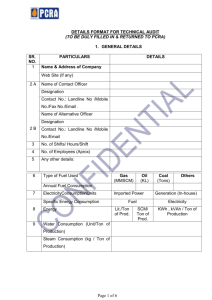

File

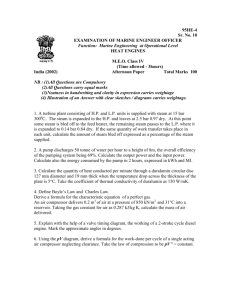

advertisement