gen testing schedule..

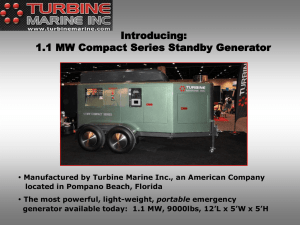

advertisement

STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 1 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 1. PLANT DETAILS : The 500 MW generator is coupled to the 500 MW KWU turbine. The rated parameters of the generator are listed in plant details (Section-1) of Testing schedule for generator protection and generator bay. The design and constructional features are outlined briefly below. Generator manual supplied by the manufacturer may be referred for details of above. STATOR BODY : The stator body is a totally enclosed gas tight fabricated structure suitably ribbed internally to ensure high rigidity. Hydrogen coolers are housed longitudinally inside the stator body. Rigid end shields close the casing and support the fan shields. STATOR CORE : The stator core is made up of segmental varnish insulated punchings of cold rolled grain oriented silicon gel and is assembled in an interleaved manner on core bars. Steel spacers for ventilating ducts are provided for radial cooling of core by hydrogen. The core is held pressed by means of heavy non-magnetic steel press rings which are bolted to the ends of the core bars. Additional support is provided to the teeth portion. In order to isolate the stator body and thus the foundations from magnetic vibrations, the core bars are designed to provide elastic suspension of the core in the stator frame. STATOR WINDING AND INSULATION: The stator has a three phase, double layer short corded bar type windings having two parallel paths. Each coil side consists of glass insulated solid and hollow conductors with cooling water passing through the latter. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 2 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING The elementary conductors are Rosbel transposed in the slot portion to minimize eddy current losses. The coil sides are firmly held in position by fibrous slot wedges. The overhang portion of the coil is securely lashed with glass chord to bondage rings and special brackets of nonmagnetic steel, which are in turn fixed to the core press rings. DISTILLATE HEADERS: Ring type water headers, made of copper are provided separately for distillate inlet and outlet in the stator on turbine side. The headers are supported on insulators and isolated from stator body. The winding ends are solidly soldered into the coil legs which are then ultrasonically tested. Individual bars are provided with water inlet/outlet connections made of P.T.F.E Hoses, The bar heads are insulated by fiber molded covers. TERMINAL BUSHINGS: Water cooled terminal bushings are housed in the lower part of the stator on the slip ring side, Porcelain insulators are provided to insulate the terminal bars from the stator body. Effective sealing is provided between the terminal bushings and the stator body to avoid any possible leakage of hydrogen. Terminal bushings are housed inside a chamber made of non-magnetic steel plates. Three phase terminals and three neutral terminals are brought out. The terminal plate of the end terminals, where bus bar connections are made is silver plated. ROTOR The rotor is of cylindrical type; the shaft and body being forged in one piece from chromium nickel molybdenum and vanadium steel. The rotor with all the details assembled is dynamically balanced to a high degree of accuracy subjected to 20% over speed for 2 minutes. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 3 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING FIELD WINDING: The field winding is made from hard drawn silver bearing copper. The winding is held in position and by nonmagnetic rotating ring in the overhang portion. Gap pickup method is used for direct hydrogen cooling of rotor. The main slot insulation is of glass cloth impregnated with Epoxy resin. The inter turn insulation consists of layers of prepped glass cloth glued to the bottom of each conductor. The end windings are packed with blocks of glass laminates to separate and support the coils and to restrict their movement under stress. The end windings are insulated from the retaining rings with the help of glass epoxy molded segments. SHAFT MOUNTED FANS For circulating the cooling gas inside the generator two propeller type fans are shaft mounted on either end of the rotor body. Fan hubs are made of alloy steel forging and are a shrunk fit on the rotor shaft. The alloy steel cast fan blades are machined in the tail portion to suit the fan hub and held in position with the help of conical pins. The blades can be easily removed from or assembled in the fan hub. Fan shields fixed to the end shields guide the gas flow. RETAINING RINGS: The end windings are held in position by retaining rings of floating type shrunk fit on the rotor body. The rings are screwed to prevent axial movement by locking nuts. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 4 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING SLIP RINGS: The slip rings consists of helically grooved alloy steel rings shrunk on the rotor shaft and insulated from it. They are mounted on a single, common steel bush, which has an insulating jacket pre-molded on it. The complete bush with sliprings are provided with inclined holes for self ventilation. The helical grooves cut on the outer surface help improve the brush performance. FIELD LEAD: The slip rings are connected to the field winding through semi-flexible copper leads and current carrying bolts, placed radially in the shaft. Two semicircular hard copper bars insulated from each other and from the rotor shaft are placed in the central bore or the rotor joining the two sets of current carrying bolts with special profiled precision conical threads. GAS COOLERS Four longitudinally mounted gas the stator body. They are made with coiled copper wire wound on as to expose maximum surface area coolers are mounted in out of admiralty brass them staggered form so to hydrogen. BEARINGS: Generator bearings are of pedestal type with spherical seating to allow self alignment and are supported on a separate pedestal on slip ring side and in the L.P casing on the turbine side, Bearing bush is of cast steel lined with white metal. Oil catchers and deflectors are provided to prevent axial leakage of oil. To prevent shaft currents slip ring side bearing and connecting pipes are insulated from earth. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 5 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING SHAFT SEALS: In order to prevent leakage of hydrogen from the generator casing radial thrust type shaft seals are provided on either side where the shaft extends out from the generator. The seal consists of seal liner with babbit pressing against the shaft caller of the rotor. Seals are defined in testing schedule of seal oil system. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 6 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING NAME PLATE DETAILS RATED DATA & O/P APPARENT POWER ACTIVE POWER CURRENT VOLTAGE FREQUENCY PF STATOR WDG CONN HYDROGEN PRESS CONT PERM UNBAL LOAD RATED FIELD VOLTAGE CURRENT TURBO GEN. 588 MVA 500 MW 16166 A 21 + 1.05 KV 50 HZ 0.85(LAG) YY 3.5 BAR 8 % 340 V 4040 A MAIN EXCITER -----3780 KW 6300 A 600 V ------------------------- PILOT EXCITER 65 KVA -----195 A 220 + 22 V 400 HZ ------------------ ------ ------- STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 7 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 2. TESTING OBJECTIVE : TO TEST THE GENERATOR AND MAKE IT READY FOR SYNCHRONIZATION. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 8 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 3.0 PROPOSAL 3.1 Tests as detailed in item-8 shall be carried out on generator, confirming the manufacturers test reports. 3.2 Generator short circuit test will be carried out and the values will be recorded. 3.3 The current based relays will be dynamically tested for their function and the values will be recorded. 3.4 Generator open circuit test will be carried out and the values will be recorded. 3.5 The voltage based relays will be dynamically tested for their function and the values will be recorded. 3.6 The synchronizing circuit will be checked and the phasing out will be carried out. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 9 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 4. SERVICES REQUIRED 4.1 Laboratory equipments/test sets for measurement of electrical parameters required. 4.2 Illumination at required locations. 4.3 240 V A.C power supply for testing. 4.4 Communication facility at test area. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 10 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 5.0 S A F E T Y PRECAUTIONS: 5.1 The test area shall be clearly defined and cordoned off. 5.2 The test team leader is fully aware of the location, and probable duration of the tests. 5.3 The other agencies working in the test area are informed about the test in progress. nature, STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 11 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 6. EMERGENCY PROCEDURE : 6.1 Shock treatment available. 6.2 Emergency telephone numbers of fire and hospital shall be prominently displayed near by. 6.3 The test in progress shall immediately be stopped and all line apparatus disconnected and equipment suitably earthed in case of a accident or abnormality. Such instruction will be received from the team leader. 6.4 The test team is fully aware of measures to be taken in the event of injuries to any personnel / damage to any machinery. chart and first aid box shall be STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 12 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 7. 7.1 STATE OF PLANT : Generator Erection complete and satisfactory. erection test results/log sheets available for following : - Mounting of embedded parts and foundation plates. - Erection of stator. - Gas tightness and Hydraulic tests. - Measurement of insulation resistances of All the various parts of generator, D.C. resistances and impedances. - Continuity, D.C. resistance and IR checks of RTDs. - Purge tests of rotor ventilation canals. - Rotor insertion tests. - Bearing adjustment tests. - Alignment or generator rotor. - Inclination or shaft journal test results. - Coupling alignment results of generator and LP rotor. Magnetic Axis adjustment results. - Fan and shield clearance results. - DTI checks on generator rotor. - Shaft seal adjustment results. - Temperature monitoring system. - Centering and offset-setting of brush gear. - Fixing of brush holder and brushes. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 13 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 7.2 Following Testing/Commissioning schedules satisfactorily and results/records available : completed - Generator Gas Tightness Test. - Hydraulic test and oil flushing of seal oil system. - Seal Oil System – Circulation - Hydraulic test and flushing of primary water system. - Generator test schedule - Generator, generator bay protection test schedule 7.3 All the systems mentioned in 7.2 are in totally normalised condition and available for generator testing. 7.4 Fire protection system (CO2 system) is made available. 7.5 For carrying out short circuit test, short generator transformers HT terminals R,Y,B together at 400 KV side by earth switch or by the links capable of carrying 1500A current. Isolate 400 KV supply and earth. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 14 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 1. The following measurement circuits to be made through for monitoring and taking readings : a. b. c. d. e. f. g. h. Generator Voltage – RY, YB, BR Generator Current – R, Y, B Excitation Voltage Excitation Current Active Power Reactive Power Power Factor Energy meter Synchronising circuits and protection circuits also to be kept ready alongwith recommended settings set in the protection relays. 2. Testing / measuring equipments to measure PMG Voltage(3 Phase AC), main exciter Voltage (DC) and PMG’s phase sequence in AVR are to be kept ready. 3. Excitation Circuit : Fuses of PMG input to AVR and main exciter input from AVR output are to be checked for their healthiness. Cables of PMG and main exicter are to be cnfirmed that they are properly connected and are free from earth short or any other faults. Winding resistances of PMG and main exciter are to be taken only to check their healthiness. Healthiness of stroboscope and DAVR to be checked. trip should come from DAVR. 4. Ensure that Gen PTS are racked in and Gen bus duct are in pressurised condition. No STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 15 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 5. Systems : i. ii. Stator water cooling system is to be kept on line. Rotor cooling is to be confirmed by parameters of H2 temp. iii. Seal oil circulation in service is to be confirmed. iv. All RTDs are to be monitored in control room. v. Busduct pressuring unit must be in service. vi. Rotor earth fault circuit to be made ready and kept on line. vii. Operation of UT-A&B-11KV breakers and GCB are to be checked and found OK. UT-A & B breakers are to be put in test position. 6. Following modifications to be carried out normalised after synchronisation of generator. i. ii. iii. iv. v. and to be Excitation system on manual Auto channel in blocked condition. Field breaker closing from ATRS inhibited. Auto synchronised isolated from circuit. Turbine trip from generator trip removed. GRP TB3 – 9 & 10 GRP TB3 – 11 & 12 7. LBB LINKS to be kept out 8. Interlock between be defeated. 9. GT differential protection input CT Sec. Links. switchyard isolated and field beaker to to be disabled by shorting At 3000 rpm Measure PMG voltage frequency and phase sequence . STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 16 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 7.6 Excitation system panels are kept in ON condition. 7.7 The steam turbine run start-up procedure. 7.8 The spill currents in the CT terminals in the relay panel,control panel& AVR panels are first checked when the machine is at 3000rpm. to 3000rpm after following the STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 17 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 8.0 TEST METHOD : 8.1 8.1.1 8.1.2 Short circuit characteristics test : AVR in manual mode. FB is off and no trip from tripping relays and AVR. Hence, FB close permissive available. Close GCB in dead circuit. Measure CT secondary current of GT CT at switchyard. Control room. Switch on the excitation Slowly raise excitation till generator current reaches 500 A and note the readings of field voltage, current, generator excitation current, terminal voltage and stator currents in three phases. Slowly raise excitation and measure the above parameters at diff. Stator currents till the rated stator current. Draw a graph between field current and gen. Current. 8.1.3 8.1.4 8.1.5 8.1.6 8.1.7 8.1.8 S.No 01. 02. 03. 04. 05. 06. 07. 08. 09. 10. 11. 12. 13. 14. 15. 16. 17. Gen.Field Current (Amps) Gen. current 500 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000 15000 16000 A A A A A A A A A A A A A A A A A Exciter field voltage Exciter field current Gen. Termina l Voltage AVR control Voltage STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 18 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 9 Find overall Transformer. 8.2 1. short circuit ratio of Generator and Generator PROTECTION CHECKING: Proving of Rotor Earth Fault protection (64E) : At machine stand still condition, connect the ground fault detection brush to earth and ensure that rotor earth fault relay operates (Refers 3-562-006-0357 / Rev.2, Sheet-37). Either TE or EE side (TB1-40 OR TB1-41 to be earthed). 2. When GCB closed and , out. a. the following checks can be carried Proving of negative phase sequence (46G). Change the polarity of anyone phase of 3 Phases currents by interchanging relay terminals A5 and A6 or A7 and A8 or A9 and A10 (sheet 36). i. Ensure that the relays flags are reset. ii. Close field breaker and slowly raise excitation till the current is about __________ alarm will appear after 5 Seconds trip will occur at K1 times operating time. Operating time depends on the current setting I23 . iii. Reduce excitation and switch off FB. iv. Normalise wires on relays terminals. b. Proving of Generator field failure protection (40G1 & 40G2). i. Set K1K5 to the maximum setting. ii. Check K3 + K4 = K2. iii. The Voltage across terminals 7 & 8 of the relay and current through terminal 6. iv. Close FB and slowly raise the excitation. Check relay operates at Vs = 2I (K1K5 + (K3+K4) STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 19 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING v. Record Vop = Iop = Volts Apms. vi. Reduce the excitation and trip FB. C. Proving of Generator Trasnformer Differential Protection (87GT R,Y,B) Keep Relay setting in the minimum value so as to avoid generator to run in fault condition for a long time and for the maximum fault current R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP 7 TB1-1&4 (wire nos. A411, A470) and monitor differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current . Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP 7 TB1-2&4 (wire nos. A431,A470) and monitor differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. PHASE R Y B OPERATING CURRENT GENERATOR CURRENT STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 20 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING D. Proving of Generator Differential Protection (87G1) R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP1 TB1-1&4 (wire nos. A11,A70) and monitor differential current at relay terminal 6. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current . Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP1 TB1-2&4 (wire nos. A31,A70) and monitor differential current at relay terminal 8. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current . Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. B phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP1 TB1-3&4 (wire nos. A51,A70) and monitor differential current at relay terminal 10. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current . Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. E. Proving of Gen. Trf HV winding Diff Protection (87HV) R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP2 TB1-22&25 (wire nos. A511,A570) and monitor differential current at relay terminal 6. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 21 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING Generator current . Switch off Excitation and breaker. Normalise TB wirings and relay settings. trip field Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP2 TB1-23&25(wire nos. A531, A570) and monitor differential current at relay terminal 8. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. B phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP2 TB1-24&25 (wire nos. A551,A570) and monitor differential current at relay terminal 10. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. F. Proving of Generator Differential (87G 2R,Y,B) R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP6 TB1-1 & 4 (wire nos. A111,A170) and monitor differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP6 TB1-2&4 (wire nos. A131, A170) and monitor differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current . Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 22 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING B phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP6 TB1-3&4 (wire nos. A151, A170) and monitor differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. G. Proving of GT overhead connection Diff (87TL R,Y,B) R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP2 either TB1-1 & 4 (A211,A270) or TB1-6&9(A221&A280) or TB1-11&14(A311&A370) or TB1-16&19 (A321&A380) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP2 either TB1-2 & 4 (A231,A270) or TB1-7&9(A241&A280) or TB1-12&14(A331&A370) or TB1-17&19 (A341&A380) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker.Normalise TB wirings and relay settings. B phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP2 either TB1-3 & 4 (A251, A270) or TB1-8&9(A261&A280) or TB1-13&14(A351&A370) or TB1-18&19 (A361&A380) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current . Switch off Excitation and trip field breaker.Normalise TB wirings and relay settings. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 23 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING H. Proving of Unit Transformers Differential (87 UTA R,Y,B & 87UTB R,Y,B) UNIT TRANSFORMER - A R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP3 either TB1-1 & 4 (A111A, A170A) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP3 either TB1-2 & 4 (A131A,A170A) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. B phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP3 either TB1-3 & 4 (A151A, A170A) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. UNIT TRANSFORMER - B R phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP3 either TB1-16 & 19 (A111B,A170B) and measure differential current at relay STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 24 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. Y phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP3 either TB1-17 & 19 (A131B, A170B) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. B phase: with machine in de-excited condition, block contribution of current to differential relay by shortcircuiting CT secondary wires on GRP3 either TB1-18 & 19 (A151B, A170B) and measure differential current at relay terminal 27. Switch on excitation & slowly raise till generator current is around 2000A. Record the values of operated current and Generator current. Switch off Excitation and trip field breaker. Normalise TB wirings and relay settings. I. Proving of Backup Impedance(21GRY,YB,BR) Excite the machine and slowly raise the current till the relay operates. Measure current at relay terminal 5 & voltage across 7 & 8. Note the values of Operating current and Voltage. iii) Normalise Generator Transformer HT terminals. Open Generator Circuit Breaker. 8.3 Open Circuit Characteristic Test 1. Keep DAVR in manual 2. Ensure that no trip from protection panel as well as DAVR are not present. 3. Field breaker close permissive is available STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 25 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 4. Close field breaker 5. Excite slowly upto Generator Terminal Voltage reaches 2 KV. Note down the values of Field voltage,field current,Generator field current and Generator current against Generator terminal voltage. 6. Increase the excitation in steps of stator terminal voltage 2 KV and note down the above values. 7. Tabulate the values noted and draw a graph between Generator field current Vs Generator terminal voltage. 8. Find Characteristic impedance of Generator Gen. Termina l voltage 2000 v 4000 v 6000 v 8000 v 10000 v 12000 v 14000 v 16000 v 18000 v 20000 v 21000 v 8.4 Exciter field voltage Exciter field current Gen. current S.No. Gen.Fie ld Current (Amps) AVR control Voltage 01. 02. 03. 04. 05. 06. 07. 08. 09. 10. 11. Proving of Stator earth fault (64G1 & 96G) 64 G1 1. Earth any one of the phases at 400 KV side. 2. Keep stator Earth fault relay settings at minimum value. Close FB and slowly raise the excitation. Note the values of voltage operated and current flown through earthed phase when relay operates. Normalise the earth and relay setting connection after reducing excitation and tripping FB. 3. 4. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 26 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 96G : 1. Earth the point where neutral grounding transformers and generator neutral connected together. 2. Set the relay setting in minimum in order to avoid over strain of generator. Close FB and slowly raise excitation fill relay operateds note the values of current operated. Reduce excitation, trip FB and then normalise the earth connection made for testing as said in point No.1. 3. 4. a. Proving of Over voltage(59G) & under voltage (27G1,27G2) Excite the machine & reach the rated terminal Voltage across Generator stator terminals i.e.21 KV . Measure the voltage across 9 & 10 of 27G1 & 27G2. Reduce the voltage to the set value percentage of the above relays and check that the relays are operated. Increase the terminal voltage further above rated voltage by 5 or 10 %. Check over voltage relay 59 G1 operated CAUTION: KEEP AS MINIMUM SETTINGS AS POSSIBLE SO THAT GENERATOR STATOR TERMINALS WILL NOT OVERSTRAIN FOR SUDDEN VOLTAGE FLUCTUATIONS DURING TESTING. 8.5 Proving of Under frequency Protection(81G1) 1. Short GRP4 TB1-11 &12 to bypass GCB close temporarily. 2. Increase the relay setting above 50 HZ for testing so that it senses normal frequency as under frequency. 3. Excite the machine and maintain rated terminal voltage 4. Once terminal voltage is reached, underfrequency relay will operate. 5. Normalise TB shortings and relay settings as recommended. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 27 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING b. Proving of Gen overfluxing (99G) 1. 2. 3. 8.6 8.6.1 8.6.2 8.6.3 8.6.4 8.6.5 8.6.6 8.6.7 8.6.8 Keep the setting to minimum of 1.o Excite the machine such that the secondary voltge of PT at the relay terminals is 110V. Relay will operate. After that reduce exdcitation and trip field breaker. SYNCHRONISING: Now set all the relays as per the recommended values. The following are the steps for synchronizing the generator to the Grid: Excite the generator to the rated voltage. Switch the synch.selector switch to Manual position and also switch on the synchroscope. By monitoring the double voltmeter, match the generator voltage by raising or lowering the excitation. The generator in coming voltage to be marginally greater than the running bus voltage. No check that the phase sequence of the running bus and the incoming bus are same. Now raise or lower the speed such that the synchroscope pointer rotates in the clockwise direction at a rate such that the check sync. Relay operates when the pointer is about 12’ O clock position. Close the generator breaker, when the ‘Check sync in’ lamps glows. Now, manually load the generator to 5 % of the rated load by giving raise command to the speed reference. Further loading of the generator is done from the turbine control panel. STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 28 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 9. COMPLETION CRITERIA : 9.1 THE RECORD VALUES OF TESTING CARRIED OUT ARE COMPLETED AND ON GENERATOR KEPT ALONG WITH THIS TESTING SCHEDULE. 9.2 GENERATOR AUX SYSTEM FOR RUNNING GENERATOR ARE LISTED KEPT ALONG WITH THIS SCHEDULE. 9.3 GENERATOR IS READY FOR SYNCHRONIZATION. AND STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 29 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 10. APPENDICES Drawings :1. Schematic Diagram of Gen, GT & UT protection (3562-006-0357) Rev.02 2. Schematic diagram Electrical control panel-1. (3659-0050610) Rev. 3. Line 1 & line 2 diameter circuits isolator interlock (3-562-006-0296) Rev.02. 4. Schematic diagram of 400 KV bus-1&2 protection (TBDG 1865100101/02) MANUALS : 1. 2. Relay manuals (Volume – I to Volume IV) 500 MW Turbo Generator O&M manual. GENERATOR SYNCHRONIZATION CIRCUIT Sl Source location phases No. values Phase sequenc e 1 400 KV Bus 1 2 400 KV Bus 2 ECP1 TBG-23a & 24a R - Y TBG-24a & 25a Y – B TBG-25a & 23a B – R ECP1 TBG-27a & 28a R – Y TBG-28a & 29a Y – B TBG-29a & 27a B – R STATION: NTPC SIMHADRI BHEL REF NO : PS-DC-186-500-0020 NTPC REF NO: SIM/1/TS/ 2 / 008 SHEET 30 OF 30 PLANT AREA : ELECTRICAL SYSTEM TESTING SCHEDULE : GEN. TESTING PROCEDURE FOR FIRST SYNCHRONISING 3 Generator GRP1 VT 2 (LV VT TB1-23 & 27 SIDE) TB1-27 & 31 R - Y TB1-31 & 23 Y – B GRP8 B - R TB1-36 & 38 VT 4 (HV TB1-38 & 40 SIDE) TB1-40 &36 R – Y ECP1 Y – B TBG-31a & 32 a B – R TBG-32a & 33a TBG-33a & 31a R – Y Y – B B – R `