Six Sigma Project Report Template - MEonline

advertisement

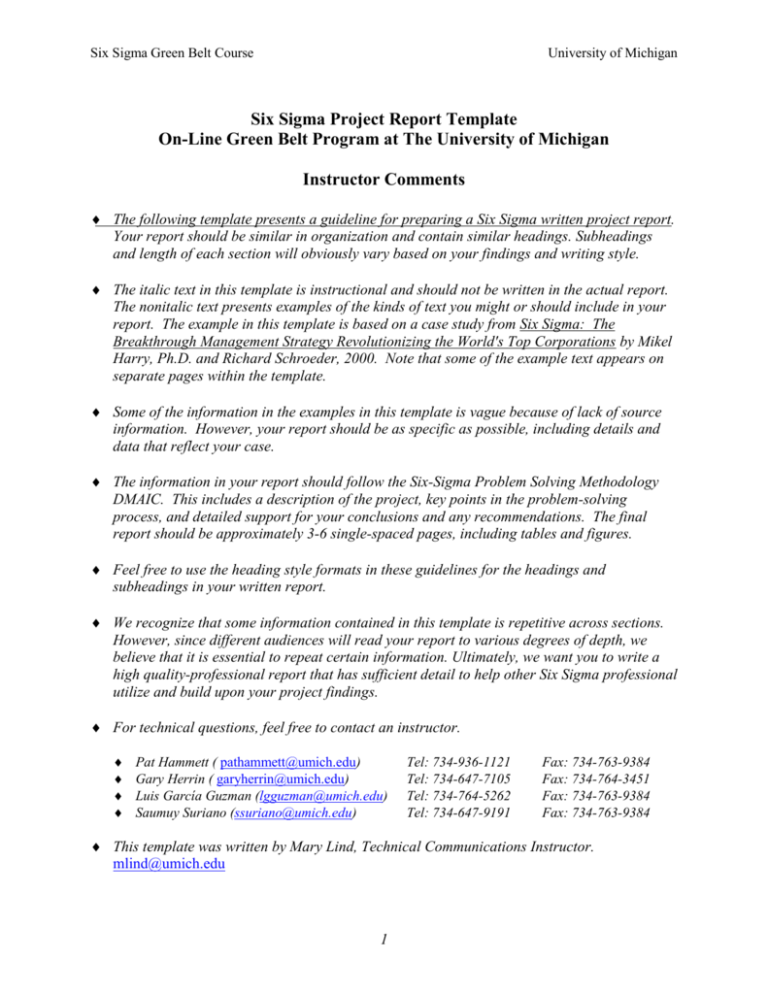

Six Sigma Green Belt Course University of Michigan Six Sigma Project Report Template On-Line Green Belt Program at The University of Michigan Instructor Comments The following template presents a guideline for preparing a Six Sigma written project report. Your report should be similar in organization and contain similar headings. Subheadings and length of each section will obviously vary based on your findings and writing style. The italic text in this template is instructional and should not be written in the actual report. The nonitalic text presents examples of the kinds of text you might or should include in your report. The example in this template is based on a case study from Six Sigma: The Breakthrough Management Strategy Revolutionizing the World's Top Corporations by Mikel Harry, Ph.D. and Richard Schroeder, 2000. Note that some of the example text appears on separate pages within the template. Some of the information in the examples in this template is vague because of lack of source information. However, your report should be as specific as possible, including details and data that reflect your case. The information in your report should follow the Six-Sigma Problem Solving Methodology DMAIC. This includes a description of the project, key points in the problem-solving process, and detailed support for your conclusions and any recommendations. The final report should be approximately 3-6 single-spaced pages, including tables and figures. Feel free to use the heading style formats in these guidelines for the headings and subheadings in your written report. We recognize that some information contained in this template is repetitive across sections. However, since different audiences will read your report to various degrees of depth, we believe that it is essential to repeat certain information. Ultimately, we want you to write a high quality-professional report that has sufficient detail to help other Six Sigma professional utilize and build upon your project findings. For technical questions, feel free to contact an instructor. Pat Hammett ( pathammett@umich.edu) Gary Herrin ( garyherrin@umich.edu) Luis García Guzman (lgguzman@umich.edu) Saumuy Suriano (ssuriano@umich.edu) Tel: 734-936-1121 Tel: 734-647-7105 Tel: 734-764-5262 Tel: 734-647-9191 Fax: 734-763-9384 Fax: 734-764-3451 Fax: 734-763-9384 Fax: 734-763-9384 This template was written by Mary Lind, Technical Communications Instructor. mlind@umich.edu 1 Six Sigma Green Belt Course University of Michigan Title Stating Subject and Purpose of Report Submitted to: Name, Title Department/Organization Address (optional) Prepared by: Name, Title Department/Organization Address (optional) Date Submitted 2 Six Sigma Green Belt Course University of Michigan Example: Damage-Free Delivery Project: Solving Problems with Products Damaged in Shipping Submitted to: Name Unknown, CEO Polymerland, A Division of GE Plastics Prepared by: Name Unknown, Champion Also Name Unknown, Black Belt Polymerland, A Division of GE Plastics December 20, 1997 Note: Do not put a page number on your title page. Begin numbering the pages with the Executive Summary. 3 Six Sigma Green Belt Course University of Michigan Executive Summary The Executive Summary presents the major information the report contains. Its readers are typically managers who need a broad understanding of the project and how it fits into a coherent whole. These readers do not need or want a detailed understanding of the various steps taken to complete your project. Therefore, the Executive Summary allows readers to learn the gist of the report without reading the entire document, to determine whether the report is relevant to their needs, or to get an overview before focusing on the details. We consider writing a concise (one-page or less) and comprehensive executive summary a critical element of an effective Six Sigma project. The Executive Summary should include: Problem Statement Scope Methods (if appropriate) Major results, including key supporting information Conclusions Recommendations (if appropriate) An Executive Summary is not used as an introduction to the report, but is an independent, entirely condensed version–the report in miniature. It generally has the following characteristics: Length of 1 page for reports fewer than 10 pages. For longer reports, maximum length is often 5 to10% of the length of the full report. The Executive Summary should include no terms, abbreviations, or symbols unfamiliar to the reader. Readers should understand the content of the Executive Summary without reading the rest of the report. 4 Six Sigma Green Belt Course University of Michigan Example: Executive Summary On July 1, 1997 a representative of one of our largest and most lucrative customers told us he was considering taking his business elsewhere because too many of our products had been arriving contaminated. We immediately began examining the problem and determined that between January 1, 1997 and June 30, 1997, Polymerland delivered 275,501,855 pounds of products to our customers, 176,381 pounds of which were contaminated. That is, 176,381 pounds of products were damaged during shipping and then delivered to customers. We immediately told our dissatisfied customer that we would examine the problem closely and correct the situation. Next, we formed a team to determine the cause of the problem and implement a solution. Our team used the Six Sigma Strategy to examine the processes used in shipping our products and identify ways to optimize these processes. Following the Six Sigma Strategy, we determined that two of our warehouses, Maumee and Piedmont, produced the highest number of defects, while our Brampton warehouse was operating at Six Sigma levels. In the Maumee and Piedmont warehouses, 95% of the damaged boxes had two punctures at the base of one side of the box, causing leakage. In addition, we determined that 87% of the damage occurred when the boxes were moved with a forklift. We also discovered a relationship between how the product was packaged and the type of damage done. Bags were most likely to be damaged if they were scraped across the floor, but boxes were more likely to be damaged when handled by a forklift operator. We concluded there was a strong correlation between the damaged products and the use of a forklift to move them. However, the reason for the correlation was unclear since the Brampton warehouse, which was working at Six Sigma, also transported the product using forklifts. Therefore, we then looked at the forklift drivers in the Maumee, Piedmont, and Brampton warehouses and discovered that the forklift drivers in Brampton were more experienced than the drivers in Maumee and Piedmont. From this information, we determined that two factors contributed to the number of damaged products customers received: whether the product was moved in the warehouse by forklift and whether the forklift operator was experienced at operating a forklift. To reduce or eliminate the number of boxes damaged in our warehouses, we considered the following alternatives: Hire more experienced forklift operators for the Maumee and Piedmont plants. However, this would incur significant costs and may not be possible. Require extensive training for the forklift operators in the Maumee and Piedmont warehouses. This solution would also be expensive and would not guarantee fewer damaged products. Install shorter forks on all forklifts used in Polymerland warehouses. This installation would cost $350 per forklift. Beginning in December 1997, all Polymerland warehouses replaced the 42-inch forks with 36inch forks on their forklifts. Since this change, the number of damaged products delivered to our customers has reduced significantly. 5 Six Sigma Green Belt Course University of Michigan 1.0 Introduction (Not: optional as a separate section. You may include the following in the Define Phase Section) Announce the subject of the report (the problem the report addresses), the task performed in response to the problem, and the purpose of the report. Note: The purpose of the report is not the purpose of the project. The purpose of the report is to present information that will enable readers to understand a subject, to affect readers' attitudes toward some subject, or to enable readers to carry out a task. The introduction can also explain key terms used in the report (if appropriate); announce the most significant findings, including key support; announce the conclusions and, if appropriate, recommendations; and forecast the content and organization of the report (optional). Current practice supports including this information to give readers a viewpoint from which to interpret the data the report presents and to provide tools to help readers navigate through the text. Note: some of the information in an introduction may simply repeat from the executive summary. Example: 1.0 Introduction On July 1, 1997 a representative of one of our most lucrative customers told us he was unhappy that many of our products had been arriving contaminated. He complained that he had to use his company's time and resources to ship the defective products back to Polymerland for replacement, and said he would take his business elsewhere if the situation didn't improve. We immediately told him that we would correct the problem to ensure he receives only high quality products from Polymerland. Next, we formed a team chartered with using Six Sigma strategy to determine the cause of the problem and implement a solution. The purpose of this report is to present the results of our team's problem-solving process and explain the solution we adopted. Following the Six Sigma problem-solving strategy, we concluded that two factors contributed to the number of damaged products customers received: whether the product was moved in Polymerland's warehouse by forklift and whether the forklift operator was experienced at operating a forklift. In addition, we determined that the specific damage was caused by the forks on the forklift. The forks protruded six to nine inches out from under the box, so that as the fork was fully inserted under the box being retrieved, the box behind it was punctured. To reduce or eliminate the number of boxes damaged in our warehouses, we considered several alternatives and decided to install shorter forks on all forklifts used in Polymerland warehouses. Therefore, beginning in December 1997, all Polymerland warehouses replaced the 42-inch forks with 36-inch forks for $350 per forklift. This report presents a detailed explanation of the steps we followed using the six sigma problemsolving strategy—define, measure, analyze, improve, and control—to determine why our customer was receiving damaged products and to change the faulty step in our shipping process, ensuring these defects do not happen again. 6 Six Sigma Green Belt Course University of Michigan 2.0 The Improvement Opportunity: The Define Phase Some topics that should be included are: Discussion of the problem addressed in your project. Discussion of project scope, (e.g., if you choose to limit your project to a particular component within a larger problem statement due to project timing constraint or areas within your span of influence). Identification of key measures that you plan to use to evaluate the success of your project (examples: DPM, DPMO, process yield, error rates, processing or order-filling time, machine cycle time, # complaints, etc.) Discussion of impact on key business issues (e.g., reduction of error rates or improved order-filling times may result in lower operating costs or increased customer satisfaction. 3.0 Performance: The Measure Phase Analyze current performance levels and identify goals you hope to achieve. Do not present long, bulky data sets in the main report, place in appendices to the report. For our University Case Studies, the information necessary to apply some of the tools or methods listed below are not available and therefore not required. However, the techniques mentioned below provide possible things to include, particularly if you are using your own project. Among the issues that must be included in this section are:Identification of key output variable and listing of potential input variables/ sources of variation affecting your output performance (e.g., KPIV's and KPOV's) Assessment of Current Performance Levels. Need to quantify the current state of your performance metric (key output variable). Target Performance Levels. Compare current performance with target performance in terms of defects per million opportunities or Six Sigma quality level Examples of Current and Target Performance Level Assessments: Our current process requires 15 days to complete a special order and we wish to reduce this time to less than 7 days. Or, We currently are operating at 10,000 DPMsand wish to reduce this to less than 3.4 DPMs. Other issues that you may want to include in this section are: Flow chart, SIPOC Diagram or Current State Map of the process. This is highly recommended, as they are a great visual aid and allow other readers to immediately comprehend the process basics. Measurement System Validation. Discuss the validity of your measurement system using tools such as a Gage Repeatability and Reproducibility Study, and Gage Accuracy Study. For a transactional or non-manufacturing project, identify the strengths and limitations of your data collection methods. Visuals presenting results of capability studies or process audits. Process Control Charts or Run Charts Cause and Effect Diagrams 7 Six Sigma Green Belt Course University of Michigan 4.0 Analysis and Interpretation: The Analyze Phase Analyze gaps between current performance and target performance levels, explaining possible sources of variation. Include subtopics and subheadings that reflect your case. Note: Some of the analysis tools you use in the Analyze Phase may also apply in other Phases. Feel free to repeat tools for other phases as appropriate to present your argument. Among the issues that must be included in this section are: You must show evidence of the use of at least one data analysis tool/ method discussed in this course. You should support this requirement by including at least one table, graph, or diagram within the main body of the text. (e.g., include a Pareto chart, stratification analysis table, cause-and-effect diagram, scatter plot, correlation analysis, process control, chart, measurement systems analysis (gage R&R) report, etc.). Note: We encourage the use of additional data analysis tools and may request resubmittal of a project to include additional analysis if appropriate. 5.0 Recommendation: The Improve Phase Identify alternative ways to improve performance. Try to evaluate how well alternatives will be able to meet target performance goals. Specify criteria for choosing a course of action. Present conclusions regarding alternatives and identify recommended solution. Consider presenting the material in the following subtopics with appropriate second-level headings. Alternative Solutions Considered Recommended Solution 6.0 The Control Phase Identify the method of control such as process control charts, poke-yoke devices, process monitoring/ tracking systems, and standardized work. If data is available, demonstrate how your solution has achieved the desired results, where possible. Comment: We realize that it might not be possible to include data that supports that an actual improvement was made to the process because of the project time constraints. If this is the case, please at least discuss the potential benefits of implementing your recommendations. 8 Six Sigma Green Belt Course University of Michigan 7.0 Conclusion Briefly restate the problem addressed, the process followed to reach a solution, and the chosen solution. List the potential benefits to the chosen solution. Note: if your results or recommendations are incomplete or sensitive to your company, please try to discuss potential benefits in relative terms. (e.g., a 20% reduction in error rates or a 10% cost savings). If appropriate, explain any further action to be taken, including the responsible team members and schedule. Example: 7.0 Conclusion When one of our most lucrative customers complained about receiving defective Polymerland products, we immediately began working toward a solution. Using Six Sigma strategy, we determined the length of the forks on our forklifts was causing the forks to puncture the boxes during handling in our warehouses. After considering several alternatives, we replaced the 42inch forks with 36-inch forks for $350 per forklift. Now that all Polymerland forklifts are equipped with the new, shorter forks, we are seeing significantly fewer problems and our customers are again happy with our products. Appendices Use appendices to present information that is too bulky to be presented in the body of the report or that will interest only a few readers. For example, large diagrams or charts, computations, software package graphics, test data, and texts of supporting documents should appear in appendices. Appendices have the following characteristics: Titled "Appendix," not "Figure" or "Table." Usually lettered rather than numbered. Referred to at appropriate points in the body of the report so they are accessible to the reader who wants to consult them. Only use an appendix when the data is not relevant to the report but might be of interest to some of the readers. We expect most if not all of your tables and graphs to be in the main body of the report. 9 General Guidelines for Writing Reports The following list presents reminders to help you write reports that are easy to read and understand. You do not have to follow every one of these recommendations. How you present your written argument depends on your situation. These tips are offered as basic guidelines. For more information about techniques for writing clearly, consult a writing handbook or a writing website such as: http://www.plainlanguage.gov/ Know your audience and purpose when writing. Choose and organize your content around your purpose and audience. Use frequent, informative headings and subheadings. Headings and subheadings help readers preview and review the major sections of information. Divide material into short sections. Introduce the sequence of sections that follow to let readers know what's coming in the report. Limit each paragraph to one topic. Vary structure and length of sentences. However, prefer short, direct sentences. Use "you" to speak to the reader. Use "I" or "we" to refer to events in which you were involved. Note: Using "I" or "we" is now widely accepted in technical writing. Be concise. Avoid unnecessary words. Select appropriate diction. Prefer clear, simple language. Avoid inflated, obscuring words. Prefer active voice. Use the passive voice only when the identity of the agent is irrelevant. Be consistent in tenses. Prefer present tense. Prefer active verbs to abstract nouns. Use terms consistently to refer to the same object. Use lists. Use parallel grammatical structure for ideas or facts of equivalent importance (often presented in lists). For example: Instead of Accidents can be either personal injury producing or cause property damage write Accidents can either produce personal injuries or cause property damage OR Accidents can either injure people or damage property. Use visual cues to guide readers such as: - bullets or numbers to signal items in a list - indented lists - boldface to emphasize key points Use good document design: use plenty of white space; avoid all uppercase letters and underlining; use serif typefaces (such as Times New Roman used here); and use left-justified, ragged right margins. Display material suited to visual presentation in well-designed, clear visuals such as tables, charts, and maps.