section i. introduction - the Oklahoma Department of Environmental

DRAFT

OKLAHOMA DEPARTMENT OF ENVIRONMENTAL QUALITY

AIR QUALITY DIVISION

MEMORANDUM

TO:

September 18, 2007

Phillip Fielder, P.E., Permits and Engineering Group Manager, Air Quality

Division

THROUGH: Matt Paque, Supervising Attorney, Air Quality Division

THROUGH: Kendal Stegmann, Senior Environmental Manager, Compliance and

Enforcement

THROUGH: David Schutz, P.E., New Source Permit Section

THROUGH: Phil Martin, P.E., Engineering Section

THROUGH: Peer Review

FROM: Grover R. Campbell, P.E., Existing Source Permit Section

SUBJECT: Evaluation of Permit Application No.

ConocoPhillips Company

98-104-TV

Ponca City Refinery (Latitude 36.700°, Longitude -97.087°)

Sections 33 & 34, Township 26 N, Range 2 E

Sections 3 & 4, Township 25N, Range 2E

1000 South Pine, Ponca City, Kay County, Oklahoma

SECTION I. INTRODUCTION

ConocoPhillips Company owns and operates the Ponca City Refinery (PCR) (SIC 2911).

The refinery is an existing PSD major stationary source and a source category regulated by 40 CFR

Part 63 Subpart CC (MACT I) and Subpart UUU (MACT II). The refinery is also subject to the emissions reduction agreements of Consent Decree No. H-01-4430 (the Consent Decree) entered in the Southern District Court for Texas on April 30, 2002; amended on August 5, 2003; and amended on October 24, 2006.

The applicant has applied for a Part 70 permit that will combine all the applicable requirements from existing permits for this facility under one permit. Emission limits, tank throughput limits, process unit throughput limits, or maximum heater firing rates that were taken to avoid or net out of PSD review, that were based on BACT requirements, or that were taken to comply with consent orders were maintained. Current active permits include Permit No. 88-102-O (M-1), 88-

115-O (M-3), 89-029-O (M-1), 89-047-O (M-2), 90-011-O (M-4), 90-066-O, 91-008-O, 91-043-

O (M-7), 91-081-O (M-3), 91-094-O (M-3), 91-129-O (M-2), 91-143-O (M-2) (PSD), 92-018-O

PERMIT MEMORANDUM 98-104-TV

DRAFT

2

(M-1), 92-034-O, 95-130-O, 95-158-O (M-6), 97-269-O (M-2), 97-286-C (M-3), 97-485-C, 98-

104-C, 98-169-C (M-6), 2000-117-C, 2000-206-C (M-4), 2000-210-O, 2000-173-C, 2001-189-

C, 2001-194-C (M-3) (PSD), 2001-195-O, 2001-212-O (M-1), 2001-305-C, 2002-115-C (M-2),

2002-476-C (M-2) (PSD), 2003-336-C (M-3) (PSD), and 2007-050-O. The applicant requests that the following permits be voided for inactive or dismantled equipment or equipment that was never constructed: 89-047B-O, 90-076-O (M-1), 90-077-C, 91-124-O, 91-142-O, 92-028-C, 98-

287-C and 2002-138-C.

ConocoPhillips Pipeline Company owns and operates three adjacent facilities that support the transportation of non-processed petroleum into and finished products out of the refinery. These

“Pipeline Activities” consist of the Ponca City South Tank Farm, the Ponca City Products

Terminal, and the Cherokee Pump Station. These facilities are considered collocated and part of a single facility site for the purpose of emissions evaluation and regulatory applicability (see

Section II); however, they are operated under a separate Part 70 permit, Permit No. 2006-206-

TV. Future permitting and modifications of the PCR and associated permits need to be based on the combined emissions from both the PCR and the Pipeline Activities and need to be considered prior to making a determination for each permitting action. Applicability of Part 70 requirements or New Source Review (NSR) requirements should also be based on the combined emissions of the PCR and the Pipeline Activities.

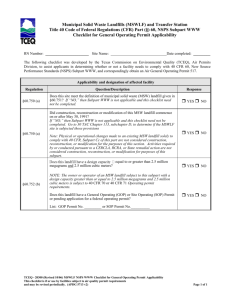

Total facility site emissions, excluding trivial and insignificant activities, are shown in the following table.

EUG

PCR

Pipeline

Total (1)

NO

X

TPY

1,520

2

1,520

CO

TPY

1,240

5

1240

1. Shown to a precision of 10 TPY.

SO

2

TPY

1,210

-

1,210

VOC

TPY

4,790

190

4,980

PM

10

TPY

640

-

640

SECTION II. APPLICABILITY OF OTHER FACILITIES ADJACENT TO THE PCR

The PCR complex and adjacent areas contain other facilities with activities that may or may not be related to the operation of the refinery. The applicant supplied an analysis of these facilities to determine if any need to be included in the site emissions for this permit. AQD has reviewed and agrees with the following analyses.

Global Facilities Management

Global Real Estate and Facilities Services (GRFS) is a business unit of ConocoPhillips Company that manages general systems and services at facilities in which the company conducts business.

At the Ponca City Refinery, GRFS is responsible for facility building and building complex grounds maintenance. This includes operation of non-process boilers, emergency generators, fuel storage tanks, and cooling towers located within the building complex where refinery employees work. Steam produced in the refinery is used for heating buildings. Fuel storage tanks are used for grounds keeping and building complex maintenance activities. Cooling towers are used to

PERMIT MEMORANDUM 98-104-TV

DRAFT

3 provide cooling for buildings and for boiler feed water. Since these activities support or are supported by the refinery, the GRFS equipment is considered to be associated with the operation of the Ponca City Refinery and is included in the refinery’s Title V permit application.

Technology Facility

SIC Code 8731 - Commercial, Physical and Biological Research (Major Group 87: Engineering,

Accounting, Research, Management, and Related Services). The ConocoPhillips Technology

Facility is a research and development facility located on the northwest edge of the refinery outside of the refinery fenceline. The refinery handles wastewater streams from the R&D facility and the refinery lab is located within the R&D facility. However, the primary activities of the

R&D facility are not associated with refinery operations. The personnel, management, and fiscal decision-making relative to the R&D facility are separate from those same functions at the refinery. The employees responsible for the R&D facility are not refinery employees and cannot be disciplined by the refinery manager. In summary, this facility is not associated with, is not under common control with, and belongs to a different SIC Code Major Grouping than the refinery. Therefore the R&D facility is not included in the refinery’s Title V permit application.

OSU-University Multi-Spectral Laboratory

SIC Code 8733 – Noncommercial Research Organizations (Major Group 87: Engineering,

Accounting, Research, Management, and Related Services). The Oklahoma State University

Multi-Spectral Laboratory (OSU-UML) is an Oklahoma Not-for-Profit, Limited Liability

Company created as a wholly owned subsidiary of OSU. The OSU-UML is located in the building formerly known as the Research & Development East facility on the Ponca City

Refinery complex. Operation of the facility is contracted by OSU to American Manufacturing and Technologies, Inc. (AMTI). The personnel, management, and fiscal decision-making relative to the UML are separate from those same functions at the refinery. The employees responsible for the facility are not refinery employees and cannot be disciplined by the refinery manager. In summary, this facility is not under common control with and does not belong to the same SIC

Code Major Grouping as the refinery. Therefore the UML is not included in the refinery’s Title

V permit application.

Jupiter Sulfur LLC (JSLLC)

SIC Code 2873 - Nitrogenous Fertilizers (Major Group 28: Chemicals and Allied Projects).

The Jupiter facility is located on the southeast edge of the refinery outside of the refinery fenceline. This facility produces ammonium thiosulfate and elemental sulfur and is presently permitted separately from the refinery. The facility receives acid gas from the refinery as one of its feedstocks. ConocoPhillips owns a 50 percent interest in JSLLC. JSLLC employs

Tessenderlo Kerly, Inc. (TKI) as the operator of the facility. TKI is responsible for management, operation, and maintenance of the facility. The structure and operation of the Jupiter facility are independent of the refinery, since there is outside ownership and operation.

Consent Order No. 00-196, which was filed on July 11, 2000, contains the following language in

Attachment C, Section VIII.D for compliance measures dealing with NSR/PSD Analysis

Methodology: “Based upon DEQ’s review of information provided by Conoco related to the

Jupiter Facility, Jupiter shall be excluded from this methodology description as a separate

PERMIT MEMORANDUM 98-104-TV

DRAFT

4 stationary source”. Based on the consent order, emissions from the Jupiter facility will not be aggregated with the refinery’s emissions for NSR/PSD or NESHAP applicability. The Jupiter facility will continue to be permitted separately and is not included in the refinery’s Title V permit application.

South Tank Farm

SIC Code 4612 – Crude Petroleum Pipelines (Major Group 46 – Pipelines, Except Natural Gas).

The South Tank Farm is comprised of eighteen (18) tanks, most of which are separated from the refinery by fencing, although three (T-629, T-630, and T-631) are located just within the refinery side of the fenceline. These tanks receive crude oil via pipeline from Cushing, OK. The tanks are dedicated to the refinery (they do not act as “terminal” tanks to ship crude to other locations), and some South Tank Farm tanks feed directly to refinery process units. However, all of this tankage is owned and operated by ConocoPhillips’ transportation company, ConocoPhillips

Pipeline Company. The personnel, management, and fiscal decision-making relative to these tanks are separate from those same functions at the refinery. The employees responsible for the tanks are not refinery employees and cannot be disciplined by the refinery manager. Although the South Tank Farm is not under common control with and belongs to a different SIC Code

Major Grouping than the refinery, operation of the tankage is contiguous with the refinery. The

South Tank Farm is not included in the refinery’s Title V permit application, but emissions from the facility will be aggregated for NSR/PSD and NESHAP applicability purposes. However, the

South Tank Farm will be operated under Permit No. 2006-206-TV.

Ponca City Truck Rack

SIC Code 5171 - Gasoline & Oil Bulk Stations (Wholesale) (Major Grouping 51: Wholesale

Trade – non-durable goods). The Ponca City Truck Rack is located southwest of the main refinery operations and generally south of the refinery tank farm. This facility serves to load refinery products out to tanker trucks which then make deliveries to commercial or retail customers. The truck rack consists of tanks, pumps, and truck loading equipment. All of this equipment is operated by personnel of ConocoPhillips’ transportation company, ConocoPhillips

Pipeline Company. The personnel, management, and fiscal decision-making relative to these tanks are separate from those same functions at the refinery. The employees responsible for the tanks are not refinery employees and cannot be disciplined by the refinery manager. Although the truck rack is not under common control with and belongs to a different SIC Code Major

Grouping than the refinery, operation of the truck rack is contiguous with the refinery. The Ponca

City Truck Rack is not included in the refinery’s Title V permit application, but emissions from the facility will be aggregated for NSR/PSD and NESHAP applicability purposes. However, the

Ponca City Truck Rack will be operated under Permit No. 2006-206-TV.

Cherokee Pump Station

SIC Code 4612 – Crude Petroleum Pipelines (Major Group 46 – Pipelines, Except Natural Gas).

The Cherokee Pump Station (CPS) is a pipeline pumping station that ships finished products, including gasoline, out of the refinery through pipelines to various terminals. Most of the equipment related to the operations is located outside of the refinery fenceline, and within a discrete area dedicated to these operations, located to the southwest of the main refinery operations. There are approximately five pumps that are located on the refinery side of the

PERMIT MEMORANDUM 98-104-TV

DRAFT

5 fenceline near the product tanks. All of this equipment is operated by personnel of

ConocoPhillips’ transportation company, ConocoPhillips Pipeline Company. The personnel, management, and fiscal decision-making relative to these tanks are separate from those same functions at the refinery. The employees responsible for the tanks are not refinery employees and cannot be disciplined by the refinery manager. Although the CPS is not under common control with and belongs to a different SIC Code Major Grouping than the refinery, operation of the CPS is contiguous with the refinery. The CPS is not included in the refinery’s Title V permit application, but emissions from the facility will be aggregated for NSR/PSD and NESHAP applicability purposes. However, the CPS will be operated under Permit No. 2006-206-TV.

Warren Petroleum Company Lease

SIC Code 1311 – Crude Petroleum and Natural Gas (Major Group 13 – Oil & Gas Extraction).

The Warren Petroleum Company lease consists of 2 crude tanks, 2 salt water tanks, and associated crude oil pumping equipment. This equipment is physically located within the refinery fenceline but the equipment is not associated with refinery operations. Warren Petroleum

Company owns, operates, and maintains the equipment. In summary, this equipment is not associated with, is not under common control with, and does not belong to the same SIC Code

Major Grouping as the refinery. Therefore the Warren Petroleum Company Lease is not included in the refinery’s Title V permit application.

Groundwater Recovery/Containment Wellfield

The Groundwater Recovery/Containment Wellfield, located inside and outside the fenceline of the refinery, consists of groundwater pumping and containment equipment. Recovered groundwater and product are pumped to the refinery’s slop recovery and wastewater treatment systems. Emissions from the operation of groundwater remediation wells are considered to be an insignificant activity under OAC 252:100 Appendix I. This equipment is operated and maintained by refinery personnel, however, management, and fiscal decision-making relative to this equipment are handled by ConocoPhillips’ Corporate Health, Safety, and Environment

Business Unit, which is separate from those same functions at the refinery. It is unclear whether these activities should be aggregated with the refinery for the purposes of Title V permitting.

This remedial activity is exempt from NESHAP Supbart GGGGG since it is permitted under

RCRA. There are no regulatory obligations associated with these activities so their inclusion in the refinery’s Title permit will not be of issue. Therefore, the Groundwater

Recovery/Containment Wellfield activities will be considered to be included the refinery’s Title

V permit application as “Insignificant Activities”.

4 th Street Clubhouse SVE System

The 4 th

Street Clubhouse Soil Vapor Extractor (SVE) System is a remediation activity located on the east edge and outside the fenceline of the refinery. The SVE system is an insignificant activity under OAC 252:100 Appendix I since emissions are less than 5 TPY of any criteria pollutant. This equipment is operated and maintained by refinery personnel, however, management, and fiscal decision-making relative to this equipment are handled by

ConocoPhillips’ Corporate Health, Safety, and Environment Business Unit, which is separate from those same functions at the refinery. The SVE system is independent of refinery operations.

This remedial activity is exempt from NESHAP Supbart GGGGG since it is permitted under

PERMIT MEMORANDUM 98-104-TV

DRAFT

6

RCRA. It is unclear whether these activities should be aggregated with the refinery for the purposes of Title V permitting. The only regulatory obligation associated with this equipment is to maintain a record that emissions are insignificant, so their inclusion in the refinery’s Title permit will not be of issue. Therefore, the 4 th Street Clubhouse SVE System activities will be considered to be included the refinery’s Title V permit application as “Insignificant Activities”.

SECTION III. EXISTING PERMIT CHANGES INCORPORATED INTO TV PERMIT

The PCR is presently operated under many construction and operating permits issued over a 20 year period. The applicant has requested changes for some specific conditions contained in these permits because of outdated applicability requirements, correction of overlapping conditions, equipment removed from service, etc. The following table summarizes the changes requested in the application that were reviewed by AQD and made in the Part 70 permit.

Permit

General Changes

General Changes –

Storage Tanks

Description and Reason for Specific Condition Change

1. Did not include requirements to update Title V application, conduct onetime performance testing, remove equipment, install control technology, or restrictions on using emission reduction credits if these activities had already been completed.

2. Did not include the specific conditions that nullified and/or voided previous versions of the permits.

3. TPY, lb/hr, fired duty, and throughput limits were designated as either

12-month rolling or 365-day rolling values where feasible.

4. Equipment identification numbering was modified to bring a consistent format to the Title V permit.

5. Specific conditions that are identical to or overlap with federal and state regulatory requirements were removed since applicable state and federal requirements are included in the Title V permit

6. Specific conditions identical to or covered by those in the Title V

Standard Conditions were removed since the Standard Conditions will be included with the Title V permit.

7. Ponca City Truck Rack, South Tank Farm, and Cherokee Pump Station equipment were removed from the application, while Global Real Estate and

Facilities Services equipment was added to the application.

1. Tank capacities were updated to reflect recently verified physical volumes versus working volumes.

2. Many of the existing state permits indicated applicability or negative applicability for storage tank regulations such as 40 CFR Part 60 Subpart Kb and QQQ and 40 CFR Part 61 Subpart FF. Since issuance of some permits,

40 CFR Part 60 Subpart Kb was modified to reduce recordkeeping requirements for certain storage vessels and the refinery MACT standards

(40 CFR Part 63 Subpart CC) were promulgated. The refinery MACT standards include storage tank overlap provisions covering 40 CFR Part 60

Subpart Kb and QQQ and 40 CFR Part 61 Subpart FF. Due to these regulatory changes and as an effort to correct and streamline regulatory applicability for the Ponca City Refinery storage tanks, the applicability of

PERMIT MEMORANDUM 98-104-TV

Permit

General Changes –

Heaters & Boilers

General Changes –

Fugitive Equipment

Leaks

88-102-O (M-1)

88-115- O (M-3)

88-117-O

89-029-O (M-1)

89-047-O (M-2)

89-047B-O

DRAFT

7

Description and Reason for Specific Condition Change

40 CFR Part 60 Subparts Kb and QQQ, 40 CFR Part 61 Subpart FF, and/or

40 CFR Part 63 Subpart CC for some storage tanks was revised.

3. Many of the existing state permits included vapor pressure limitations.

Where the vapor pressure limitations are based on the cutoff levels above which controls are required under 40 CFR Part 60 Subpart Kb or 40 CFR

Part 63 Subpart CC, the vapor pressure limitations have been designated as such. Where vapor pressure limitations are more restrictive than allowed by these regulations, the relevant averaging time has been designated. 40 CFR

Part 60 Subpart Kb and 40 CFR Part 63 Subpart CC reference vapor pressure cutoffs in units of kilopascals. This permit specifies the vapor pressure cutoff level in units of psia derived as follows: psia = kilopascals

/ 6.89478. For example, 5.2 kPa and 76.6 kPa equal 0.75 psia and 11.1 psia, respectively.

4. Tank throughput limits were rounded up or down to a precision of 1,000 gallons per day by AQD.

1. For consistency, all permitted SO

2

emission limits were recalculated based on the same SO

2

emission factor. The basis for SO

2

emission limitations in existing permits ranged from 0.031 lb/MMBtu to 0.041 lb/MMBtu depending on the molar volume and fuel gas heating values used.

The recalculated SO

2

emission limits are based on an SO

2

emission factor of

0.031 lb/MMBtu derived from the NSPS Subpart J limit of 160 ppmv, a molar volume at 60 °F, and a fuel gas higher heating value (HHV) of 867

Btu/scf. A heating value of 867 represents the average HHV in the West

Plant over the past year, which is the area with the lowest HHV average in the refinery.

2. For VOC and PM

10

emission limitations, demonstration of compliance is specified as operation of the equipment using good combustion practices.

3. NSPS Subpart J permit citations, as they apply to gas-fired equipment, reference the refinery fuel gas limit of 0.10 grains H

2

S/dscf. Conversion of this limit to ppmvd H

2

S requires use of a gas molar volume and the molar volume varies based on the standard temperature used. For compliance demonstration purposes, the facility will use a molar volume of 0.02406 cubic meters/g-mol based on a standard temperature of 60°F and, using metric units, will convert 0.10 grains H

2

S/dscf to 160 ppmvd H

2

S.

1. Removed VOC emission limitations, specified that equipment counts are estimates solely for the purpose of documenting regulatory applicability, and that exact counts are not to be construed as operating limitations.

No changes.

No changes.

Nullified by Permit No. 91-043-O (M-1).

SC1: T-0147 limits have been superceded by those in Permit No. 2001-194-

C (M-2).

SC3: Removed T-0147 requirements because they have been superceded by those in Permit No. 2001-194-C (M-2).

Limits and references to T-160 nullified by Permit No. 2007-050-O.

Soil remediation air stripping equipment and activated sludge unit in this permit is permanently inactive. Requested that this permit be voided.

PERMIT MEMORANDUM 98-104-TV

90-011-O (M-4)

90-066-O

90-076-O (M-1)

90-077-C

Permit

91-008-O

91-042-O

91-043-O (M-7)

91-060-O (M-2)

91-081-O (M-3)

91-094-O (M-3)

91-124-O

91-129-O (M-2)

91-142-O

91-143-O (M-2) (PSD)

92-018-O (M-1)

92-028-C

92-034-O

93-003-O (M-3)

95-130-O

DRAFT

8

Description and Reason for Specific Condition Change

SC1: Updated T-0120, T-0143 and T-0163 VOC emission limits using latest version of EPA TANKS program.

SC1: Updated H-0023 and H-0029 NO

X

, CO, VOC, & PM emission limits to reflect the latest version of AP-42. Updated H-0023 and H-0029 SO

2 emission limits to reflect latest fuel gas heating value basis and molar volume basis.

Soil/groundwater remediation equipment in this permit is permanently inactive. Requested that this permit be voided.

Permit voided because soil vapor extraction pilot unit was never constructed.

SC1: Removed limits for toxics formerly regulated under Subchapter 41.

SC3: Removed since this equipment is no longer in MTBE service and 40

CFR Part 60 Subpart NNN no longer applies.

Permit voided by Applicability Determination 91-042-AD (M-1).

SC1: Removed limits for H-0047 and H-0015 since heaters are no longer in service. Changed H-7501 CO lb/hr limit to 1.23 lb/hr. An error was made in transferring the limits over from Permit No. 91-043-O (M-4). Removed

SRU limits because equipment has been permanently shut down.

SC3: Removed because SRU has been permanently shut down.

SC5: Removed because SRU has been permanently shut down.

SC10: Changed SO

2

emission compliance demonstration method.

SC14.b: Removed requirement to monitor and record 365-day average fuel gas H

2

S concentration. There is no regulatory basis for this requirement.

SC14.c: Changed fuel gas monitoring and recordkeeping to monthly.

Nullified by Permit No. 2007-050-O.

SC1.A.vi.b: Changed fuel gas monitoring and recordkeeping to monthly.

SC9.a: Removed condition to provide the facility the flexibility to determine throughputs from any type of operational data available.

Soil/groundwater remediation equipment in this permit is permanently inactive. Requested that this permit be voided.

SC 1.A.iii: Removed the methods specified for determining monthly throughput to provide the facility the flexibility to determine throughputs from any type of operational data available.

Voided. Biomedical waste incinerator was dismantled.

No changes.

No changes.

Permit voided because permitted T-0115 reconstruction activities were not conducted.

SC1: Removed limits for toxics formerly regulated under Subchapter 41.

SC7: Removed. There is no regulatory basis for this requirement. If pressure relief devices were not routed to flare, it only means they would not be exempt from the requirements of 40 CFR 60 Subpart GGG, which is already an applicable requirement for other equipment covered under the permit.

Nullified by Permit No. 2007-050-O.

SC1: Updates emission limits using latest version of EPA TANKS program.

SC12: Removed. T-0122E and T-0525 that were demolished.

PERMIT MEMORANDUM 98-104-TV

Permit

95-158-O (M-6)

96-280-O (M-1)

97-269-O (M-2)

97-286-C (M-3)

97-485-C

1998-104-C

98-169-O (M-1)

98-169-C (M-6)

DRAFT

9

Description and Reason for Specific Condition Change

SC14: Added a qualifier that testing is required once during the term of the

Title V operating permit if the boiler is operated, other than on hot standby, during that period.

Nullified by Permit No. 2000-206-C.

No changes.

SC1: Lb/hr emission limits were lowered to make them equivalent to the

TPY limits.

SC1: Removed references to the storage tanks because they were never constructed.

SC3: Removed 30,000 gallon per hour loading rate limit because there is no basis for hourly limitations.

SC4: Removed references to the storage tanks because they were never constructed.

SC3: Removed. Using MDEA as the amine solution would require compliance with NSPS Subpart GGG and 40 CFR 63 Subpart CC, which are already an applicable requirement for other equipment in the permit.

Removing the restriction on MDEA use and applying 40 CFR 63 Subpart

CC to the amine system would not have affected the analysis of the Tier II permitting project at that time.

Superceded by Permit No. 98-169-C (M-2).

SC1: SO

2

and PM

10

emission limits superceded by Permit No. 2003-336-C

(M-1) (PSD).

SC2: Removed. This method of measurement is unsuitable for the No. 5

FCCU after a wet gas scrubber is installed. An alternative method of compliance has been requested from EPA and is pending approval.

SC3: Removed. Process rate limit no longer applies after installation of the wet gas scrubber per Permit No. 2003-336-C (M-1) (PSD).

SC5: SO

2

limits superceded by Permit No. 2003-336-C (M-1) (PSD).

Removed control additive reference to allow flexibility to maintain compliance with emission limits using other controls available.

SC6: Removed. This methodology is unsuitable for the No. 5 FCCU after a wet gas scrubber is installed. The No. 5 FCCU is already subject to other

PM limitations through the provisions of 40 CFR 60 Subpart J and Consent

Decree C.A. H-01-4430 requirements.

SC7: Removed. There is no regulatory driver for using alternative monitoring methods when a CEMS is down.

SC8: Reworded to clarify that use of alternative monitoring methods are not mandatory when flow monitors are down and that they may be used in lieu of a flow monitor to demonstrate compliance with the mass emission rate limits.

SC14: Removed. The requirement to obtain CEMS data for 18 hours per day in at least 22 out of 30 consecutive days comes from NSPS J and

NESHAP 63 Subpart UUU standards, which are already included as applicable requirements elsewhere in the Title V permit.

SC15: Removed to allow facility the flexibility to maintain compliance with emission limits using other controls available.

SC20: Removed recordkeeping requirements for fresh feed which is no longer a requirement per Permit No. 2003-336-C (M-1) (PSD), sulfur

PERMIT MEMORANDUM 98-104-TV

98-287-C

Permit

2000-117-C

2000-206-C (M-4)

2000-210-O

2001-173-C

2001-189-C

DRAFT

10

Description and Reason for Specific Condition Change content of feed (not necessary because using CEMS to measure SO

2 emission rate), additive composition (not necessary because using CEMS to measure NO

X

and SO

2

emission rates), opacity readings (unsuitable method of measurement after wet gas scrubber installed), and SO

2

emissions

(superceded by Permit No. 2003-336-C (M-1) (PSD)).

Permit voided because permitted decant storage tankage upgrade project was not conducted.

No changes.

SC1: NO

X

, SO

2

& PM

10

emission limits superceded by Permit No. 2003-

336-C (M-1) (PSD).

SC2: Removed reference to Alternate Opacity Approval and replaced with the actual opacity limitation and other ongoing obligations from the

Approval. Added allowance to use an alternate opacity monitoring method after installation of a wet gas scrubber.

SC4: Removed. Superceded by Permit No. 2002-276-C (PSD).

SC5: Removed to allow facility the flexibility to maintain compliance with emission limits using other controls available.

SC6: Removed. There is no regulatory driver for using alternative monitoring methods when a CEMS is down.

SC7: Removed. There is no regulatory driver for using alternative monitoring methods when a CEMS is down.

SC8: Reworded to clarify that use of alternative monitoring methods are not mandatory when flow monitors are down and that they may be used in lieu of a flow monitor to demonstrate compliance with the mass emission rate limits.

SC12: Removed. PM

10

compliance demonstration methodology superceded by Permit No. 2003-336-C (M-1) (PSD).

SC14: Removed recordkeeping requirements for SO

2

& NO

X

control additive addition (not necessary because using CEMS to measure SO

2

and

NO

X

emission rates), sulfur content of feed (not necessary because using

CEMS to measure SO

X

emission rate).

SC18: Removed. The requirement to obtain CEMS data for 18 hours per day in at least 22 out of 30 consecutive days comes from NSPS J and

NESHAP 63 Subpart UUU standards, which are already included as applicable requirements elsewhere in the Title V permit.

SC3: Changed to require the temporary flare to utilize the same NSPS

Subpart J-compliant technology utilized by the flare it is temporarily replacing.

SC4: Removed. The most recent version of OAC 252:100-31-26 does not apply to flares.

SC5: Removed. The most recent version of OAC 252:100-31-26 does not apply to flares.

SC6: Changed to require only the same records necessary to demonstrate

NSPS Subpart J compliance as the flare it temporarily replaces. Removed reference to SC4 because it is no longer applicable.

No changes.

No changes.

PERMIT MEMORANDUM 98-104-TV

DRAFT

11

Permit

2001-194-C (M-3) (PSD)

2001-195-O

2001-212-O (M-1)

2001-252-O

2001-305-C

2001-311-C

2002-115-C (M-2)

Description and Reason for Specific Condition Change

SC1.F.ii: Removed. Not necessary to place design restrictions on the flare since it is already required to comply with NSPS Subpart J.

SC6: Removed. There is no requirement to submit operational data with the annual Title V compliance certification, only a requirement to provide details for deviations from permit obligations.

SC4: Removed reference to T-0254 because NSPS Subpart Kb changed and no longer requires records for tanks of this size.

SC6: This condition only applies to T-0253 since NSPS Subpart Kb changed and no longer applies to T-0254.

SC7: This condition only applies to T-0253 since NSPS Subpart Kb changed and no longer applies to T-0254.

SC8: This condition only applies to T-0253 since NSPS Subpart Kb changed and no longer applies to T-0254.

No changes.

Voided. The East Plant Flare limits and specific conditions were previously voided by Permit No. 2003-336-C (M-3) (PSD).

SC1: H-6007 limits superceded by Permit No. 2003-336-C (M-1) (PSD).

SC4: H-6007 limits superceded by Permit No. 2003-336-C (M-1) (PSD).

SC5: H-6007 compliance demonstration methods superceded by Permit No.

2003-336-C (M-1) (PSD).

SC6: H-6007 compliance demonstration methods superceded by Permit No.

2003-336-C (M-1) (PSD).

SC10: H-6007 recordkeeping requirements superceded by Permit No. 2003-

336-C (M-1) (PSD).

Voided. All permit conditions referring to heater H-0001 in Permit No.

2001-311-C were previously voided by 2002-476-C (PSD).

SC1: Removed maximum heat input limits because there is no regulatory basis and no compliance demonstration specified for these limits.

2002-138-C Permit voided because temporary boiler was never constructed.

SC1.A.H-0048.i: Removed because this heater was not modified as to increase the emissions of NO

X

since its original construction date of 1957.

2002-476-C (M-2) (PSD)

SC6: Removed. This is already a requirement in the standard conditions of the Title V permit.

2003-336-C (M-3) (PSD) No changes.

2007-042-C (PSD) No changes.

2007-050-O No changes.

SECTION IV. FACILITY DESCRIPTION

In 1911, E. W. Marland purchased land south of the Ponca City town-site and built the Marland

Refining Company refinery, which is now ConocoPhillips Company Ponca City Refinery. A small skimming plant began operating in 1914, which was designed to process oil into gasoline, kerosene, and naphtha. Marland Refining Company merged with Continental Oil Company in

1929 and the merged company became known as the Continental Oil Company. By this time more complex equipment had been added to the refinery and the plant was capable of processing

30,000 barrels of crude oil per day. In 1943, the aviation gasoline facility was built by the

PERMIT MEMORANDUM 98-104-TV

DRAFT

12

Defense Plant Corporation of the U.S. government and was operated during World War II by

Continental Oil Company. After the war, Continental Oil Company purchased and integrated the aviation gasoline facility into the refinery, which is the present-day South Plant area. The

Sequoia (former Cities Services until 1966) refinery was purchased in 1970, which is the presentday East Plant area. In 1979, the company name was changed to Conoco Inc. Conoco Inc. merged with and became a wholly owned subsidiary of E. I. DuPont de Nemours Company, Inc. in 1981, but became an independent company again in 1999. In 2003, Conoco Inc. merged with

Phillips Petroleum Company to form ConocoPhillips Company. The facility’s refining capacity at the time of this permit application is approximately 195,000 barrels per day of crude oil.

The facility is divided into six main areas based on the layout of the operations: East Plant, West

Plant, North Plant, South Plant, Coker Combo/Alky, and Oil Movements. The facility converts crude oil into a variety of saleable products such as liquid fuels, LP gas, and feedstocks for other industries.

Primary process units include crude distillation units, a saturate gas plant, catalytic reforming units, an isomerization unit, hydrodesulfurization units, hydrotreating units, merox units, a bender unit, amine units, fluid catalytic cracking units, a coker unit, an alkylation unit, and catalytic polymerization unit. Saleable products are blended in the gasoline blending, diesel blending, and jet fuel blending processes. Auxiliary equipment includes emergency flares, steam boilers, hydrogen plants, fuel gas recovery systems, cooling towers, sour water treatment units, activated sludge and other wastewater treatment systems, intermediate and product storage, coke loading, and liquid hydrocarbon loading.

The following is a general explanation of unit operations at the PCR.

Crude Oil

Approximately 99 percent of the crude oil to be processed at the Ponca City Refinery arrives via pipelines.

Distillation

Distillation is the process of boiling a liquid and collecting the condensed vapor. In petroleum refining, distillation is used to separate crude oil into more useful components. A tall tower called a fractionating column is used to distill the crude oil. As crude enters the column, the lighter, lower boiling point components vaporize and rise to a level where the surrounding temperature and pressure correspond to their boiling point. Meanwhile, heavier, higher boiling point components descend in a liquid stream to a level where conditions match their boiling point. The column is filled with trays containing holes, which allow the ascending vapor to bubble through the descending liquid, increasing contact between the two phases. The vapors are cooled, condensed and drawn off as distillates at various points up the column – gas oil first, then diesel, kerosene, naphtha and finally, petroleum gases such as propane and butane. The heavy oils that are not vaporized because of their very high boiling points are piped off from the bottom of the tower.

PERMIT MEMORANDUM 98-104-TV

DRAFT

13

Cracking

Cracking is used to convert the heavier gas oils into more valuable products. This is done by breaking down the complex molecule chains which make up the heavier hydrocarbon compounds into simpler, lighter ones. There are three different types of cracking:

Thermal cracking using heat alone.

Fluid catalytic cracking using heat in the presence of a catalyst, which enhances the chemical conversion without itself being changed. This has certain advantages over thermal cracking in giving higher gasoline yields, while the lighter gases produced can be used as feed for alkylation.

Hydrocracking using heat and catalyst plus hydrogen. This has an advantage when there is a need to produce diesel rather than gasoline.

Alkylation

Alkylation is the opposite of cracking. Instead of breaking down larger hydrocarbon molecules into smaller ones, alkylation units convert two smaller molecules into one larger one to produce alkylate, a high-octane gasoline-blending component.

Desulfurization

Increased processing of high-sulfur crudes, coupled with the need for greater product blending flexibility and ever tighter fuel specifications (largely due to environmental considerations) has driven the development of treating technology to remove sulfur compounds and other impurities from oil feedstock and petroleum products.

Hydrodesulfurization uses hydrogen to remove sulfur compounds by converting them into hydrogen sulfide in the presence of a catalyst. The hydrogen sulfide produced is removed from the product gas stream by an amine wash and converted into elemental sulfur for sale to the chemical industry.

Reforming

Naphtha produced by some refinery processes, such as crude distillation or thermal cracking, does not have a high enough octane rating for direct use. However, it can be modified in a catalytic reformer to convert low-octane molecules into high-octane molecules.

Coking

The PCR utilizes delayed coking to upgrade heavy oil to petroleum coke and more valuable lighter products. Heavy oil feedstock from the bottom of the coker fractionator is heated in a furnace where it begins to crack into liquid and vapor mixture. This flows to the coke drums where solid petroleum coke forms and hydrocarbon vapors are released. The coke remains in the drum, solidifies and gradually fills the vessel. The vapors are returned to the fractionator where high-value products are recovered. When the coke drum is full, it is taken out of service and the other drum is put on. The full drum is taken out of service and a pilot hole is drilled in the coke bed. A horizontal water cutting tool is inserted through the pilot hole and breaks the coke into large chunks, which fall into rail cars. The empty drum is sealed, steamed and put into service again.

PERMIT MEMORANDUM 98-104-TV

DRAFT

14

Products

Petroleum products are delivered to customers by pipeline, rail, and road (trucks). The vast majority of products from the PCR are delivered by pipeline to distribution terminals in the midcontinent region of the United States. Intermediate and finished products are stored in more than

150 tanks, bullets, and spheres. Some finished products are produced directly from the process units, such as propane and jet fuels. However, gasoline and diesel fuel products are blended to the required specifications before being stored in product tanks and subsequently distributed to customers. Green anode petroleum coke is stored on a small pad in the refinery and delivered to customers by truck.

SECTION V. EQUIPMENT

Emission units (EUs) have been arranged into Emission Unit Groups (EUGs) as shown below.

EUs with no applicable federal or state standards, recordkeeping, or reporting requirements are not included in the TV permit.

TANKS

EUG TNK-1: Storage Vessels Subject to 40 CFR Part 63 Subpart CC (Refinery MACT I)

EUG TNK-2: Storage Vessels Subject to 40 CFR Part 60 Subpart Kb and 40 CFR Part 63

Subpart CC (MACT I)

EUG TNK-3: Storage Vessels Subject to 40 CFR Part 63 Subpart CC (Refinery MACT I)

Recordkeeping Only

EUG TNK-4: 40 CFR Part 63 Subpart CC (Refinery MACT I) Group 1 Wastewater Streams

Handled by Either Storage Tanks or Oil Water Separators

EUG TNK-5: 40 CFR Part 63 Subpart CC (Refinery MACT I) Group 2 Wastewater Streams

Handled by Storage Tanks

EUG TNK-6: 40 CFR Part 63 Subpart EEEE (OLD MACT) Fixed Roof Storage Tanks

EUG TNK-7: Storage Tanks Subject to Oklahoma Rules or Permit Requirements Only

EUG TNK-8: Insignificant Activity Storage Tanks

HEATERS & BOILERS

EUG HTR-1: 40 CFR Part 60 Subparts J & Db, and 40 CFR Part 63 Subpart DDDDD

(Heater/Boiler MACT) Boilers

EUG HTR-2: 40 CFR Part 60 Subpart J and 40 CFR Part 63 Subpart DDDDD (Heater/Boiler

MACT) Heaters & Boilers

EUG HTR-3: Heaters & Boilers Subject to Oklahoma Rules, Permit Limits, or 40 CFR Part 63

Subpart DDDDD (Heater/Boiler MACT)

EUG HTR-4: Insignificant Activity Heaters & Boilers

PERMIT MEMORANDUM 98-104-TV

DRAFT

15

MISCELLANEOUS

EUG ENG-1: Fuel-Fired Engines Subject to Oklahoma Rules Only

EUG ENG-2: Insignificant Activity Engines

EUG ENG-3: Emergency Fuel-Fired Engines Subject to 40 CFR Part 60 Subpart IIII

EUG FCC-1: Fluid Catalytic Cracking Unit Catalyst Regenerators Subject to 40 CFR Part 60

Subpart J and 40 CFR Part 63 Subpart UUU (Refinery MACT II)

EUG CRU-1: Catalytic Reforming Unit Catalyst Regenerator Vents Subject to 40 CFR Part 63

Subpart UUU (Refinery MACT II)

EUG FLR-1: Flares Subject to 40 CFR Part 60 Subpart J

EUG LOD-1: Loading Racks Subject to 40 CFR Part 63 Subpart CC (Refinery MACT I)

EUG LOD-2: Loading Racks Subject to Oklahoma Rules or Permit Requirements Only

EUG LOD-3: Insignificant Activity Loading Racks

EUG VNT-1: 40 CFR Part 63 Subpart CC (Refinery MACT I) Group 1 Miscellaneous Process

Vents

EUG VNT-2: 40 CFR Part 63 Subpart CC (Refinery MACT I) Group 2 Miscellaneous Process

Vents

EUG VNT-3: Atmospheric Process Vents Subject to Oklahoma Rules Only

EUG VNT-4: Atmospheric Process Vents with No Applicable Requirements

EUG VNT-5: Insignificant Activity Atmospheric Process Vents

FUGITIVE EMISSION EQUIPMENT

EUG FUG-1: Fugitive Equipment Leaks Subject to 40 CFR Part 63 Subpart CC (Refinery

MACT I) and/or 40 CFR Part 60 Subpart GGG

EUG FUG-2: Fugitive Oily Water Sewer System Component Leaks Subject to 40 CFR Part 63

Subpart CC (Refinery MACT I) and 40 CFR Part 61 Subpart FF (BWON)

EUG FUG-3: Fugitive Oily Water Sewer System Component Leaks Subject to 40 CFR Part 60

Subpart QQQ

EUG FUG-4: Fugitive Oily Water Sewer System Component Leaks Subject Only to 40 CFR

Part 61 Subpart FF (BWON) Exemption Recordkeeping Requirements

EUG FUG-5: Fugitive Storm Sewer System Component Leaks with No Applicable

Requirements

EUG FUG-6: Cooling Tower Fugitive Sources Subject to Oklahoma Rules or Permit

Requirements Only

EUG FUG-7: Materials Handling Fugitive Sources Subject to Oklahoma Rules or Permit

Requirements Only

EUG FUG-8: Insignificant Activity Fugitive Sources

FACILITY-WIDE

EUG FW: Facility-Wide Applicable Requirements

PERMIT MEMORANDUM 98-104-TV

DRAFT

16

TANKS

Tank contents will vary depending upon refinery requirements, but will be limited by the suitability of a particular tank for a particular hydrocarbon. Roof types noted are external floating roof (EFR), internal floating roof (IFR), vertical fixed roof (VFR), horizontal fixed roof (HFR), open top (OT), and sphere. The capacities listed represent the physical tank volumes using the internal cross sectional area and tank shell heights (not taking into consideration safe fill levels).

EUG TNK-1: Storage Vessels Subject to 40 CFR Part 63 Subpart CC (Refinery MACT I)

EU ID Point ID

Normal

Contents

Physical

Capacity

(gallons)

Roof

Type

Construction/

Modification

Date

T-0021E

T-0101

T-0114

T-0148

T-0149

T-0150

T-0151

T-0153

T-0154

T-0155

T-0158

T-0159

T-0160

T-0021E

T-0101

T-0114

T-0148

T-0149

T-0150

T-0151

T-0153

T-0154

T-0155

T-0158

T-0159

T-0160

Naphtha

Alkylate

Gasoline

Gasoline

Gasoline

Gasoline

Gasoline

Reformate

Reformate

Gasoline

Gasoline

Gasoline

Gasoline

3,348,342

440,608

439,433

3,377,633

3,377,633

3,377,633

3,377,633

3,357,528

6,344,761

3,377,633

3,351,095

3,391,305

3,343,857

IFR

IFR

EFR

IFR

IFR

IFR

IFR

EFR

IFR

IFR

IFR

IFR

IFR

1954

1919

1919

1923

1923

1923

1923

1923

1977

1923

1924

1923

1924

T-0162

T-0163

T-0164

T-0167

T-0170

T-0901

T-0162

T-0163

T-0164

T-0167

T-0170

T-0901

Gasoline

LSR Gasoline

LSR Gasoline

Gasoline

Gasoline

Gasoline

3,310,885

3,330,990

3,351,095

1,363,316

1,078,341

3,330,990

IFR

IFR

IFR

IFR

IFR

IFR

1924

1924

1924

1976

1920

1924

T-0902

T-0953

T-0902

T-0953

Naphtha

Gasoline

3,357,528

2,339,924

IFR

IFR

1971

1944

EUG TNK-2: Storage Vessels Subject to 40 CFR Part 60 Subpart Kb and 40 CFR Part 63

Subpart CC (Refinery MACT I)

EU ID

T-0014E

T-0015

Point ID

T-0014E

T-0015

Normal

Contents

Naphtha

Naphtha

Physical

Capacity

(gallons)

258,678

541,420

Roof

Type

EFR

EFR

Construction/

Modification

Date

1995

1995

PERMIT MEMORANDUM 98-104-TV

DRAFT

17

EU ID Point ID

Normal

Contents

Physical

Capacity

(gallons)

Roof

Type

Construction/

Modification

Date

T-0017E

T-0117

T-0119

T-0121

T-0141

T-0147

T-0156

T-0165

T-0166

T-0176

T-0177

T-0017E

T-0117

T-0119

T-0121

T-0141

T-0147

T-0156

T-0165

T-0166

T-0176

T-0177

Crude Oil

Naphtha

Naphtha

Diesel

Slop Oil

Naphtha

Gasoline

Alkylate

Gasoline

Toluene

Toluene

485,310

9,340,615

9,340,615

4,964,188

30,455

3,383,872

3,826,376

3,405,021

4,060,647

1,355,859

116,512

EFR

EFR

EFR

IFR

EFR

EFR

EFR

EFR

EFR

IFR

IFR

1987

1990

1990

2005

1990

1989

1993

1991

1991

1988

1988

T-0178

T-0357

T-0402

T-0540

T-0690

T-0178

T-0357

T-0402

T-0540

T-0690

Aviation

Gasoline

Slop Oil

Slop Oil

Methanol

Slop Oil

454,087

8,812

11,844

170,040

13,324

IFR

EFR

EFR

IFR

EFR

1988

1993

1993

1987

1992

EUG TNK-3 Storage Vessels Subject to 40 CFR Part 63 Subpart CC (Refinery MACT I)

Recordkeeping Only

EU ID

D-0924

T-0002

T-0003

T-0038

T-0041E

T-0051

T-0059

T-0063

T-0064

T-0070

T-0077

T-0103

T-0105

T-0106

T-0106E

T-0107E

Point ID

D-0924

T-0002

T-0003

T-0038

T-0041E

T-0051

T-0059

T-0063

T-0064

T-0070

T-0077

T-0103

T-0105

T-0106

T-0106E

T-0107E

Normal

Contents

MDEA

Tetraethyl Lead

Dye

Crude Oil

Distillate

Residuum

Diesel

Residuum

Diesel

Spent Caustic

Spent Caustic

Diesel

Residuum

Gas Oil

Gas Oil

Gas Oil

Physical

Capacity

(gallons)

27,900

22,428

48,661

Roof

Type

HFR

HFR

VFR

424,453 EFR

1,650,789 Sphere

1,063,329

495,122

VFR

EFR

431,772

369,089

425,921

215,898

436,937

2,814,694

2,278,246

1,143,749

1,143,749

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

Construction/

Modification

Date

2004

1974

Post-1984

1950

1957

1921

1926

1926

1926

1921

1921

1919

1922

1918

1991

1990

PERMIT MEMORANDUM 98-104-TV

EU ID

T-0133

T-0135

T-0136

T-0138

T-0142

T-0143

T-0144

T-0152

T-0161

T-0168

T-0169

T-0116

T-0120

T-0122

T-0123

T-0124

T-0125

T-0126

T-0127

T-0128

T-0129

T-0130

T-0131

T-0171

T-0179

T-0253

T-0254

T-0260

T-0500

T-0501

T-0536

T-0561

T-0633

T-0636

T-0639

T-0640

Point ID

T-0116

T-0120

T-0122

T-0123

T-0124

T-0125

T-0126

T-0127

T-0128

T-0129

T-0130

T-0131

T-0133

T-0135

T-0136

T-0138

T-0142

T-0143

T-0144

T-0152

T-0161

T-0168

T-0169

T-0171

T-0179

T-0253

T-0254

T-0260

T-0500

T-0501

T-0536

T-0561

T-0633

T-0636

T-0639

T-0640

Normal

Contents

Diesel

Diesel

Diesel

Diesel

Residuum

Residuum

Residuum

Gas Oil

Gas Oil

Jet Fuel

Jet Fuel

Vendor

Chemical

Jet Fuel

Spent

Caustic/HC

Diesel

Gas Oil

Gas Oil

Diesel

Diesel

Diesel

Diesel

Gas Oil

Jet Fuel

Diesel

Diesel

Diesel

Spent

Caustic/HC

Caustic/HC

Gas Oil

Coker Fines

Water/HC

Seal Oil

Hydrocarbon

Jet Fuel

Jet Fuel

Jet Fuel

Jet Fuel

Physical

Capacity

(gallons)

435,762

11,088,636

2,695,693

3,684,661

3,684,661

3,684,661

3,684,661

2,814,694

3,619,157

3,619,157

6,831,266

6,831,266

2,772,713

4,586,000

4,586,000

2,788,156

3,398,254

6,644,304

6,644,304

3,377,633

3,363,962

424,453

424,453

20,000

46,998

31,724

13,535

26,437

2,819,894

229,213

16,919

26,418

3,383,872

3,349,806

2,298,399

2,298,399

DRAFT

18

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

Roof

Type

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

1992

1992

1992

1921

1992

1992

1920

1989

1990

1991

1974

1974

1950

1950

Construction/

Modification

Date

1919

1990

1922

1992

1992

1992

1992

1921

1992

1943

1988

1994

1994

1987

1983

1990

1983

1971

1985

1929

1926

1926

D-5292

T-0037

T-0201

T-0202

T-0203

T-0204

T-0205

T-0551

T-0552

T-0553

T-0554

T-0555

T-0651

T-0652

T-0654

T-0665

T-0667

PERMIT MEMORANDUM 98-104-TV

DRAFT

19

EU ID

T-0641

T-0904

T-0905

T-0906

T-0913

T-0914

T-0916

T-0946

T-0947

Point ID

T-0641

T-0904

T-0905

T-0906

T-0913

T-0914

T-0916

T-0946

T-0947

Normal

Contents

Jet Fuel

Gas Oil

Gas Oil

Gas Oil

Gas Oil

Gas Oil

Gas Oil

Gas Oil

Gas Oil

Physical

Capacity

(gallons)

2,298,399

3,317,318

3,317,318

1,047,993

1,050,262

1,054,295

66,091

3,323,752

3,307,668

Roof

Type

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

Construction/

Modification

Date

1926

1924

1924

1944

1943

1943

1944

1924

1924

T-0948

T-0970

T-0971

T-0972

T-0948

T-0970

T-0971

T-0972

Gas Oil

Residuum

Residuum

Residuum

1,050,000

1,903,428

1,903,428

1,903,428

VFR

VFR

VFR

VFR

1944

2000

2000

2000

EUG TNK-4: 40 CFR Part 63 Subpart CC (Refinery MACT I) Group 1 Wastewater

Streams Handled by Either Storage Tanks or Oil Water Separators

EU ID

D-0777

D-0779

Point ID

D-0777

D-0779

Normal

Contents

Construction/

Modification

Date

Pre-1991

Pre-1991

D-5292

T-0037

T-0201

T-0202

T-0203

T-0204

T-0205

T-0551

T-0552

T-0553

T-0554

T-0555

T-0651

T-0652

T-0654

T-0665

T-0667

Wastewater

Wastewater

Spent

Caustic/HC

Slop Oil

Slop Oil

Slop Oil

Slop Oil

Wastewater

Wastewater

Wastewater

Wastewater

Slop Oil

Slop Oil

Slop Oil

Wastewater

Wastewater

Wastewater

Wastewater

Slop Oil

Physical

Capacity

(gallons)

Roof

Type

564 HFR

10,403

HFR

1,900

HFR

586,200

EFR

490,573

EFR

490,573

EFR

21,995

IFR

490,573

EFR

490,573

EFR

490,573 EFR

490,573

EFR

256,651

EFR

256,651 EFR

21,995

IFR

3,363,962

VFR

3,377,423 VFR

3,077,933

EFR

3,752,617

EFR

21,995 IFR

1943

1993

1991

1991

1991

1991

1991

1991

1992

1991

1992

1993

1923

1923

1923

1991

1991

PERMIT MEMORANDUM 98-104-TV

DRAFT

20

EU ID

EU ID

Point ID

Point ID

Normal

Contents

Normal

Contents

Physical

Capacity

(gallons)

Roof

Type

Roof

Type

Construction/

Modification

Date

T-0669 T-0669

Spent

Caustic/HC

270,401

EFR 1991

T-0701

T-0702

T-0703

T-0704

T-0705

T-0706

T-0701

T-0702

T-0703

T-0704

T-0705

T-0706

Slop Oil

Slop Oil

Slop Oil

Wastewater

Wastewater

Wastewater

256,651

EFR

256,651

EFR

22,068 IFR

270,401

EFR

270,401

EFR

270,401 EFR

1991

1991

1991

1991

1991

1991

T-0909

T-0910

T-0909

T-0910

Spent

Caustic/HC

Slop Oil

661,945 IFR

663,215

IFR

1943

1943

D-0777, D-0779, D-5292, T-0651, and T-0652 were or are currently in MACT Group 2 wastewater service. However, the vessels can be operated with carbon canister controls such that they could store a Group 1 material, and the facility prefers to list the tanks with Group 1 wastewater tanks.

EUG TNK-5: 40 CFR Part 63 Subpart CC (Refinery MACT I) Group 2 Wastewater

Streams Handled by Storage Tanks

Physical

Capacity

(gallons)

Construction/

Modification

Date

D-0232

D-0774

D-0775

D-0776

D-0780

D-0783

D-0786-1

D-0787

D-6801

D-6812

T-0016 E

T-0055

T-0069

T-0071

T-0080

T-0140

D-0232

D-0774

D-0775

D-0776

D-0780

D-0783

D-0786-1

D-0787

D-6801

D-6812

T-0016 E

T-0055

T-0069

T-0071

T-0080

T-0140

Wastewater

Wastewater

Wastewater

Wastewater

Wastewater

Wastewater

Wastewater

Wastewater

Wastewater

Wastewater

Spent

Caustic/HC

Slop Oil

Slop Oil

Wastewater

Slop Oil

Wastewater

924

10,300

10,300

10,300

10,403

3,475

564

564

5,000

16,044

104,351

433,871

443,105

428,494

105,000

4,053

HFR

HFR

HFR

HFR

HFR

HFR

HFR

HFR

VFR

HFR

VFR

VFR

VFR

VFR

VFR

VFR

1989

1990

1990

1990

1990

1990

Est. 1990

1990

1964

1991

1939

1926

1921

1926

1941

1990

PERMIT MEMORANDUM 98-104-TV

DRAFT

21

EU ID Point ID

Normal

Contents

Physical

Capacity

(gallons)

Roof

Type

Construction/

Modification

Date

T-0173

T-0648

T-0680

T-0173

T-0648

T-0680

Brine

Water/HC

Wastewater

ASU Lift

Station overflow

Sour Water

Sour Water

5,558

4,576

250,000

VFR

VFR

OT

1992

1992

1993

T-0907

T-0908

T-0944

T-0966

T-0973

T-0907

T-0908

T-0944

T-0966

T-0973

Sour Water

Slop Oil

Spent

Caustic/HC

1,056,563

1,052,278

1,043,961

14,161

213,523

IFR

IFR

IFR

VFR

VFR

1943

1943

1944

1945

1960

T-0974

T-6601

T-0974

T-6601

Spent

Caustic/HC

Caustic/HC

110,446

14,687

VFR

VFR

1960

1951

EUG TNK-6: 40 CFR Part 63 Subpart EEEE (OLD MACT) Fixed Roof Storage Tanks

The facility is an existing source for the purposes of 40 CFR Part 63 Subpart EEEE. The compliance date for existing sources was February 5, 2007.

EU ID

D-5250

EP Methanol

Tote

T-0017

T-0018

T-0018 E

T-0027

T-0057

T-0058

T-0104

T-0212 E

T-0230

T-0542

TNK-Misc.

Vendor

Point ID Normal Contents

D-5250

Physical

Capacity

(gallons)

Vendor Chemical 2,100

EP Methanol

Tote

T-0017

T-0018

T-0018 E

T-0027

T-0057

T-0058

T-0104

T-0212 E

T-0230

T-0542

TNK-Misc.

Vendor

Methanol

Perchloroethylene

Per-

Methanol

Methanol

Methanol

Methanol

Vendor Chemical

Glycol Water

Methanol

Vendor Chemical

400

350

550 chloroethylene

Vendor Chemical 2,153

550

550

550

1,680

564

4,230

550

< 5,000

Roof

Type

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

VFR

Construction/

Modification

Date

Pre-2004

2006

1994

1994

1990

2006

2005

2005

1922

1971

Pre-2004

Pre-2000

Any

PERMIT MEMORANDUM 98-104-TV

DRAFT

22

EU ID Point ID Normal Contents

Physical

Capacity

(gallons)

Roof

Type

Construction/

Modification

Date

Tanks/ Totes Tanks/ Totes

EUG TNK-7: Storage Tanks Subject to Oklahoma Rules or Permit Requirements Only

EU ID Point ID

Normal

Contents

Physical

Capacity

(gallons)

2,016

2,016

Roof

Type

VFR

VFR

Construction/

Modification

Date

1986

2005

T-0024

T-0186

T-0024

T-0186

Gasoline

Dye

TNK-MP

Gasoline

TNK-MP

Gasoline

Gasoline

EUG TNK-8: Insignificant Activity Storage Tanks

1,000 VFR 2002

EU ID Point ID Normal Contents Insignificant Activity Reason (1)

D-0060

D-0062

D-0066

D-0067

D-0077

D-0078

D-0079

D-0234

D-0409

D-0669

D-0700

T-0005

D-0060

D-0062

D-0066

D-0067

D-0077

D-0078

D-0079

D-0234

D-0409

D-0669

D-0700

T-0006 T-0006

T-0006 E T-0006 E

T-0007

T-0005

T-0007

Liquids Recovery

(gasoline)

App. I: Miscellaneous - < 5

TPY

Proto Tank 3B – Gasoline App. I: Miscellaneous - < 5

TPY

Proto Tank 2B – Gasoline App. I: Miscellaneous - < 5

TPY

Proto Tank 3A – Gasoline App. I: Miscellaneous - < 5

TPY

Proto Tank 2A – Gasoline App. I: Miscellaneous - < 5

TPY

Proto Tank 1B – Gasoline App. I: Miscellaneous - < 5

TPY

Proto Tank 1A – Gasoline App. I: Miscellaneous - < 5 TPY

Dye

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

Corrosion Inhibitor

Spent Caustic

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

Spent Caustic

Fuel Stabilizer (Day Pot, T-

973267)

Antioxidant

Diesel fuel

Manganese Additive

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

PERMIT MEMORANDUM 98-104-TV

DRAFT

23

EU ID

T-0085

T-0086

T-0087

T-0221

T-0224

T-0247

T-0265

T-0266

T-0267

T-0513

T-0530

T-0534

T-0008

T-0011

T-0012

T-0014

T-0008

T-0011

T-0012

T-0014

T-0015 E T-0015 E

T-0023

T-0028

T-0031

T-0084

T-0023

T-0028

T-0031

T-0084

T-0085

T-0086

T-0087

T-0221

T-0224

T-0247

T-0265

T-0266

T-0267

T-0513

T-0530

T-0534

Point ID Normal Contents Insignificant Activity Reason (1)

Kerosene wash tank

Pressed Alky Sludge Mix

Tank

Jet Water Pump Surge,

Fines Filtering

Diesel fuel

Fuel oil additive

Diesel Storage at Fuel

Pump

Reclaimed Oil

Spent Naphthenic Caustic

Emulsion Breaker (T-

980190)

Emulsion Breaker (T-

930269)

Filmer (T-930272)

Corrosion Inhibitor (T-

930270)

Diesel fuel

Diesel Fuel

Training Tank (Salvage yard)

Antifoam tote

Antifoam tote

Antifoam tote

Pour Point Depressant (T-

960590)

Antifreeze (ethylene glycol)

Diesel fuel

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal/ < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

PERMIT MEMORANDUM 98-104-TV

EU ID Point ID

T-0535

T-0603

T-0604

T-0535

T-0603

T-0604

T-0649

T-0922

T-0649

T-0922

T-0923 T-0923

T-890848 T-890848

T-900670 T-900670

T-900671 T-900671

T-942232 T-942232

T-951509 T-951509

T-960590 T-960590

T-970228 T-970228

T-970244 T-970244

T-970245 T-970245

T-970246 T-970246

T-971286 T-971286

T-972868 T-972868

T-982607 T-982607

T-BETZ

SBC

T-BETZ

SBC

DRAFT

24

Normal Contents

Diesel fuel

Diesel fuel

Diesel fuel

Polymer Additive for

Lagoon

Diesel fuel

Diesel fuel

Neutralizer

Corrosion Inhibitor

Emulsion Breaker

Antioxidant

Metal Passivator

Pour Point Depressant

Antioxidant

Biocide

Corrosion Inhibitor

Deposit Control Agent

Metal Passivator

Fuel Stabilizer

Red dye

Pour Point Depressant

Insignificant Activity Reason (1)

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

PERMIT MEMORANDUM 98-104-TV

DRAFT

25

EU ID Point ID Normal Contents Insignificant Activity Reason (1)

8Q506

TNK-Fire

Training #1

TNK-Fire

Training #2

TNK-

GFMHL #1

TNK-

GFMHL #2

TNK-

GFMST

TNK-Misc.

Vendor

Totes /

Tanks

TNK-MP

Diesel

8Q506

TNK-Fire

Training

#1

TNK-Fire

Training

#2

TNK-

GFMHL

#1

TNK-

GFMHL

#2

TNK-

GFMST

TNK-

Misc.

Vendor

Totes /

Tanks

TNK-MP

Diesel

Kerosene storage at Fire

Training Grounds

Kerosene Storage at Fire

Training Grounds

Gasoline fuel

Diesel fuel

Diesel fuel

Vendor chemicals with

TVP < 1.0 psia and containing < 4% RM1

HAPs, < 5% OLD MACT

HAPs, or inorganic

Diesel fuel

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Miscellaneous - < 5

TPY

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

App. I: Storage Tanks/Distribution

- < 40,000 gal / < 1.5 psia

1. Tanks that are insignificant due to emissions being less than 5 TPY require recordkeeping.

HEATERS & BOILERS

EUG HTR-1: 40 CFR Part 60 Subparts J & Db, and 40 CFR Part 63 Subpart DDDDD

Boilers

EU ID Point ID Equipment

Fired Duty

MMBtu/hr

Construction/

Modification Date

B-0008 B-0008

B-0009/0010 B-0009/0010

Steam Boiler

Steam Boiler

483

734

(1)

1. The boilers share a common stack. The fired duty shown is a total for both boilers.

2003

2005

EUG HTR-2: 40 CFR Part 60 Subpart J and 40 CFR Part 63 Subpart DDDDD

(Heater/Boiler MACT) Heaters & Boilers

Note: The Consent Decree requires all of the facility’s heaters and boilers that combust refinery fuel gas to be subject to Subpart J, regardless of the construction or modification date.

PERMIT MEMORANDUM 98-104-TV

EU ID

B-0006

B-0007

B-5004

H-0001

H-0003

H-0004

H-0005

H-0010

H-0011

H-0016

H-0023

H-0028

H-0029

H-0046

H-0048

H-0057

H-0058

H-0059

H-1001

H-5001

H-5002

H-6005

H-6007

H-6008

H-6012

H-6013

(5)

Point ID

B-0006

B-0007

No. 5 FCCU/B-

5004

H-0001

H-0003

H-0004

H-0005

H-0010

H-0011

H-0016

H-0023

H-0028/0029

H-0028/0029

H-0046

H-0048

H-0057/58/59

H-0057/58/59

H-0057/58/59

H-1001

H-5001

H-5002

H-6005

H-6007

H-6008

H-6012

H-6013

DRAFT

26

Equipment

Steam Boiler

Steam Boiler

Waste Heat Boiler

No. 1 CTU Atm

Tower Feed Heater

No. 4 CVU Feed

Heater

No. 4 CTU Feed

Heater

No. 1 CTU Tar

Stripper Feed Heater

Saturate Gas Plant

Naphtha Reboiler

No. 7 HDT Heater

No. 1 CVU Feed

Heater

No. 5 HDT Heater

No. 7 Coker Heater

No. 7 Coker Heater

No. 2 HDS Feed

Heater

No. 2 CRU Heater

Alky Depropanizer

Heater

Alky Depropanizer

Heater

Alky Depropanizer

Heater

No. 4 HDT Heater

No. 5 FCCU Feed

Preheater

No. 5 FCCU Feed

Preheater

No. 2 CTU Preflash

Reboiler Heater

No. 3 CRU Heater

Butane Dryers

Regenerator Heater

No. 3 HDS Heater

No. 3 CRU Heater

Fired Duty

MMBtu/hr

>250

>250

Construction/

Modification Date

1953

Pre-8/17/71

>250 1977 / 2002

(1,2)

175

28.0

106

85.0

55.0

15

107

52.4

129

75.0

48.0

241

70.0

49.0

70.0

30.0

104

120

157

150

2.0

25.0

75.8

1949 / 1987

1929/2002

1945/2002

1940

1972

1988

2004

1984

1954

1983

1964

1957

1974

1974

1974

2005

1944

Construction planned for 2007

1997

1956 / 1990

(1,2)

1955

1971

2002

(1,2)

(1,2,3)

(1,2,3)

PERMIT MEMORANDUM 98-104-TV

DRAFT

27

EU ID

EU ID

Point ID

Point ID

Equipment

Equipment

Fired Duty

MMBtu/hr

Construction/

Modification Date

H-6014

H-6015

H-6151

H-7501

H-6014

H-6015

H-6151

H-7501

No. 2 CVU Feed

Heater

No. 2 CTU Feed

Heater

No. 4 FCCU Feed

Preheater

No. 6 HDT Heater

80.0

95.0

80.0

41.0

1978

1980

1958

1991

H-8601

H-8602

H-8601

H-8602

No. 8 HDT Splitter

Reboiler Heater

No. 8 HDT Heater

No. 1 Hydrogen Plant

120

36.0

2003 (Pre-12/13/03)

2003 (Pre-12/13/03)

H-8801/8802 H-8801/8802

H-9851

H-9901

H-9851

H-9901

Reformer Heater

No. 2 Hydrogen Plant

Reformer Heater

No. 9 HDT Heater

123

282

40.0

2003 (Pre-12/13/03)

2005

2005

H-9902

NH-0057

(4)

H-9902

NH-0057

No. 9 HDT Stripper

Reboiler Heater

Alky Depropanizer

Heater

50.0

128

2005

Construction planned for 2007

1. Subchapter 31 modification.

2. Subchapter 33 modification.

3. NSPS modification or reconstruction.

4. Will replace H-0057, H-0058, and H-0059.

5. Will replace H-5001.

EUG HTR-3: Heaters & Boilers Subject to Oklahoma Rules, Permit Limits, or 40 CFR

Part 63 Subpart DDDDD (Heater/Boiler MACT)

Fired Duty

MMBtu/hr

Construction/

Modification Date

BLR-GFMST1 BLR-GFMST1

H-6037A/

6037B

HTR-5FCC

Converter Air

Preheater

No. 4 FCCU

No. 5

FCCU/B-5004