neeraj chauhan

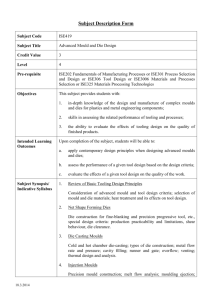

advertisement

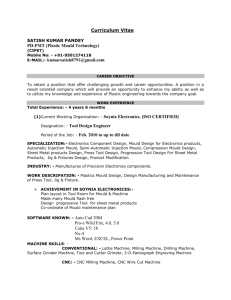

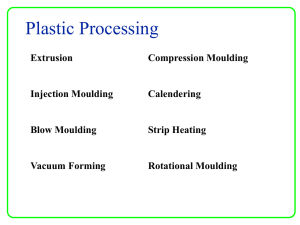

NEERAJ CHAUHAN Email: iengineer1@rediffmail.com; Res.: 011-28522716; Mobile:+91-9717299539 Seeking Dynamic & Challenging assignments in Manufacturing Operations / New Product Development / Project Planning & Management & Marketing in Organisation of Repute EPITOME: A Result Oriented & Innovative techno-commercial professional with more than 16.5 years of multifunctional experience in Strategic Analysis & Planning , Production & Manufacturing Operations, New Product Development , Prototyping & Tooling , Value Engineering , Project / Program Planning & Management . Set-up experience of state-of-the-art TOOLROOM & INJECTION MOULDING UNIT for the manufacturing of moulds/dies for Plastics Injection, Die Casting , moulded products for car interior & exterior, sheet metal dies for seat & under body car parts. Presently associated with SKH TECHNOLOGIES (Tooling division of Krishna Maruti Group) as Asst. General Manager – PLASTIC DOMAIN . Currently responsible for Business & Technical Strategies, Mould Manufacturing & Quality and Profitability of the Domain. Handling entire process of development of new products from RFQ receiving to Costing , Mould Designing , validation of design , Mould Manufacturing , Prove-outs to commence production along with handling of related documents till Mould Buy-Off & after sales service. Expertise in managing Plant Operations using tools & techniques like - Ratios Analysis regarding Profitability, Manufacturing Excellence, Manufacturing Engineering, Planning Part , Target Vs Actual Gap Analysis, Requirement Mapping, Budgeting & Control, Relationship Management , Competitor Tracking & Corporate Presentation. Strong Leadership ability from the front with excellent man management & analytical skills, problem solving & organizational abilities. CORE COMPETENCIES A. Project Planning & Management Planning & Managing the project(s) from Inception to Installation ( including survey of Other Market Players, identification of Machines/Equipment, preparing comparison based on QCD & After sales service, Negotiation with suppliers ,Final selection of Machines/Equipment) ,Test Run of Machines & SOP . Handled two big projects- set up of State-of- the –art TOOL ROOM & INJECTION MOULDING UNIT. Forecasting PBT at the stage of Project set-up. Project Analysis & Costing. Strong understanding of Project Economics , Budgeting / Fund Allocation & Control. B. Manufacturing & Production Operations Production / Capacity Planning and Execution as per production plan. Achieving and improving production targets. Minimizing/ Eliminating risk on Manufacturing / Designing by doing WHY-WHY analysis , Skill Identification, resources required, Time line preparation , Risk analysis, RASIC matrix prior to start up of Production & Manufacturing Operations. Well versed with Best Manufacturing Practices like TPM, Low Cost Automation , Poka Yoke, Lean Manufacturing Concepts, Line Balancing, SMED, Kaizens etc. Controlling unit performance through CFTs /QCs / SGAs. Implementing preventive maintenance schedules of various machines and equipments to increase machine’s up time and equipment’s reliability. Proactively identifying areas of obstruction/breakdowns and taking steps to rectify the equipments through application of trouble shooting tools. Foreseeing performance bottlenecks and taking corrective measures to avoid the same. Mould manufacturing & Preventive / predictive maintenance of existing moulds to improve product’s quality. Maintaining awareness of new / emerging technologies and implementing the same in the organization( where ever is possible). Having adequate exposure and worked with Organizations having ISO – 9001/9002, QS-9000 / TS 16949, OHSAS -18000. Cont-2....... C. NPD , VE & PROGRAM MANAGEMENT New Product Development & Program Management Planning & Managing entire strategy of product development functions including APQP / Feasibility Study, DFMEA finalizing specifications, Designing, Mould Development ,trials, Feedback Assessment & Corrective Actions. Managing overall operations for improvement in the existing products based on customer requirement. Providing sound technical inputs and engineering support to the team from conception to completion stage of the mould(s). Handled more than 25 Projects for MARUTI SUZUKI ,CHRYSLER,JCB,SUZUKI BIKE,VALEO,FAURECIA . Value Engineering Initiating Value Engineering initiatives to streamline internal processes & achieve cost reduction. Process Re-Engineering :Eliminating redundant / obsolete processes involved in the design, development processes and working towards value-addition. Conceptualizing innovative mechanisms for design & development. D. Man Management Assessing the training needs of the various employees in co-ordination with the various department heads in the respective departments. Coaching employees & counselling, appraising and reviewing performance, ensuring optimum performance. Inspiring co-workers to attain goals and pursue excellence. CAREER SNAPSHOT May`07 – Till Date SKH Technologies, Gurgaon (A unit of Krishna Maruti Group), India Asst. General Manager – Plastic Domain SKH TECHNOLOGIES is a unit of KRISHNA MARUTI LTD for the manufacturing of injection moulds for car interiors & exteriors like Boards & its Child Parts(Door Trims) , Trims, Pillars, Scuffs, Recliners, Fender Linings, Garnish, Rear View Mirrors & its child parts and injection moulds for two wheelers like visor, Cover Frame, Box Halmet Front & Rear Fenders etc. Company also manufactures Sheet Metal dies for under body car parts. Capable for making PLASTIC MOULDS up-to 1800Tons & SHEET METAL DIES up-to 1000Tons .Company has technology alliance with MING MOLD for PLASTICS & EJEE(Taiwan) for SHEET METAL. Krishna Group is a reputed automotive components manufacturing group , manufacturing almost total interiors for cars (like Seats, Doors Trims, Roof Headliner, Rear view Mirrors etc) and exterior Metal Products (like Fuel Tanks, Axles, Exhaust manifolds etc).Present turn over of the Group is Rs.2700 Crore .Its Seat Division is the only Seat making youngest company in the world to have received prestigious Deming Prize. Role:- Monitoring & Controlling a state-of-the-art Machine Shop , Plastic Domain (Design, Mould manufacturing ,Assembly section & Moulds prove-out). Reporting to SBU HEAD (VICE PRESIDENT). Preparing Annual Business Plan and also Establish & Implement Business & Technical Strategies to achieve Annual Sales Target for the DOMAIN. Oversee activities directly related to Machine Shop management, Mould Design & Manufacturing. Handling RFQ's, Customers , Order Receiving . Technical discussion , getting JCB,SMIPL,FAURECIA etc). Samples and moulds approvals from Customers (Like SUZUKI, Quality Circles/SGAs Kick-Off , Ensuring Action Implementation for cause & Identifying resource(s) management. Supporting group companies for Existing Moulds/fixtures/Panel Checkers Rectifications. Direct and coordinate activities concerned with the manufacturing, pricing, sales. Review financial statements , sales and activity reports and other performance data to measure productivity and goal achievement and to determine areas needing cost reduction and program improvement . Manage staff, preparing Job Responsibilities and assigning specific duties. Coordinate organization's financial and budget activities to fund operations and increase efficiency. Cont-3....... Project Cost Control through alternate / suitable / low cost Design , Machining & Assembly. Determine staffing requirements and interview, hire and train new employees against their KRAs(for existing & new employees). Plan and direct activities such as Mould Prove-outs ,Buy-off activities related to Moulds & Panel Checkers/Fixtures and achieving the Sales Target for the PLASTIC DOMAIN & the Company . & monitoring the performance Notable Contributions Set up of a state -of-the-art Tool room . Handled the project from inception to installation i.e preparing Technical ,Cost ,Quality, Delivery & after Sales service comparison for Tool Room machines and all the Utility Equipments, Release of purchase orders, machine’s layout, installation , test run and start of production. facility includes:- - VMCs from 6000 RPM to 24,000 RPM, XYZ range from 650*450*450 to 3000*2500*1000(including 3+2 axis double column, Graphite machining VMCs & On Machine Verification of machined jobs on all VMCs make the Tool Room a biggest tooling facility in NORTH INDIA for PLASTICS & SHEET METAL TOOLING under one roof),with best combination of Utility Equipments to eliminate the chances of rejection during machining. Plastic parts developed for CHRYSLER(18 moulds /25 Components). Visited JAPAN & SINGAPORE for inspection & testing of tool room machines prior to shipment. Visited KOREA for testing of PLASTIC MOULDS ( upcoming models) of MARUTI SUZUKI. Successfully developed more than 60 moulds(40T-1800T) for New WagonR-YR9 & ALTO (including DOOR MOULDS with Child parts), New Swift(YP-8) PROJECT (GARNISHES , ORVM MOULDS,COVER RECLINERS) including “INNER BASE”(DIE CASTING) for MARUTI SUZUKI, Cabin components for JCB and Rear & Front Fenders, Cover Frames , Side Covers for SUZUKI MOTOR CYCLE (XB-474 & GE 110),Console moulds for Faurecia. Sep`06 – Apl ‘07 Krishna Maruti Ltd-DTD-I, Gurgaon(India) Manager – New Product Development & Mould Maintenance A company with TS-16949,ISO/TS 14001 & OHSAS 18001 AWARDS. Company is a part of Krishna Maruti Group. Company manufactures injection moulded DOOR TRIM & NON-DOOR TRIM parts for MARUTI SUZUKI. Role: Monitoring & controlling “NEW PRODUCT DEVELOPMENT & TOOL MAINTENANCE”(UNIT I & II). Monitoring technical & cost aspects related to “RFQs” . Key role in identification & retention of potential Suppliers/ Vendors/ Toolmakers based on their Cost ,Quality,Delivery and after sales service. Monitoring mould(s) development ,trials and performed key role for parts approval from the customer.Significantly contributed in completion of projects viz DOOR TRIM & NON DOOR TRIM Plastic Part Development of ZEN-ESTILO(2006) , SX4 (2007) , SWIFT DZIRE (2007) & A-STAR(2007) for MARUTI SUZUKI. Mould maintenance of existing moulds for Trims, Pillars,Scuffs ,Borads , Mirror housings and its child parts. Capably developed VARIANT-3 parts for SUZUKI BIKE(SMIPL) and handled YN-4 LIMITED EDITION –colour change(B03) for door trims and non-door trim parts (for SWIFT). Notable Contribution ● HEADED “KRISHNA MARUTI LTD -DOOR TRIM DIVISION-II” (An Inj. Moulding unit) with higher tonnage machines (350,450,650,900,1400T) as Plant Head. ●During the year 2007, management gave the chance to set-up a state-of-the-art Tool RoomSKH TECHNOLOGIES. Cont-4....... Feb`03 – Sep`06 Craftech Udyog (P) LTD., Noida Manager – Injection Moulding & Engineering A TS-16949 company, part of CRAFTECH Group well established in production of plastics products for Maruti, Minda, Technico, Bright, Delphi-Packard , Krishna Maruti & Valeo (France, Turkey, Maxico, Germany) etc. Role: Administered & directed activities pertaining to moulding and super heading NPD & assembly section in coordination with Production & Development Engineers, Supervisors & over 60 workers. Also involved in finalizing & Procurement of Moulding Machines & its accessories, Plant Set-up (Commissioning of moulding machines & Utility Equipments) . Prepared Monthly Billing/Sales Target, raw material plan, monthly and daily machine loading as per monthly Production schedules. Conducted review & reduction of daily rejection & oversaw man power planning. Elimination of 3Ms, implementation of kaizens & 5S. Conducted monthly presentation on plant/productivity improvements to the Management. Headed Development of VALEO (includes Prototyping, Mould Manufacturing & Prove-outs). Notable Contributions Significantly contributed in accomplishment of GREEN REVOLUTION project for implementation of best manufacturing practices in the plant with focus on: SGAs (small group activities), bringing down FTOVs to zero level, improving FTT, OEE , BTS,MTTR & MTBF, reduction of mould change over time, implementation of suggestion scheme & Kaizens in the plant, pounce upon to solve operational & technical problems from the root level as a team . Acknowledged as founder & coach of GREEN TEAM. EXPORT LOGISTICS-Successfully Managed SHIPMENTS to VALEO (FRANCE, TURKEY & CHINA) on monthly bases (more than 50 Containers/month). May`00 – Oct`02 Standard Packaging (Nigeria) Ltd, Nigeria Manager / In charge-Plastics Shop Floor(Injection Moulding & Tool room) Involved in manufacturing of plastic items for automotive , industrial & domestic use, part of multimillion dollars “MADANDOLA GROUP” of Nigeria, with active interest in more than fourteen other manufacturing Industries. Role: Managing shop floor team for turn around of the company, Managed Factory Refurbishment , imparting training, implementing laying down quality manufacturing procedures and systems. Supervised & controlled plastic shop & Tool Room in coordination with Mechanical Engineer, Maintenance Superintendent and Electrical Supervisor for SIXTEEN INJ. MOULDING m/cs(Battenfeld, Billion, Engel and Arburg) with 50,75,90,250 and 650 Tons. Monitored mould manufacturing , maintenance of moulds , product costing, capital and revenue budgeting for the shop floor. Notable Contributions Successfully accomplished Techno-commercial projects (created extra capacity on moulding machines by eliminating process wastes thus giving a hike in the annual sales by 11%). Feb`97 – May`00 Sumi Motherson Innovative Engg. Ltd, Noida Shift In-charge (Injection Moulding) (Joined as Engineer – Inj.-Moulding & Development & rose to the position of Shift In charge - INJ Moulding) Company is into the manufacturing of plastic components & products for leading Automobile & Electronic Companies in collaboration with SUMITOMO of JAPAN. Role: Administering production of 61 Injection Moulding m/cs of world’s best 7 different brands and models with wide variety of tonnages from 20tons- 650 tons. Super heading engineers, supervisors and more than fifty workers. Cont-5....... Notable Contributions Conducted internal “QS9000” audits of various departments, prepared exhibits, work instructions & formats related to “QS9000” . Managing & Controlling “Visual Control System” for the deptt. Identified training requirements of engineers, supervisors and workers and developed, organized training programs accordingly. Awarded internal auditor certificate for “QS-9000” by Qualiquest Consultants Pvt. Ltd in July , 1997. Awarded certificate by TQM division of the group for obtaining “ A - GRADE” in MSA+FMEA test May,1997 conducted at GROUP LEVEL. Involved in the Development of FORD,GM & Maruti Suzuki Development Programs ( Technical discussion with Customers ,Moulds development & Prove-outs). PREVIOUS ASSIGNMENTS Commenced career with Motherson Auto Components Ltd, Noida as Engineer – Design & Development from Aug`95 – Jan`97. Transferred to “SUMI MOTHERSON INNOVATIVE ENGG LTD (SMIEL)” to contribute during plant set-up phase. In the year 1998 “Motherson Auto Component Ltd” merged with SMIEL. SIGNIFICANT TRAINING Bench Marking, Institute of Quality, India. 5S & Kaizens by QUALIQUEST. QS-9000 Internal Auditor Course- QUALIQUEST. Project Planning & Management(Manipal University) Production Management by CII. Lean Manufacturing by CII. FMEA, TQM Div- Motherson Group. MSA, TQM Div-Motherson Group . ACADEMIC CREDENTIALS 2007 1995 1994 1994 1995 1994 MBA(Dual Specialization in Finance & Marketing) from Manipal University(INDIA) Post Diploma in Plastics Mould Designs from Central Institute of Plastics Engg. & Technology (CIPET), Chennai(INDIA) Diploma in Plastics Mould Making Technology from CIPET (H.Q.), Chennai(INDIA) Diploma in TQM & ISO-9000 - Distant Learning Programme from National Institute of Labour Education & Management, NILEM, Chennai(INDIA) Diploma in Industrial Relations & Personnel Management - Distant learning Programme from NILEM, Chennai(INDIA) AUTO-CAD (Level – I & 11) from TECS, Chennai (INDIA) PERSONAL VITAE Date of Birth Address : 25th August, 1974 : WZ-110, Lajwanti Garden, New Delhi-110046(INDIA) (NEERAJ CHAUHAN)