Chronologie Airbus

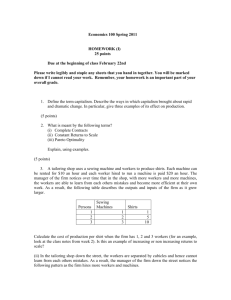

advertisement