an interference fit in bascule bridges

advertisement

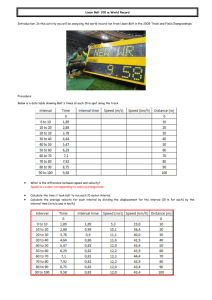

HUB-GIRDER BOLT ASSEMBLY WITHOUT AN INTERFERENCE FIT IN BASCULE BRIDGES Dr. Glen Besterfield, Principal Investigator Dr. Autar Kaw, Co-Principal Investigator Dr. Daniel Hess, Co-Principal Investigator Dr. Niranjan Pai, Research Associate Progress Report for Period: October 16, 2002 – March 10, 2003 submitted to Florida Department of Transportation Tallahassee, FL William Nickas, P.E. Project Monitor Contract Monitor Contract Number BC353 RPWO #35 March 13, 2003 Progress Report HUB-GIRDER BOLT ASSEMBLY WITHOUT AN INTERFERENCE FIT IN BASCULE BRIDGES Executive Summary This report outlines the procedure for design of bascule bridge hub-girder assembly without an interference fit. The interference fit between the girder and the hub is replaced with a slip-critical bolted joint. The procedure involves identifying the different loads that affect the requirement for bolt tension in the hub-girder joint and subsequently providing sufficient number of bolts to meet this requirement. The joint analysis considers shear loads, torsion, axial loads and bending moments. In addition, the bolt tension computation also accounts for friction force developed at the interference fit between the backing ring and the hub. Two software tools, one for design and other for analysis of hub-girder joint developed using the above procedure are described. The impact of the proposed design is compared to existing designs with interference fits. Finally, future tasks towards completion of the project are identified. 2 1. Introduction Failures of trunnion-hub assembly during shrink-fitting with the girder prompted the Florida DOT to seek alternative means to assemble the trunnion-hub assembly to the girder. Figure 1 shows a typical hub design currently used [1]. The web of the bridge girder is assembled between the hub and the backing ring. While current designs utilize an FN2 interference fit between the girder and the hub, the design proposed here replaces this with a slip critical joint with high strength bolts. The current practice of using interference fit between the backing ring and the hub is retained. Figure 1 Trunnion Hub Design Guide [1]. This report contains a summary of the design procedure. Loading that influences the design (see Figure 2) are shear (V), torsion (T), axial load (P), and bending moment (M). In addition, the influence of friction force developed due to the interference fit between the hub and the backing ring is also considered. Results from finite element 3 analysis are used to illustrate the importance of considering the interference fit friction force in the design using a representative bridge (Royal Park Bridge in Palm Beach, FL). V Friction at backing ring Interference fit T P Figure 2 M General loading on Hub-Girder Assembly. Based on the above procedure, two design tools have been developed for use with Microsoft Excel using the Visual Basic for Applications (VBA) feature. Feature of these tools are summarized in the latter part of the report. Finally, tasks for the final part of the project are identified. 2. Design Procedure This section summarizes the design procedure for designing a hub-girder assembly without an interference fit by forming a slip critical bolted connection between the hub and the girder. The objective of the design process is to determine the bolt diameter, grade, number of bolts and their placement on the hub to obtain a slip critical joint between the girder and the hub. The design is checked for the following items - 4 a. Slip resistance of the joint b. Shear strength of fastener (in bearing) c. Tensile strength of fastener d. Bearing strengths of members The specifics of the different loads shown in Figure 2 are considered next. 2.1 Loading 2.1.1 Shear The primary load resisted by the hub-girder joint is the load transferred from the girder to the trunnion bearings. This is obtained from determining the controlling service load case combinations of dead load, live load, impact, wind etc. as specified by AASHTO [2] (See Table 3.4.1-1 in Ref. [2], Section 2 in Ref. [3], Section 6.8.1.3.2 in Ref. [3]). 2.1.2 Torsion Torsion that must be resisted by the hub-girder joints are a result of the friction at the trunnion bearings. This is specified as 6% of the maximum radial load for bronze bushing (see Section 6.7.7.1.3 [3]) acting at the circumference of the trunnion. Earlier AASHTO specifications [4] required the loading acting at the circumference to be 1/5 the maximum radial load for bearings with bronze bushing and 1/100 the maximum radial load for anti-friction bearings (see Section 2.6.17 in Ref. [4]). 2.1.3 Axial The axial load acting on the joint is specified as 15% of the maximum bearing reaction per Section 6.8.1.3.2 in Ref. [3]. 2.1.4 Bending Moment The hub-girder assembly is subjected to small bending moment that can be neglected in general design. The bending moment is a function of the member stiffness, and in cases where the moment has been determined, for example using finite element models, it may be included in the analysis if desired. 5 2.2 Design for Slip Resistance Loads specified above must be resisted by friction force developed between the hub, girder and the backing plate (see Figure 1) by the bolted joint. The resistance provided by a slip critical joint is given by following (eqn. 6.13.2.8-1, Ref. [2]). Rn=Kh Ks Ns Pt (1) where Rn = the nominal slip resistance Kh = the hole size factor (1 for standard holes) Ks = the surface condition factor (either 0.33 or 0.5) Ns = the number of slip planes per bolt (two for hub-girder-backing plate assembly) Pt = the minimum required bolt tension (preload). The design task is to determine Pt and specify the bolt size and grade to develop the bolt tension. The loads that act on the assembly and control the required tension were discussed earlier. In addition, the bolt tension must overcome friction developed at the interference fit between the backing ring and the hub, which is assembled before the bolts are tightened (see Figure 1). The expression for Pt required is Pt= (Pv+Ptor+Pa+Pbm+Pbpf) (2) where Pv = the bolt tension required to resist shear load, V Ptor = the bolt tension required to resist the torsion, T Pa = the bolt tension required to resist the axial load, P Pbm = the bolt tension required to resist bending moment Pbpf = the bolt tension required to overcome the friction forces due to interference fit between the backing ring and the hub. 6 2.2.1 Shear The bolt tension required to resist shear, V, may be obtained by rearranging equation 1. Factored loads must be used to determine PV as specified in the AASHTO LRFD code. Pv V K h K s Ns (3) 2.2.2 Torsion Bolt Tension requirement to resist torsion can be estimated from the expression for frictional moment developed on an annular disk [5] to be Ptor 2 3 T (R out R in2 ) 2 K s K h N s (R 3out R 3in ) (4) where Rout = hub outer radius Rin = hub inner radius This equation assumes a uniform distribution of the pressure due to bolt tension Ptor, In the actual assembly, the bolt pressures is located mainly on the outer parts of the hub, therefore the actual frictional resistance developed is more than predicted by the above equation (i.e., the above equation is conservative). The final design can be refined using the actual distribution of bolts using the equation below T n b 1 K s K h N s Ptn rbn n (5) where nb is the number of bolts Ptn is the part of bolt tension for resisting torsion in bolt n rbn is the radius of bolt n 2.2.3 Axial Load Bolt tension required to resist axial loads can be obtained based on eq. 6.13.2.11.3 in Ref. [3] as 7 Pa=P (6) 2.2.4 Bending Moments Bending moments acting on the bolted assembly are generally not significant. If desired, it may be included in the analysis using the following expression (Section 7-11, Ref [6]). Pbm M rm (7) where M = the bending moment acting on the joint rm = the distance from the bending axis passing through the center of the trunnion to the location of resultant of bolt tension in half the hub 2.2.4 Friction at the backing collar Based on current practice, the typical assembly process of the trunnion-hub to girder is expected to be as shown in Figure 3. During assembly, the girder is laid horizontally (with the axis of the trunnion-hub vertical) on several supports. First, the backing ring is heated until sufficient clearance is obtained and supported below the girder. Next, the trunnion-hub assembly is lowered into the girder and the backing ring allowed to cool and form an interference fit between the hub and the backing ring. Finally, bolt holes are drilled into this assembly, followed by bolt tensioning. As a result of the above sequence of assembly, when the backing ring cools to form the interference fit with the hub, significant contact pressures are developed due to the shrink fit. The friction developed between the backing ring and the hub resists the bolt tension, and therefore must be included as one of the loads that must be overcome to develop sufficient normal force between the faying surfaces of the hub-girder and girderbacking plate. 8 Trunnion Hub Bolts Girder Backing Ring STEP 2 - BOLT HOLES DRILLED THROUGH HUB, GRIDER, BACKING RING & ASSEMBLY IS BOLTED . STEP 1 - TRUNNION - HUB ASSEMBLY PLACED INTO GIRDER & SHRINK -FIT WITH BACKING RING Figure 3 Expected Assembly procedure of Trunnion-Hub to Girder. To estimate the magnitude of frictional resistance expected due to the above process, an axisymmetric finite element model of the trunnion-hub-girder-backing plate assembly was developed. The model is shown in Figure 4. To simplify the analysis, the gusset plates used to stiffen the hub are not modeled and the trunnion-hub are modeled as a single entity since they are assembled prior to the hub-girder assembly. The other parts modeled are the girder and the backing plate. Contact elements are used to determine the contact pressures and friction forces developed during the assembly. The assembly is carried out in two steps. First, an interference fit is formed between the backing plate and the hub. This is followed by application of equal and opposite loads on the outer surfaces of the hub and the backing plate to simulate bolt tension. The part of the load resisted due to the friction force at the backing plate is determined. The results of the finite element analysis for a representative bridge (Royal Park Bridge, [8]), it was found that this friction accounts for about 7% of the total bolt tension applied. Also, this influences the contact pressure distribution between the hub, girder and the backing plate, (see Figure 5), which in turn affects the resulting frictional torsion resistance since it is a function of the radius at which the friction force acts. 9 1 ELEMENTS MAR 13 2003 08:58:07 Y Z Trunnion-Hub Assembly X Hub Flange Girder Backing Ring 1 ELEMENT SOLUTION STEP=3 SUB =10 TIME=2 CONTPRES (NOAVG) DMX =.014978 SMX =5484 MAR 13 2003 08:57:31 Figure 4. Finite element Mesh for Axisymmetric Hub-Girder Assembly. Y Z X MN MX 0 609.363 1219 1828 2437 3047 3656 4266 4875 5484 Figure 5. Contact pressures from finite element results Analytically, the friction force an be conservatively estimated using the following equation Pbpf bp p i A bpc (8) where bp = the coefficient of friction between the backing ring and the trunnion Abpc = the area of the backing collar in contact with trunnion 10 pi = the pressure due to interference fit given by the following equation based on axisymmetric analysis of thick cylinders [7]. pi E(rbo2 rt2 ) 2rt rbo2 (9) where E = the modulus of elasticity = the interference rt = the hub outer radius (also inner radius of the backing ring) rbo = the backing ring outer radius 2.3 Bolt Sizing For a given set of loads and dimensions, the required bolt tension, PT can be determined using the above equations. Based on the PT requirements size of standards bolts used for slip critical joints may be determined. These are then placed in different number of bolt circles (generally 2). The design can be refined using equation 5 and additional checks listed below can be performed to finalize the design. 2.4 Additional Checks Once the bolts are sized based on slip-critical connection, other checks maybe undertaken, which check the bearing strength of the different members. These are as follows. 2.4.1 Shear strength of fastener (in bearing) Considering the case where threads are excluded from shear plane, (Sections 6.13.2.7, Ref. [2]), the shear strength of a fastener is given by Rn=0.48 Ab Fub Ns (10) where Rn = nominal resistance of the bolt Ab = area of the bolt corresponding to nominal diameter 11 Fub = specified minimum tensile strength of the bolt (see 6.4.3 in Ref. [2]) Ns = Number of slip planes. 2.4.2 Tensile strength of fastener For combined shear and tension from (Section 6.13.2.11, Ref [2]), the tensile strength of a faster is given by Tn=0.76 AbFub (11) where Tn = nominal tensile resistance of bolt 2.4.3 Bearing strengths of members Bolted members of the assembly (hub flange, girder and backing plate) are checked for bearing strength as follows (Section 6.13.2.9, Ref. [2]) Rn=2.4d t Fu (12) where d = nominal bolt diameter t = thickness of connected material (i.e., hub flange, girder or backing plate) Fu = tensile strength of the connected material Lc = clear distance between holes, or between holes and end of the member in the direction of the bearing force 2.5 Detailing considerations Changes in the span configurations while opening and closing, causes the loads to change and corresponding elastic deformations to change (see Figure 6). The change in elastic deformation at the faying surfaces alter the frictional resistances locally in bolted joint. In light of possibility of small amounts of localized slip, it recommended that the bolts used be turned bolts with small clearances fit between the bolt and the hole. EC Driver and Associates utilized an LC6 clearance fit to minimize the amount of slip [9] for 17th 12 Street Causeway Bridge, which utilized a hub-girder assembly without an interference fit. It is possible that use of shear dowels installed with an interference fit between hub-girder and backing plate can minimize any slip and supplement the frictional force resistance as required. Note that most of the load will be carried by friction with dowels merely minimizing the possibility of slip. Dead Load Tensile Elastic Deformation Compressive Elastic deformation Dead Load Moment Tensile Elastic Deformation Compressive Elastic deformation Figure 6 Change in elastic deformations due to span movement. 3. Design Tools The above procedure has been implement in two Microsoft Excel spreadsheet that utilize typical Excel formula features, and also advanced features provided by Visual Basic for Application (VBA). The first spreadsheet maybe used for obtaining different bolting configurations once the pertinent information is provided. The second spreadsheet provide a means to check bolting configurations for the specified loading. spreadsheet maybe downloaded along with help files from the following URL http://www.eng.usf.edu/~besterfield/bascule/THG_Design_No_Interference.xls 13 The 3.1 Design Given the loading, geometry and material of the hub, girder and backing plate, it is possible to arrive at different bolted configurations (different bolt size, grade, bolt circles) that meet the design requirements. 3.2 Analysis Given the loading, geometry and material of the hub, girder and backing plate, and a given bolt pattern, the design is checked for all the different failures modes mentioned above. 4. Impact of using slip critical connection As one might expect, the bolting requirements for a joint with slip critical connection are more than the current practice of using interference fit. It is common practice to design the bolted joint in assemblies with interference fit for shear strength and to resist the torsion load in bearing. Typical values of allowable shear loads in comparison to the tensile strength of fasteners are 0.48 (where threads excluded from the shear plane) and 0.38 (when threads are included in the shear plane). In comparison, when using a slip critical connection, using 0.33 or 0.5 as the surface factor, and 0.7 as the minimum tension required, each bolt provides resistance of approximately 0.23-0.35 times the tensile strength. In addition, the friction at the backing force increases the demand by about 7%. All these factors means that a slip critical bolted joint would require nearly twice as many bolts as a joint that uses an interference fit. This in turn requires larger hub diameters and twice as many bolt circles as commonly found (typically two instead of one). 5. Future Work The final phase of the project would involve analyzing several existing bridges using the above procedures. The designs would be verified using simplified finite element models of the bridges. Although shear lag is not likely to be an important consideration in a slip critical joints, its influence can be ascertained using the finite element model. Other uses of the model include determining the effect of different loading on the frictional 14 resistance (such as temperature loading and span opening and closing). As noted earlier, changes in loading cause change in elastic deformations at the joint and can temporarily alter the frictional resistance at the joint leading to small amounts of slip. Finally, the model will be used to estimate the influence of tightening sequence on the resulting contact pressure distribution at the faying surfaces and also on any bolt relaxation as the adjacent bolts are tightened. 6. References 1. SDO. Structures Design Guidelines for Load and Resistance Factor Design. Florida Department of Transportation Structures Design Office, Tallahassee, FL, 2002. 2. AASHTO. LRFD Bridge Design Specification, 2nd Edition, American Association of State Highway and Transportation Officials, Washington, D.C., 1998. 3. AASHTO. LRFD Movable Highway Bridge Design Specifications, 1st Edition, American Association of State Highway and Transportation Officials, Washington, D.C., 2000. 4. AASHTO. Standard Specification for Movable Highway Bridges, American Association of State Highway and Transportation Officials, Washington, D.C., 1988. 5. Hibbler, R.C. Engineering Mechanics: Statics, 9th Edition, Prentice Hall, NJ, 2000. 6. AISC. Manual of Steel Construction: Load and Resistance Factor Design. American Institute of Steel Construction, 3rd Edition, Chicago, IL, 2001. 7. Ugural, A. and S. K. Fenster. Advanced Strength and Applied Elasticity, 3rd Edition, Prentice Hall, New Jersey, 1995. 8. EC Driver. Final Design Plans for royal Park Replacement Bridge in Palm Beach (Nos. 930506 & 930507), EC Driver & Associates, Tampa, FL, 2000. 9. EC Driver. Final Design Plans for 17th Street Causeway Bridge in Miami, EC Driver & Associates, Tampa, FL, 1997. 15