KREW Quality Assurance Project Plan

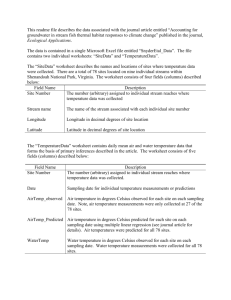

advertisement