TLC - Chemistry With BT

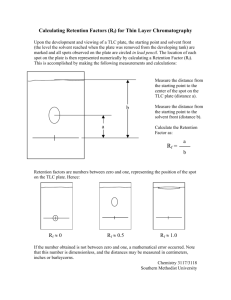

advertisement

CH 323 L B. Terem THIN LAYER CHROMATOGRAPHY –TLC Principles: Chromatography is an analytical (sometimes preparative) technique used in the separation and identification of mixtures. Numerous types of chromatographic techniques, one of which is TLC, are routinely carried out in organic labs. There are three principal components in most chromatography experiments: Stationary Phase (SP)- Interacts differently (through non-covalent attractive forces) with each constituent of the mixture. Mobile Phase (MP)- Carries the mixture through the stationary phase –usually a solvent or a solvent mixture (can also be a gas with certain techniques). Sample- usually dissolved in a solvent same as or compatible with the mobile phase. TLC Plates: usually a sheet of glass, metal, or plastic which is coated with a thin layer of a solid adsorbent (usually silica or alumina) –the stationary phase. A small amount of the mixture to be analyzed is “spotted” near the bottom of this plate. The TLC plate is then placed in a shallow pool of a solvent in a developing chamber so that only the very bottom of the plate is in the liquid. This liquid, or the eluent, is the mobile phase, and it slowly rises up the TLC plate by capillary action. As the solvent moves past the spot that was applied, an equilibrium is established for each component of the mixture between the molecules of that component which are adsorbed on the solid and the molecules which are in solution. In principle, the components will differ in solubility and in the strength of their adsorption to the adsorbent and some components will be carried farther up the plate than others. When the solvent has reached the top of the plate, the plate is removed from the developing chamber, dried, and the separated components of the mixture are visualized. If the compounds are colored, visualization is straightforward. Usually the compounds are not colored, so a UV lamp is used to visualize the plates. (The plate itself contains a “fluor” which fluoresces everywhere except where an organic compound is on the plate.) TLC Adsorbent (Stationary Phase): In this lab the adsorbent is silica gel (SiO2). The plates are aluminum-backed and you can cut them to size with scissors. The adsorbent is impregnated with a “fluor”, zinc sulfide. The fluor enables most organic compounds to be visualized when the plate is held under a UV lamp. In some circumstances, other visualization methods are used. The strength with which an organic compound binds to an adsorbent depends on the strength of the dipole-dipole interactions between the adsorbent and the materials to be separated. Highly polar molecules interact fairly strongly with the polar Si—O bonds of these adsorbents and will tend to stick or adsorb onto the fine particles of the adsorbent, while weakly polar molecules are held less tightly. Weakly polar molecules, thus, generally tend to move through the adsorbent more rapidly than the polar species. The Retention (retardation) Factor, Rf : Rf, is defined as the distance traveled by the compound divided by the distance traveled by the solvent. CH 323 L B. Terem For example, if a compound travels 2.1 cm and the solvent front travels 2.8 cm, the Rf is 0.75: The Rf for a compound is a constant from one experiment to the next only if the chromatography conditions below are also constant: solvent system adsorbent thickness of the adsorbent amount of material spotted temperature Since these factors are difficult to keep constant from experiment to experiment, relative Rf values are generally considered. “Relative Rf” means that the values are reported relative to a standard, or it means that you compare the Rf values of compounds run on the same plate at the same time. The larger an Rf of a compound, the larger the distance it travels on the TLC plate. When comparing two different compounds run under identical chromatography conditions, the compound with the larger Rf is less polar because it interacts less strongly with the polar adsorbent on the TLC plate. Conversely, if you know the structures of the compounds in a mixture, you can predict that a compound of low polarity will have a larger Rf value than a polar compound run on the same plate. Procedure: The developing container for TLC can be a specially designed chamber, or a beaker with an aluminum foil on the top: -2- CH 323 L B. Terem Pour solvent into the beaker to a depth of just less than 0.5 cm. To aid in the saturation of the TLC chamber with solvent vapors, line part of the inside of the beaker with filter paper Cover the beaker with a watch glass (or aluminum foil), swirl it gently, and allow it to stand while you prepare your TLC plate -3- CH 323 L B. Terem Preparation of the TLC plate: After the plates are cut to the appropriate size (this will be done by your instructor) draw a line across the plate at 0.5 cm from the bottom using a pencil . This is the “origin”, the line on which you will “spot” the plate. Spotting the TLC plate: The sample to be analyzed is added to the plate in a process called "spotting". Dissolve about 1 mg of your sample in 10 drops of acetone in a vial. Label the vial with the name of the substance. Take a capillary tube (these will be supplied to you, but you will also be instructed how to “draw” a capillary tube from a disposable pipette using a Bunsen burner) and dip it into the solution of the sample to be spotted. Then, touch the end of the capillary tube gently to the adsorbent on the origin in the place which you have marked for the sample. Let all of the contents of the capillary tube run onto the plate. Be careful not to disturb the coating of adsorbent. Here is a TLC plate spotted, and ready to be developed -4- CH 323 L B. Terem Developing the Plate: Place the prepared TLC plate in the developing beaker, cover the beaker with the watch glass, and leave it undisturbed on your bench top. Run until the solvent is about half a centimeter below the top of the plate (see photos below). place the TLC plate in the developing container - make sure the solvent is not too deep . In this photo, it is about 3/4 of the way up the plate. The solvent will rise up the TLC plate by capillary action. In this photo, it is not quite halfway up the plate The solvent front is about 0.5 cm below the top of the plate. It is now ready to be removed. -5- Remove the plate from the beaker. CH 323 L B. Terem Quickly mark a line across the plate at the solvent front with a pencil. Allow the solvent to evaporate completely from the plate. If the spots are colored, simply mark them with a pencil. Visualizing the spots: If your samples are colored, mark them before they fade by circling them lightly with a pencil (see photo above). Most samples are not colored and need to be visualized with a UV lamp. Hold a UV lamp over the plate and mark any spots which you see lightly with a pencil. Beware! UV light is damaging both to your eyes and to your skin! Make sure you are wearing your goggles and do not look directly into the lamp. Protect your skin by wearing gloves. This is a UV lamp. here are two proper sized spots, viewed under a UV lamp You would circle these while viewing them -6- CH 323 L B. Terem Compounds to be tested: There are three samples which you need to test in connection with the recent synthesis and purification experiment you have carried out: Aniline (starting material) and acetanilide (charcoal treated and untreated). Note that dipole properties of aniline and acetanilide are somewhat different. Therefore, you may need to use different solvent systems as mobile phase. You will decide on the optimum solvent system for your purpose. The choice of mobile phase is one of the most important tasks in tlc analysis. You will use a mixed solvent system (as the MP). We will start with hexane/ethyl acetate, 80/20, for this purpose, but vary the concentrations until we get an rf value of about 0.5. Ideally, we would like to spot all three compounds on the same tlc plate so that we could detect any unreacted starting material or impurities in the product(s). This exercise would give us an indication about the purity of the product. We will try various concentrations of the solvent mixture, so that all rf values are roughly between 0.2 to 0.8. We gratefully acknowledge University of Colorado, Boulder, Chemistry Department, for the material used in this handout. -7-