ISE4017 - Department of Industrial and Systems Engineering

advertisement

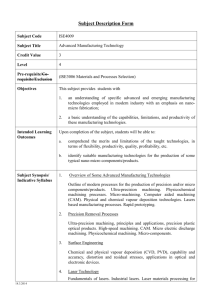

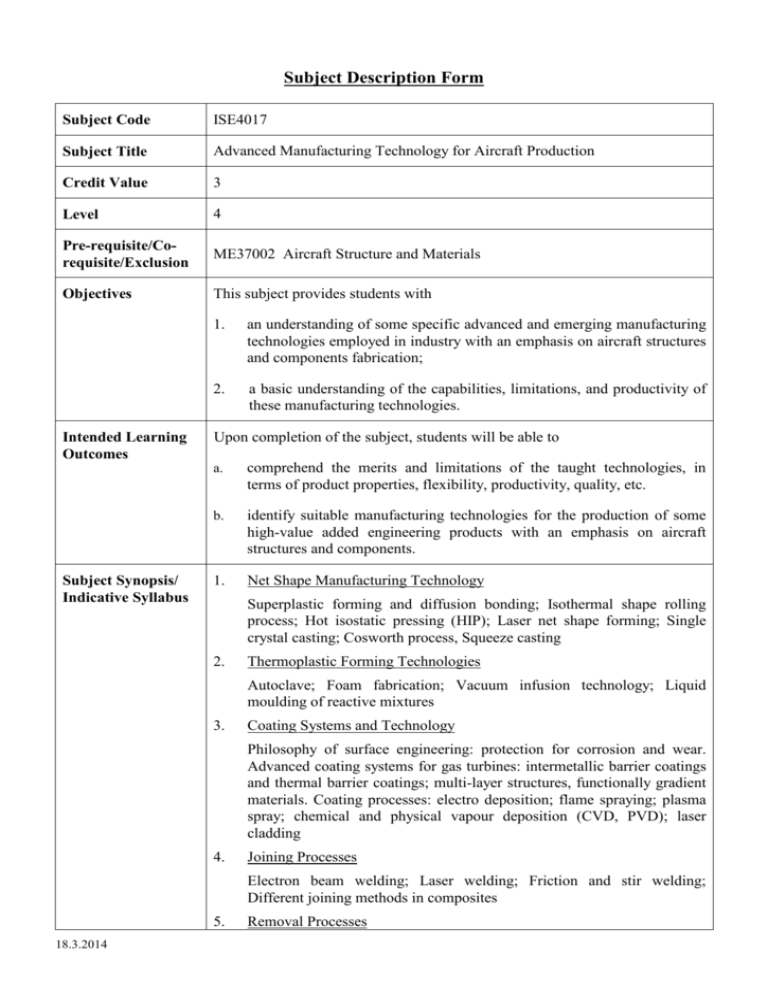

Subject Description Form Subject Code ISE4017 Subject Title Advanced Manufacturing Technology for Aircraft Production Credit Value 3 Level 4 Pre-requisite/Corequisite/Exclusion ME37002 Aircraft Structure and Materials Objectives This subject provides students with Intended Learning Outcomes Subject Synopsis/ Indicative Syllabus 1. an understanding of some specific advanced and emerging manufacturing technologies employed in industry with an emphasis on aircraft structures and components fabrication; 2. a basic understanding of the capabilities, limitations, and productivity of these manufacturing technologies. Upon completion of the subject, students will be able to a. comprehend the merits and limitations of the taught technologies, in terms of product properties, flexibility, productivity, quality, etc. b. identify suitable manufacturing technologies for the production of some high-value added engineering products with an emphasis on aircraft structures and components. 1. Net Shape Manufacturing Technology Superplastic forming and diffusion bonding; Isothermal shape rolling process; Hot isostatic pressing (HIP); Laser net shape forming; Single crystal casting; Cosworth process, Squeeze casting 2. Thermoplastic Forming Technologies Autoclave; Foam fabrication; Vacuum infusion technology; Liquid moulding of reactive mixtures 3. Coating Systems and Technology Philosophy of surface engineering: protection for corrosion and wear. Advanced coating systems for gas turbines: intermetallic barrier coatings and thermal barrier coatings; multi-layer structures, functionally gradient materials. Coating processes: electro deposition; flame spraying; plasma spray; chemical and physical vapour deposition (CVD, PVD); laser cladding 4. Joining Processes Electron beam welding; Laser welding; Friction and stir welding; Different joining methods in composites 5. 18.3.2014 Removal Processes High-speed machining; Electric discharge machining (EDM); Electrochemical discharge machining (ECDM); Water-jet machining; Laser cutting and drilling Teaching/Learning Methodology The subject is taught through a combination of lectures, laboratory exercises, and tutorial assignments integrated with a mini-project. The lectures introduce the student to in-depth knowledge in the current practices of advanced manufacturing technologies. The laboratory and tutorial exercises provide opportunities for student to learn and practice with guiding materials. The mini-project promotes students’ ability to conduct a literature search and their self-learning skills. Assessment Methods in Alignment with Intended Learning Outcomes Specific assessment methods/tasks % weighting Intended subject learning outcomes to be assessed a b 1. Assignments 10% 2. Lab report 10% 3. Mini-project 20% 4. Final examination 60% Total 100% The assignments, which are administered periodically throughout the course, are designed to facilitate students to reflect on and apply the knowledge learnt. The laboratory exercise is designed to assess students’ problem-solving skills in advanced manufacturing technology. The mini-projects follow a problem-based format and include case studies, presentations, and report writing. They are designed to facilitate students to acquire the relevant knowledge and demonstrate their ability to apply different technologies. The final examination is used to assess students’ individual achievement in all of the intended learning outcomes. Student Study Effort Expected Class contact: Lectures 26 Hrs. Tutorials 6 Hrs. Laboratory work and mini-project 7 Hrs. Other student study effort: 18.3.2014 Guided reading , Assignments, Laboratory report 25 Hrs. Self-study, preparation for examination Total student study effort Reading List and References 18.3.2014 40 Hrs. 104 Hrs. 1. D.F. Horne 1986, Aircraft Production Technology, Cambridge University Press 2. S. Kalpakjian and S.R. Schmid 2006, Manufacturing Engineering and Technology, Prentice Hall 3. Advanced Materials & Processes (serial), ASM International 4. Steve Krar and Arthur Gill 2003 Exploring Advanced Manufacturing Technologies, Industrial Press 5. Hassan Ei-Hofy 2005 Advanced Machining Processes-Nontraditional and Hybrid Machining Processes, McGraw-Hill