For conduct of practical T-9

advertisement

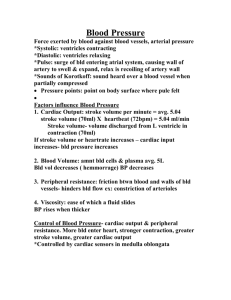

1 OCCUPATIONAL HEALTH SAFETY & ENVIRONMENT For conduct of practical T-9 (precipitation hardening) for undergraduate students enrolled in MTE3502 or MSC3011 1. Authorisation 2. Undergraduate students shall not enter or conduct laboratory experiments without the presence of demonstrator during class hours. Undergraduates are not allowed within the laboratories without the supervision of a demonstrator or lecturer in charge of the lab outside of class hours. Hazards associated with equipment/machinery/technique/process: Chemicals Electrolytic polishing solution (Lenoirs Reagent) containing Perchloric acid and methanol Salt used in salt baths Oil used in the oil baths Ethanol Equipment Salt and oil baths Hounsfield Tensile Tester Hardness tester Electropolisher Compressed air gun 3. Before you start work: 4. The risk assessments and MSDS of the constituents of the electrolytic polishing solution are provided in the folders to be found on the door of the Metallography Lab (Rm 186/Bld 37). The risk assessments and MSDS of the salt and oil baths provided in the folders to be found on the door of the Heat treatment Room (Rm 177/Bld 37) The risk assessments for the Hounsfield Tensile Tester provided in the folders to be found on the door of the Metallography Lab (Rm 186/Bld 37) The risk assessments for the hardness tester provided in the folders to be found on the door of the Undergraduate lab 2 (Rm 183/Bld 37) Personal protective equipment to be used: Requirements for entering the laboratories and performing experiments Safety glasses; enclosed shoes with preferably a leather upper region. No loose hair and long hair should be tied back away from the face. No loose clothing or jewellery that may be caught on the machines Laboratory coats or dustcoats should be worn when conducting experiments Specific requirements when performing electrolytic polishing experiments Wear latex gloves when performing electrolytic polishing experiments Some people may be allergic to latex gloves or the powder used in the gloves, in this case inform the demonstrators in charge. Specific requirements when performing heat treatment experiments Wear heat resistant gloves, face shield and a leather apron when taking samples in and out of the salt baths or oil baths 1 5. The environment where the task is to be undertaken: Heat treatment room (Rm 177/Bld 37) equipped with a local exhaust system and an extraction fan. Metallography Lab (Rm 186/Bld 37) equipped with fume cupboards Undergraduate laboratory 2 (Rm 183/Bld 37) 6. Step by step procedures for task There are four main activities in the practical class which include Heat treatment, Electrolytic polishing, Hardness testing, Tensile Testing. Each of these activities and the safe work procedures associated are discussed below. Heat Treatment (Heat Treatment Room Rm177/Bld 37) Prior to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Homogenisation Ensure samples are fully dried to minimise the risk of splattering molten salt or superheated steam on contact. Place samples on steel wire and carefully lower into a salt bath using tongs (560oC for 2 hours). Replace the salt bath lid immediately to minimise exposure to vapours. After required solution treatment time place a metal quenching bucket filled with cold water close to the salt bath. Do not overfill the bucket to avoid spillage. Clean up any spills immediately. While wearing full furnace PPE, remove the wire containing the sample using tongs and place in the quenching bucket. Take care to avoid entanglements with other samples. Ageing Ensure samples are fully dried to minimise the risk of splattering molten oil or superheated steam on contact. Place samples on steel wire and carefully lower into a oil bath using tongs (190oC for 520 minute). Replace the salt bath lid immediately to minimise exposure to vapours. After required solution treatment time place a metal quenching bucket filled with cold water close to the salt bath. Do not overfill the bucket to avoid spillage. Clean up any spills immediately. While wearing full furnace PPE, remove the wire containing the sample using tongs and place in the quenching bucket. Take care to avoid entanglements with other samples. Hardness Testing (Undergraduate Lab 2 Rm 183/Bld 37) Prior to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Testing Make 5 indents in the end of the sample. Record indent size and calculate VHN and standard deviation. Do not indent the thin section, as this will cause premature failure in the tensile test. Schedule 10 minute breaks after 50 minutes operating hardness tester - move and stretch. 2 Electrolytic polishing (Metallography Lab Rm 186/Bld 37) Piror to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Check Lenoirs reagent for discolouration and evolution of gas- this should be done by the demonstrator and not the students enrolled Operation Select glass (not plastic) sample holder and metal holder with fingers and feet Water on Check current setting (60V / 20 A) Set polishing control to 55-60 Time to automatic Selector to polish only Flow rate 3.25 Time 22s Wait until the procedure stops before taking the sample out of the electrolytic polishing unit. Wash with running water to remove excess etchant from sample Wash by spraying ethanol on to the sample using the spray gun. Dry the sample by blowing compressed air from the spray gun (half depress the lever) Look at the microstructure using the optical microscope. Tensile Testing using Hounsfield Tensile Tester (Metallography Lab Rm 186/Bld 37) Piror to any activities Comply with any special requirements for Safety See above. Check that electrical leads are tagged appropriately and are current. If there is any visible damage inform the demonstrator immediately Stage 1 testing Secure sample in grips using Alan key. If necessary adjust height of top grip using manual control. With speed set to low, manually increase tension until load cell just starts to register. Reverse direction and reduce tension until it just reaches zero. (Ensures there is no slack in sample, causing erroneous strain measurements) On computer; enter sample details. Gauge length is 25mm Set max strain to 2.5mm (10%) Load max to 10000N. Auto reverse OFF (IMPORTANT) Press return until red Y/N bar appears. Press Y. Enter sample cross section details Thickness, t, 2 mm Width, w, 10mm. Press <space> to start test. Once sample reaches 2.5mm extension, test will cease. Print graph using <F7>. NB wait until printing has ceased before touching computer! Some commands appear to disrupt printing – data will be lost! Set speed to low and manually lower gripper until load falls to zero. (this removes the elastic strain in the sample which otherwise makes it difficult to remove). Remove sample from grippers using Alan Key Once printing has ceased; press <F6> three times to exit. Check that sample details have been recorded on graph. If not do so manually Insert next sample and repeat 3 Stage 2 – test to failure Secure sample in grips using Alan key. If necessary adjust height of top grip using manual control. Note that the sample will have plastically deformed and will be longer than in the initial test. With speed set to low, manually increase tension until load cell just starts to register. Reverse direction and reduce tension until it just reaches zero. (Ensures there is no slack in sample, causing erroneous strain measurements) On computer; enter sample details. Gauge length is 27.5mm Set max strain to 20mm Load max to 10000N. Auto reverse OFF (IMPORTANT) Press return until red Y/N bar appears. Press Y. Enter sample cross section details *Assume no change Thickness, t, 2 mm Width, w, 10mm. Press <space> to start test. Once sample fails or reaches 20mm extension, test will cease. Print graph using <F7> NB wait until printing has ceased before touching computer! Some commands appear to disrupt printing – data will be lost! If sample has completely fracture the pieces can be removed immediately. Otherwise set speed to low and manually lower gripper until load falls to zero. (this removes the elastic strain in the sample which otherwise makes it difficult to remove). Remove sample from grippers using Alan Key. Take care as the fractured edges can be extremely sharp Once printing has ceased; press <F6> three times to exit. Check that sample details have been recorded on graph. If not do so manually Insert next sample and repeat 7. Clean-up procedures Heat Treatment (Heat Treatment Room Rm177/Bld 37) Ensure work area is need and tidy before leaving. Ensure there are no unattended spills left on the floor Hardness Testing (Undergraduate Lab 2 Rm 183/Bld 37) Ensure work area is need and tidy before leaving. Electrolytic polishing (Metallography Lab Rm 186/Bld 37) Ensure work area is need and tidy before leaving. Check caps on solutions of nitric acid / methanol – ensure caps an on but loose to allow for evolution of gases Tensile Testing using Hounsfield Tensile Tester (Metallography Lab Rm 186/Bld 37) Ensure work area is need and tidy before leaving. Do not leave samples lying around 8. Waste disposal procedures If the solution is discoloured notify the demonstrator and the technician in charge of the lab who would organise for urgent disposal of the solution Consult with the demonstrator in charge to dispose the solution after one month or immediately following the completion of the practical cycle for the year 4 9. Emergency procedures Power outage or in case of emergency alarm leave the lab in an orderly manner as directed by the demonstrator in charge In case of chemical spill notify the demonstrator in charge. The demonstrator to clean up the spill following appropriate procedures listed in the MSDS of the constituents In case of thermal burn – notify the demonstrator in charge or technician in charge of the lab and run affected part under running water. Depending on the severity of burn medical attention may be required. In case of chemical burn- run the affected part under water and notify the demonstrator in charge or the technician in charge of the laboratory. Seek medical attention For chemical burns follow instructions in the MSDS of the constituents. 10. After hours access procedures No after hours access is available for the undergraduates 11. Related documentation Document description Heat Treatment Process Risk Control document for salt baths Risk Control document for oil baths MSDS for salt used in salt baths MSDS for silicone oils used in oil baths Hardness Testing Risk Control document for Hardness Testing Electrolytic polishing Risk Control Document for use of the Lenoir’s solution Risk Control Document for use of the compressed air gun Risk Control Document for the use of Electrolytic polisher MSDS for Perchloric acid MSDS for Methanol MSDS for Glycerol MSDS for ethanol Hounsfield Tensile Testing Risk Control Document for Tensile Testing using Hounsfield Also The T-9 Prac Risk assessment Prepared by: … ………. Signed: …………………………….. Location Risk Assessment folder Rm 177/Bld 37 Risk Assessment folder Rm 177/Bld 37 MSDS folder Rm 177/Bld 37 MSDS folder Rm 177/Bld 37 Risk Assessment folder Rm 183/Bld 37 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 MSDS folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 Risk Assessment folder Rm 186/Bld 37 Rm 177/Bld37, Rm 183/Bld37 Date: ……………………………..