2. All Questions carry equal marks

advertisement

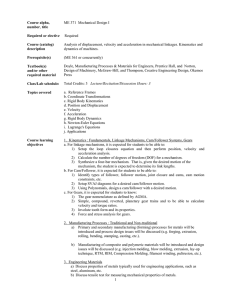

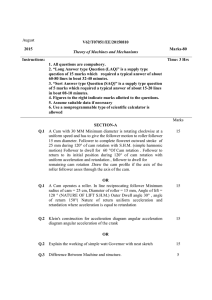

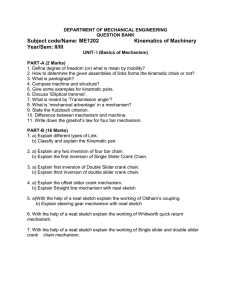

Regulation : R10 Code No: ME206 VIGNAN UNIVERSITY :: VADLAMUDI - 522 213 Vignan’s Foundation for Science, Technology and Research (Estd. U/s 3 of UGC Act of 1956) II B.Tech II Semester Regular Examination, May 2013 KINEMATICS OF MACHINES (ME) Time: 3 hours Max. Marks : 60 Instructions: 1. Answer ONE question from each unit 2. All Questions carry equal marks 3. Assume missing data, if any *** UNIT – I 1. a) What is the significance of degrees of freedom of a kinematic chain when it functions as a mechanism? Give examples. [5M] b) A crank and slotted lever mechanism used in a shaper has a centre distance of 300 mm between the centre of oscillation of the slotted lever and the centre of rotation of the crank. The radius of the crank is 120 mm. Find the ratio of the time of cutting to the time of return stroke. [7M] (OR) 2. a) What are straight line mechanisms? Describe one type of exact straight line motion mechanism with the help of a sketch. [5M] b) Design a pantograph for an indicator to obtain the indicator diagram of an engine. The distance from the tracing point of the indicator is 100 mm. The indicator diagram should represent four times the gas pressure inside the cylinder of an engine. [7M] UNIT – II 3. a) Describe the method to find the velocity of a point on a link whose direction is known and the velocity of some other point on the same link in magnitude and direction are given. [5M] b) A slider crank mechanism is as shown in Fig 1. The lengths of crank OB and connecting rod AB are 100 mm and 400 mm respectively. If the crank rotates clockwise with an angular velocity of 10 rad/s, find: i) Velocity of the slider A, and ii) Angular velocity of the connecting rod AB. [7M] (OR) 4. a) Explain why two Hooke’s joints are used to transmit motion from the engine to the differential of an automobile. [4M] b) PQRS is a four bar chain with link PS fixed. The lengths of the links are PQ = 62.5 mm; QR = 175 mm; RS = 112.5 mm; and PS = 200 mm. The crank PQ rotates at 10 rad/s clockwise. Draw the velocity and acceleration diagram when angle QPS = 60° and Q and R lie on the same side of PS. Find the angular velocity and angular acceleration of links QR and RS. [8M] 1 of 3 Regulation : R10 Code No: ME206 UNIT – III 5. a) Explain the different types of cams and followers. [3M] b) A cam is to be designed for a knife edge follower with the following data: i) Cam lift = 40 mm during 90° of cam rotation with simple harmonic motion. ii) Dwell for the next 30°. iii) During the next 60° of cam rotation, the follower returns to its original position with simple harmonic motion. iv) Dwell during the remaining 180°. Draw the profile of the cam when 1) the line of stroke of the follower passes through the axis of the cam shaft, and 2) the line of stroke is offset 20 mm from the axis of the cam shaft. The radius of the base circle of the cam is 40 mm. Determine the maximum velocity and acceleration of the follower during its ascent and descent, if the cam rotates at 240 rpm. [9M] (OR) 6. a) Draw the displacement, velocity and acceleration diagrams for a follower when it moves with simple harmonic motion. [4M] b) A flat faced reciprocating follower has the following motion: (i) The follower moves out for 80° of cam rotation with uniform acceleration and retardation, the acceleration being twice the retardation.(ii) The follower dwells for the next 80° of cam rotation.(iii) It moves in for the next 120° of cam rotation with uniform acceleration and retardation, the retardation being twice the acceleration.(iv) The follower dwells for the remaining period. The base circle diameter of the cam is 60 mm and the stroke of the follower is 20 mm. The line of movement of the follower passes through the cam centre. Draw the displacement diagram and the profile of the cam very neatly showing all constructional details. [8M] UNIT – IV 7. a) Derive an expression for the velocity of sliding between a pair of involute teeth. State the advantages of involute profile as a gear tooth profile. [5M] b) Two gears of module 4mm have 24 and 33 teeth. The pressure angle is 20° and each gear has a standard addendum of one module. Find the length of arc of contact and the maximum velocity of sliding if the pinion rotates at 120 rpm. [7M] (OR) 8. a) Derive an expression for minimum number of teeth required on a pinion to avoid interference when it gears with a rack. [5M] b) Two mating gears have 20 and 40 involute teeth of module 10 mm and 20° pressure angle. If the addendum on each wheel is such that the path of contact is maximum and interference is just avoided, find the addendum for each gear wheel, path of contact, arc of contact and contact ratio. [7M] 2 of 3 Regulation : R10 Code No: ME206 UNIT – V 9. a) Explain briefly the differences between simple, compound, and epicyclic gear trains [3M] b) In a reverted gear train, as shown fig.3, two shafts A and B are in the same straight line and are geared together through an intermediate parallel shaft C. The gears connecting the shafts A and C have a module of 2 mm and those connecting the shafts C and B have a module of 4.5 mm. The speed of shaft A is to be about but greater than 12 times the speed of shaft B, and the ratio at each reduction is same. Find suitable number of teeth for gears. The number of teeth of each gear is to be a minimum but not less than 16. Also find the exact velocity ratio and the distance of shaft C from A and B. [9M] (OR) 10. a) Write the merits and demerits of belt, rope and chain drive for transmission of power.[4M] b) An open belt 100 mm wide connects two pulleys mounted on parallel shafts with their centres 2.4 m apart. The diameter of the larger pulley is 450 mm and that of the smaller pulley 300 mm. The coefficient of friction between the belt and the pulley is 0.3 and the maximum stress in the belt is limited to 14 N/mm width. If the larger pulley rotates at 120 rpm, find the maximum power that can be transmitted. [8M] 3 of 3