Thickness_of_Paper

advertisement

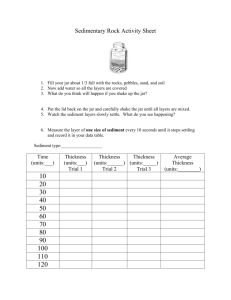

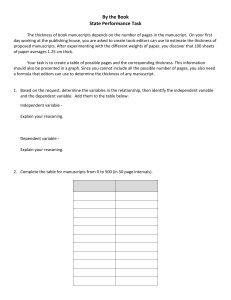

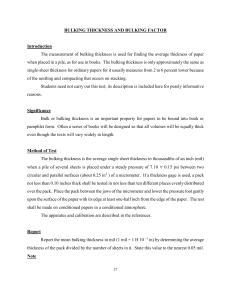

THICKNESS OF PAPER AND PAPERBOARD Introduction Thickness is defined as the perpendicular distance between the two principal surfaces of paper or paperboard as measured under specified conditions. The accurate determination of thickness requires an instrument of high precision that is correctly calibrated and used in a careful manner. Significance Thickness is an important property of most grades of paper and paperboard as it affects density, air resistance, rigidity and many other important properties. For many end use requirements, a low level of thickness variation is necessary in addition to meeting the average thickness specified. The thickness of book paper controls the thickness of the finished book and also affects the opacity. The electrical insulation efficiency of capacitor paper is directly related to the square of the thickness. Newsprint, linerboard, tabulating cards, blotting paper, printing papers, and many other paper grades require thickness uniformity for subsequent processing or performance. Method of Test The thickness is measured in a micrometer between two circular and parallel plane surfaces (about 0.25 in2 ) under a steady pressure of 7.10 0.15 psi. Extremely thin papers are measured using a specimen of several sheets between the micrometer surfaces. For some paper and paperboard, a single sheet is employed. The pressure foot of the micrometer automatically lifts up and comes down on an inserted sample. During the upstroke of the instrument, the sample is placed between the jaws of the micrometer. Wait for the pressure foot to come down and quickly make a reading just before it lifts up again. The thickness reading is affected by the moisture content of the sample so the test shall be made on samples and in an atmosphere both conditioned according to TAPPI standards. Test Specimens From each sample, cut ten sheets at least 40 mm x 120 mm. Cut the strips so that the longer 24 dimension is in the cross direction. Board samples only need one sheet for this test. For hand sheet testing, use entire hand sheet, five sheets thick. For board, use one sheet. Test Procedures (T 411) Before using the micrometer, make sure the pressure foot and anvil surfaces are clean. There is a soft bristle paintbrush located beside the micrometer that can be used to brush the dust off. After the pressure foot and anvil are clean allow the instrument to make two more cycles. On the left side of the machine is a knob that when turned will line the indicating pointer with zero. This has to be done when the pressure foot is down. After the zero has been checked, place the sheets on the anvil in such a position that all points on the contact surfaces are at least 6mm from the edges. Measure the thickness of each stack at ten nonoverlapping intervals. Calculate the average of the intervals and then divide by the number of sheets in the testing stack. Report Report the mean caliper in units of mil (1 mil = 110-3 in) and cm. Also report a 95 % confidence interval for the mean. Adjustment and Calibration of the Micrometer Because of the close tolerances maintained in these instruments, it is difficult for unskilled personnel to make repairs. It is suggested that the person in charge of the lab be notified of a problem, and then have it sent off for repairs. When the instrument is not in use continuously, it should be protected from dirt and other foreign matter with the dust cover. Feeler gauges can be used for determining the accuracy of your instrument. The machine should be calibrated once a month by the person in charge of the lab. DO NOT ATTEMPT TO CALIBRATE OR REPAIR THIS MACHINE! Equipment Information Precision Dead Weight Micrometer – Model 549M 25 Testing Machines, Inc - Margaret Sexton 2910 Expressway Drive South Islandia, New York 11749 (631) 439-5400 Note A description of the apparatus can be found in the references. References ASTM D 645 TAPPI T 411 26