Unofficial Translation

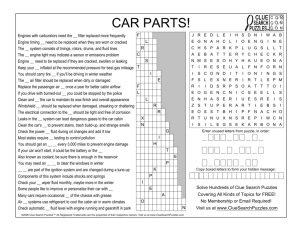

advertisement

Unofficial Translation G/TBT/N/THA/118 In the event of any doubt or misunderstanding arising from this translation, the standard in Thai will be held to be authoritative TIS 787-2531(1988) Thai Industrial Standard for Small Size Water Cooled Diesel Engine 1. Scope 1.1 This standard specifies requirements, mark and label, sampling and criteria for conformity, and tests of water cooled four-stroke diesel engines with a continuous rated power of not more than 22 kW, to be used for agricultural and industrial purposes, which shall be referred to hereinafter as “engines”. 2. Definitions For the purpose of this standard, the following definitions apply: 2.1 RATED POWER: The brake power of the engine under running conditions as specified by the manufacturer. 2.2 CONTINUOUS RATED POWER: The brake power of the engine at a continuous running period as specified by the manufacturer. 2.3 MAXIMUM POWER: The maximum brake power of the engine under running continuous as specified by the manufacturer. 2.4 FULL LOAD: The load designated for the engine running at rated revolutions and at a continuous rated power. 2.5 RATED REVOLUTION: The revolutional speed at the crank shaft of the engine at full load as specified by the manufacturer. 2.6 SPECIFIC FUEL CONSUMPTION: The amount of fuel consumed, expressed in units of weight per engine power per unit of time. 2.7 ENGINE WEIGHT: Total weight of all engine parts excluding driving pulley, fuel, lubricating oil, cooling water, spare part and tool kit. 2.8 TYPE: Engine model displaying detailed design of major parts, such as type of engine, stroke, cooling system, and piston position. 3. Requirements 3.1 General specification 3.1.1 Cooling system Either hopper or radiator type shall be required as follows. 3.1.1.1 Hopper type The hopper shall be of a capacity that will not necessitate replenishment of cooling water for an interval of at least 30 minutes during the running of the continuous cruising power. Test shall be in accordance with clause 6.5.1.1. 3.1.1.2 Radiator type 1 The radiator shall be of a capacity that will not necessitate replenishment of cooling water for an interval of at least 12 hours during the running of the continuous cruising power. Test shall be in accordance with clause 6.5.1.2. 3.1.2 Lubricating system The lubricating oil chamber or tank shall be of a capacity that will not necessitate replenishment of lubricating oil for an interval of at least 12 hours during the running of the continuous cruising power. Test shall be in accordance with clause 6.5.2. 3.1.3 Fuel system The fuel tank shall be of a capacity that will not necessitate replenishment of fuel for an interval of at least 3 hours during the running of the continuous cruising power. Test shall be in accordance with clause 6.5.3. 3.1.4 Flywheel The flywheel shall ensure smooth continuous running performance of the engine with a difference in the revolution speed not to exceed 1/20 of the rated revolution. 3.2 Performance 3.2.1 Load running performance The engine shall prove that its load running performance meets the following requirements, when tested in accordance with clause 6.6. 3.2.1.1 The engine shall run smoothly without any abnormal vibrations. 3.2.1.2 The colour of the exhaust gas shall not exceed 40% by the Bosch system or 52% by the Hartridge system. 3.2.1.3 The engine shall run without bringing about any gas leakage from the parts of the engine. 3.2.1.4 The engine shall run without abnormal over-heating. 3.2.1.5 Noise level shall not exceed 100 dB (A). 3.2.2 Continuous running performance The engine shall prove that its continuous running performance meets the following requirements, when tested in accordance with clause 6.7. 3.2.2.1 The engine shall run smoothly without any abnormal vibrations. 3.2.2.2 The colour of the exhaust gas shall not exceed 40% by the Bosch system or 52% by the Hartridge system. 3.2.2.3 The engine shall run without bringing about any gas leakage from the parts of the engine. 3.2.2.4 The engine shall run without abnormal over-heating. 3.2.2.5 Noise level shall not exceed 100 dB (A). 3.2.2.6 The specific fuel consumption shall not exceed those values specified in Table 1 by more than 5%. Table 1 Specific fuel consumption (clause 3.2.2.6) Rated revolution (rpm) Continuous rated power (kW) Under 3.7 3.7 to under 7.35 7.35 to under 14.7 14.7 to 22 320 333 347 306 320 333 292 306 320 279 292 306 Under 1 500 1 500 to under 2 500 2 500 and over 2 3.2.3 Overload running performance The engine shall prove that its overload running performance meets the following requirements when tested in accordance with clause 6.8. 3.2.3.1 The engine shall run smoothly without any abnormal vibrations. 3.2.3.2 The colour of the exhaust gas shall not exceed 40% by the Bosch system or 52% by the Hartridge system. 3.2.3.3 The engine shall run without bringing about any gas leakage from the parts of the engine. 3.2.3.4 The engine shall run without abnormal over-heating. 3.2.3.5 Noise level shall not exceed 100 dB (A). 3.2.3.6 The engine shall be capable of stable running for more than 30 minutes at the rated revolution. 3.2.4 Maximum power running performance The engine shall prove that its maximum power running performance meets the following requirements when tested in accordance with clause 6.9. 3.2.4.1 The engine shall run smoothly without any abnormal vibrations. 3.2.4.2 The colour of the exhaust gas shall not exceed 40% by the Bosch system or 52% by the Hartridge system. 3.2.4.3 The engine shall run without bringing about any gas leakage from the parts of the engine. 3.2.4.4 The engine shall run without abnormal over-heating. 3.2.4.5 Noise level shall not be more than 100 dB (A). 3.2.4.6 The engine shall be capable of stable running for more than 15 minutes at the rated revolution. 3.2.5 Speed of revolution 3.2.5.1 No-load low speed running performance The engine shall be capable of running at steady speed with exhaust gas of a normal colour when tested in accordance with clause 6.10.1. 3.2.5.2 No load high speed running performance The engine shall be capable of running at steady speed without abnormal vibrations and over-heating when tested in accordance with clause 6.10.1. 3.2.6 Starting The engine shall be capable of easy starting, when tested in accordance with clause 6.11. 4. Mark and label 4.1 Each engine shall bear at least number, letter or mark indicating clearly and legibly the following i n f o r m a t i o n . (1) L o t c o d e * (2) Eng ine power ( cont inuous r at ed power or maxim um power or bot h), in kW (3) Revolution speed (speed of the driving shaft at the specified engine power), in rpm (4) S t r o k e (5) E n v o l u m e g i n o r d i s p l a c e m e n t e n 3 u m v o l u m e b e r (6) N a m e o f m a n u f a c t u r e r o r f a c t o r y , o r r e g i s t e r e d t r a d e m a r k (7) C o u n t r y o f o r i g i n Notes: 1. * Manufacturer’s code to indicate the difference of each engine lot, such as different p o w e r , c o o l i n g s y s t e m , e t c . 2. The information as in clauses (1) and (5) shall be permanently embossed in the metal o f t h e c r a n k c a s e . 4.2 In case foreign language is used, the meaning shall correspond to that in Thai specified above. 4.3 Each engine shall be provided with manual which shall include at least the following. (1) D i r (2) M e a (3) L i s t c t i of i o n details, n t s f e diagrams o n r u a displaying n the s e c e components (4) S p e c i f i c a t i o n o f t h e e n g i n e , c o m p l y i n g w i t h A p p e n d i x A c l a u s e A . 5 . 4.4 Any person who manufactures product complying with this standard may use the Standards Mark in connection with his product only after having received a licence from the Industrial P r o d u c t S t a n d a r d s C o u n c i l . 5. Sampling and criteria for conformity 5.1 Lot: Engines of the same lot code, having equal engine power which are manufactured or intended for consignment at a period. 5.2 Sampling and acceptance shall comply with the following sampling plan or with other technically equivalent plan. 5.2.1 Sampling and acceptance for tests on general requirements, mark and label 5.2.1.1 One engine shall be drawn at random from the same lot. 5.2.1.2 Provided the test results comply with clauses 3.1, 4.1, 4.2 and 4.3, the lot shall be deemed to comply with the requirements. 5.2.2 Sampling and acceptance for performance test 5.2.2.1 One engine shall be drawn at random from the same lot. 5.2.2.2 Provided the test results comply with clause 3.2, the lot shall be deemed to comply with the requirement. 5.3 Criteria for conformity Provided the samples tested comply with all the requirements of clauses 5.2.1.2 and 5.2.2.2, the lot shall be deemed to comply with this standard. 6. Tests 6.1 T T e s t y p s h a l l b e (1) G (2) L e o n a e d r r e c a r r i e d a u l n (3) C o n t i n u o u s (4) O v e r l o a d (5) M a x i m u m r n i t o u t e n g q e o n u p i e o u t p u t s t s f o l l o w i n g : e f o m r e m n a n t s c e p e r f o r m a n c e p e r f o r m a n c e r u n n i n g 4 r r r u n n i n g r u n n i n g t h e p e r f o r m a n c e (6) S p e (7) S e d t o f a r r e v o t l u t i i o n n g 6.2 A c c e p t a n c e t e s t A l l t e s t s o f c l a u s e 6 . 1 e xc e p t i t e m s ( 3 ) , ( 4 ) a n d ( 5 ) s h a l l b e c a r r i e d o u t . 6.3 P r e p a r a t i o n f o r t e s t 6.3.1 The particulars of the engine shall be recorded. (See Appendix A, clause A.1.) 6.3.2 The engine shall be adjusted to the normal running conditions before testing and details r e c o r d e d . ( S e e A p p e n d i x A , c l a u s e A . 2 . ) 6.3.3 Install the equipment or components necessary for engine operation as specified by the m a n u f a c t u r e r . 6.3.4 R u n n i n g i n In case of type test, the engine may be required to be “run-in” for a duration and under conditions specif ied by the manufacturer, unless otherwise agreed upon. 6.3.5 F u e l a n d l u b r i c a t i n g o i l The particulars of fuel and lubricating oil shall be recorded. (See Appendix A, clause A . 3 . ) 6.4 M e a s u r e m e n t c o n d i t i o n For each of the following tests, the temperature, relative humidity and atmospheric pressure at commencement and at completion of testing shall be recorded. 6.4.1 O u t p u t a n d t o r q u e Dynamometer (electric, water or prony-type friction) accurate to within 2% shall be used to measure the output and torque at the crank shaft or at the driving shaft. 6.4.2 S p e e d o f r e v o l u t i o n Tachometer accurate to within 2% shall be used to measure the speed of revolution at t h e c r a n k s h a f t o r a t t h e d r i v i n g s h a f t . 6.4.3 R a t e o f f u e l c o n s u m p t i o n The equipment set for measuring fuel consumption shall be as given in Figure 1, comprising a burette or other vessel for measuring the volume of fuel used. The burette shall be of a volume that will contain fuel sufficient for running the engine longer than 10 seconds. Alternatively, other equivalent apparatus may be used. Figure 1 Measurement of rate of fuel consumption (clause 6.4.3) 5 6.4.4 T e m p e r a t u r e of cooling water and consumption rate 6.4.4.1 For engine using a circulation cooling system, the temperature shall be measured a t t h e i n l e t a n d o u t l e t o f t h e e n g i n e . 6.4.4.2 The cooling water consumption rate shall be measured from the quantity of water r e q u i r e d f o r r e p l e n i s h m e n t . 6.4.5 T e m p e r a t u r e of lubricating oil and consumption rate. 6.4.5.1 The temperature of the lubricating oil shall be measured at about the middle part o f t h e o i l d e p t h i n t h e t a n k . 6.4.5.2 The lubricating oil consumption rate shall be measured from the amount of l u b r i c a t i ng oi l r eq u i r e d f o r r e p l e n i s h m e n t . 6.4.6 T e m p e r a t u r e a n d c o l o u r o f t h e e x h a u s t g a s . The temperature of the exhaust gas shall be measured at the end of the exhaust pipe, and the colour of the exhaust gas shall be measured using the Bosch or the Hartridge s y s t e m . 6.4.7 I n j e c t i o n t i m i n g o f n o z z l e With engine manually turned, the position of injection shall be recorded. When this method is not practicable, other appropriate methods may be used. 6.4.8 N o i s e l e v e l Measurement shall be made using a noise level meter having a time weighting characteristic “F”. During measurement, a microphone shall be positioned so that it is parallel to the engine base, facing the engine at a distance of 1 m from the engine body and a height of 200 mm from the base. Measurement shall be made at 4 points around t h e e n g i n e a n d t h e m a x i m u m v a l u e r e p o r t e d . 6.5 T e s t s o n g e n e r a l r e q u i r e m e n t s The cooling water and lubricating oil shall be filled to the level specified by the manufacturer. Fuel shall then be filled in an amount sufficient for carrying out the continuous running test of the specified duration. Check the following systems as follows: 6.5.1 C o o l i n g s y s t e m 6.5.1.1 In the case of a hopper, the level of water shall be checked after the engine has been running for not less than 30 minutes and allowed to cool. The water level indicator shall not be at its lowest position. 6.5.1.2 In the case of a radiator, the level of water shall be checked after the engine has been running for not less than 12 hours and allowed to cool. The water level shall not be below the upper part of the water hose. 6.5.2 L u b r i c a t i n g s y s t e m The level of lubricating oil shall be checked when the engine has been running for at least 12 h. The level of the lubricating oil shall not be below the lowest mark of the oil g a u g e . 6.5.3 F u e l s y s t e m The level of fuel shall be checked when the engine has been running for at least 3 hours. The level of the fuel shall not be below the lowest level of the fuel gauge. 6.5.4 F l y w h e e l The engine shall be adjusted to the specified revolution speed. The speed fluctuation of the flywheel shall be calculated by comparing the difference between the maximum and the minimum readings of the speed obtained in a period of 5 minutes with the rated s p e e d . 6.6 L o 6.6.1 P a d r r o u n n c i e 6 n g d t u e r s t e Install the engine to a dynamometer, then carry out the test under the loads in the sequence as shown in Table 2 after the engine has reached the stable condition. 6.6.2 T e s t r e p o r t The test values and any abnormality of the engine shall be recorded in compliance with A p p e n d i x A c l a u s e A . 3 . 6.7 C o n t i n u o u s r u n n i n g t e s t 6.7.1 P r o c e d u r e The test shall be carried out with the engine running at its rated continuous power, constant load and without engine adjusting for 5 hours continuously unless interrupted for reason other than engine trouble in which case the duration of running shall be extended by the same amount of time lost by the interruption. Table 2 Load and test duration (clause 6.6.1) Test sequence Load % Test duration 1 100 20 2 110 10 3 75 10 Once every 4 50 10 10 minutes 5 25 10 6 0 10 N o t e 6.7.2 T : L e o a s d 1 0 0 t % Number of measurements : r f e u l p l l o o a r d t (1) Record shall be taken as specified in clause 6.6.2 every 30 minutes, 11 times in t o t a l . (2) F u e l 6.8 O v e c o n s u m p t i o n r l o a d r a t e r u s h a l l n n i b e n r e c o r d e d . g t e s t 6.8.1 P r o c e d u r e The test shall be carried out with the engine running at 110% of the full load and at the rated speed for 30 minutes; for an engine with a cylinder volume less than 100 cm 3 the t e s t p e r i o d s h a l l b e 1 5 m i n u t e s . 6.8.2 T e s t r e p o r t Record shall be taken as in clause 6.6.2 once every 15 minutes, 3 times in total; for an engine with a cylinder volume less than 100 cm 3 T h e r e c o r d i n g s h a l l b e t a k e n 2 t i m e s . 6.9 M a x i m u m o u t p u t r u n n i n g t e s t 6.9.1 P r o c e d u r e The test shall be carried out with the engine running at the rated speed, and the load increased to the maximum output until a stable condition is reached and maintained for 1 5 m i n u t e s . 6.9.2 T e s t r e p o r t Record shall be taken as in clause 6.6.2, for a total of 2 times. 6.10 R e 6.10.1 N v o o l u l t o i a o d n a l l o 7 s w p s e p e e e d d t e s t t e s t 6.10.1.1 T e s t i n g m e t h o d The test shall be carried out with the engine running for 10 minutes under a no-load condition at less than 1/2 of the rated revolution. 6.10.1.2 T e Record 6.10.2 N o - l o a s t shall be d h i r tak en g h e as in s p e p o clause e d r t 6.6.2. t e s t 6.10.2.1 P r o c e d u r e The test shall be carried out on an engine running for 10 seconds after the speed is increased to not less than 120% of the rated speed from an arbitrary low speed specified by the manufacturer. This operation shall be repeated 6 t i m e s a t i n t e r v a l s o f a b o u t 1 0 s . 6.10.2.2 T e Record 6.11 S t a r s t shall be t i r tak en n g e as in p o clause t e r t 6.6.2. s t 6.11.1 P r o c e d u r e The test shall be made when the engine is in a cooled and no-load condition by starting t h e e n g i n e a s s p e c i f i e d b y t h e m a n u f a c t u r e r . This shall be repeated not more than 3 times. 6.11.2 T e s t r e p o r t The result of the starting of the engine shall be recorded. (See Appendix A, clause A . 4 . ) 8 Appendix A Forms of engine particulars sheets and test results (clauses 4.2(4), 6.3, 6.6.2 and 6.11.2) Forms of engine particulars sheets and test reports given as a guidance for the manufacturer and for t h o s e p e r f o r m i n g t e s t s a r e a s f o l l o w s : A . 1 E n g i A . 2 E n g A . 3 E n g A . 4 E n g A . 5 E n g i n e i i i n e n p e a a n e r n e s u t r d j n a t c u n r i i t n i s p e c i f 9 s u t g n g l a r s s h e e t m e n t s h e e t t e s t r e p o r t e s t r e p o r t t i c a t i o n s s h e e t A . 1 E n g i n e p a r t i c u l a r s s h e e t Name of manufacturer: _________________________________________________________ Type: _______________________________________________________________________ Lot code: ____________________________________________________________________ Continuous rated power: ____________ kW, at rated revolution speed: _____________ r p m Starting method: ______________ Fuel: ____________ Lubricating oil: __________________ No. of cylinders: ______________ Diameter of cylinder: _________ mm Stroke ________ m Total stroke volume: ___________ cm3 m Compression ratio: ________________________ Type of combustion chamber: ____________________________________________________ Length of engine: _______________ mm Width of engine: ______________________ m m Height of engine: _______________ mm Weight of engine: _____________________ k g 3 of lubricating oil chamber: ______________ d Capacity of fuel tank: ____________ dm Cooling system, type: _______________ m 3 capacity: ____________________________ dm3 Injection pump, type: ________________ Name of manufacturer: ____________________ Injection nozzle, type: _______________ Name of manufacturer: ____________________ Injection pressure: ______________ kg/cm 2 ________________________________________ 10 A . 2 E n g i n e a d j u s t m e n t s h e e t Name of manufacturer: _____________________________________________________ _____ Type: ________________________________________________________________________ Lot code: _____________________ Engine identification No.: ___________________________ Item Intake valve Valve clearance, Normal value mm Open before top dead centre, Close behind bottom dead centre, Exhaust valve Valve clearance, mm Open before bottom dead centre, Close behind top dead centre, Fuel injection beginging Before top dead centre, Injection pressure at beginning of fuel injection o f n o z z l e , k g / c m 2 Combustion chamber volume, dm3 11 Cylinder number 1 2 3 4 A . 3 E n g i n e r u n n i n g t e s t r e p o r t Name of manufacturer: _______________________________________________________ Type: _____________________________________________________________________ Lot code: _____________________ Engine identification No.: _______________________ Date of test: _______________________________________________________________ Place of test: _______________________________________________________________ Tested by: _________________________________________________________________ F u e l Trade-mark: _______________________ Relative density: _______________________ Calorific value: _______________ kcal/kg Cetane value: __________ _______________ L u b r i c a t Trade-mark: ________________ Viscosity D y n a i n g SAE: ____________ m o m o i l API: ____________ e t e r Type: _____________________ Size: ________________________________________ Constant value: _____________ Length of arm: ______________________________ m A t m o s p h e r i c p r e s s u r e At commencement of test: ______________________________________________ m m . H g At completion of test: __________________________________________________ m m . H g R e l a t i v e h u m i d i t y At commencement of test: ________________________________________________ % At completion of test: ____________________________________________________ % R T o o m t e m p e r a t u r e At commencement of test: ________________________________________________ C At completion of: _______________________________________________________ C e s t r e p o r t Test: ____________________________________________________________________ Test No.: _________________________________________________________________ Load: ____________________________________________________________________ Room temperature: ______________________________________________________ C Colour of exhaust gas: _______________________________________________________ Temperature of exhaust gas: _______________________________________________ C Noise level: ____________________________________________________________ d B ( A ) 12 C o o l i n g w a t e r 3 Cooling water consumption rate: ___________________________________________ d m / h Specific cooling water consumption rate: ____________________________________ dm 3 /kW h L Inlet temperature: _______________________________________________________ C Outlet temperature: ______________________________________________________ C u b r i c a t i n g o i l 3 Lubricating oil consumption rate: ___________________________________________ d m / h Specific lubricating oil consumption rate: _____________________________________ g / k W h Pressure: ______________________________________________________________ k g / c m 2 Temperature during test: __________________________________________________ F u C e l Watch reading: _________________________________________________________ s Fuel reading: ___________________________________________________________ d m 3 / h Fuel consumption rate: ___________________________________________________ d m 3 / h Specific fuel consumption rate: _____________________________________________ d m 3 / h Load at dynamometer: _____________________________________________________ N Torque: _________________________________________________________________ N / Shaft driving power: ________________________________________________________ k Speed of revolution: ________________________________________________________ r m W p m Duration of test: ___________________________________________________________ m i n / s Starting time: __________________________________________________________________ R e m a r k s o n a b 13 n o r m a l i t i e s : A . 4 E n g i n e s t a r t i n g t e s t r e p o r t Name of manufacturer: __________________________________________________________ Type: ________________________________________________________________________ Lot code: _______________________ Engine identification No.: ________________________ Date of test: ___________________________________________________________________ Place of test: __________________________________________________________________ Tested by: ____________________________________________________________________ F L u e l : Trade-mark: ___________________ Relative density: _____________________________ Calorific value: __________ kcal/kg Cetane value: _______________________________ u b r i Trade-mark: ____________ c a t Viscosity i n g o SAE: ______________ i l : API: ________________ Atmospheric pressure: ______________________________________________________ m m . H g Room temperature: ______________________________________________________ Manual starting Test No. Lubricating oil temperature Result C Start/Failure 14 C A . 5 E n g i n e 1. L o s p e c i f i c a t t c 2. T u m b e 4. D i a m e t e r 5. S t r o o f c e v y c y l i n d e r k d e p r o f s h e e t o y 3. N i o n s o e l i n d s t r o k e , l u m e e r m m , s m m c 3 m 6. Power engine (continuous rated power or maximum output or both) and related revolution s p e e d , k W / r p m 7. S p e c i f i c 8. C o 9. V 10. M m p a a r l x f u e l i v m a p a c i 14. T y 15. T y 16. T y t 17. T y p e 18. T y 19. T e p y p e 21. D i r e e i f l c f t h i t e u t , l , d i c o m b u s t f s o a t n o i s y s t em c r o f f e 15 d m 3 3 ( t o i n a t i o r t i n r n e g v i o n p m r o s e ) t l i e l m r a d i a t o r ) y s l y u , t g y l e i e i s r u s g e ( l i t r e ) o r f / l s n o ( l i t r e ) 3 n ( h op p e r i a a i c m f r i . d m f b r m t n f o i l , u b g w a t e r , e a a k l u o o g f c o o l i ng e u g / k W h r s o c o n l u b r i c a t i n g f e o i q r f wa t er y r e of p o o f o r o 20. T 22. W f o i c o o l i n g y e p t f o r p p s d m 13. C a p a c i t y s e u 11. C a p a c i t y 12. C e c o n s u m p t i o n , t t e m e r s t e m t i o n k g .