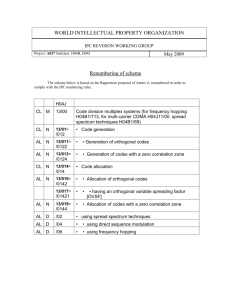

Annex to the Polish comments on ISO/DIS 286

advertisement

ISO/TC 213 N 560-11 (Poland) Document: DIS 286-1 Date: 2003-04-29 1 2 (3) 4 5 (6) (7) MB1 Clause No./ Subclause No./ Annex (e.g. 3.1) Paragraph/ Figure/Table/ Note (e.g. Table 1) Type of comment2 Comment (justification for change) by the MB Proposed change by the MB Secretariat observations on each comment submitted PL 3.2.8 PL 3.2.8 PL 3.2.8 PL te See our comment on 3.2.8.1. Modify the definition: “difference between the upper and lower limits of size”. NOTE 2 te The term “tolerance zone” is not used in this standard. “Tolerance zone” should be replaced by “tolerance interval”. NOTE 3 te See our comment on 3.2.8.1. Modify the text: “For the calculation limits of size can be replaced by the upper limit deviation and the lower limit deviation”. 3.2.8.1 te/ge It seems that “tolerance limit” means here exactly the same as “limit of size” according to 3.2.4. The term “tolerance limit” was not used in CD 286-1. It should be noted that the standard deals only with sizes (see Scope), not with “characteristics” in general. Delete 3.2.8.1, replace in the whole document “tolerance limit” by “limit of size”. PL 3.3.2, 3.3.2.1, 3.3.2.2 te The definitions are incomplete. Interference is the absolute value of the hole and shaft sizes. See our analysis of problems related to fit and its characteristics given in an annex. Add “absolute value of …” in definitions of interference. PL 3.3.3 te The definition of fit is not clear because the term “assembly” is ambiguous. For engineers it means a set of machine parts mounted together. “Assembly of features”, mentioned here, has not been defined and this term can confuse users of the standard. A fit is not just an assembly of two machine parts (e.g., a bush and a mandrel) but it is a property (characteristic) of such assembly. Therefore, the definition in the CD was much better. The NOTE is very important and this pre-condition should be also considered in Annex B. Adopt the definition according to CD 286-1, 3.3.3. (NOTE is OK!) PL 3.3.3.4 te The calculation of the span explained here is based on two different meanings of interference (see our analysis annexed). The result of calculating the span of an interference fit, according to the given rule, is wrong: see example in B.2, where – to get the correct result – another formula was used (minimum interference – maximum interference). The 2nd sentence should read: “The span of a transition fit is the sum of the maximum clearance and the maximum interference”. NOTE 2 1 MB = Member body (enter the ISO 3166 two-letter country code, e.g. CN for China; comments from the ISO/CS editing unit are identified by **) 2 Type of comment: ge = general te = technical ed = editorial NOTE Columns 1, 2, 4, 5 are compulsory. page 1 of 3 ISO electronic balloting commenting template/version 2001-10 ISO/TC 213 N 560-11 (Poland) Document: DIS 286-1 Date: 2003-04-29 1 2 (3) 4 5 (6) (7) MB1 Clause No./ Subclause No./ Annex (e.g. 3.1) Paragraph/ Figure/Table/ Note (e.g. Table 1) Type of comment2 Comment (justification for change) by the MB Proposed change by the MB Secretariat observations on each comment submitted PL 4.3 te In technical documentation the values of limit deviations are usually expressed in mm. Add information, e.g.: “In practical applications limit deviations should be given in millimetres”. PL 5.1 te Adoption of the pre-condition mentioned in 3.3.3 allows for performing calculations of clearances and interferences without using limits of sizes, but basing only on limit deviations. Therefore, an additional subclause on calculation of fits would be useful. Add: 5.1.3 Calculation of fits If the nominal sizes of the hole and the shaft are identical (see 3.3.3), in calculations of clearances and interferences the limit deviations instead of the limits of sizes can be applied.” PL 5.1.1 EXAMPLE ed Error in the 2nd designation of the fit. PL 5.2.1 1st para ed The term “element” does not seem to be correct here. Instead of “element” use e.g. “factor”. PL A.2 2nd ed The modifier E should be written in a circle (not in parentheses). Correct the code: 30H6 PL B.1 te/ge See the comment concerning calculation of fits (5.1, new subclause 5.1.3). Modify all calculations basing them on limit deviations (not using limits of sizes). E.g., in EXAMPLE 1: PL B.1 PL B.2 para EXAMPLE 1, 4th line Correct the code; it shall read: 52 H7 g6 lower hole deviation – upper shaft deviation = 0 – (–0,025) = 0,025 mm upper hole deviation – lower shaft deviation = +0,035 – (–0,025) = 0,089 mm ed Spelling error lower te According to the definition of span (see 3.3.3.4), span of a fit is arithmetic sum of the size tolerances of hole and shaft – and this definition, preferably, should be applied here. Change the calculations, e.g. for the clearance fit: 0,039 mm + 0,025 mm = 0,064 mm. If another way of span calculation is to be presented (not based on definition!), in the cases of transient and interference fits the calculations should read: 0,008 mm + 0,033 mm = 0,041 mm 0,059 mm – 0,018 mm = 0,041 mm. 1 MB = Member body (enter the ISO 3166 two-letter country code, e.g. CN for China; comments from the ISO/CS editing unit are identified by **) 2 Type of comment: ge = general te = technical ed = editorial NOTE Columns 1, 2, 4, 5 are compulsory. page 2 of 3 ISO electronic balloting commenting template/version 2001-10 ISO/TC 213 N 560-11 (Poland) Document: DIS 286-1 Date: 2003-04-29 1 2 (3) 4 5 (6) (7) MB1 Clause No./ Subclause No./ Annex (e.g. 3.1) Paragraph/ Figure/Table/ Note (e.g. Table 1) Type of comment2 Comment (justification for change) by the MB Proposed change by the MB Secretariat observations on each comment submitted Annex to the Polish comments on ISO/DIS 286-1 (analysis prepared Prof. S. Bialas, ISO/TC 213/WG 12 member) There is no doubt that the method of calculating clearances and interferences presented in Annex B is clear and correct. But if we consider subclause 3.3 (in particular – 3.3.2) and try to do the same calculations as e.g. in Example 3 in B.1, but using the relationships given directly in 3.3.2, the results obtained will be quite different than in B.1. According to 3.3.2.1: maximum interference = – 0,059 mm minimum interference = – 0,018 mm – end of calculation! According to B.1: Interference of a given fit is calculated in two steps: 1. Computing the differences of limit sizes of hole and shaft. 2. Interpreting the results – taking their absolute values: maximum interference = 0,059 mm minimum interference = 0,018 mm Therefore two different “interferences” can be distinguished: according to 3.3.2.1, a quantity of negative value; let it be named interference* according to B.1, a quantity of positive value; let it be named interference**. If interference* is considered, the following contradictions can be observed: The terms “maximum interference” (3.3.2.2) and “minimum interference” (3.3.3.1) are illogical, because the first is lesser than the second (–0,059 mm < –0,018 mm); The span of an interference fit (3.3.3.4, NOTE 2) is negative: –0,059 mm – (–0,018 mm) = – 0,041 mm (note that in the case of transient fit the result will be correct). In B.2 another formula was used; to get the correct result, the span was calculated as difference of minimum interference* – maximum interference*. So it is obvious that in fact interference* is not the interference yet. It is only a kind of “semi-product” and the final quantity is interference**, after taking the absolute value of interference*. Conclusion – the correct definitions In 3.3.2: the absolute value of the difference between … In 3.3.2.1: in an interference fit, the absolute value of the difference between … In 3.3.2.2: in an interference or transition fit, the absolute value of the difference between … In 3.3.3.4, NOTE 2: The span of a transition fit is the sum of the maximum clearance and the maximum interference. 1 MB = Member body (enter the ISO 3166 two-letter country code, e.g. CN for China; comments from the ISO/CS editing unit are identified by **) 2 Type of comment: ge = general te = technical ed = editorial NOTE Columns 1, 2, 4, 5 are compulsory. page 3 of 3 ISO electronic balloting commenting template/version 2001-10