curriculum proposal transmittal

advertisement

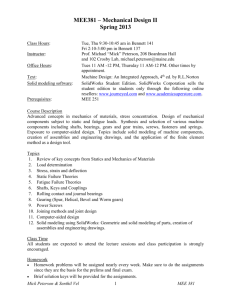

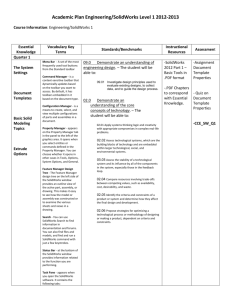

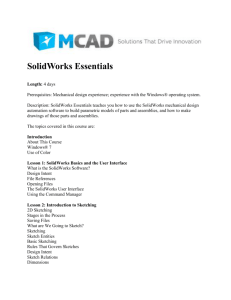

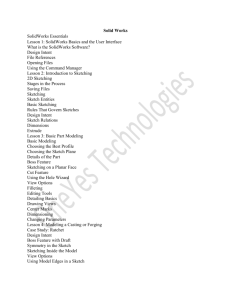

ST. PETERSBURG COLLEGE APPROVED COURSE OUTLINE ETD 2368C Prefix Number ADVANCED SOLIDWORKS Course Title 3 Cr Hrs Was 2367C; # changed by State F/R effective 20081(0400) A. Course Description: Prerequisite: ETD 2364C or permission of instructor. This course presents the advanced use of new designing techniques and capabilities of solid modeling using the SolidWorks software, including the integration of the advanced parametric modeling and drawing tools for SolidWorks. The course topics to be covered include advanced 3D sketching, advanced work planes, advanced assembly construction, bottom up and top down, part configuration, Solid Works Tool Box applications, concept of mold design, and creation of sheet metal parts and assemblies. 77 contact hours. B. Major Learning Outcomes: 1. The student will understand the advanced functionality of SolidWorks software. 2. The student will apply knowledge of advanced 3D sketching techniques. 3. The student will understand all phases of work planes in SolidWorks. 4. The student will understand how parts and assemblies work in an advanced application in SolidWorks. 5. The student will understand and apply advanced techniques in drawing relations. 6. The student will apply the appropriate techniques using SolidWorks parts Configuration and Toolbox. 7. The student will understand basic drawing concepts of Mold Design in SolidWorks. 8. The student will understand the techniques to create sheet metal drawings. C. Course Objectives Stated in Performance Terms: 1. The student will understand the advanced functionality of SolidWorks Software by: a. creating and executing advanced templates. b. applying attributes to titleblocks. c. creating multiple templates for parts, assemblies, and drawings. d. resizing titleblocks for multiple size drawings. 2. The student will apply knowledge of advanced 3D sketching techniques by: a. creating multiple sketches using the sketch feature. b. applying and editing Dimensions features in a sketch. c. describing the characteristics of converting multiple sketches into construction lines. d. creating the desired sketch to document the design procedures. e. performing analyses on the computer model and refining the sketch design as needed. 3. The student will understand all phases of work planes in SolidWorks by: a. creating and modifying a work plane. b. performing advanced extrusion using multiple work planes. c. defining the interrelation between work planes on multiple levels. d. creating multiple work planes by copy, offset, and editing from the design tree. 4. The student will understand how parts and assemblies work in an advanced application in SolidWorks by: a. defining and describing the basics of assemblies. b. creating and modifying bottom up assemblies. c. modifying and inserting of parts to create Top-Down assemblies. d. creating an Assembly drawing. 5. The student will understand the advanced techniques in drawing relations by: a. applying basic relations to multiple features in a part drawing. b. identifying the status related to Dangling, Satisfied, Over Defining or Not Solved of the selected relation. c. editing relations through the Property Manager. d. modifying an assembly using the mating relation through the design intent. 6. The student will apply the appropriate techniques using SolidWorks parts Configuration and Toolbox by: a. defining parts of an assembly in a directory. b. modifying Toolbox part definitions to customize standard Toolbox parts. c. verifying that Toolbox and Toolbox Browser are set up and running. d. creating multiple configurations of an individual part. 7. The student will understand basic drawing concepts of Mold Design in SolidWorks by: a. applying basic drawing concepts to molded parts. b. creating detailed molds or die cavities of parts and assemblies. c. deriving component parts from the edited mold base. d. discussing and describing the problems created by cut derived parts to make the two halves of a mold. 8. The student will understand the techniques to create sheet metal drawings by: a. applying basic extrusion to a thin feature. b. applying insert bends onto a part. c. modifying and editing a sheet metal part by rolling back a design. d. creating section, detail, and auxiliary views of a sheet metal part. e. creating insert parts for a sheet metal assembly. D. Criteria Performance Standards: Upon successful completion of the course the student will, with a minimum of 70% accuracy, demonstrate mastery of each of the above stated objectives through classroom measures developed by individual course instructors. C&I 2/24/04, BOT 3/22/04, Effective 20033. Was 2367C; Number and Prereq # changed by F/R effective 20081(0400). 3 Year Review 2007.