CE 326 Experiment _Coagulation

advertisement

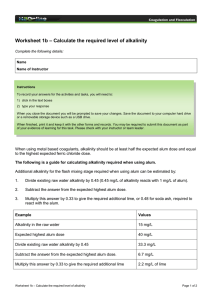

CE 326 Principles of Environmental Engineering, Civil, Construction and Environmental Engineering Iowa State University JAR TEST: Chemical Coagulation and Disinfection BACKGROUND Coagulation and flocculation are important unit processes in water and wastewater treatment plants. The purpose of coagulation/flocculation is to remove suspended matter, turbidity, color, microorganisms and odor producing substances. Coagulation involves the addition of chemicals to destabilize the suspended particles, colloidal materials, and macromolecules. Some common coagulants used are aluminum sulfate (alum) and ferric sulfate. Flocculation is usually defined as the aggregation of destabilized particles into larger flocs under slow mixing conditions. The flocs formed are subsequently removed by sedimentation and/or filtration (see pages 229-235, Davis and Cornwell, 4th edition) A useful laboratory experiment for the evaluation of coagulation/flocculation of untreated water is the jar test. This test provides information on the effects of the concentrations of the coagulants, mixing of the raw water, and the water quality parameters such as pH and alkalinity on the coagulation process. The jar test is often used for the design of treatment facilities and in the routine operation of treatment plants. OBJECTIVES The objectives of the jar test experiment are to estimate the optimum concentration of aluminum sulfate for the removal of suspended matter and to investigate the change in alkalinity as a result of aluminum sulfate addition. MATERIALS Phipps Bird Six-Place Stirrer Aluminum sulfate solution (1000 mg/L as Al3+) Pipettes/syringes Erlenmeyer Flasks Water sample (from Lake Laverne) Methyl orange (MO) indicator Chlorine Producing Unit (CPU) Salt 1 or 2-liter beakers Turbidimeter Burettes 0.02 N H2SO4 Volumetric cylinder 50-ml syringes 12 volt battery 500 mL beaker PROCEDURE Coagulation Experiment 1. Determine the turbidity, pH, and alkalinity of the raw water sample. 2. Add 2 liters of raw water into each of the six beakers of the laboratory stirrer. Immerse blades and stir the raw water samples at about 100 rpm. 3. In small beakers, prepare different volume of alum solution and calculate final alum concentration in each beaker. Volume (ml) of Alum solution to be added to each beaker 5 10 20 4. 5. 6. 7. Conc. (mg/L as Al3+) in Water Sample (Dosage) Volume (ml) of Alum as Al3+ to be added to each beaker 30 40 50 Conc. (mg/L as Al3+) in Water Sample (Dosage) At approx. the same moment, add Alum solution into each beaker and stir at approx. 100 rpm for 1 minute. Decrease the speed to approx. 30 rpm and allow the sample to mix for a period of 10 minutes. Observe any changes in the suspended matter in the sample. At the end of the mixing period, turn off the stirrer and let the flocs settle for about 20 minutes. With syringe, carefully remove the supernatant (clear liquid) from each beaker and determine the turbidity and pH of each of the samples. For the sample with the lowest turbidity, measure the alkalinity of the supernatant. Alkalinity Measurement 1. Add 50 mL of water sample (Vs) to an erlenmeyer flask 2. Add 4 to 5 drops of methyl orange indicator 3. Read the starting volume of standard 0.02 N H2SO4 on the burette. Titrate water sample with standard 0.02 N H2SO4 until color changes from yellow-orange to red. 4. Read the final volume of the acid in the burette. Record volume used (Va). 5. Compute alkalinity as follows: Alkalinity (in mg/L CaCO3) = [mL acid (Va) x Normality of acid x 50,000] / [mL sample (Vs)] RESULTS Beaker # Dosage mg/L of Alum as Al3+ RAW 1 2 3 4 5 6 0 Turbidity NTU of all samples pH of all samples Alkalinity mg/L as CaCO3 of RAW and one of beakers with lowest turbidity Third World Chlorinator (see www.swimforhim.net for more information) 1. Mix salt & water solution (approx. ¼ cup salt to 16 oz water) 2. Connect wires to 12 volt source (negative, or black, to negative; positive, or red, to positive) 3. Pour the saltwater solution through the CPU into another bottle (observe the bubbling process) 4. Carefully repeat the pour-through process 5 times. 5. Unhook the battery wires. 6. Rinse the CPU by pouring clean water through it. 7. Add 10 drops of the solution for each gallon of water (adjust accordingly to sample volume) to disinfect (use Lake Lavern (LL) water sample as a test). 8. After 15 and 30 minutes of disinfecting time, run a coliform test on the following 4 samples (see procedure from last week): Lake Lavern as sampled, LL after flocculation w/o disinfection, LL as sampled after 15 min disinfection time , and LL as sampled after 30 minutes disinfection time. REPORT FORMAT Introduction. Describe the purpose of jar testing and summarize the theoretical background. You need to expand on the information that is already presented in this handout (please read the textbook). Procedure: Describe the experimental procedure (summarize the procedure in the lab). Results Report all results in a Table format. Plot turbidity and pH as a function of coagulant dosage (x-axis = dosage; y-axis = turbidity or pH). Discussion What is the best coagulant dosage and why? Why did the pH and alkalinity change with dosage? (What made them change?) Compare the measured alkalinity change with that of the theoretical alkalinity change? Are they matched? (See textbook page 233-234, it will be a bit different since in the lab we use Alum as Al3+, not Alum as Al2(SO4)314H2O) (HINT: mg/L of Alum as Al3+ x 594 g/mole-Alum = mg/L of Alum as Al2(SO4)314H2O) 2 x 27 g/mole-Al3+ Conclusions: Summarize your findings.