is Slot Car? A slot car (sometimes, slotcar) is a powered miniature auto or other vehicle that is guided by a groove or slot in the track on which it runs. A pin or blade extends from the bottom of the car into the slot. Though some slot cars are used to model highway traffic on scenic layouts, the great majority are used in the competitive hobby of slot car racing or slot racing. 2. What is the Abbreviation of TCU? Transmission control unit 3. Whatis TCU? A transmission control unit or TCU is a device that controls modern electronic automatic transmissions. 4. What is the use of TCU? A TCU generally uses sensors from the vehicle as well as data provided by the Engine Control Unit to calculate how and when to change gears in the vehicle for optimum performance, fuel economy and shift quality. 5.What is PCM? Powertrain Control Module Section-B 1.Explain Brake-by-wire concept? Drive-by-wire technology in automotive industry replaces the traditional mechanical and hydraulic control systems with electronic control systems using electromechanical actuators and human-machine interfaces such as pedal and steering feel emulators. Brake-by-wire represents the replacement of traditional components such as the pumps, hoses, fluids, belts and vacuum servos and master cylinders with electronic sensors and actuators. Some x-by-wire technologies have been already installed on commercial vehicles such as steer-by-wire, and throttle-by-wire. Brake-by-wire technology is still under development by some automobile and automotive parts manufacturers industry worldwide and has not been widely commercialized yet. This is mainly due to the safety-critical nature of brake products. So far, Mercedes-Benz (Sensotronic) and Toyota (Electronically Controlled Brake) already use almost fully brake-by-wire systems, on the Mercedes-Benz E-class and SL models and on Toyota's Estima. 2.Explain the Architecture of an Electromechanical Braking System Fig. 1. General architecture of an EMB system. General architecture of an electromechanical braking (EMB) system in a drive-by-wire car is shown in Fig. 1. The system mainly comprises five types of elements: 1. 2. 3. 4. 5. Processors including an Electronic Control Unit (ECU) and other local processors Memory (mainly integrated into the ECU) Sensors Actuators Communication network(s). Once the driver inputs a brake command to the system via a human-machine interface HMI (e.g. the brake pedal), four independent brake commands are generated by the ECU based on high level brake functions such as anti-lock braking system (ABS) or vehicle stability control (VSC). These command signals are sent to the four electric calipers (ecalipers) via a communication network. As this network might not be able to properly communicate with the e-calipers due to network faults, HMI sensory data are also directly transmitted to each e-caliper via a separate data bus. In each e-caliper a controller uses the brake command (received from ECU) as a reference input. The controller provides drive control commands for a power control module. This module controls three phase drive currents for the brake actuator which is a permanent magnet DC motor, energised by 42V sources. In addition to tracking its reference brake command, the caliper controller also controls the position and speed of the brake actuator. Thus, two sensors are vitally required to measure the position and speed of the actuator in each e-caliper. Because of the safety critical nature of the application, even missing a limited number of samples of these sensory data should be compensated for. 3. Explain the Voting system Voting A brake-by-wire system, by nature, is a safety critical system and therefore fault tolerance is a vitally important characteristic of this system. As a result, a brake-by-wire system is designed in such way that many of its essential information would be derived from a variety of sources (sensors) and be handled by more than the bare necessity hardware. Three main types of redundancy usually exist in a brake-by-wire system: 1. Redundant sensors in safety critical components such as the brake pedal. 2. Redundant copies of some signals that are of particular safety importance such as displacement and force measurements of the brake pedal copied by multiple processors in the pedal interface unit. 3. Redundant hardware to perform important processing tasks such as multiple processors for the electronic control unit (ECU) in Fig. 1. In order to utilize the existing redundancy, voting algorithms need to be evaluated, modified and adopted to meet the stringent requirements of a brake-by-wire system. Reliability, fault tolerance and accuracy are the main targeted outcomes of the voting techniques that should be developed especially for redundancy resolution inside a brakeby-wire system. Example of a solution for this problem: A fuzzy voter developed to fuse the information provided by three sensors devised in a brake pedal design. 4. Explain the Missing data compensation In a by-wire car, some sensors are safety-critical components, and their failure will disrupt the vehicle function and endanger human lives. Two examples are the brake pedal sensors and the wheel speed sensors. The electronic control unit must always be informed of the driver’s intentions to brake or to stop the vehicle. Therefore, missing the pedal sensor data is a serious problem for functionality of the vehicle control system. Wheel speed data are also vital in a brake-by-wire system to avoid skidding. The design of a bywire car should provide safeguards against missing some of the data samples provided by the safety-critical sensors. Popular solutions are to provide redundant sensors and to apply a fail-safe mechanism. In addition to a complete sensor loss, the electronic control unit may also suffer an intermittent (temporary) data loss. For example, sensor data can sometimes fail to reach the electronic control unit. This may happen due to a temporary problem with the sensor itself or with the data transmission path. It may also result from an instantaneous short circuit or disconnection, a communication network fault, or a sudden increase in noise. In such cases, for a safe operation, the system has to be compensated for missing data samples. Example of a solution for this problem: Missing data compensation by a predictive filter. 5. Explain the Accurate estimation of position and speed of brake actuators in the e-calipers The caliper controller controls the position and speed of the brake actuator (besides its main task which is tracking of its reference brake command). Thus, position and speed sensors are vitally required in each e-caliper and an efficient design of a measurement mechanism to sense the position and speed of the actuator is required. Recent designs for brake-by-wire systems use resolvers to provide accurate and continuous measurements for both absolute position and speed of the rotor of the actuators. Incremental encoders are relative position sensors and their additive error needs to be calibrated or compensated for by different methods. Unlike the encoders, resolvers provide two output signals that always allow the detection of absolute angular position. In addition, they suppress common mode noise and are especially useful in a noisy environment. Because of these reasons, resolvers are usually applied for the purpose of position and speed measurement in brake-by-wire systems. However, nonlinear and robust observers are required to extract accurate position and speed estimates from the sinusoidal signals provided by resolvers. Example of a solution for this problem: A hybrid resolver-to-digital conversion scheme with guaranteed robust stability and automatic calibration of the resolvers used in an EMB system 6. Explain the Measurement and/or estimation of clamp force in the electromechanical calipers A clamp force sensor is a relatively expensive component in an EMB caliper. The cost is derived from its high unit value from a supplier, as well as marked production expenses because of its inclusion. The later emanates from the complex assembly procedures dealing with small tolerances, as well as on-line calibration for performance variability from one clamp force sensor to another. The successful use of a clamp force sensor in an EMB system poses a challenging engineering task. If a clamp force sensor is placed close to a brake pad, then it will be subjected to severe temperature conditions reaching up to 800 Celsius that will challenge its mechanical integrity. Also temperature drifts must be compensated for. This situation can be avoided by embedding a clamp force sensor deep within the caliper. However, embedding this sensor leads to hysteresis that is influenced by friction between the clamp force sensor and the point of contact of an inner pad with the rotor. This hysteresis prevents a true clamp force to be measured. Due to the cost issues and engineering challenges involved with including the clamp force sensor, it might be desirable to eliminate this component from the EMB system. A potential opportunity to achieve this presents itself in accurate estimation of the clamp force based on alternative EMB system sensory measurements leading to the omission of a clamp force sensor. Example of a solution for this problem: Clamp force estimation from actuator position and current measurements using sensor data fusion. Section-c 1.Explain the Common slot Car 1. The diagram at right shows the wiring of a typical 1:24 or 1:32 slot car setup. Power for the car's motor is carried by metal strips next to the slot, and is picked up by contacts alongside the guide flag (a swiveling blade) under the front of the slot car. The voltage is varied by a resistor in the hand controller. This is a basic circuit, and optional features such as braking elements or electronic control devices are not shown. Likewise, the car's frame or chassis has been omitted for clarity. HO slot cars work on a similar principle, but the current is carried by thin metal rails that project barely above the track surface and are set farther out from the slot. The car's electrical contacts, called "pickup shoes", are generally fixed directly to the chassis, and a round guide pin is often used instead of a swiveling flag. Today, in all scales, traction magnets are often used to provide downforce to help hold the car to the track at higher speeds, though some enthusiasts believe magnet-free racing provides greater challenge and enjoyment and allows the back of the car to slide or "drift" outward for visual realism. Common slot car scales Models of the Ford GT-40, in 1:24, 1:32 and nominal HO scales. Note that the 1960s-era HO model has been widened to accept the mechanism. There are three common slotcar scales (sizes): 1:24 scale, 1:32 scale, and so-called HO size (1:87 to 1:64 scale). These are also commonly written as 1/24, 1/32, 1/87 and 1/64. Usual pronunciation is "one twenty-fourth," "one thirty-second," and so on, but sometimes "one to twenty-four," "one to thirty-two," et cetera. - 1:24 scale cars are built so that 1 unit of length (such as an inch or millimetre) on the model equals 24 units on the actual car. Thus, a model of a Jaguar XK-E (185" or 4.7 m overall length) would be 7.7" long (19.6 cm) in 1:24 scale. 1:24 cars require a course so large as to be impractical for many home enthusiasts, so most serious 1:24 racing is done at commercial or club tracks. - 1:32 scale cars are smaller and more suited to home-sized race courses but they are also widely raced on commercial tracks, in hobby shops or in clubs. This scale is the most popular in Europe, and is equivalent to the old #1 Gauge (or "standard size") of toy trains. Our Jaguar XK-E would be about 5.8" (14.7 cm) in 1:32 scale. - HO-sized cars vary in scale. Because they were marketed as model railroad accessories, the original small slot cars of the early 1960s roughly approximated either American/European HO scale (1:87) or British OO scale (1:76). As racing in this size evolved, the cars were enlarged to take more powerful motors, and today they are closer to 1:64 in scale; but they still run on track of approximately the same width, and are generically referred to as HO slot cars. They are not always accurate scale models, since the proportions of the tiny bodies must often be stretched to accommodate a standard motor and mechanism. The E-Jaguar scales out to 2.1" (5.3 cm) in 1:87 and 2.9" (7.3 cm) in 1:64). Though there is HO racing on commercial and shop-tracks, probably most HO racing occurs on home racetracks. In addition to the major scales, slot cars have been commercially produced in 1:48 and 1:43 scale, corresponding to O scale model trains. 1:48 cars were promoted briefly in the 1960s, and 1:43 slot car sets are generally marketed today (2007) as children's toys. So far, there is little organized competition in 1:43, but the scale is gaining some acceptance among adult hobbyists for its affordability and moderate space requirements. The E-Jag would be 4.3" (10.9 cm) in 1:43. 2. Explain the Related systems and developments Digital track (SCX, 1995). Digital technology allows cars to change lanes at crossing points and passing-lane sections. A number of technological developments have been tried over the years to overcome the traditional slot car's limitations. Most lasted only a few years, and are now merely historical curiosities. Only digital control is currently in production. Around 1962, AMT's Turnpike system (USA) used multiple electrical pickups within the slot itself to allow drivers to control, to a limited extent, the steering of special 1:25 cars. In the late 1960s the Arnold Minimobil system (Germany), also marketed as the Matchbox Motorway (UK), used a long hidden coil, powered by trackside motors, to move die-cast or plastic cars down the track via a slot and detachable pin. Cars in different lanes could race, but cars in the same lane moved at the same speed, separated by a fixed distance. In the mid and late 1970s several manufacturers including Aurora, Lionel and Ideal (USA) introduced slotless racing systems that theoretically allowed cars to pass one another from the same lane. Most used a system of multiple power rails that allowed one car to speed up momentarily and move to the outside to pass. Though briefly successful as toy products, none of these systems worked well enough to be taken up by serious hobbyists.[24] In 2004, a number of traditional slot car manufacturers introduced digital control systems, which enable multiple cars to run in the same lane and to change lanes at certain points on the course. Digitally-coded signals sent along the power strips allow each car to respond only to its own controller. In addition, imaginative manufacturers have used the slot track system to allow the racing of a variety of unusual things, including motorcycles,[1] boats,[28] airplanes,[29] spacecraft,[29] horses,[1] fictional and cartoon vehicles,[24] snowmobiles,[24] futuristic railroad trains,[30] and no doubt many more. 3. Explain the Slot car track The first sectional slot tracks from Scalextric and VIP were molded rubber and folded metal, respectively, but modern slot tracks fall into two main categories: plastic tracks and routed tracks. Three-lane routed track inspired by the Targa Florio Plastic Tracks are made from the molded plastic commercial track sections. Sectional track is inexpensive and easy to work with and the design of the course can be easily changed. The joints between the sections, however, make a rough running surface, prompting the derisive term "clickety-clack track." The many electrical connections cause voltage drop and contribute to more frequent electrical problems. For a permanent setup, the joints can be filled and smoothed, and the power rails soldered together or even replaced with continuous strips, but the surface is seldom as smooth as a good routed track. Routed Tracks have the entire racecourse made from one or a few pieces of sheet material (traditionally chipboard or MDF, but sometimes polymer materials) with the guide-slots and the grooves for the power strips cut directly into the base material using a router or CNC machining. This provides a smooth and consistent surface, which is generally preferred for serious competition. 4. Explain the Electrical equipment Power for most slot car tracks comes from a powerpack. Powerpacks contain a transformer, which reduces high voltage house current to a safe 12 to 20V (depending on car type), and usually a rectifier, which changes AC to DC, for cooler running and simpler motors. High-capacity lead-acid batteries are sometimes used for hobby slot cars. Toy race sets may use dry cell batteries at 3 to 6 volts. Types of Slot Car Controllers (L to R, from top) - Telegraph Key, c.1955. Thumb button, c.1957-1970 (1967 shown). Wheel or Dial Rheostat, c.1959-1965 (Aurora 1963 shown). Carbon Disc Plunger, c.1965-1970 (Aurora). Rheostat Plunger, c.1960-1970 (Cox 1966 shown). Full-Grip Style, c.1962 (Marx). Pistolgrip Rheostat 1965 onward (Aurora/Russkit 1972 shown). Electronic Controller, 1970s onward. Controllers ("throttles") vary car speed by modulating the voltage from the powerpack. They are usually hand-held and attached by wires to the track. Besides speed control, modern racing controllers usually feature an adjustable "brake", "coast", and "dial-out". Braking works by temporarily connecting the rails together by a switch (or via a resistor for reduced braking); this converts the car's motor into a generator, and the magnetic forces that turned the motor are now slowing it down. Coast allows a certain amount of power to continue to the track after the driver has "let-off" (which would otherwise cut all power to the car). A dial-out allows the driver to limit the maximum power that can reach the car. The early rail-car tracks used telegraph keys, model-train rheostats and other improvised means to control car speed. The first commercial race sets (1957) used handheld controllers with a thumb-button; like the telegraph key, these were either on or off, requiring the driver to "blip" the throttle for intermediate speeds. Later versions had an intermediate speed, and one late version used a buzzer mechanism to provide full-range speed control. From 1959 to about 1965, most HO slot sets had a table-mounted controller with a miniature steering wheel or simple dial-knob operating a rheostat (variable resistor), which gave precise control throughout the car's speed range. This type could be left on a particular speed setting, making it very suitable for model highway layouts, but they were awkward for racing. Around 1960, handheld rheostats began to appear. Most early examples had vertical, thumb-operated plungers with the rheostat in the grip. Aurora had a plunger design in which a stack of carbon/silicon discs replaced the rheostat. Less common styles included a horizontal thumb-plunger and a full-grip squeeze controller. In 1965, Russkit introduced the trigger-operated pistolgrip controller. The pistolgrip quickly became the standard rheostat-controller style both for race sets and serious hobbyists, and has remained so to the present day. Control is by the index finger, and the heat-generating rheostat is above the grip for comfort and effective ventilation. For good response, rheostats must be matched to the particular cars involved. To race different classes of cars, several controllers with different resistance ratings are often required. In the 1970s, electronic additions to the rheostat controllers became popular, which allowed them to be tuned to the particular car being raced. Some modern electronic controllers dispense with the rheostat altogether, and can be used for all classes and types of car. Digital slot cars generally use a controller that is trigger operated, though the rheostat housing is replaced by a slim bulge containing the electronics. On most tracks, a driver will plug or clip his personal controller to his lane's "driver's station," which has wired connections to the power source and track rails. Modern controllers usually require three connections - one to the power terminal of the driver's station (customarily white), one to the brake terminal (red), and one to the track terminal (black). Conventional slot car tracks are wired in one of two ways: with the power terminal connected to the power source positive and the brake terminal negative (called "positive gate"), or the other way around ("negative gate"). Resistance type controllers can be used with either positive or negative track wiring, most electronic controllers can only be used with one or the other, although a few electronic controllers feature a switch that adapts them for either gate configuration. Formal Competition Slot car racing ranges from casual get-togethers at home tracks, using whatever cars the host makes available, to very serious competitions in which contestants painstakingly build or modify their own cars for maximum performance and compete in a series of races culminating in national and world championships. For information on types of formal competition, racing organizations, standards, etc., see slot car racing. **********************************