PBL Session 1: Revenue Cycle (50 marks)

advertisement

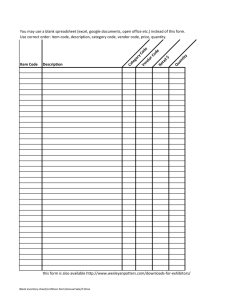

CASE 1: EXPENDITURE CYCLE Question - Part I The MDEKA Sdn Bhd is a manufacturer of agriculture equipments servicing the southern region of peninsular Malaysia. The management generally has been pleased with the overall operations of the company to date. Procurement System However, the present procurement system has evolved through practice rather than having been formally designed. The management is of the opinion that the present procurement system is inadequate and needs revising to ensure the objectives of the procurement system are met. With the intention of understanding the current procurement system, the development team has analyzed and identified several documents that are crucial to the system. The documents identified are: 1. 2. 3. 4. 5. 6. 7. Vendor Invoice Purchase Order Disbursement Voucher Purchase Requisition Packing Slip Receiving Report Cheque The management of MDEKA intends to redesign the procurement system from the point in time when an item needs to be ordered until payment is made. The system should be designed to ensure that all the proper controls are incorporated into the system. Required: a) Identify the internally generated documents and indicate the number of copies of each document that would be needed. Why? b) Describe the application controls that should be place if each of these internally generated paper documents were replaced by electronic forms. Suggested Solutions Part I (a) (b) Document Source # of copies 5 Purchase order Internal Purchase requisition Receiving report Internal 2 Internal 3 Check Internal 2 Disbursement voucher Internal 1 Purpose 1 - vendor 2 - accounts payable 3 - receiving 4 - requesting department 5 - purchasing 1 - purchasing 2 - requesting department 1 - to accounts payable via inventory stores 2 - purchasing 3 - files in receiving 1 - original to vendor 2 - copy in voucher pkg. authorizes payment of invoice(s) A large number of controls are possible, including: Document Purchase Order Application Controls Validity checks on item number and vendor number; limit checks on amount; completeness check Purchase Requisition Validity checks on item, clerk, and supervisor numbers; completeness checks; reasonableness test comparing date needed to date requested Receiving Report Validity checks on vendor, item, and employee numbers; completeness check Check Sequence check on check number; validity check on vendor, invoice, and employee numbers; limit check on amount Disbursement voucher Validity checks on purchase order, receiving report, and vendor numbers 2 Question - Part II MDEKA recently purchased over RM1 million worth of office equipment under its “special ordering” system, with individual orders ranging from RM500 to RM5000. Special orders are for low volume items that have been included in an authorized users’ budget. As part of their annual budgets, department heads request equipment and specify estimated cost. The budget, which limit the types and ringgit amounts of office equipment a head department can requisition. The special ordering system functions as follows: Upon receiving a purchase requisition, one of the five purchasing agents verifies that the requester is indeed a department head. The purchasing agent next selects the appropriate supplier by searching the various catalogs on file. The purchasing agent then phones the supplier, requests a price quote and places a verbal order. A prenumbered purchase order is processed, with the original sent to the supplier and copies to the department head, receiving and account payable. One copy is also filed in the open-requisition file. When the receiving department verbally informs the purchasing agent that the item has been received, the purchase order is transferred from the open to the closed fie. Once a month, the purchasing agent reviews the open file for follow up purposes. The receiving department gets a copy of each purchase order. When equipment is received, that copy of the purchase order is stamped with date and noted with red ink if there is any differences between the quantity ordered and quantity received. The receiving clerk then forwarded the stamped purchase order and equipment to the requisitioning department head and verbally informs the purchasing department that the equipments were received. Upon receipt of purchase order, the account payable clerk files it in the open purchase order file. When the supplier invoice is received, it is matched with the applicable purchase order, and a payable is created by debiting the requisitioning department’s equipment account. Unpaid invoices are filed by due date. On the due date, a cheque is prepared and forwarded to the treasurer for signature. The invoice and purchase order are then filed by purchase order number in the paid invoice file. Cheques received daily from the accounts payable clerk are sorted into two groups: those over and those under RM3000. Cheques for less than RM3000 are machine signed. The cashier maintains the cheque signature machine’s key and the signature plate and monitors its use. For cheque amounting more than RM3000 are signed by the cashier and the treasurer. Required: a) Draw a flowchart of MDEKA’s special ordering system procedures. b) Discuss what could be done to improve the company’s system of internal control for “special ordering” procedures. 3 Suggested Solutions Part II (a) PURCHASING AGENT RECEIVING CLERK Purchase requisition A A/C PAYABLE CLERK 5 Purchase order Verify PR & select vendor Vendor catalog C 4 Unsign cheque Vendor Purchase order Vendor D Match PO & equipment ACCOUNTING B Invoice PO Open file Sort Cheque < RM3000 Prepared purchase order Match Invoice with PO Stamp PO Cheque > RM3000 1 2 Payable process 3 Machine sign Move stamp PO & equipment 4 5 Purchase order Unpaid invoice D Vendor D Dept Head A Open requisition file Dept Head Prepare cheque on due date B Transfer file Paid invoice Signed by Cashier & Treasurer Vendor D Unsign cheque Closed requisition file D C 4 (b) Weakness 1. Buyer does not verify that department head’s request is within budget. Control Compare requested amount to total budget and YTD expenditures. 2. No procedures established to ensure best price obtained. Solicit quotes/bids for large orders. 3. Buyer does not check vendor’s past performance. Prepare vendor performance report and use it when selecting vendors. 4. Blind counts not made by receiving. Black out quantities ordered on copy of Purchase Order sent to receiving; provide incentives if discrepancies between packing slip and actual delivery are detected. 5. Written notice of equipment receipt not sent to purchasing. Send written notice of equipment receipt to purchasing. 6. Written notice of equipment receipt not sent to accounts payable Send written notice of equipment receipt to accounts payable 7. Mathematical accuracy of vendor invoice not verified. Verify mathematical accuracy of vendor invoice. 8. Invoice quantity not compared to receiving report quantity. Compare/verify invoiced quantity with quantity received. 9. Notification of acceptability of equipment from requesting department not obtained prior to recording payable. Obtain confirmation from requisitioner of the acceptability of equipment ordered prior to recording payable. 10. No alphabetic file of vendors from whom purchases are made is maintained. Establish vendor master file. Restrict access and vouch all updates. 5 CASE 2: PRODUCTION CYCLE The production process of Tower Holding Bhd consisted of the usual planning, scheduling, and controlling of the physical products through the manufacturing process. The company’s manufacturing process begins in the production planning and control department. Hani, the production manager, determines the materials and operations requirements and combines information from various departments to assess the inventory requirements for production. Marketing provides the sales forecast, engineering provides the engineering specifications and inventory provides the inventory status. When this information is combined with the bill of materials and route sheet, Hani is able to prepare purchase requisition document. The purchase requisition is then sent to purchasing and inventory control. Hassan, as Hani’s assistant, will prepare production and control documents by comparing the bill of materials and route sheets. The documents produced are the move ticket, work order, and materials requisitions. A copy of the work order, move ticket and material requisitions documents are sent to cost accounting. The other two copies are sent to Roger the manager in the work center. Once Roger receives the production control documents, he initiates production. Unfortunately for the company, Roger is not a good supervisor. One of Roger’s duties is to review the job tickets which are sent to cost accounting, and the employee time cards, which are sent to payroll. Roger doesn’t pay attention to the amount of time his employees spend working, so they can easily enter any time onto their time cards. Roger also doesn’t pay close attention to the production process and the use of raw materials. Roger sends the materials requisitions to the inventory department, but never sends back any excess material or returns. Materials are left in the work centre department and are used in the future if they run out of materials. Seagal, the storekeeper, in the inventory department takes the materials requisitions from the work center and releases the raw materials to the work centers. Seagal then files a copy of the materials requisition and updates the inventory records with the other two copies. He then updates the material inventory records and creates a journal voucher that is sent to the accounting department. The finished goods inventory is updated and a journal voucher is created and sent to the accounting department. A copy of the materials requisition is filed and the other copy is sent to accounting. The cost accounting department will monitor the flow of cost information related to production. Information flows from the production planning, work centers, and inventory departments. The production department sends a work order to Shania in cost accounting, which is used to initiate work-in-process recording, and then the work order is filed. The work center sends a job ticket and the production planning and control department sends a materials requisition. Shania then updates the work in process and calculates the variances. Shania creates a journal voucher and then updates the general ledger after she compares it with the journal voucher from inventory. Finally, Shania files both journal vouchers.2 Required: a) Prepare a flowchart of the existing production system incorporating all the documents 6 Suggested Solutions (a) Page 1 Production Planning & Control Department Route Sheet BOM Work Center Engineering Marketing Inventory Engineering Spec Sales Forecast Inv Status A Initiates Prod. Purchase Requisition Access Inv Req. Review Inv. Control Purchasing Job Ticket Employee Time card B Payroll Material Requisition Route Sheet BOM C Preparation of control documents Work Order Move Ticket Material Requisition A A 7 (a) Page 2 Inventory Department Cost Accounting/Accounting Department C A B Inventory Records Material Requisition Issue material to work center Finished Good Inv Work Order Initiate WIP recording WIP Material Inventory Records Material Inv. Journal Voucher Material Requisition Calculates variance Finish Good Journal Voucher Journal voucher B B Compare 8