Certified Product Procedural Guide - National Air Filtration Association

advertisement

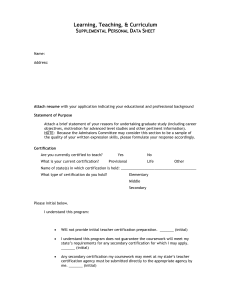

NAFA PRODUCT CERTIFICATION PROGRAM PROCEDURAL GUIDE Approved Version 1 April 10, 2000 With revisions Aug, 2000 Second Revision February 2001 National Air Filtration Association PO Box 68639 Virginia Beach, VA 23471 NAFA Product Certification Procedural Guide Approved Version 1 Table of Contents Title, Purpose and Scope - Basis of Participation Page 3 Abbreviations and Definitions Page 4-6 Reported Testing Criteria Procurement Procedure Page 7 Page 7-8 Testing Procedure Test Standard Certification Timetable Page 8 Page 8 Page 9 Filters in Compliance Filters Out Of Compliance Page 9 Page 10-11 Testing of Filter Types Page 11-12 NAFA Product Certification Symbol NAFA Product Certification Symbol Advertising NAFA Product Certification Certificate Page 12 Page 13 Page 13 Funding Page 13-14 NAFA Administrative Agency Page 14 Challenge to Certified Values Challenge Confirmed – Not Confirmed Participant Refusal to Comply Page 14-15 Page 15-16 Page 16 NAFA Product Certification Forms and Documents Page 17 Participation Request for NAFA Product Certification Participant Product Release Form Chain of Custody Product Description Form Compliance Challenge Submittal Form NAFA Certificate of Certification Page 18 Page 19 Page 20 Page 21 Page 22 Page 23 Page Number 2 NAFA Product Certification Procedural Guide Approved Version 1 Title , Purpose, and Scope 1.0 Title: NAFA Product Certification Program 2.0 Purpose: 3.0 2.1 To provide on-going certification of performance claims made by air filter Participants. 2.2 To develop a database of test results that provides performance data to the end user. Scope: All media-style air filtration products used in general ventilation heating, ventilating and air conditioning (HVAC) systems. 4.0 Basis of Participation 4.1 The NPC will be a voluntary program with voluntary participation by air filter Participants for the purpose of certifying that their air filter devices submitted under this program meet the published criteria and performance levels as stated by the Participant and submitted for certification on the NAFA’s Product Specification Form. Page Number 3 NAFA Product Certification Procedural Guide Approved Version 1 5.0 Abbreviations and Definitions 5.1 Media Area - designated effective filtration area of media given in square feet. Arithmetic symbol is “A” 5.2 Standard Cubic Feet Per Minute (scfm) – volumetric rate of flow of air at standard conditions (dry air at 70 F and 14.696 psia (20C and 101.325 kPa). Under these conditions, air has a mass density of 0.075 lb/ft3 . Arithmetic symbol is “Q” 5.3 Certify/Certification – to give credibility to a technology as meeting a standard or performance criteria. 5.4 Certification Certificate – a certificate issued to a specific end-user or other designee, requested by the filter Participant. This document will be the only official hard copy document and will bear the NAFA Seal cut into the paper along with the name of the client for whom it was requested. This document will be mailed directly to the client along with a copy to the filter Participant. 5.4 Challenge Procedure – a specific protocol for the challenging of test results published or filtration performance otherwise represented by a Participant. 5.5 Efficiency (Particle Size Efficiency - PSE) – quantifiable term used to measure the ability of a filter to remove particles from an air stream per Section 10 of ASHRAE 52.2. Results are reported in a Minimum Efficiency Reporting Value (MERV) and a Particle size vs. Efficiency Chart as shown in Figure 11-1c in the ASHRAE 52.2 Standard. 5.7 NAFA Product Certification Participant - A company that assembles air filter devices from products of a filter manufacturer. 5.8 Feet Per Minute – (fpm) measurement of air delivery by flow. Arithmetic symbol is “V” 5.9 Filter Manufacturer - A company that produces filter media or component from raw goods, i.e. fibers, metal, etc. 5.10 In Compliance – description of a tested filter that falls within NAFA Product Certification testing specifications. This filter will be listed on the NAFA Website and will have a NAFA Certification Symbol. 5.11 NAFA Product Certification Administrative Agency (CAA) – designated agency that handles all of the administrative affairs of the NAFA Product Certification Program. Page Number 4 NAFA Product Certification Procedural Guide Approved Version 1 5.12 NAFA Product Certification Administrative Board – a group of individuals from the membership of NAFA composed of three (3) media manufacturers (not filter Participants), one (1) Associate Council appointee, one (1) Professional member, and two (2) Active members along with one (1) Administrative Agency Representative. Associate appointee is an annual rotation. Other terms to initially be 1, 2 or 3 years (depending on number) for rotation with terms renewable for three years. The NAFA CAB shall oversee the administration of the program along with the testing protocol, review problems and concerns from the user and Participant community, handle complaints, and administer noncompliance issues. NAFA CAB picks their own chairperson. NAFA CAB members must sign a confidentiality agreement as to discussions and results. 5.13 NAFA Product Certification Database - a computer database of filter test results maintained at the NAFA Headquarters. The name of the Participant, model of the filter, and type (general description) will be listed on the NAFA Webpage along with the four (4) reporting criteria listed in Section 7. 5.14 NAFA Product Certification Symbol – symbol used to denote product has completed and passed NAFA certification procedures. 5.15 NAFA Product Certification Testing Criteria - a set testing criteria to which filters will be tested. These include criteria from ASHRAE Standard 52.2 along with NAFA required test criteria 5.16 NAFA Testing Laboratory – an independent laboratory designated by NAFA as one approved to perform NAFA Product Certification testing. .5.17 NAFA Website – electronic website maintained by NAFA listing certified products by company and type. 5.18 Non-statistical Random Sample – term identifying the selection from Participant warehouse stock of a sample number of filters for testing. 5.19 Out-of-Compliance – description of a tested filter that falls outside Participant claims as submitted for NAFA Product Certification. 5.20 Participant – any business or organization that is participating in the NAFA Product Certification Program. A filter fabricator. 5.21 Procurement Agency – company designated to do a non-statistical random sample procurement of filter(s) from the filter Participant for testing. 5.22 Product Specification Form – form describing product submitted for NAFA Product Certification. Page Number 5 NAFA Product Certification Procedural Guide Approved Version 1 5.23 Published: Specifications and performance criteria which is printed, advertised or in electronic format. 5.24 Weight Gain – Loading Dust Weight Gain (weight gain): The total of the loading dust weight gains for all dust increments performed during a complete ASHRAE 52.2-1999 test. The synthetic dust weight gain for each dust increment is determined as the weight of the dust fed (as specified in section 10.7.2.2 of ASHRAE 52.2-1999 minus the weight of the synthetic dust passing the air cleaning device, as determined in accordance with sections 11.3.2 through 11.3.14 of ASHARE 52.1-1992. Objective: Determine the ASHRAE loading dusting weight gain of an air filter, by defining additional test procedures and observations to be made during a 52.2 test. Constraint: None of the additional procedures may conflict with the requirements of 52.2. The test must be a complete test in accordance with 52.2, with additional procedures and observations reported. Procedure: Perform the Test Program for Dust Loading and Particle Size Efficiency in accordance with section 10.7 of 52.2, with the following additional steps described below. Establish the test parameters and dust increments according to section 10.7.1 of 52.2. For each dust increment: 1. Weight the final filter to the nearest 0.1 gram (52.1 : 11.2.1) 2. Proceed with the Dust Loading procedure as specified in 10.7.2.1 through 10.7.2.8 of 52.2. While performing step 10.7.2.6 of 52.2, also brush dust remaining in the feeder tray into the aspirator, as required in section 11.3.7 of 52.1. 3. Stop the air flow and remove the final filter in accordance with 10.7.2.9 of 52.1, also collecting and weighing the test dust remaining in the duct, as specified in section 11.3.12 and 11.3.13 of 52.1. 4. Add the weight of the dust collected between the test device and the final filter to the weight increase of the final filter to establish the amount of synthetic dust passing the device during the feed period, as specified in 11.3.14 of 52.1. 5. Calculate the weight gain for the increment as the weight of the dust fed minus the sum of the weight increase of the final filter and the weight of dust collected between the device and the final filter. Calculate the weight gain of the filter as the sum of the weight gains for all of the dust increments. Page Number 6 NAFA Product Certification Procedural Guide Approved Version 1 6.0 Reported Testing Criteria 6.1 Airflow rates for tests conducted for MERV reporting purposes shall be at the upper limit of the test air cleaner’s application range (as claimed in Participant’s data sheet). Also, they shall be calculated by first selecting one of the following face velocities in m/s (fpm) and then multiplying by the air cleaner’s face area in m2 (ft2). Velocity m/s (fpm): 0.60 (118) 1.25 (246) 1.50 (295) 1.90 (374) 2.50 (492) 3.20 (630) 3.80 (748) Tests will be done at the upper limits of filter participants claims in Data Sheets ( per 52.2) 6.2 Initial Pressure Drop – given in inches of water and Pascals 6.3 Final Pressure Drop – given in inches of water and Pascals 6.4 Minimum Efficiency Reporting Value (MERV) – at the given flow rate - given as a numerical value determined by ASHRAE 52.2 specifications 6.5 Weight Gain – given in grams using ASHRAE Synthetic Test Dust per definition in 5.24 & Weight Gain will be a reported value only. 6.6 All filters with a MERV of 5 through 8 will be run to a final pressure drop of 0.6 inch w.g. 6.7 All filters with a MERV of 9 through 12 will be run to a final pressure drop of 1-inch w.g. 6.8 All filters with a MERV of 13 through 16 will be run to a final pressure drop of 1.4 inch w.g. 7.0 Reserved for Future Use 8.0 Procurement procedure 8.1 The Procurement Agency will advise the Participant that they wish to come and select a case of filters from a warehouse of filters for the NAFA Product Certification process. The agency shall give the Participant the size that will be selected and the Participant shall Page Number 7 NAFA Product Certification Procedural Guide Approved Version 1 confirm an adequate stock of size with a minimum quantity to assure a non-statistical random sample and the Participant shall provide the date the product was fabricated. 8.1.1 For filters with an MERV of 5 – 8, there shall be at least 500 filters in the random sample stock. 8.1.2 For filters with an MERV >8, there shall be at least 50 filters in the random sample stock. 8.2 If there is a question as to the MERV rating, reference may be made to the ASHRAE 52.2 draft document table showing anticipated crossover values to ASHRAE 52.1 test numbers. The Procurement Agency shall give the Participant no more than two hours notice before arrival to procure the test filter(s). 8.3 Upon arrival agency representative and Participant representative will immediately go to warehouse and select a case(s) of filters by size and type. 8.4 A material release sheet and the chain of custody sheet shall be completed and the agency representative shall return to their office to send the case via (best way) to the NAFA Testing Laboratory. The ship ticket shall contain the chain of custody documentation. Agency personnel should keep one copy and send one copy along with material release document(s) to the Certification Administrative Agency. 9.0 Testing procedure 9.1 Upon arrival at the NAFA Testing Laboratory, the testing technician shall date and initial the case and shall randomly select one filter from the case. This filter will be checked to assure no damage by shipment and the laboratory designee shall confirm that all necessary paperwork has been completed. This paperwork shall be copied and forwarded to the NAFA Certification Administrative Agency. 9.2 The filter will be labeled with the initials of the designee (Technician) along with the date received. Remaining filters will be secured and stored until testing of the selected filter is completed and certified. 10.0 Test Standard 10.1 Filter testing will be done using the removal efficiency by particle size method (minimum efficiency method) as detailed in ASHRAE 52.2 along with the inclusion of weight gain as designed in section 5.24. Page Number 8 NAFA Product Certification Procedural Guide Approved Version 1 11.0 Certification Timetable 11.1 Year One 11.1.1 The NAFA certification timetable will allow each Participant registering to participate in the program to submit an application to the NAFA Certification Administrative Agency for the number of filters they wish tested. If the total number of filters requested is within the ability of the NAFA Testing Laboratory’s capacity, all applicants filters will be tested (without regard to model or type). If applicant requests exceed the capacity of the NAFA Testing Laboratory, the NAFA Certification Administrative Agency will decide the number of filters to be tested and will prorate between the applicants with each applicant designating which model of filters they wished to be tested in the first year. 11.2 Succeeding Years 11.2.1 Each year, Participants will submit an application for filters to be tested. It is anticipated that the NAFA Designated Laboratory would be able to complete testing on all filters during succeeding years. If this is not possible, the NAFA Certification Administrative Agency will perform the same procedure of prorating as outlined above. 11.3 Ongoing Re-certification 11.3.1 All Certified filters will be re-tested on a random basis and at least every 24 months at a minimum. 12.0 NAFA Testing Laboratory 12.1 All laboratories must be approved by the NAFA Certification Administrative Board. All testing information must be submitted to the NAFA Certification Administrative Agency. 13.0 Filter In Compliance Filters submitted for certification shall be tested by the NAFA Testing Laboratory according to the NAFA Product Certification Testing Criteria. If the filter performs to the specifications designated by the Participant’s data and with the approval of the Participant of same, the filter will be issued a NAFA Product Certification Symbol and the filter model(s) and four (4) test criteria will be listed on the NAFA Product Certification Website. Page Number 9 NAFA Product Certification Procedural Guide Approved Version 1 13.2 Weight Gain will not be a condition of compliance, only a reported value, unless filter participant publishes a weight gain value in printed data. 14.0 Filters Out of Compliance 14.1 Filters submitted for initial testing or selected by the NAFA non-statistical random selection for testing and found to be out of compliance will be handled in the following manner; 14.2 The filter Participant shall be notified by the NAFA Product Certification Administrative Agency of the test results and provided copies of testing information. The filter Participant shall be given the opportunity to evaluate their raw materials, components and the fabrication process. 14.3 Within 5 working days, the Participant will discuss with the NAFA Testing Laboratory personnel the nature of the failure and corrective measures that must be taken (if any) to bring the filter into compliance. Conference information shall be documented and shall become part of the testing file. This information will be transmitted to the NAFA Product Certification Administrative Agency. 14.4 Within 90 calendar days, a second filter will be randomly selected for retest. A procurement and testing fee will be assessed for this service. If this filter fails the test, the Participant will be notified by the NAFA Product Certification Administrative Agency that their filter is out of compliance and the use of the NAFA Product Certification Symbol will be suspended. Suspended means they can not obtain a NAFA Product Certification Certificate until the product is back into compliance. 14.5 Within 45 calendar days, the Participant, the NAFA Product Certification Administrative Agency and the NAFA Testing Laboratory will work to correct the deficiency and a third filter will be randomly tested. A procurement and testing fee will be assessed for this service. 14.6 If the third filter fails to pass the test, the Participant will be notified by the NAFA Product Administrative Agency and the license to use the NAFA Certification Symbol will be revoked. The NAFA Product Certification Administrative Board will receive notification. The filter registration will be shown as delisted on the NAFA Website for a period of 6 months or until the filter is reclassified. The NAFA Product Certification Symbol must be removed from the product (or physically marked out on the product). Distribution of any material – printed or electronic – with reference to the NAFA Certified Product that has Page Number 10 NAFA Product Certification Procedural Guide Approved Version 1 failed three tests, will cease. The Participant must reapply for NAFA Product Certification for this product as if it were a new applicant. 14.7 At anytime during the certification testing, compliance challenge or retesting process, the Participant may withdraw the reference and published performance data about the filter and adjust data to reflect new test data. 14.8 Any product that is reclassified shall be so noted on Website. 15.0 Testing of Types (Models) of Filters 15.1 Panel Filters: To obtain NAFA Product Certification a flat panel filter commonly referred to as fiberglass panels, are tested at the manufacturers advertised velocity (normally 300 fpm for a 1” panel). Polyester panels shall be tested at ASHRAE 52.2 velocities or the manufacturer’s listed upper limit velocity, whichever is higher. NAFA Product Certification of filters will be listed by manufacturers’ model reference. (For example, a fiberglass panel with a certain style of backing will allow the NAFA Product Symbol to be placed on all fiberglass panels with that style of backing of exactly the same Model Number and construction and fabrication – size being the only difference). Other filter sizes may be evaluated using the same calculated media/velocity ratio. 15.2 Pleats: To obtain NAFA Product Certification a pleated panel filter shall be tested at a velocity listed in the NAFA Guide to Air Filtration, page 4.7 or the manufacturers advertised upper limit velocity, whichever is greater. NAFA Product Certification of filters will be listed by manufacturers’ model reference. (For example, testing of a high capacity pleat will allow the NAFA Product Certification Symbol to be placed on all high capacity pleats of exactly the same Model Number and construction and fabrication – size being the only difference). Other filter sizes may be evaluated using the same corresponding media/velocity ratio. 15.3 Extended Surface Filters: To obtain NAFA Product Certification an extended surface (pocket or bag filter) shall be tested at the velocity listed in the NAFA Guide to Air Filtration, page 4.7 or the manufacturers advertised upper limit velocity, whichever is greater. (For example, testing of an extended surface filter will allow the NAFA Product Certification Symbol to be placed on all extended surface filters of exactly the same Model Number and construction Page Number 11 NAFA Product Certification Procedural Guide Approved Version 1 and fabrication – size being the only difference). Other filter sizes may be evaluated using the same corresponding media/velocity ratio. Page Number 12 NAFA Product Certification Procedural Guide Approved Version 1 15.4 ASHRAE Box-type Filters: To obtain NAFA Product Certification an ASHRAE box-type filter shall be tested at the velocity listed in the NAFA Guide to Air Filtration, page 4.7 or the manufacturers advertised upper limit velocity, whichever is greater. (For example, testing of an ASHRAE box-type filter will allow the NAFA Product Certification Symbol to be placed on all extended surface filters of exactly the same Model Number and construction and fabrication – size being the only difference). Other filter sizes may be evaluated using the same corresponding media/velocity ratio. 15.5 Other Filter Types: 15.5.1 To obtain NAFA Product Certification, “Other” style filters shall be tested at the velocity listed in the NAFA Guide to Air Filtration, page 4.7 or the manufacturers advertised upper limit velocity, whichever is greater. Certification of one style of “other” types of filters may not necessarily allow the NAFA Product Certification Symbol to be placed on “other” products of the same construction and fabrication – size being the only difference. See 14.6. 15.6 Any Participant receiving license to use the NAFA Product Certification Symbol must have the review and approval of the NAFA Product Certification Administrative Board. When there is a question as to flow rate used for testing, Participant published data, or results of testing, the NAFA Product Certification Administrative Board shall resolve the issue based upon; 1) NAFA Guide to Air Filtration or 2) ASHRAE Standards 52.2 or 3) accepted industry standards and practices. All matters not resolved by the NAFA Product Certification Administrative Board shall be referred to the NAFA Board of Directors for final resolution. 16.0 The NAFA Product Certification Symbol When issued, the NAFA symbol maybe displayed on the following; Page Number 13 NAFA Product Certification Procedural Guide Approved Version 1 16.1 Advertising Literature 16.2 Advertisements in newspapers and print media and electronic media 16.3 On each filter and filter carton 16.4 Listed on Company website 17.0 NAFA Product Certification Certificate Upon certification of a filter for the first time or upon recertification, Participants will be given a NAFA Certification Certificate and test report showing results of the complete ASHRAE 52.2 test results including the four (4) criteria as designated by this Guide in Section 6 as part of the NAFA Product Certification process. 17.1 The Participant may request additional Certification Certificates be sent to an end-user or other designee. The NAFA Product Certification Certificate will consist of; The test document addressed to the specific designee of the Participant Complete test data including the four (4) criteria as designated by NAFA in Section 6. The NAFA Product Certification Symbol embossed into the document. 17.2 Examples of when this document would be used but are not limited to: Architectural specifications Mechanical contractor specifications End-user requests Public or private bid specifications 17.3 Fee for any special requested NAFA Product Certification Certificates will be set by the NAFA Product Certification Administrative Board. 18.0 NAFA Product Certification Funding 18.1 Administrative Fee The administrative fee for funding the NPC program will be $ 2,500.00 per Participant, per year. This fee will include all of the costs for administration, webpage support, advertising and promotional, and all other incidental expenses. Page Number 14 NAFA Product Certification Procedural Guide Approved Version 1 18.2 Fees for non-NAFA Members shall be $ 5,000.00 per year. Testing & Procurement Fee 18.3 Fee for testing will be $ 1,250.00 per filter plus $ 400.00 per filter procurement fee for a total of $ 1,650.00 per filter tested. 18.4 Fees for non-NAFA Members shall be $ 2,500.00 and $800.00 respectively. 18.5 All fees are determined by the yearly budget of fees set by the NAFA Board of Directors and may from time to time be adjusted to reflect changes in program costs, CPI adjustments, etc. 19.0 NAFA ADMINISTRATIVE AGENCY The NAFA Product Certification Administrative Agency will be ITS, Inc., 3933 US Route 11, Cortland, New York, 13045. Duties of the NAFA Certification Administrative Agency are detailed in Addendum A of this Guide. The NAFA Certification Administrative Agency will work in conjunction with the NAFA Product Certification Administrative Board. The Administrative Board will report directly to the NAFA Board of Directors. 20.0 Challenge to Certified Values: 20.1 In the event that a Participant in good standing desires to submit a “Challenge of NonCompliance” the following procedure will be used by NAFA Participants in the challenge of a members products to their published/certified values, which have been submitted and certified by the NAFA Product Certification Program. 20.2 Challenges made to a Participants Certified product can only be made by another participant with a certified product in the same MERV ranges (1-4; 5-8; 9-12; 13-16) or product in the same “Type” category as listed in the NPC document. The Participant who is making the Challenge (challenger) must complete the Non-compliance challenge submittal form along with the following support documentation: Copies of the published certified values being challenged Test data or other supporting documentation to claim of non-compliance Advance payment of testing and product selection - $ 2,000.00. Page Number 15 NAFA Product Certification Procedural Guide Approved Version 1 20.3 All documentation shall be sent to the NAFA Certification Administrative Agency. The NAFA Certification Administrative Agency will make copies of the challenge and distribute them to the NAFA Product Certification Administrative Board for review and place the challenge fee in escrow. All challenges will be reviewed for: Completeness Merit Validity 20.4 After review, the NAFA Product Certification Administrative Board will – within 15 days - A.) affirm the challenge and notify the Challengee, and send all documents to the designated NAFA Designated Testing Laboratory for testing, B.) contact the Challenger to request clarification or further information regarding the challenge, or C.) contact the Challenger and deny the challenge. Any NAFA Product Certification Administrative Board member who is associated with the Challenger or Challengee company in any way will abstain from comment or vote on the challenge. 21.0 Challenge Confirmed (Filter Fails to Meet Participant Listed Specifications) 21.1 If the NAFA Product Certification Administrative Board agrees that a possible noncompliance issue is valid, notification of the challenge is sent to the Challengee. The Challengee must – within 5 days – either accept the challenge or resubmit their product for testing to new specifications. If accepted, the process of testing begins as outlined in regular certification. In the event that the challengee would agree with the challenger and the nature of the challenge, or the filter tests out of compliance, the challengee must immediately agree to cease using the NAFA Product Certification Symbol for the product in question. The NAFA Certification Administrative Agency will inform the NAFA Certification Administrative Board and will show the product certification as suspended or removed on the NAFA website. The Challengee firm will be billed for all costs related to the challenge. The $2,000.00 will be returned to the challenger. 22.0 Challenge Not Confirmed (Filter Performs to Participant Listed Specifications) 22.1 If the challengee wishes to maintain its certified values are correct, the NAFA Testing Laboratory will continue with their certification procedure. The NAFA Testing Laboratory will test the product and inform the NAFA Product Certification Administrative Agency of Page Number 16 NAFA Product Certification Procedural Guide Approved Version 1 the results. Should the product meet the challenge the challenger will pay for all cost associated with the process. This includes but is not limited to; Procurement Testing Administration The NAFA Product Certification Administrative Board will be notified that the challenge has been sustained and the issue is completed. 23.0 Participants Refusal to Comply 23.1 If either the Challenger or the Challengee refuses to accept the determination of the compliance status of the challenged product or otherwise refuse to comply with challenge procedure, the issues will be submitted to the NAFA Product Certification Administrative Board for resolution. If either the Challengee or the Challenger refuse to accept the final ruling of the NAFA Product Certification Administrative Board, their participation in the NAFA Product Certification program will be considered terminated. Their products and company will be delisted on the NAFA website, and they must cease using the NAFA Product Certification Symbol on products or for promotion. 24.0 Confidentiality Agreement 24.1 See Attachment – Confidentiality Agreement 25.0 Participation Agreement 25.1 See Attachment - Participation Agreement Page Number 17 NAFA Product Certification Procedural Guide Approved Version 1 NAFA PRODUCT CERTIFICATION ATTACHMENTS AND DOCUMENTATION FORMS Filter Participant Request for NAFA Certification Filter Participant Product Release Chain of Custody Form General Product Components and Product Description Form Compliance Challenge Submittal Form Sample NAFA Certificate Page Number 18 NAFA Product Certification Procedural Guide Approved Version 1 Filter Participant Request for NAFA Product Certification ________________________________________(Participant) request that the following products be submitted for testing and certification according to the NAFA Product Certification Program. We understand that limitations may be imposed upon the total number of filters tested in any given year based upon the capacity of the NAFA Testing Laboratory and will abide by this limitation if necessary. Product Type/Model to be Submitted: Representative Name: Signature Page Number 19 NAFA Product Certification Procedural Guide Approved Version 1 National Air Filtration Association Product Certification Program Participant Statement of Product Release As authorized below, I am releasing the product described below for inclusion in the National Air Filtration Association’s Product Certification Program. Case Product Name & Date Fabricated Type & Model Number 1 2 3 4 Quantity Having released the product described to: Agent Name: Agency Name: Product selected by agent was chosen at random from regular inventory stock of at least the minimum quantity of filters as designated by the NAFA Product Certification Program Procedural Guide and of the same type and size as shown above. I further attest that this case was removed from the premises immediately after selection. Representative Name: Participant Name: Signature Date/Time Page Number 20 NAFA Product Certification Procedural Guide Approved Version 1 National Air Filtration Association Product certification program Chain of Custody Product procurement I Attest that the product secured from _____________________________________, on _______________________(date) @ ___________________(time) was selected at random from an inventory stock of at least the minimum quantity of filters as designated in the NAFA Product Certification Program Procedural Guide and of the same type and size as the product selected. Further, I verify that the product selected at the time and location shown above did not leave my possession since selection until ship Via______________________ to the destination requested by NAFA Administrative Agency. Attached to this verification statement is the shipper documentation and or tracking numbers along with a copy of the signed Participant statement of release: Agent Name Company Name Signature of Agent Date/Time Shipping Carrier Name NAFA Laboratory Receiving Agent Name and Signature Page Number 21 NAFA Product Certification Procedural Guide Approved Version 1 NAFA Product Certification Products Components List Manufacture Name Address City State Zip Contact Person Product Name Product Type/Model Date COMPONENTS OF PRODUCT FRAME MEDIA TYPE COMPOSITION MEDIA – SQ./FT. BACKING MATERIAL ADDITIVES (I.E. TACK) Values (as published) I/P S/I AVERAGE ARRESTANCE ASHRAE 52.1 INITIAL PRESSURE DROP FINAL PRESSURE DROP FLOW RATE FACE VELOCITY ____FPM WEIGHT GAIN MERV (ASHRAE 52.2) Page Number 22 NAFA Product Certification Procedural Guide Approved Version 1 National Air Filtration Association Product certification program COMPLIANCE CHALLENGE SUBMITTAL Our Company is a Participant in good standing with NAFA. It is our opinion the product described below is not in compliance with the currently published certified values from the NAFA Product Certification Program. The Participant of the product being challenged is named below along with our specific challenge. Supporting documentation for the basis of this challenge is attached for review. Participant Name: Type of Product: Model Number: Challenged Values of Product: We submit this information and request that a challenge test be performed as described in the NAFA Product Certification Program Procedural Guide. We further agree to post the attached check for the fee associated with the challenge procedure, and that if the product we are challenging meets the published values that said monies are forfeited and will pay any additional fee associated with this challenge. Further it is agree that the information in this procedure will be held in confidence until a final determination by the NAFA Certification Administrative Agency. Further, I attest that I have the authority of company listed to enter this challenge and authorize the payment of fees. Authorized Signature:____________________________ Date:_________________ Print Name: ____________________________ Challengor Company Name: ______________________________________________________ Attachments Copies of Published certified value(s) being challenged Data in Supporting Challenge Advance Payment of certification Process Page Number 23 NAFA Procedural Guide Final Draft for Board Review September 25, 1999 National Air Filtration Association Certified Product Filter Model Number Is registered with the National Air Filtration Association as a NAFA Certified Product Initial P___Final P____MERV____Weight Gain ___ NAFA Certified Product Administrative Agency Page Number 24 Not valid without raised seal