section 15888-kitchen hoods

advertisement

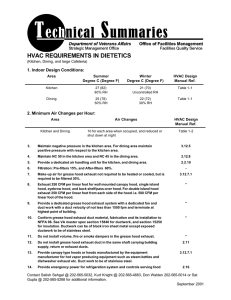

NOTE IF THE GUIDE SPECIFICATION CONVENTIONS PAGE DOES NOT APPEAR CLICK ON SHOW/HIDE ICON ON MENU BAR OR CHOOSE TOOLS ON MENU BAR, CLICK OPTIONS, VIEW TAB, UNDER FORMATTING MARKS, CHECK HIDDEN TEXT (delete this note before printing) SECTION 15888 KITCHEN HOODS PART 1 - GENERAL 1.1 SUMMARY 1.1.1. Section Includes: a. b. c. 1.1.2. 1.1.2.1. a. b. c. d. e. f. g. 1.2 1.2.1. a. b. c. d. e. f. g. h. i. j. Kitchen hoods Fire extinguishing equipment Fuel shutoff devices Related Sections: Specified elsewhere: Section 01042 - Mechanical, Refrigeration, Food Service Equipment and Electrical Coordination. Section 01400 - Quality Control. Section 01720 – Phased Turnover and Contract Closeout. Section 15010 –General Provisions - Mechanical. Section 15240 – Vibration Isolation and Seismic Controls. Section 15890 –Ductwork. Section 15990 – Testing, Adjusting, and Balancing. QUALITY CONTROL The following publications form a part of this specification to the extent they are applicable: Section 01400 – Quality Control. NSF labeled NFPA 96-Latest edition UL 710 listed as complete system NFPA 17A: Standard on Wet Chemical Extinguishing Systems IMC – Latest edition. UL 1570 and 1571 – Light Fixtures. NFPA70. SMACNA – “Kitchen Equipment Fabrication Guidelines”. SMACNA – “Duct Construction Standards”. <insert project name and location> June 2010 KITCHEN HOODS 15888-1 1.3 SUBMITTALS a. b. c. d. e. Submit under provisions of Section 01300. Shop Drawings showing detailed dimensions and capacities and layout of fire extinguishing system. Manufacturer's literature demonstrating compliance with this specification. Catalog cuts of all components. Operation and Maintenance data. PART 2 - PRODUCTS 2.1 ACCEPTABLE MANUFACTURERS a. (1) (2) (3) (4) (5) (6) Kitchen hoods: Greenheck Gaylord Seco Econovent Duo-Air Greasmaster 2.2 MATERIALS 2.2.1. Factory manufactured hoods: a. b. c. d. e. f. g. h. i. j. 2.2.2. a. b. c. d. Hoods shall be Type 1 for grease laden service unless noted. All parts of hood shall be 18 gauge type 304 stainless steel with #4 finish where exposed, #2B where concealed. Exposed welds shall be polished to #4 finish. UL listed stainless steel grease extractors (not filters). Mounting hardware. All joints shall be externally welded liquid-tight and ground smooth. Provide internal structural steel framework consisting of channels and angles at 3 ft. 0 in. O.C. maximum. Removable stainless steel drip pan. Matching fascia panels to close space between hood and ceiling. All welds shall be continuous, liquid-tight on exterior of hood. Light switch and 4 hour timer by Division 16. Provide enclosure in front of front left corner of hood. Fire suppression system: The exhaust hood, entire exhaust duct system and all grease producing appliances under the hood shall be protected against fire by the wet chemical fire suppression system. The system shall be designed and installed by a factory authorized distributor in accordance with Underwriter's Laboratories and Factory Mutual's listings and to conform to all local authorities having jurisdiction including NFPA #96. Provide automatic gas and electric fuel shutoff devices (manual reset) to the Plumbing and Electrical Contractors for all cooking appliances wired to stop appliances upon the actuation of the system. Nozzles located in the plenum and exhaust duct shall be of the spring loaded, self-closing type, capable of functioning with a heavy accumulation of grease. <insert project name and location> June 2010 KITCHEN HOODS 15888-2 e. Nozzles for deep fat fryer and other associated cooking equipment shall be either of the self-closing type or shall be fitted with nozzle covers as supplied by the manufacturer. Entire system shall be self-purging. The installer shall have regularly available contract maintenance of this type system plus 24 hour emergency service for same. He shall furnish as a part of this work a maintenance contract for one year from the date of Substantial Completion with inspection at least once each 6 months and 24 hour emergency service when required. All exposed piping and devices shall be chrome plated, chrome sleeved or stainless steel. Remote manual release at exit door (10 feet minimum from exhaust system, 4 ft. 6 in. AFF). Furnish all required wiring to connect fire extinguishing system to building fire alarm system. All wiring or cabling shall be concealed. f. g. h. i. j. k. PART 3 - EXECUTION 3.1 PREPARATION a. Field verify all dimensions. 3.2 INSTALLATION a. (1) (2) b. c. d. e. f. g. Electrical contractor will provide all field wiring to do the following (upon fire extinguisher system actuation): Disconnect power and fuel to all appliances under hood. Signal fire alarm system Electrical contractor will provide power wiring to lights. He will also furnish and install wall mounted light switch. Section 15888 contractor shall do all other electrical wiring required, if any. Coordinate work with that of the kitchen equipment installer. Fabricate in accord with “Kitchen Equipment Fabrication Guidelines” and “Duct Construction Standards” unless specified in Section 05500. Provide seismic restraints. Coordinate with Division 5 “Metal Fabrications” for stainless steel wall panels required behind equipment item 1D09 chicken rotisserie. **** A/E Edit for Bakery Oven **** (h. Provide fire protection for the Bakery oven integral hood.) END OF SECTION <insert project name and location> June 2010 KITCHEN HOODS 15888-3