tc101redispecec - TEMP-COAT® Brand Products, LLC

advertisement

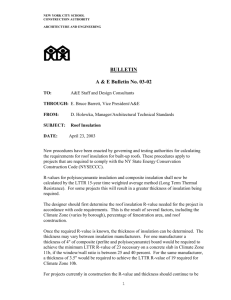

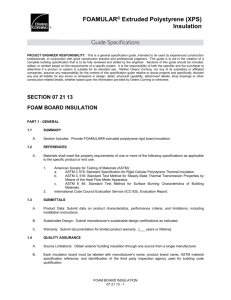

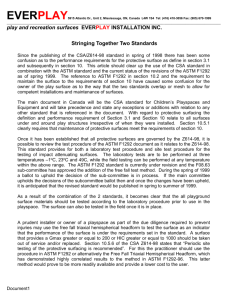

P.O. Box 725 LaPlace, LA 70069 (985)651-2911 Fax (985)651-2964 1-800-950-9958 E-mail SWSPL@AOL.COM INSULATION 971-9 TEMP-COAT® “101” TEMP-COAT® “Roofing & Siding” Insul-All™ other fine products coming soon REDI SPEC I PRODUCTS TEMP-COAT® “101” Insul-All™ II APPROVALS & ACCEPTANCE GSA/NSN #8030 01 387 1027 Lloyd's Register of Shipping #SAS FOI0506 Approved: U.S. Coast Guard, MLCA Std 6300N P .35 Accepted for Certification by: USDA Accepted by: FDA Approved by: Dept. of Energy Accepted by: Navy Safety & Survivability S.I.C. Code: 5033 All Ingredients TSCA Listed III DESCRIPTION TEMP-COAT®“101” is a general purpose insulation which comes in liquid form. It is widely used as a rooftop insulation, but performs extremely well on piping, air and heat duct work, exposed water pipes, oxygen lines, water tanks, steam lines and has many other uses. TEMP-COAT®“101” provides an inexpensive alternative to the high cost of industrial insulations. Because it physically adheres to the surface that it is insulating, it significantly reduces corrosion and rust formations found under conventional insulations. Insul-All™ is a reformulation of TEMPCOAT®"101" pointed to the homeowner and do-it yourselfer. Polymers are added increasing the products ease of application. Insul-All™ contains less than .001% ethylene glycol. May be applied to surfaces up to 225 F. 15 mil thickness provides an equivalence of R18. Make Up: TEMP-COAT®“101” and Insul-AII™ are a complete mixture of various silicas and ceramic beads immersed in a high quality latex base with acrylic binders. This combination of materials makes the product extremely light weight and pliable, therefore, it expands and contracts with the surface to which it is applied. The resiliency of TEMP-COAT®“101” and Insul-AII™ allow it to double as a leak stop even though it is not sold or warranted for that purpose. Other Properties: TEMP-COAT®“101” works well on boat and barge decks and other surfaces as a method of controlling the surface temperature. TEMP-COAT®“101” and lnsul-All™ can be tinted virtually any medium to pastel color. The tinting does have some affect on the radiant effectiveness of the product. Product Qualities: TEMP- COAT® “101” works well on both convective and conductive heat and cold. When used in ways, which does not require solar reflective qualities, its effectiveness has different values. Unlike conventional insulation such as fiberglass batting, blankets, foam, fiber insulations, or calcium silicate type pre-formed insulation for piping or enclosures having temperatures below 400O F*, TEMPCOAT® “101” is impervious to water and is not affected by salt water. As this product is a liquid, it forms a continuous covering and not sectioned as installed conventional products. It also forms an excellent weatherproof coating over the other forms of insulation. ACCORDING TO RADIANT HEAT TEST RESULTS IN A ROOF TOP APPLICATION. TEMP-COAT® “101” WHEN APPLIED TO A THICKNESS OF 15 MILS. PERFORMS AS WELL AS A 4" THICKNESS OF FOAM WITH AN R20 RATING. * Test results for Roof Top Applications Product Limits: TEMP-COAT® “101” and Insul-All™ aid in sealing leaks but is not sold as a leak-stop material. Product must he applied over a clean, dry, grease and dirt free substrate. TEMP-COAT® “101”s operating temperatures can be from –0oF to 400°F*. It can be applied to temperatures ranging from 45oF to 350°F**. On extremely warm to hot surfaces, beginning coats must be thin to avoid blistering. ** In some instances for temperatures 350oF to 400°F a mesh/membrane must be used and the High Heat Application Instructions must be followed. IV. APPLICATION Apply TEMP-COAT® “101” /Insul-All™ on any clean, dry substrate which is free from oil, grease, wax or dirt. A sufficient amount of Primer on all surfaces prone to rust and to prevent bleed through is recommended. Apply by use of brush, roller, airless spray or air assisted QuikGun. Strain product before spraying. Spray equipment requirement: 5.4 GPM, 28: 1 ratio airless sprayer or the air assisted "QuikGun". Allow product to dry between coats. This is a one-coat system with curing time of 24 hours under normal conditions. Approximate Coverage: Spray: 60 SF per gallon at 15 mil thickness on a flat surface. On Pipe: 20 mil thickness 4" O.D. LF per gallon = 56 8" O.D. LF per gallon = 24 12" O.D. LF per gallon = 15 Clean-Up: TEMP-COAT® “101” /Insul-All™ is a latex based product. Clean up immediately after use with soap and water. Caution: Use drop cloths and necessary protection to pre- vent damage from drips or overspray under windy conditions. V. TEST RESULTS: IX. MSDS INFORMATION: TEMP-COAT® “101” - has been tested under a number of varying conditions to produce "R" factor equivalence which is available in the information below. The product has also undergone a number of ASTM tests including: All ingredients are TSCA registered and are not harmful. For Material Safety Data Information, contact TEMP-COAT® Brand Products, LLC 1-800-950-9958, Fax (985)651-2964, E-mail TEMPCOAT@AOL.COM. CERTIFIED LAB & ASTM RESULTS THERMAL PROPERTIES THERMOPHYSICAL PROPERTIES RESEARCH LAB, PURDUE UNIVERSITY SAYS: 30 MILS EQUIVALENT TO R 19/20 FOR INTERNAL USE. ASTM E-1461-92 & E-1269 ROOF COATING, THERMAL AND REFLECTIVE COMPARATIVE TESTING BY CERTIFIED LABS SHOW TEMP-COAT® EQUIVALENT TO 4" OF STYROFOAM RATED AT R-20 SOLAR REFLECTANCE RATING TESTED TO EMITTANCE RATING TESTED TO 74% 85% DUE TO THE ABSENCE OF AIR, TEMP-COAT® IS BEST VIEWED AS HAVING A COMPARATIVE "R" VALUE. FLAMMABILITY LLOYDS REGISTER CLASSIFIED AS "FIRE RESISTING MATERIAL" HAVING LOW FLAME SPREAD (ISSUED 13 DEC. 2001) FLAME SPREAD 5 ASTM E-84 SMOKE DEVELOPED 5 TOXICITY -OMECHANICAL PROPERTIES CROSS HATCH ADHESION TENSILE STRENGTH (LB/IN2) ELONGATION PHYSICAL PROPERTIES ACCELERATED AGING 100% 66.7 65% ASTM D-3359 D-882 X. PRICE: Contact your local distributor or TEMP-COAT® Brand Products, LLC for cost information. XI SURFACES: TEMP-COAT® “101” /Insul-All™ can be applied to any of the following clean, dry surfaces. Steel Chrome Galvanize Aluminum Iron Fiberglass Brass Cloth Copper Stone Slate Stainless Tar Vinyl Glass Polyurethane Foam Plexiglass Cardboard Paper Magnesium Plastic Pipe Plastics Masonite Primed Surfaces Asbestos Fiberboard Painted Surfaces Wood Granulated Roof Shingles …and many more Application 200 HR. PASSSED ASTM 3 DENSITY (g/ch ) @ 24C DRIED FILM 0.41 WEIGHT PER GAL. IN LBS. 5.9 VOLUME NON-VOLATILES 43% VOLUME DRIED FILM 83% (+/-2) BROOKFIELD. VISCOSITY #3 SPINDLE @ 30 RPM CENTAPOISE Ph 8.7 SPECIFIC GRAVITYY .69 HEAVY METALS NONE DETECTED CHLROIDES - MERCURY NONE DETECTED G-53 D- 792 3564 SEVERE SERVICE AND WEATHER TESTING BY ARCO ALASKA, PROD. - APPROVED. PIPE COATING, SEVERE SERVICE FOR P&G - PASSED SALT FOG, McDONNELL DOUGLAS - PASSED PERSONNEL SAFETY TEST INGALLS SHIPBUILDING - PASSED DB INSERTION REDUCTION CHARACTERISTICS NOTED IN BOEING TESTS ALGAE TEST SINGAPORE NONE IN AGING TEST VI. OTHER EXCEPTIONAL FEATURES: The product, in addition to its outstanding insulating qualities and superior adhesion, has low flame spread, is impact and abrasion resistant, is flexible and assists in protecting coated surfaces from wind driven rain, cold-heat cycling, chemical vapors and mildew. These qualities make it the standard in ceramic coatings. Caution: Apply in a ventilated area. VII. SHIPPING AND SUPPLY METHOD: TEMP-COAT® Brand Products are available FOB shipping point or from a distributor near you. Call 1-800-950-9958 for availability in your area and price information. VIII. WARRANTY: Limited Warranty: TEMP-COAT® Brand Products, LLC. warrants TEMPCOAT® “101” as an insulation under normal use and installation conditions for a period of 10 years from the date of application. lnsul-All™ 8 years. Complete warranty and installation information is available upon request. * Conserves Energy * Substantially Reduces Fluctuations in Temperature * Keeps Steam and Fluid Hot in the Pipe * Holds Steam and Fluid Temperature More Constant Within Pipes Rooftop Installation: 15 mil thickness will reduce underroof temperature by up to 20° F. Results could vary with application. ACCORDING TO RADIANT HEAT TEST RESULTS IN A ROOF TOP APPLICATION, TEMP-COAT® “101” WHEN APPLIED TO A THICKNESS OF 15 MILS, PERFORMS AS WELL AS A 4" THICKNESS OF FOAM WITH AN R-20 RATING. "R" FACTOR EQUIVALENCE: NOTE. Due to the absence of air flow, an "R" factor cannot be used and all tests are performed comparing the usefulness of this insulation with an "R" Factor Equivalence. DO NOT ALLOW TO FREEZE TEMP-COAT® Brand Products, LLC Span-World Distribution P.O. Box 725 * LaPlace, LA 70069-0725 (985)651-2911 * Fax (985)651-2964 1-800-950-9958* E-mail TEMPCOAT@AOL.COM Revised August 2002