Word File- Chapter 8

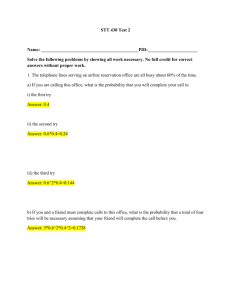

advertisement

Chapter 8: Quality Management Review Questions 1. What is the role of quality in strategic planning within any company? Answer: Quality affects every aspect of an organization. High quality products and processes allow a company to gain a competitive advantage through higher customer satisfaction and lower scrap and rework costs. In addition, as the text mentions, higher quality also affects worker morale positively. It is not just the quality products that count. It is the quality ethic that relates to integrity and is a source of pride in workmanship for all employees. One of Deming’s 14 points is “remove barriers to pride of workmanship.” 2. What is the competitive role of quality externally (in the marketplace)? Answer: There are several areas where quality is an important agent to gaining competitive advantage. Products having better quality have a marketplace advantage. Better quality protects against competitors that compete on price. Better quality saves money by decreasing defectives that must be scrapped or reworked. Better quality increases customer loyalty. Better product quality obtained at a reasonable price generally leads to growth in market shares and increases in revenues. The function of price-elasticity is well-known but equally important is the quality-price-elasticity relationship which (among other effects) depicts the impact of quality on substitutability. Low quality products are not substitutable for high quality products when a consumer can afford to pay more. Quality differentials change the price-elasticity relationship. As an example, a Coach purse sells at a high price because Coach –aficionados do not believe that there is anything that can substitute for it. Other examples are Apple iPhones and Tiffany bracelets. 3. Since quality is important in different ways to different providers of services, why do we need to teach what is so obvious? Answer: Surprisingly consumers are far more sensitive to quality of services rendered than are the providers of those services. There are many good reasons for this. In particular note the answer to Review Question 6. We will offer a different interpretation of the same cause here. Providers of services have many things to consider beside quality. For example, they must take into account costs and reasonable charges for services provided. For reasons that psychologists can probably explain, as consumers we wear one hat; as producers selling out services we wear a different hat. We must teach producers to listen to the voice of the customer and to learn to walk in the customer’s shoes. When we say that something about quality is obvious—we must be very careful. Steak lovers and vegetarians will not have the same opinion about restaurants. 4. What is TQM and why is it important for attaining better quality? Answer: TQM was never directly addressed in this chapter because some teachers like the concept but others do not. We did give a number of References for further reading. For those of us who like it, TQM stands for Total Quality Management. There was a decade of adoration of the TQM concept. It was supposed to solve all existing problems. The time has now come to define and explain the idea behind total quality management. TQM is a management strategy that requires a company-wide systems approach to quality. If quality management is company-wide, then, everyone who works in any capacity is part of the team responsible for achieving the best quality results. TQM is the procedure of choice. The attainment of TQM is the critical precursor to excellence in quality. TQM enables the systems approach to operate effectively. TQM could have been called SMQ, for Systems Management of Quality, because the systems approach is so important to TQM success. 5. Friends have said that TQM means the quickest method. Is that correct? Answer: It is not correct. Criticism of TQM could be based on there being better ways to develop a quality culture but not on its being a quick and dirty approach. Far from that, it may seem to be too sweeping an effort to instill quality goals. 6. What are the differences between consumer and producer definitions for quality? Sometimes the consumer is called the buyer and the producer is called the supplier. What are the differences between them? Answer: The producer’s definition of quality is about the properties of goods and services without distinctions about being good or bad. It is based on the commitment to deliver according to specifications. Many of these properties are tangible and measurable. The producer is primarily dedicated to achieving conformance to specifications. If specs are met, then there are no defectives and quality is acceptable. The producer ships to the buyer (aka consumer, customer, purchasing agent). Producers are aka suppliers and vendors. The consumer’s view is that quality relates to the degree of excellence of things that matter to that consumer’s market segment. Comparisons are relative being based on experience of the user with the product-class. Value for money paid is conditioned by opinions of friends and family as well as by the utility derived from use. The consumer’s view is quite likely to be intrinsic, innate and subjective. 7. How does the systems approach apply to the following statement: Quality—like a chain—is betrayed by its weakest link. Answer: Like the orchestra that must play in synchronization to achieve quality music, the company needs to synchronize its elements to achieve company-wide quality. One musician that cannot or will not play in sync with the others will surely spoil the overall musical effect. To mix metaphors, that one musician is the orchestra’s weak link. In the organization, omit any one of its elements from participation and the systems concept fails. Let one element, person, or department exclude itself from participation, and the systems concept fails. The quality chain from an operations viewpoint is vulnerable when any element that fails produces a defective product. The systems approach spots the problem and corrects the weakness. Organizational weak links may show up only for certain production items. 8. Discuss the statement “Although the name TQM may be viewed by some as faddish, the fundamental concept is not.” Answer: Some people do not like the name TQM, and they think that it has been overblown or overused. However, everyone agrees that what TQM stands for is here to stay. While the label TQM is cosmetic, and assures no one of anything, the ingredients of TQM, what TQM stands for, are both individually--and as a systems approach—relevant. An alternative label that is more recent is Six Sigma. Both labels include statistical methods but the latter uses probability to a more intense degree. 9. What quality dimensions apply to the software industry? Answer: The eight quality dimensions noted by Garvin apply to services, as well as to manufactured goods. Treating a piece of computer software as a service (as compared to hardware), and dropping the conformance item (not consumer-oriented), the dimensions apply as follows. Appropriate quality dimensions for the software industry: Performance: Does the program do what it is designed to do? How well, how fast does it perform its basic task? How easy is the program to use? Is there network support and links to other types of software? How steep is the learning curve? Features: What does this product do that is beyond the standard for this class of software? Is the product customizable? Is context-sensitive help provided? Does the program perform additional classes of tasks, etc.? Reliability: Is the program free of bugs, glitches, and General Protection Faults? Durability: Holding up under stress of use may be an important software issue. Protection against hacker’s malware creating a computer overload is sometimes necessary. Serviceability: How easy is it to do software maintenance? Are upgrades frequent? Can upgrades be accomplished while other programs are running? How good and how available is customer support? Aesthetics: How are the sensory communications accomplished? Are voice and touch part of the control system? Are the visuals and sounds pleasing or disturbing? Perceived quality: Is management satisfied with the cost, quality, and delivery time of the software programs? Are users content with the operations of the programs? 10. Set down appropriate quality dimensions for buying or designing a hybrid automobile. a. Explain the differences in the systems approach. Answer: Appropriate quality dimensions for a hybrid automobile: Power Safety features Capacities Fuel economy Reliability Durability Resale value Serviceability Other features (accessories) Design (ergonomics) Design (style) Perceived quality a. The designer and the buyer use different criteria in their systems approach to the qualities of the auto. From the company’s point of view it would be best if the two perspectives are as aligned as possible. However, in actuality there are likely to be differences. The designer will consider how to make the car look as elegant as possible because the fuel economy issue is paramount in the marketing of this auto. It must not look as though the owner is being frugal—rather it should send a signal of a good citizen with a green conscience. Elegance of design style often trumps comfort (design ergonomics). The buyer will check on the believability of stated fuel economy and if satisfied will read in consumer magazines about possible weaknesses including safety features (often overlooked by designers). Ultimately the comfort of the auto will play a major role in the buyer’s decision. 11. What problem exists because quality standards can age? Answer: Standards change over time. What is an acceptable level of product quality one year is not sufficient the next year. What is an appropriate quality program at one time, if not dynamic, becomes unacceptable by staying the same. Companies that fail to keep up with new standards may be barred from participating in markets that adhere to those standards. This has been true with ISO 9000 criteria and Japanese national quality standards. It is clear that market dynamics demand tracking results and that good market research is essential. Products and processes must be altered to match changed expectations. The change agents are P/OM and marketing. The information is provide my IT and market researchers. 12. Explain P/OM’s relationship with market research. Answer: Market research is the direct connection to the customer and how he/she uses the product and perceives its quality. Market research is needed to explore alternative uses for a product. This relates to “purpose utilities,” which may require reconsideration of the quality standards for product performance. Frequently, there are regional differences in quality perceptions, which may lead P/OM to have different standards for different regions. Market research is important for determining the extent of choice or variety desired by customers. Operations must produce the variety level demanded by the marketing strategy. Additional variety in the product mix generally introduces additional production costs. To summarize, P/OM needs to hear the voice of the customer. Marketing and market research provide the channel but there needs to be a listener before anyone can hear. 13. Explain how consistency of conformity translates into low reject rates. Answer: Conformance is the degree to which measured product attributes correspond to the design specifications. If there is consistency in conformance, then there is consistency in meeting design specifications. That is, the product as manufactured meets the design established for the product; such an item is acceptable under quality control standards. Consistency of conformance removes or reduces a source of rejected items. The possible disconnect lies between design specifications and customer satisfaction with them. 14. Discuss the strengths and weaknesses of quality circles. Are they similar to student cohort work groups? Answer: We expect the students to look up Quality Circles (QC). Wikipedia has a very good entry. Using a systems point of view, the strengths of Quality Circles include: (1) Teamwork for productivity is enhanced; (2) Absenteeism and turnover are diminished; (3) Pride in work is real, not fictional. The weaknesses of quality circles include: (1) QCs can fail in their mission if top management is not sincere; (2) QCs may impair quality achievement when the team is improperly chosen and the program not well-designed; (3) Poor training dooms QCs. Excellent training is required for QC success. 15. What are the ways to reduce the cost of detailing? Answer: Detailing involves removing defective items from a lot rejected by acceptance sampling. Then, every item in this detailed lot conforms to specifications. Some methods of reducing the cost of detailing are: (1) Reduce the percent defective so that there are fewer defectives to begin with and a lower chance the lot will be rejected; (2) Raise the rejection number so that fewer lots are rejected; (3) Redefine defective more liberally to allow more items to pass inspection; (4) Reduce the wage of detailers; (5) Stop performing acceptance sampling. Although all of these methods decrease the cost of detailing, not all of these are compatible with a systems approach. Number 1 is the only cost reduction method that treats the problems and not the symptoms. That is what the systems approach advocates. Explain what the House of Quality does and how it works. (Look up House of Quality in Wikipedia. Follow up on Quality Function Deployment before answering this question.) 16. Answer: The House of Quality (HOQ) is a model for mapping the relationships that exist between customers—and those that supply them (i.e., producers of goods and services). By using the HOQ model there is a graphical picture that maps the interactive and mutual concerns of sales and marketing with those of design, production/operations, engineering, and the voice of the customer. As such, HOQ is a combination of description and analysis. Customer needs are identified by marketing. Operations identifies process capabilities and design factors that are supposed to satisfy those needs. HOQ includes means to identify differential needs of market segments and the comparison of the current product to its competition. This results in a set of interrelated matrices that form a TQM scoring model. The end result is a graphic “house” that attempts to show how well the product meets the needs of customers. This is often referred to as listening to the voice of the customer. 17. What prize competitions exist for quality and why are these prizes given? Answer: Prize competitions for quality include the Deming Prize and the Malcolm Baldrige National Quality Award*. The Deming Prize emphasizes success with Statistical Process Control and with Quality Function Deployment. This prize results from Deming’s profound influence on Japanese manufacturing practices. The Malcolm Baldrige National Quality Award was conceived as a program to trigger competition among U.S. companies with respect to their adherence to management principles that resulted in quality products. This award was created in 1987 in reaction to the outstanding success of Japanese export firms, and was undertaken to spur improvement in the quality of American products. *Established by Congress for manufacturers, service businesses and small businesses, the Baldrige Award was designed to raise awareness of quality management and recognize U.S. companies that have implemented successful qualitymanagement systems. Problems 1. After setup in the job shop, the first items made are likely to be defectives. If the order size (X) calls for 125 units, and the expected percent defective (p) for start-up is 7 percent, how many units should be made? Solution: This problem (i.e., one like it) is repeated in Chapter 11 where it is used to reveal the potential for innovation to cut down on waste. Brainstorming to cut 7 percent in half is a smart goal. In this case, we want to show the fundamental costs of producing defective items. After removing the defectives, more items must be produced to fill this order for X units. The defective’s cost is usually large enough to warrant rework. If not it might be sold as scrap. A lot of time and effort has gone into non-value-adding activities. This is the very essence of a non-lean system. Time is lost. Rather than adding value, defectives subtract value. Inventory is wasted. Now, let us turn to the calculation (the derivation of β will be found in Problem 8 of Chapter 11: ORDER SIZE (X) = (RUN QUANTITY; X + β) = X + X(p/(1 – p)) = 125 + (125)(p/(1-p)) = 125[1+(0.07)/(0.93)] = 125(1.075) = 134.4086. A simpler alternative formulation is: RUN QUANTITY = ORDER SIZE (X)/(1-p) = 125/(1 – p) = 125/(0.93) = 125(1.075) = 134.4086. The number of defectives is 134.4086 x 0.07 = 9.4086 units (on average). 2. A subassembly of electronic components, called M1, consists of 5 parts that can fail. Three parts have failure probabilities of 0.03. The other two parts have failure probabilities of 0.02. Each M1 can only be tested after assembly into the parent DVR. It takes a week to get M1 units (the lead time is one week), and the company has orders for the next five days of 32, 44, 36, 54, and 41. How many M1 units should be on hand right now so that all orders can be filled? Solution: This is a generalization of the second solution method used in Problem 1: BATCH SIZE = ORDER QUANTITY/ in i0 (1 – pi). Here, the order quantity = 32 + 44 + 36 + 54 + 41 = 207 and p1 = p2 = p3 = 0.03 and p4 = p5 = 0.02: BATCH SIZE = 207(1 – 0.03)3(1 – 0.02)2 = 236.16. 3. Use SPC with the following table of data to advise this airline about its on-time arrival and departure performance. These are service qualities highly valued by their customers. The average total number of flights flown by this airline is 660 per day. This represents three weeks of data. It is suggested that a late flight be considered as a defective. Draw up a p-chart and analyze the results. Discuss the approach. The Number of Late Flights (NLF) Each Day Day NLF 1 31 2 56 3 65 4 49 5 52 6 38 7 47 8 43 9 39 10 41 11 37 12 48 13 45 14 33 15 22 16 34 17 29 18 31 19 35 20 44 21 37 Assuming that days 1, 8, and 15 are Mondays; 2, 9, and 16 are Tuesdays, etc., Use the concepts from chapter on forecasting to determine if there is any correlation between day of the week and the number of late flights. Solution: This problem is covered in Section 8.9 of the text. See Excel file SMCh08 (worksheet P3) for calculations and p chart. First, chart the p-values for the NLF per day as a percent of total flights per day (660). Day NLF p Day 1 NLF 31 0.047 8 43 2 56 0.085 9 3 65 0.098 4 49 5 p Day NLF p 0.065 15 22 0.033 39 0.059 16 34 0.052 10 41 0.062 17 29 0.044 0.074 11 37 0.056 18 31 0.047 52 0.079 12 48 0.073 19 35 0.053 6 38 0.058 13 45 0.068 20 44 0.067 7 47 0.071 14 33 0.050 21 37 0.056 Sample calculation: for day 1, p = 31/660 = 0.0469. Second, determine the p-chart parameters. p = Total NLF/(21*660) = 856/13,860 = 0.06176 or 0.0618. σ = p 1 p / n = 0.0618(0.9382) / 660 = 0.00937. Using the conservative 1.96 sigma limits means that if the process is under control, about 95 percent of the observations will be within the limits, which are UCL = p + 1.96σ = 0.0618 + 1.96(0.00937) = 0.080, and LCL = p – 1.96 σ = 0.0618 – 1.96(0.00937) = 0.043. The above p-chart has 3 out of 21 (0.143) observations (on days 2, 3 and 15) out of bounds, which is a little high (you would expect about 5 out of 100 = 0.05). Two extreme observations are at the beginning of the first week, which possibly indicates that there was some reason (such as start-up effects) for the clustering at that particular time. Neglecting the first two observations, it appears that the lateness rate is 1:19 or 0.0526 which is close enough to 5 percent (which is what you expect for 1.96-sigma). That does not mean it is acceptable to the airlines or its customers. We ran a correlation between day of the week and number of late flights (NLF). There are many ways to do that. We chose to rank order days by their total number of late flights. Mondays were assigned 1 because they had the lowest total NLF (96). Thursdays and Sundays with 117 were tied for number 2. Saturdays were assigned number 3, etc. The correlation coefficients (under two different schemes) were very high. See Excel file SMCh08 (worksheet P3). They ranged from 0.925 to 0.929. Result: We found a strong correlation exists between day of the week and the number of late flights. Mondays had the best record with the least number of late flights. Wednesdays and Fridays had the worst records. Now, look at the p-chart. The highest NLF value (above the UCL) occurred on a Wednesday (Day 3). The next highest NLF value (also above the UCL) occurred on a Tuesday (Day 2). The lowest NLF value (below the LCL) occurred on a Monday (Day 15). All of these observations align with the correlational results that we just determined. 4. New data have been collected for the BCTF. It is given in the following table. Start your analysis by creating an x-bar chart and then create the R-chart. Provide interpretation of the results. Weight of Chocolate Truffles (in Grams) Subgroup Time- 1 2 3 4 I II III IV V 10 A.M. 30.00 30.50 29.95 30.60 11 A.M. 30.25 31.05 30.00 29.70 1 P.M. 29.75 29.80 30.05 29.80 3 P.M. 29.90 29.00 29.95 29.65 4 P.M. 30.05 29.60 29.90 29.85 Using Linear Regression, analyze the effect of the time of day on the truffle weights of samples. Solution: For purposes of correlation and regression we have numbered subgroups I, II, III, IV and V as 1, 2, 3, 4 and 5 respectively. See Excel file SMCh08 (worksheet P4) for calculations. Subgroup j = 1 2 3 4 5 Time 10:00 A.M. 11:00 A.M. 1;00 P.M. 3:00 P.M. 4;00 P.M. 1 30.00 30.25 29.75 29.90 30.05 2 30.50 31.05 29.80 29.00 29.60 3 29.95 30.00 30.05 29.95 29.90 4 30.60 29.70 29.80 29.65 29.85 Sum SUM Rj 121.05 121.00 119.40 118.50 119.4 599.35 30.26 30.25 29.85 29.63 29.85 149.8375 0.65 1.35 0.30 0.95 0.45 3.70 Quality Control Models (Statistical Quality Control [SQC]) will help create the x -chart and the R-chart. x = 149.84/5 = 29.9675, R = 3.70/5 = 0.74 Conversion factors are in Table 8.2 in the text. To develop the 3-sigma control limits for the x -chart, A2 = 0.73 when n = 4, So UCL = x + A2 R = 29.97 + 0.73(0.74) = 30.51 and LCLx = x – A2 R = 29.97 – 0.73(0.74) = 29.43. To develop the 3-sigma control limits for the R-chart, D3 = 0 and D4 = 2.28 when n = 4, So UCLR = D4 R = 2.28(0.74) = 1.69 and LCLR = D3 R = 0(0.74) = 0 The x-bar and the R-charts are drawn below. Studying the two graphs (above) reveals that this process appears to be under control. However, there is a run of decreasing x-bar values starting at 11:00 A.M. and ceasing at 3:00 P.M. That may reflect management’s urging supervisors to get as close to the ideal of 28.35 grams. It is worth analyzing so we will perform a regression analysis using the average candy weights for each time period. Let us employ an Excel spreadsheet for linear regression. There is a line (y = mx + b) which has a negative slope -0.145. The correlation coefficient for these data is high with a negative value. This is apparent from the graph as well as the slope of the regression line. That correlation coefficient is – 0.82123. The following data were used for regression analysis. Time (X) X-bar (Y) 1 30.26 2 30.25 3 29.85 4 29.63 5 29.85 5. Analyze the following data to calculate the parameters for the x-bar chart and draw the revised chart. Discuss the results. Using Linear Regression, analyze the effect of the time of day on the revised truffle weights of samples. Also calculate the R-chart parameters and discuss the results. Subgroup I II III IV V Time- 10 A.M. 11 A.M. 1 P.M. 3 P.M. 4 P.M. 1 30.50 30.30 30.15 30.15 30.15 2 29.75 31.00 29.50 29.95 30.25 3 29.90 30.20 29.75 29.80 30.50 4 30.25 30.50 30.00 30.05 29.70 Solution: See Excel file SMCh08 (worksheet P5) for calculations. The difference between this table and Table 8.3 is in column IV. The 3:00 pm data in Table 8.3 have been removed and in their place we have substituted the following four values of xi: (30.15), (29.95), (29.80), and (30.05). Since the 3 P.M. data of Table 8.3 are the four items that are changed, only revised calculations are given here. Recalculating parameters for the x -chart: For 3 pm: x = (30.15 + 29.95 + 29.80 + 30.05)/4 = 29.99 and R = 0.35. Thus, x = 150.59/5 = 30.12 and R = 3.35/5 = 0.67. To develop the 3-sigma control limits for the x -chart, A2 = 0.73 when n = 4, so UCL x = x + A2 R = 30.12 + 0.73(0.67) = 30.61 and LCL x = x – A2 R = 30.12 – 0.73(0.67) = 29.63 The old 3 pm data in Table 8.3 had the highest data point (32), the largest mean (30.9), and the largest range 2.0); in short, the noisiest and highest data set. From the information and graph above, the new 3 P.M. data set was much less noisy and had an average in the overall center. The overall effect is a process more in control and desirable. Changing time as we did in Problem 4 to 1, 2, 3, 4 and 5 we performed a regression analysis using the average candy weights for each time period. Employing an Excel spreadsheet, there is a line (y = mx + b) which has a minimal negative slope (- 0.0413). That negative slope is not very meaningful because the correlation coefficient for these data is low enough (minus – 0.2684) to let us state that the data pattern is fairly random around the mean. This would indicate that there is no pattern of changing p values from early morning till late afternoon. The following data were used for regression analysis. Time (X) X-bar (Y) 1 30.10 2 30.50 3 29.85 4 29.99 5 30.15 6. For the following tabulated data, draw the p-chart. NR = number of rejects and n = sample size. Also analyze the effect of the day on the number of rejects in each sample using regression analysis Subgroup No. 1 - Monday 2 - Tuesday 3 - Wednesday 4 - Thursday 5 - Friday NR 1 2 1 3 1 n 9 9 9 16 9 Solution: This is similar to the bottom of Table 8.4 in the text. See Excel file SMCh08 (worksheet P6) for calculations. Subgroup No. NR n p 1 1 9 0.111 2 2 9 0.222 3 1 9 0.111 4 3 16 0.187 5 1 9 0.111 SUM 8 52 p = 8/52 = 0.15; now addressing the standard deviation for subgroups with n = 9: z= p(1 p) / n = 0.15(0.85) / 9 = 0.12 Using the conservative 1.96 sigma limits means that if the process is under control, about 95 percent of the observations will be within the limits, which are UCL = p + 1.96σ = 0.15 + 1.96(0.12) = 0.39 and LCL = p – 1.96σ = 0.15 – 1.96(0.12) = – 0.08 (so use 0.00). Change the UCL for subgroup 4 because it does not have a sample size of 9, as follows: σ= p(1 p) /16 = 0.09 UCL = 0.15 + 1.96(0.09) = 0.33 LCL = – 0.03 (so use 0.00). These data are better than those of Table 8.4 and the process looks in control for the information that we have, but the value of p is uncomfortably high. We arranged the data so that days with the lowest p value (0.111) were called 1; next highest p value days (0.187) were called 2; the highest p value day (0.222) was called 3. Monday, Wednesday and Friday were each labeled 1. Thursday was labeled 2 and Tuesday was labeled 3. The regression line has a minimal positive slope of 0.05816, which means that variations by day are not large. However, the correlation coefficient is 0.98529 indicating that the variations that exist may not be large but they are very significant. Mondays, Wednesdays and Fridays have low p values; Tuesdays bring high values. However, this amount of data is not enough to draw sound conclusions. We need many more Mondays, Tuesdays, etc. See Excel file SMCh08 (worksheet P6) for calculations. The following data were used for rank correlation. Rank p-values 1 0.11111 Coefficient of Correlation 1 1 0.11111 0.11111 Slope 2 0.1875 3 0.22222 0.98529 0.05816 7. A food processor specified that the contents of a jar of salsa should weigh 14 ± 0.10 ounces net. A statistical quality control operation is set up, and the following data are obtained for one week: Sample No 1 - Monday 2 - Tuesday 3 - Wednesday 14.10 13.90 14.40 14.06 13.85 14.30 14.25 13.80 14.10 14.06 14.00 14.20 4 - Thursday 5 - Friday 13.95 14.05 14.10 13.90 14.00 13.95 14.15 14.60 Using regression analysis, analyze the effect of the day on the sample means for the weight of the contents of the salsa jars. a. b. c. d. Construct an x- bar chart based on these 5 samples. Construct an R-chart based on these 5 samples. What points, if any, have gone out of control? Discuss the results. Solution: This is similar in approach to the analysis of Table 8.3. See Excel file SMCh08 (see worksheet P7) for calculations. In the table below, we have rearranged the data so that days are shown as columns. First, we are looking for any effect related to which day of the week is considered. Day Total Weights x R 1 14.10 14.06 14.25 14.06 56.47 2 13.90 13.85 13.80 14.00 55.55 14.12 0.19 13.89 0.20 3 14.40 14.30 14.10 14.20 57.00 14.25 0.30 4 13.95 14.10 14.00 14.15 56.20 5 14.05 13.90 13.95 14.60 56.50 14.05 0.20 14.13 0.70 x = 14.09, R = 0.32. a. For the 3-sigma x -chart, A2 = 0.73 for n = 4, so UCL = x + A2 R = 14.09 + 0.73(0.32) = 14.32 and LCL = x – A2 R = 14.09 – 0.73(0.32) = 13.85. b. For the 3-sigma R-chart, D3 = 0 and D4 = 2.28 for n = 4, so UCL = D4R = 2.28(0.32) = 0.73 and LCL = D3R = 0(0.67) = 0. c. There are no points out of control. d. Even though there are no points out of control, we have only 5 data points and would expect about 5 out of 100 to be out of bounds. So far, so good, but we need more data. The linear regression can take various forms. In this case, we will arrange the daily sample averages of the contents of a jar of salsa for each day of the week in rank order. We were asked to look for “the effect of the day on the sample means.” Day 2 (Tues.) with rank order 1 has the lowest total weight at 55.55. Day 3 (Wed.) with rank order 5 has the highest total weight at 57.0. When we run our linear regression against the rank order values we get a line with a positive slope of 0.32. The correlation coefficient is high at 0.955. There is a day effect in these data, but too little data exists to bank on it. We should ask the company’s managers if it makes sense to them that Tuesday has the lowest averages and Wednesday the highest. 8. Use a data check sheet to track the Dow Jones average, regularly reported on the financial pages of most newspapers. Record the Dow Jones closing index value on a data check sheet every day for one week. Do an Ishikawa analysis, trying to develop hypotheses concerning what causes the Dow Jones index to move the way it does. Draw scatter diagrams to see if the hypothesized causal factors are related to the Dow Jones. Solution: The solution to this problem will vary based upon the days used and how well the student understands the factors affecting the Dow. Note that explanations often can be found for any series of numbers after the fact. These explanations have no predictive value. 9. In developing control lines for a “p” chart the total number of defective items from all samples is 3,000, the number of samples is 150, and the sample size is 50. What would be the standard deviation used in developing the control lines? Solution: The number of defectives divided by the number of samples (3000/150 = 20) gives us the average number of defectives in a sample. Since the sample size is 50, the p-bar value is 20 divided by 50 which equals 40 percent and that is the grand mean value of p in this example. The standard deviation is then the square root of (0.4)(0.6)/50 = 0.069. Three sigma is almost 0.21 which indicates too much variability in this process. 10. What are the values of UCL and LCL for the following data? Sample size = 100. The fraction defective is 0.06 and the standard deviation is 0.01. The desired confidence level is 95.00 percent. Give your answer and we will compare your answer with those of our friends and colleagues down under. Solution: UCL = p + 1.96s = 0.06 + 1.96(0.01) = 0.0796 and LCL = p – 1.96s = 0.06 – 1.96(0.01) = 0.0404. Note: Ignore the following part of this question. “Give your answer and we will compare your answer with those of our friends and colleagues down under.” 11. In a double sampling plan the two acceptance numbers are: c1 = 4 and c2 = 7. The number of defectives found in the first sample is 5. Therefore, a second sample is taken. What is the maximum number of defectives allowed in the second sample for the lot to be accepted? Solution: The maximum number of defectives allowed is 7 so only two more defectives can be permitted. 12. A manufacturing process is being monitored using a sample of size 50. The upper and lower control limits on percentage defectives p are 6.30 % (.063) and 4.80 % (.048) respectively. On a given day 6 defective items were found in the sample of 50. Is the process in control? Solution: Six defectives divided by the sample size of 50 (6/50 = 0.12) gives us the p value. It is very high (way above the maximum acceptable value of (0.063) which indicates that something bad has happened to the process. Investigators better get going. 13. In a single sampling plan, the manufacturer will prefer to have a large acceptance number c. Explain why you agree or disagree. Solution: The classical (greedy) manufacturer would like to have an acceptance number so high that nothing is ever rejected. The manufacturer (aware of sustainability) would prefer to catch an unexpected number of defectives as early as possible to protect the customers from misery. Thus, the smart manufacturer wants to find out when there are problems while avoiding costs incurred by statistical errors. That c number is not too high and not too low. P/OM is ideally able to derive what it should be set at. 14. Buyers prefer to have lower values of c. Is this statement True or False? Explain. Solution: In general, buyers will prefer lower values of c. However, the answer to this question requires more discussion. We will be direct and transparent in our response. On the face of it, the buyer would like to reject any lot that has some defectives. However, this buyer wants to be able to produce and ship without disruptions. Too low values of c will reject lots that are quite acceptable. Rejection will disrupt production for the buyer. The purchasing agent will be held accountable. The systems approach says that the buyers and producers should have the same goals in setting values of c. Therefore, they will agree on the selection of c.