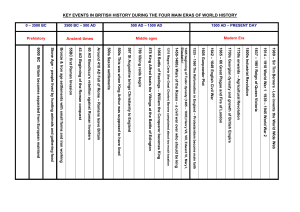

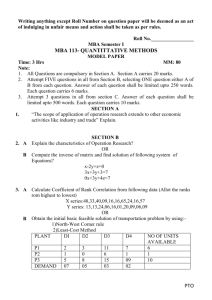

Summary of the minimum – cost method

advertisement

1 Transportation Problem: A network Model and a Linear Programming Formulation Example: 1) Production capacities over the next 3-month planning period for one particular type of generator are: Origin Plant Production Capacity (units) 1 Cleveland, Ohio 5000 2 Bedford, Indiana 6000 3 York, Pennsylvania 2500 Total 13,500 2) The 3-month forecast of demand for the distribution centers is: Destination Distribution Center Demand Forecast (units) 1 Boston, 6000 2 Chicago, 4000 3 St. Louis, 2000 4 Lexington 1500 Total 13,500 3) Transportation cost per unit shipped via each route is: Destination Origin Boston Chicago St. Louis Lexington Cleveland 3 2 7 6 Bedford 7 5 2 3 York 2 5 4 5 Determine how much of the production should be shipped from each plant to each distribution center to minimize the transportation cost. 2 Plants Distribution Centers (Origin nodes) (Destination nodes) 3 1 5000 Cleveland 1 Boston 6000 2 Chicago 4000 2 6 7 7 6000 2 Bedford 5 5 2 3 2 2500 3 York 5 3 St. Louis 5 4 4 Lexington Supplies 2000 Distribution routes (arcs) 1500 Demands 3 For a transportation problem having m origins and n destinations: xij =number of units shipped from origin i to destination j where i = 1, 2, …, m, and j = 1, 2, …, n 3 x11 2 x12 7 x13 6 x14 Min 7 x21 5 x22 2 x23 3 x24 2 x31 5 x32 4 x33 5 x34 s.t. x11 x12 x13 x14 5000 x21 x22 x23 x24 6000 x31 x32 x33 x34 2500 x11 x21 x31 6000 x12 x22 x32 4000 x13 x23 x33 2000 x14 x24 x34 1500 xij 0 for i = 1, 2,3; j = 1, 2,3,4 The general linear programming model of the m origins, n destinations transportation problem is: m n Min cij xij i 1 j 1 s.t n xij si i = 1, 2,…;m Supply j 1 m x i 1 ij dj xij 0 j = 1, 2,…,n for all i and j Demand 4 Summary of the transportation simplex method: To apply the transportation simplex method, you must have a transportation problem with total supply = total demand; thus, for some problems you may need to add a dummy origin or dummy destination to put the problem in this form. The transportation simplex method applies a two-phase solution procedure. In phase I, apply the minimum–cost method to find an initial feasible solution. In phase II, begin with the initial feasible solution and iterate until you reach an optimal solution. Start Determine Initial feasible solution Is Solution Optimal ?? NO Improve solution by reallocating YES STOP 5 The steps of the transportation simplex method for a minimization problem are summarized as follows. Phase I: Minimum–Cost Method Step 1 Identify the cell in the transportation tableau with the lowest cost, and allocate as much flow as possible to this cell. In case of a tie, choose the cell corresponding to the arc over which the most units can be shipped. If ties still exist, choose any of the tied cells. Step 2 Reduce the row supply and the column demand by the amount of flow allocated to the cell identified in Step1. Step 3 If all row supplies and column demands have been exhausted then STOP; the allocations made will provide an initial feasible solution. Otherwise, continue with Step 4. Step 4 If all row supply is now zero, eliminate the row from further consideration by drawing a line through it. If the column demand is now zero, eliminate the column by drawing a line through it. Step 5 Continue with Step 1 for all unlined rows and columns. 6 Phase II Step 1 If the initial feasible solution is degenerate with less than m+n-1 occupied cells, add an artificially cell or cells so that m+n-1 occupied cells exist in locations that enable use of the MODI method. Step 2 Use the MODI method to compute row indexes, ui , and column indexes, v j . Step 3 Compute the net evaluation index eij cij ui v j for each unoccupied cell. Step 4 If eij 0 for all unoccupied cells, STOP; you have reached the optimal solution. Otherwise, proceed to Step 5. Step 5 Identify the unoccupied cells with the smallest (most negative) net evaluation index and select it as the incoming cell. Step 6 Find the stepping-stone path associated with the incoming cell. Label each cell on the stepping-stone path whose flow will increase with a plus sign and each cell whose flow will decrease with a minus sign. Step 7 Choose as the outgoing cell the minus-sign cell on the stepping-stone path with the smallest flow. If there is a tie, choose any one of the tied cells. The tied cells that are not chosen will be artificially occupied with a flow of zero at the next iteration. Step 8 Allocate to the incoming cell the amount of flow currently given to the outgoing cell; make the appropriate adjustments to all cells on the steppingstone path, and continue with step 2. 7 Transportation tableau Origin Cleveland Boston 3 Bedford York Demand Destination Chicago St. Louis Lexington 2 7 6 7 5 2 3 2 5 4 5 6000 4000 2000 1500 Supply 5,000 6,000 2,500 13,500 Final Tableau showing the initial feasible solution using the Minimum-Cost Method Origin Boston 3 Cleveland 1000 7 Bedford 2500 2 York 2500 Demand 6000 Total Cost = Destination Chicago St. Louis Lexington 2 7 6 4000 5 2 3 2000 1500 5 4 5 4000 2000 1500 Supply 5,000 6,000 2,500 13,500 1000 $3 4000 $2 2500 $7 2000 $2 =$42000 1500 $3 2500 $2 8 Net Evaluation Indexes for the initial feasible solution using the MODI method Destination Origin 0 4 -1 Demand 3 2 3 1000 -2 2 7 5 -1 2500 2 2500 6000 7 9 4000 Supply -1 7 2 2000 6 5,000 3 6,000 1500 5 4 5 4 7 7 4000 2000 1500 2,500 13,500 Stepping-Stone Path Origin Cleveland Bedford York Demand Boston + 3 1000 - Destination Chicago St. Louis Lexington 2 7 6 4000 7 + 5 2500 2 2000 2 5 3 1500 4 5 2500 6000 4000 2000 1500 Supply 5,000 6,000 2,500 13,500 9 New Solution after one iteration Origin Destination Chicago St. Louis Lexington 2 7 6 Boston 3 Cleveland 3500 5,000 1500 7 Bedford 5 2 2500 2000 2 York Supply 3 6,000 1500 5 4 5 2,500 2500 Demand 6000 4000 2000 1500 13,500 MODI Evaluation of each cell in solution Origin 0 3 -1 Destination 2 -1 2 7 3 3 3500 1 5 2500 2 2500 6 2 2000 5 4 6 8 1500 7 0 3 1500 4 6 3500 $3 1500 $2 2500 $5 2000 $2 Total Cost = 1500 $3 2500 $2 5 6 =$39500 10 1) Total supply not equal to total demand. Origin Cleveland Boston 3 Bedford York Dummy Demand Destination Chicago St. Louis Lexington 2 7 6 7 5 2 3 2 5 4 5 0 0 0 0 6000 4000 2000 1500 Supply 4,000 6,000 2,500 1,000 13,500 2) Maximization objective function Pick the incoming cell for which eij is largest. If eij 0 for all unoccupied cells, we STOP; the maximization solution has been reached. 3) Unacceptable routes. a) FOR MINIMIZATION problem, assign the unacceptable route an extremely high cost M. b) FOR MAXIMIZATION problem, assign the unacceptable route a profit per unit of -M. Origin Cleveland Boston 3 7 5 2 3 M 5 4 5 Bedford York Demand Destination Chicago St. Louis Lexington 2 7 6 6000 4000 2000 1500 Supply 5,000 6,000 2,500 13,500