Chapter 6 Quality Management And Six

advertisement

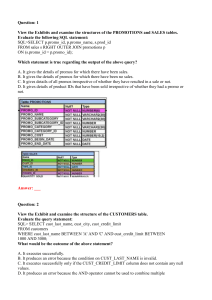

Stat process control: (TQM) Monitors prod process during process against standards to prevent poor quality (pro-active). Acceptance sampling (old school, not TQM), inspects random sample of product to determine whether or not a lot is acceptable (after-the-fact). 1:10:100 Rule fix in design stage, cost $1. Fix during prod cost $10. After Customer cost $100 to correct. Every Process Has Some Variability. Common Causes Variation inherent in process (Natural, expected, OK, allowed) Special Causes, “Assignable” variation traceable to identifiable prob mach broken, worker not trained. Out of control when special causes present A. Control Charts Attributes sample size 50 to 100+ (defect vs non-defective, good bad, is isn’t), discrete, it is countable Numbers of flaws, # accidents, good/bad… 1. P-Charts: Calculate percent detectives in sample, 2. C-Charts: Count number of defects in sample B. Variable data Continuous Metric measurable, Length, volume, weight, height, time. Sample size 4 or 5. use X- charts (for mean avg shift) and R-Charts (checks first for too high dispersion variability) 3-Sigma quality (2700 defects per mil) 6-sigma Qual (3.4 defects per mil) Process Capability Index CPk: Where is process centered, how well process meet specs., natural vari in a proc results from common causes, how well produc fit into range specified design specs, Want cpk larger than one min (nat var = design spec), more than 1better, more than 1.66 best, When two #s not close, mean shifted. Accept Qual Level (AQL): Producer-specified fraction defect in lot feel they can pawn off on cust. Average Outgoing Quality (AOQ): Expected # defects cust will get with specific sample plan. Lot Tolerance Percent Defective (LTPD): worst qual level acceptable to customer. LTPD is the max # of defect items in lot the cust will accept. Accept Sampling decisions whether to accept/reject a lot from supplier based on sampling plan. Type I Produce Risk: the prob of a good qual lot being rejected. Type II Cust Risk: the prob of accept poor qual lot. Make-to-Stock from finish inventory, applianc, TVs, shoes, sport goods, Trade-off costs inventory and level cust service Make-to-Order (Custom) produced delivered as one-of-a-kind or small quantities, weddings, $$$$ jewelry, estate plans, buildings,surgery. Assemble-to-Order (or Option) configs of standard parts subassemblies, cust-selected from set. custom computers Subway sandwich, travel agent services. 1. Projects: large-scale, cust initiatives that consist of smaller tasks finish on time, within budget. one-of-kind, large scale. 2. Job shop processes: types of gen-purpose equip flexible of custom work for cust. Signif setup, batch, low to mod volume, dif products, high labor skills, custom to specs. hospitals, legal services. 3. Flow shop: process around fixed steps. Auto, aircraft assembly line, and hospital lab work 4. contin flow: very high vol goods services, 24/7., high invest in system, continuous op, automat, chem, gas, steel; credit card auth. Value Chain A supply chain delivers product, “cradle-to-grave” model adds value. network of process which flow goods, services, info, cash suppliers to cust. Info back to suppliers. OSM design oper systems create deliver products services. Is function field of biz. clear lines of mang resp, effic and effect of sys goods or services Global Sup Chain: biz strat to matches cust pref w/ supply nets. Need sustaim strat, Trip bot line: Shareholders, social (employees), environment. Deliver growth via well design and effect process. PROCESSes: 1Planning: (process to op supply chain strategically) 2Sourcing; (suppliers) 3Produce, 4Deliver: 5Return: (defective, excess products) Durable good 3+ yrs, Nondurable good 3- yrs. Service not produce a phys product. US is Manuf 20% jobs, Service grow. US Manuf #1 in world.. Amer output highest world. Half of manuf jobs involve services ( Op Mgmt, resource, Acctg, fin) 90% of the US Jobs are service processes. Services intangible, not patented, interact w/ custr, design for cust, heterogeneous, perishable, time dependent. cannot be stored. Efficiency: Doing things at lowest cost Effectness: Doing right things create value. Can be none, one or both. max both creates conflict. Value= quality divided by price. #1 purp of org provide “value” to its customers and stakeholders. Value is the “perception” of benefits to price. CHALLENGES: 1. Coord support, sep orgs 2. Optimiz global 3. Mang cust touch pts 4. Raise senior mgt aware op as compet weapon 5. Sustain “triple bottom line (Econ, employee, and envlro viability). Op and supply strategy: set broad policies plans for use recourse firm to best support long-term compet strat. Part of a plan process that coord op goals with larger org. Op drives core biz proces to run biz. Mission umbrella then Corp Strat then ops strat to support Mission. Competitive Dimensions 1. Cost: Low-cost strat 2.Quality 3. Speed/reliabilfty 4. Flex 5. Innovat. Compet advan: a co’s ability to achieve market superiority. Core Competencies: Effective strategies develop around key competitive priorities e.g., low cost, fast service, speed/time, qual, flex, innov. Provides a focus for the org. 1. provides cust benefits 2. hard for competitors to imitate 3. lever widely to products. Compet dimensn: emphasis a co places on perform measur in value chain. Quality meas degree output of process meets cust requirs. Speed reliability are the most important sources of compet adv. Flexibility ability adapt quick effectv to change requirmnts, demand, vol, bring new goods/services fast. Mass customization produce large vol of customized goods. An op cannot excel in ALL compet dimensions. Straddle co seeks to match competitor by new features, services, to existing activ. Not Focused. Creates probs, risky. #1: how org provides value to cust.. Good decis facilitated via measure. Good measures enable mgrs to control process make decisions. Measures - not too many or too few - Safety Measur vital to all orgs, Other measur; complaints, loyalty, retention, warranty, claims, failures. Qual measurs degree to which output of process meets cust requimnts. Common measure of goods qual is number of defects per unit. Dimensions of qual (Garvin) 1Performce, 2Features, 3Reliability, 4Conformance (the degree to which charact match pre-est standards), 5ServIce QualIty (defects errors per million opportunities) 6Durability, 7Serviceability, 8Aesthetics, 9Flexibility… flexibilities respond quickly to changes in the volume and type of demand, Innovation new and unique goods and services delight customers and create compet adv. Learn refers creating, acquiring, transfer knowledge to employees as demands change. “Microsoft a/ways two years away from failure.” Bill Gates. How Productivity incr: more effic (incr input) Downsize (reduce Input costs) Expand (both I/0 Incr, but Output grows faster). Retrench (both I/O decrease, Input decreases faster) Breakthroughs (output Increases, while Input decreases) Productivity confused with effic or effect. Efficiency is degree to which process generates outputs with min inputs. Effects is achieving the orgs object, mission, goal. Wall Street Evaluate (not include EPS). Efficiency, turnover, productivity, margin, asset utilil, growth. Back Page is Below Supply Chain Network: The pipeline like movement of the materials and information needed to produce a good or service. Triple Bottom Line: A strategy that meets the needs of shareholders, employees, and preserves the environment. Planning: The processes needed to determine the set of future actions required to operate an existing supply chain. Sourcing: The selection of suppliers. Making: A type of process where the major product is produced or service provided. Delivering: A type of process that moves products to warehouses or customers. Returning: Processes that involve the receiving of worn out, defective, and excess products back from customers and support for customers who have problems. Service: A business where the major product is intangible that cannot be weighed or measured. Servitization: Refers to when a company builds service activities into its product offerings. Efficiently: Means doing something at the lowest possible cost.Effectively: Means doing the right things to create the most value for the company. Value: Metaphorically defined as quality divided by price. Total Quality Control: A philosophy which aggressively seeks to eliminate causes of production defects. Business Process Reengineering: An approach that seeks to make revolutionary changes as opposed to evolutionary changes (which is advocated by total quality management). Lean Manufacturing: An approach that combines TQM and JIT. Six-Sigma Quality: Tools that are taught to managers in “Green and Black Belt Programs. Service Science Management: A program to apply the latest concepts in information technology to improve service productivity. Sustainable: A strategy that is designed to meet current needs without compromising the ability of future generations to meet their needs. Cost: It is probably most difficult to compete on this major competitive dimension. Order Winner: A criterion that differentiates the products or services of one firm from those of another. Order Qualifier: A screening criterion that permits a firm’s products to he considered as possible candidates for purchase. Activity System Map: A diagram showing the activities that support a company’s strategy. Decoupling Point: A point where inventory is positioned to allow the production process to operate independently of the customer order delivery process. Engineer to Order: A firm that designs and builds products from scratch according to customer specifications would have this type of production environment. Cell: This is a production layout where similar products are made. Typically it is scheduled on an as—needed basis in response to current customer demand. Product Process Matrix: The relationship between how different layout structure are best suited depending on volume and product variety characteristics is depicted on this type of graph. Degree of Customer Contact: Service systems can he generally categorized according to this characteristic that relates to the customer. Service System Design Matrix: A framework that relates to the customer service system encounter. Line of Visibility: This is the key feature that distinguishes a service blueprint from a normal floss chart. Poka-Yoke: This is done to make a system mistake proof. Design Quality: This refers to the inherent value of the product in the marketplace and is a strategic decision for the firm. Conformance: Relates to how well a product or service meets design specifications Fitness for Use: Relates to how the customer views quality dimensions of a product or service. ISO 9000: The series of international quality standards. Variation: What is the enemy of good quality DMAIC: The standard quality improvement methodology developed by General Electric. Assignable: Variation that can he clearly identified and possibly managed. Common: Variation inherent in the process itself. Taguchi: An alternative to viewing an item as simply good or had due to it falling in or out of the tolerance range. Attribute: Quality characteristics that are classified as either conforming or not conforming to specification. Variable: A quality characteristic that is actually measured, such as the weight of an item. p chart: A quality chart suitable for when an item is either good or bad. c-chart: A quality chart suitable for when a number of blemishes are expected on each unit, such as a spool of yarn. Acceptance Samples: Useful for checking quality when we periodically purchase large quantities of an item and it would be very costly to check each unit individually. Op Characterisitics Curve: A chart that depicts the manufacturer’s and consumer’s risk associated with a sampling plan.