The conduct of practical M-14

advertisement

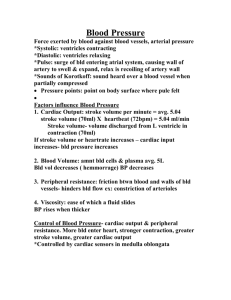

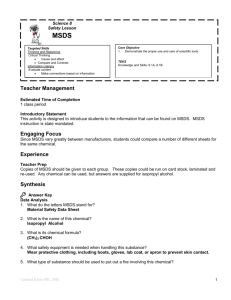

3 OCCUPATIONAL HEALTH SAFETY & ENVIRONMENT SAFE WORK INSTRUCTIONS FOR The conduct of practical M-14 (Martensitic Phase Transforamtions ) for undergraduate students enrolled in MTE3502 1. Authorisation Undergraduate students shall not enter or conduct laboratory experiments without the presence of demonstrator during class hours. Undergraduates are not allowed within the laboratories without the supervision of a demonstrator or lecturer in charge of the lab outside of class hours. 2. Hazards associated with equipment/machinery/technique/process: Chemicals Stainless steel etchant (consists of cupric sulphate, hydrochloric acid and ethanol) 5% Nitric acid in ethanol Ethanol Kerosene Equipment Muffler furnace Instron Mechanical Tester (Screw driven) Ferrite indicator Hacksaw Mounting Press Grinding machines Polishing wheels Compressed air gun Optical microscopes 3. Before you start work: The risk assessments and MSDS of the constituents of the ethcant solution are provided in the folders to be found on the door of the Metallography Lab (Rm 186/Bld 37). The risk assessments of the muffler furnace provided in the folders to be found on the door of the Heat treatment Room (Rm 177/Bld 37) The risk assessments for the grinding and polishing metals and mounting metal samples provided in the folders to be found on the door of the Metallography Lab (Rm 186/Bld 37) The risk assessments for the Instron Tester provided in the folders to be found on the door of the Undergraduate lab 2 (Rm G19A/Bld 36) 4. Personal protective equipment to be used: Requirements for entering the laboratories and performing experiments Safety glasses; enclosed shoes with preferably a leather upper region. No loose hair and long hair should be tied back away from the face. No loose clothing or jewellery that may be caught on the machines Laboratory coats or dustcoats should be worn when conducting experiments Specific requirements when performing etching or polishing metals Wear latex gloves when performing etching or polishing metals Some people may be allergic to latex gloves or the powder used in the gloves, in this case inform the demonstrators in charge. 4 Specific requirements when performing heat treatment experiments Wear heat resistant gloves, face shield and a leather apron when taking samples in and out of the salt baths or oil baths 5. The environment where the task is to be undertaken: Heat treatment room (Rm 177/Bld 37) equipped with a local exhaust system and an extraction fan. Metallography Lab (Rm 186/Bld 37) equipped with fume cupboards Mechanical Testing lab (Rm G19A/Bld 36) 6. Step by step procedures for task There are four main activities in the practical class, which consists Heat treatment, Metallographic specimen preparation, tensile testing, determination of shape memory effect. Each of these activities and the safe work procedures associated are discussed below Heat Treatment (Heat Treatment Room Rm177/Bld 37) Prior to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Heat Treatment Ensure that samples are dry Place samples into the muffler furnace held at 850oC using tongs Prepare a bucket of water to be used as quenching media. Do not overfill the bucket to avoid spillage. Clean up any spills immediately. Once the samples are fully austenised, after 1hour, remove using tongs and place one sample into the quenching bucket, filled with water Take the other sample out and place on a thermal brick and allow to air cool. Clearly label this sample as hot to prevent others from touching the sample Tensile Testing (Mechanical Testing Lab Rm G19A/Bld 36) Prior to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Tensile Testing to determine amount of martensite present C 1. Measure the length of the test sample 2. Make sure the martensite (ferrite) indicator has 1% ferrite indicator on 3. Place the sample within the grips of tensile tester and tighten the top grip. 4. Set the gauge length to zero in the Merlin™ Software program and balance to load. 5. Tighten the bottom grip and make sure sample is held securely. 6. Make sure the speed is set at 1mm/min. 7. Make sure all members of the team know you are starting the test. 8. One person will stand on the steps to the tensile tester and tap at the middle of the test piece. 9. Start the test. 10. When the person taping asks you to stop the test as required amount of martensite is formed stop the test. 11. Write down the elongation on the software program. 12. Change the ferrite indicator to 2%. 13. Restart the test. 14. Repeat step 9 to 12. Each time using the next ferrite indicator 5%, 10 and 15%. 15. Once the 15% indicator is used. Close the safety door and increase the test speed to 10mm/min. 16. Start the test and continue until the samples fails 17. Stop the test 18. Open the door and take the failed samples out of the grips. 5 Metallographic specimen preparation (Metallography Lab Rm186/Bld 37) Prior to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Cutting samples Using a hacksaw cut about 1cm x 1cm from the fracture end of tensile tested sample and from the grips. Mounting samples (there are two machines and the instructions for both machines are provided) Labopress Loading samples Press and hold ram up until ram reaches its upper limit. Place the sample need to be mounted on the top of the ram and lower the ram to its lower limit. Using the funnel provided place the appropriate amount of resin into the cylinder Place the top closure unit and tighten the lid to the full extent and then undo the lid approximately ¼ turn Mounting process Switch on the heating and apply pressure until the needle reads 30kN do not go over 40. Make sure that pressure remains about 30kN during the operation. Leave for 8 min. Switch the heating off and allow the sample to cool for at minimum 5 min with the cooling water running. Removal of the samples Switch the water off and lower the ram fully. Open the top closure unit by rotating it anticlockwise and remove it Press and hold the ram up until it reaches the top most limit. Remove the specimen, now the mounting press is ready for the next sample Primopress Loading samples and mounting process Make sure the specimen chamber is open and place the bottom part of the mould in the chamber. Place the sample need to be mounted on the top of the bottom mould. Using the funnel provided place the appropriate amount of resin into the cylinder Close the specimen chamber and place the top part of the mould on and close top backing plate. (See instruction manual). Turn the machine on and make sure the appropriate specimen chamber is heating. Push the lever to start position so the chamber is pressurized. Make sure that the heating time is set to 14 min and cooling time to 5 min. Removal of the samples Lower the ram fully and then remove the top backing plate. Raise the ram by moving the lever to start position and once the top part of the mould is fully visible move the ram to stop and remove the top part of the mould assembly. Raise the lever again to the start position and make sure it reaches the top limit and then move the ram to stop position. Remove the sample and bottom part of the mould. Move the ram to down position and wait for it to go down. Then open the specimen chamber ready for the next sample. Grinding and polishing a Make sure SiC paper with 180, 320, 800 1200 grit size are present and are placed in the grinding machine as indicated b Turn the water on slowly and make sure no water squirts on to the floor. c There should be sufficient water to wet the SiC paper d Blunt the sharp edges of the back of the bakelite encasement as sharp edges will dig into your fingers e Grinding sample only in one direction starting at the coarsest paper. f Hold on to the sample with both hands to prevent sample from flying off and hitting someone else 6 Once the sample is flat and fully observable turn in 90o clockwise and move to the paper with the next largest grit size h When grinding marks perpendicular to the current grinding direction is no longer observable moved to the next grit size down i Repeat f and g until grit size of 1200 is used j Wash the sample with water and then spray with ethanol. k Dry the sample by blowing compressed air from the spray gun (half depress the lever) l Use the polishing machine with 3m sign on it by removing the lid m Spray kerosene from the squirt bottle on the table and make sure to slightly wet the wheel don’t over spray. (If the wheel is wet then do not spray on more kerosene) n Polish the sample until the grinding marks are not visible to the naked eye. o Wash the sample with ethanol from the spray gun. p Dry the sample by blowing compressed air from the spray gun (half depress the lever) q Use the polishing machine with 1m sign on it by removing the lid r Spray kerosene from the squirt bottle on the table and make sure to slightly wet the wheel don’t over spray. (If the wheel is wet then do not spray on more kerosene) s Repeat steps o and p t Using optical microscope see whether any scratch marks are visible. Seek demonstrator’s help if you are not sure. u If scratches are present repeat steps q to t v Once the sample is ready notify the demonstrator that it is ready for etching g Etching a b c d e f g h i j Solution to be used in the fume cupboard Decant the required amount of solution to a clean beaker Place the metal sample in a mounting in the beaker with the sample fully covered with the etchant. Remove the sample from etchant after required etching period (normally 5-10s) Wash with running water to remove excess etchant from sample Wash by spraying ethanol on to the sample using the spray gun. Dry the sample by blowing compressed air from the spray gun (half depress the lever) Look at the microstructure using the optical microscope. If the sample is under etched follow steps c-h above. Once the samples show all the interesting features of microstructure take photos using optical microscope equipped with the digital camera Shape memory effect (Metallography Lab Rm 186/bld 37) Measure the length of extended metal springs provided. Place a clean beaker with water on the hot plate provided and heat the water. After about few minutes when the water is hot place the springs into the hot water using the tweezers provided. Observe what happens to the springs and how fast the reaction proceed Take the springs out hot water using tweezers Wait for the springs to cool, about a minute, and measure the final length of the springs Switch the hotplate off wait for the water to cool down and dispose of the water down the sink 7. Clean-up procedures Heat Treatment (Heat Treatment Room Rm177/Bld 37) Ensure work area is need and tidy before leaving. Ensure there are no unattended spills left on the floor Tensile Testing using Instron Mechanical Tester (Mechanical Testing Lab Rm G19A/Bld 36) Ensure work area is need and tidy before leaving. Do not leave samples lying around 7 Metallographic specimen preparation (Metallography Lab Rm 186/Bld 37) Turn the taps off after mounting process Clean up any left over Bakelite residue around the machines and on the ram Turn the taps off after grinding process and clean up any used SiC papers and clean up any water spills Close the lids of the polishing machines Wash the beaker used with running water and let to dry on the drying rack Clean any excess ethanol or etchant left on the bench top using paper towels to soak up the liquid. Wash the tong and hand them on the appropriate racks for drying Make sure the caps on the etchant bottles are not over tightened as to allow venting of any gases produced. Any chemical spill should be notified to the demonstrator in charge of the practical class who should take appropriate action Shape memory effect (Metallography Lab Rm 186/bld 37) Ensure work area is need and tidy before leaving. Ensure there are no unattended spills left on the floor 8. Waste disposal procedures 9. Once the etchant is used dispose of the solution with large quantities of water down the drain Emergency procedures Power outage or in case of emergency alarm leave the lab in an orderly manner as directed by the demonstrator in charge In case of chemical spill notify the demonstrator in charge. The demonstrator to clean up the spill following appropriate procedures listed in the MSDS of the constituents In case of thermal burn – notify the demonstrator in charge or technician in charge of the lab and run affected part under running water. Depending on the severity of burn medical attention may be required. In case of chemical burn- run the affected part under water and notify the demonstrator in charge or the technician in charge of the laboratory. Seek medical attention For chemical burns follow instructions in the MSDS of the constituents. 10. After hours access procedures No after hours access is available for the undergraduates 8 11. Related documentation Document description Heat Treatment Process Risk Control document for muffler furnace Tensile Testing Risk Control document for Tensile Testing Metallographic specimen preparation Risk Control Document for use of the 10% nitric acid in methanol solution Risk Control Document for use of the compressed air gun Risk Control Document for the use of mounting presses Risk Control Document for the use of grinding and polishing machines Risk Control Document for the use of stainless steel etchant MSDS for nitric acid MSDS for Kerosene MSDS for hydrochloric acid MSDS for Cupric sulphate MSDS for ethanol Location Risk Assessment folder Rm 177/Bld 37 Risk Assessment folder Rm G19A/Bld 36 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 Also refer to the risk control document for M13 practical, which is held in each of the laboratories where you conduct experiments Prepared by: … ………. Signed: …………………………….. Date: ……………………………..