1010256 - Extras Springer

advertisement

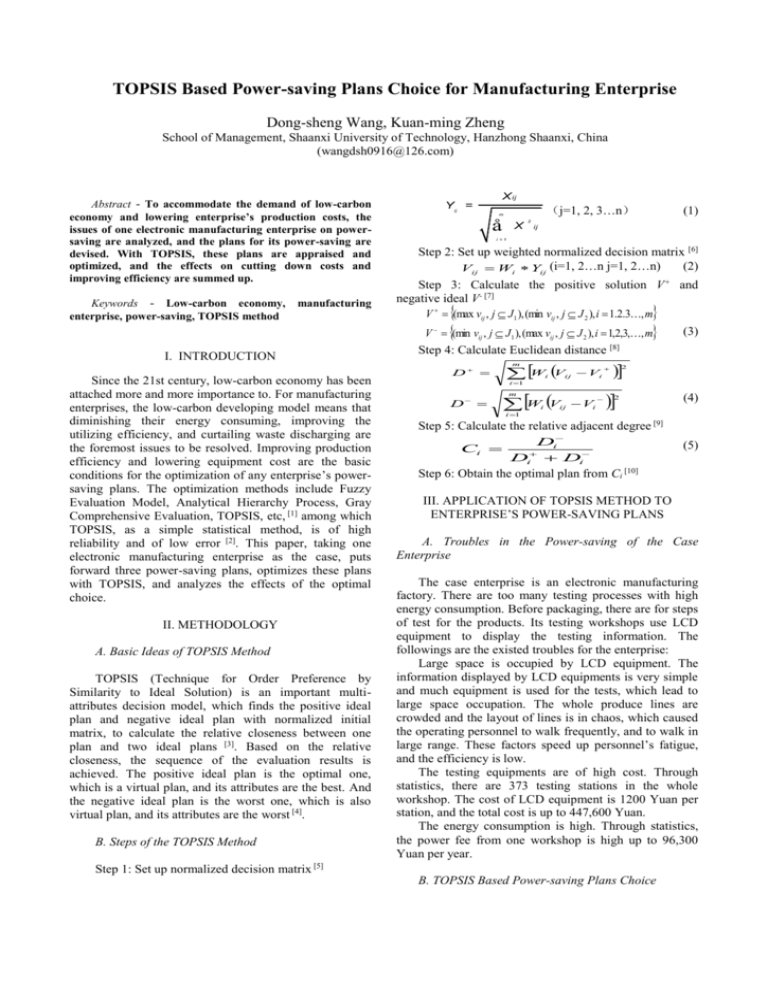

TOPSIS Based Power-saving Plans Choice for Manufacturing Enterprise Dong-sheng Wang, Kuan-ming Zheng School of Management, Shaanxi University of Technology, Hanzhong Shaanxi, China (wangdsh0916@126.com) Abstract - To accommodate the demand of low-carbon economy and lowering enterprise’s production costs, the issues of one electronic manufacturing enterprise on powersaving are analyzed, and the plans for its power-saving are devised. With TOPSIS, these plans are appraised and optimized, and the effects on cutting down costs and improving efficiency are summed up. Keywords - Low-carbon economy, enterprise, power-saving, TOPSIS method manufacturing I. INTRODUCTION Since the 21st century, low-carbon economy has been attached more and more importance to. For manufacturing enterprises, the low-carbon developing model means that diminishing their energy consuming, improving the utilizing efficiency, and curtailing waste discharging are the foremost issues to be resolved. Improving production efficiency and lowering equipment cost are the basic conditions for the optimization of any enterprise’s powersaving plans. The optimization methods include Fuzzy Evaluation Model, Analytical Hierarchy Process, Gray Comprehensive Evaluation, TOPSIS, etc, [1] among which TOPSIS, as a simple statistical method, is of high reliability and of low error [2]. This paper, taking one electronic manufacturing enterprise as the case, puts forward three power-saving plans, optimizes these plans with TOPSIS, and analyzes the effects of the optimal choice. II. METHODOLOGY A. Basic Ideas of TOPSIS Method TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) is an important multiattributes decision model, which finds the positive ideal plan and negative ideal plan with normalized initial matrix, to calculate the relative closeness between one plan and two ideal plans [3]. Based on the relative closeness, the sequence of the evaluation results is achieved. The positive ideal plan is the optimal one, which is a virtual plan, and its attributes are the best. And the negative ideal plan is the worst one, which is also virtual plan, and its attributes are the worst [4]. B. Steps of the TOPSIS Method Y ij X ij = (j=1, 2, 3…n) m å X (1) 2 ij i =1 Step 2: Set up weighted normalized decision matrix [6] (2) Vij Wi Yij (i=1, 2…n j=1, 2…n) Step 3: Calculate the positive solution V+ and negative ideal V- [7] V (max vij , j J1 ), (min vij , j J 2 ), i 1.2.3, m (3) V (min vij , j J1 ), (max vij , j J 2 ), i 1,2,3,, m Step 4: Calculate Euclidean distance [8] D W V m i i 1 D ij W V m i 1 i ij Vi Vi 2 2 Step 5: Calculate the relative adjacent degree [9] Di Ci Di Di Step 6: Obtain the optimal plan from Ci [10] (4) (5) III. APPLICATION OF TOPSIS METHOD TO ENTERPRISE’S POWER-SAVING PLANS A. Troubles in the Power-saving of the Case Enterprise The case enterprise is an electronic manufacturing factory. There are too many testing processes with high energy consumption. Before packaging, there are for steps of test for the products. Its testing workshops use LCD equipment to display the testing information. The followings are the existed troubles for the enterprise: Large space is occupied by LCD equipment. The information displayed by LCD equipments is very simple and much equipment is used for the tests, which lead to large space occupation. The whole produce lines are crowded and the layout of lines is in chaos, which caused the operating personnel to walk frequently, and to walk in large range. These factors speed up personnel’s fatigue, and the efficiency is low. The testing equipments are of high cost. Through statistics, there are 373 testing stations in the whole workshop. The cost of LCD equipment is 1200 Yuan per station, and the total cost is up to 447,600 Yuan. The energy consumption is high. Through statistics, the power fee from one workshop is high up to 96,300 Yuan per year. Step 1: Set up normalized decision matrix [5] B. TOPSIS Based Power-saving Plans Choice Through brain-storm, three plans are addressed. The first is that replace the CMC for LCD equipment which is a kind of apparatus for displaying scanning and testing information. The advantage of this plan is of comprehensive information and of good effects; and the weakness is of low visual angles and of high cost. The second plan is that substitute LED equipment for LCD. The advantage is of good visualization, of efficient information and of low equipment cost; and the weakness is of too simple in displaying information. The third plan is that change LCD equipment for LED indicator lamps with different colors. The advantage is of direct observation, of efficient information and of low price; and the weakness is of little information and of chaos in visualization. Through analysis and research, lowering equipment cost, diminishing space occupation, saving power, and improving the efficiency are the indexes for plan choice. The steps to use TOPSIS for the choice of the powersaving plans are the followings: Step 1: Set up decision indexes set C y1 = lowering - cost y = improving - efficiency 2 C y3 = occupying space y4 = saving power Step 2: Set up plans set X x1 plan1 X x 2 plan2 x 3 plan3 Step 3: Decide the weight of indexes and set up the weight set W w1(lowering cost) 0.25 w (improving efficiency) 0.15 W 2 w3 (occupying space) 0.35 w (saving power) 0.25 4 Step 4: Decide the actual value of indexes Through market survey and field measurement, the price of CMC is 1500 Yuan per station, and the space occupation is 0.00179m3; the price of LED monitor is 200 Yuan per station, and the space occupation is 0.00145m3; the price of LED indicator is 150 Yuan each, and the space occupation is 0.00062m3. According to the above data, the score of the three plans’ efficiency-improving and power-saving can be obtained as tableI: TABLE I INITIAL VALUE OF DECISION INDEXES Index Plan Plan 1 Plan 2 Plan 3 The dimensions of the above values are different. Thus it is necessary to transform the value to normalized ones with Eq.1. Y11 =0.986394 Y12 0.131519 Y13 0.098639 Y21 1.053182 ; ; ; ; Y22 1.180127 ; Y23 0.52718 ; Y31 0.32014 ; Y32 0.260452 ; Y33 0.11146 ; Y41 0.840125 ; Y42 0.744251 ; Y43 1.04825 . From the above values, the decision matrix Y can be obtained: 0.986 1.053 0.320 0.840 Y 0.132 1.180 0.260 0.744 0.100 0.527 0.111 1.048 Step 6: Calculate weighted decision matrix V with Eq.2. 0.247 0.158 0.112 0.210 V 0.032 0.177 0.091 0.186 0.025 0.079 0.039 0.262 Step 7: Calculate positive and negative ideal solution with Eq.3. V 0.025 0.177 0.039 0.262 V 0.247 0.079 0.112 0.186 Step 8: Calculate Euclidean distance D with Eq.4. D1 0.240 ; D1 0.082 ; D2 0.092 ; D2 0.236 ; D3 0.099 ; D3 0.246 According to the above value, tableII can be ascertained. Step 9: Calculate the relative adjacent degree C with Eq.5. C1 0.255 ; C2 0.720 ; C3 0.713 C 2 C3 C1 Among which, the second plan is the most optimal as the final choice. TABLE II EUCLIDEAN DISTANCE OF THE THREE PLANS Plan Plan 1 Plan 2 Plan3 D+ 0.240 0.092 0.099 D- 0.082 0.236 0.246 Item IV. PERFORMANCE ANALYSIS ON THE PLAN CHOICE Lowering Cost (Yuan) Improving Efficiency Occupying Space (m3) Saving Power 1500 200 150 8 9 4 0.00179 0.00145 0.00062 9 8 9 Step 5: Ascertain normalized decision matrix Y Until present, the case enterprise has introduced plan2 to display testing information, and the performance is fairly well. Before improvement, the total cost of equipment is up to 447,600 Yuan and the power fee from one workshop is high up to 96,300 Yuan per year. After the enforcement of plan 2, the total cost is 74,600 Yuan and the power fee is 12,000 Yuan per year. The cost saving is 373,000 Yuan, and the power fee is lowered by 84,300. At the same time, the substitute of LED monitor for LCD equipment makes the production line in order, improves personnel’s morale, and allows workers to see the information clearly without much motion. And through speech set on the equipment, the information of code type can not only be identified by visualization but also by sound, which facilitates workers’ operation. And the replaced LCD equipment can be made use by other department and production line. The goal of lowering cost and saving power is attained. V. DISCUSSION Since the early 21st century, we have focused on low carbon, which emphasizes protecting our environment. For the public, it means leading a simple and saving life. And for the enterprises, it means eliminating the redundant emission, lowering power using, comprehensively reusing the material called waste before, and recycling the materials that can be reused such as packages, bottles, and so on. Unfortunately, in the early stage of the low-carbon economy, there are a number of requirements on the publics at present. Those on enterprises seem to be neglected. Someone will say that environment protection has been awakened by many governments in the world, and the relative institutions have been initiated since the 1960s. But an obvious fact must be laid on the desk that compared with the public the amount of power-using by enterprises is fairly huge. Thus, enterprises should be the priority to low-carbon economy. For enterprises, to meet the requirement of reducing emission, reusing and recycling, they should enforce their consciousness and self-discipline besides abiding by the outer institutions, which means they should adjusting their operation strategies to cover reducing, reusing and recycling., and some scientific methods should be adopted. This paper takes a specific case to explore the way to lower its power-using with TOPSIS. But faced with the pressure of profit earning and growing, quite a few enterprises will not consider too much low-carbon. Seemingly, it is reasonable. But through deep exploring, the fact that one enterprise which complies to the demand of low-carbon usually affords high costs, which will be a burden for its development. And those enterprises that consider these factors of low-carbon will not obtain anything in return. Although some stimulus measures have been enforced in low-carbon by some governments; these measures are usually treated as temporary ones. And form the long period perspective, these measures will cause damage to the enterprises’ operation. The reasons are that some enterprises will rely highly on the allowances form government, and some will use these allowances to compete with others, which will cause unfairness, even international trade disputes such as antidumping and anti-subsidies. So, for enterprises, the low-carbon economy needs more innovations including technology, operation and management. The technology innovation means some techniques that are efficient in low-carbon will be invented and adopted by enterprises. The operation innovation means the enterprises must change their visions. From the present research and practice, lowcarbon supply chain seems as one effective strategy. Its application will equalize the costs of reusing, reducing and recycling on the supply chain. This strategy needs some supportive means such as low-carbon contracts for all members on the chain, interest-collaboration between different members, and so on. And on the basis of operation innovation, the management must innovate on some aspects such as information management, outsourcing, supplier management, channel management, etc. In a word, this paper probes the way to low-carbon development of one enterprise’s power-saving. To comprehensively realize low-carbon economy, the field must extend from the public to all industries. And enterprises should play relatively important role in the process. The cost of the realization of low-carbon economy requires a full range of innovations. REFERENCES [1] Chao-yuan Yue, Theory and methods for decision (in Chinese). BJ: Science Press, 2003, ch. 6, pp. 133-140. [2] Xiu-ying GUO, Li JIN, “Grey incidence TOPSIS for multiple attribute decision making (in Chinese),” ScienceTechnology and Management. CHN., vol.12,no.5, pp49-51, May. 2010. [3] Ke-long XU, “TOPSIS method based on pairwise comparisons (in Chinese),” Mathematics in Practice and Therory. CHN., vol.40,no.5, pp 110-114, May. 2010. [4] Kong Feng, Liu Hong-yan, “A new Fuzzy TOPSIS Algorithm for MADM based on decision maker's subjective preference,” in Proc. 24th Chinese Control Conference, Guangzhou, P.R. China, pp.1697-1701. [5] Rohit Verma, E.Pullmanb Madeleine, “An analysis of the supplier selection process,” Omega. vol.26, no.6, December 1998, pp.739-750. [6] Ming-Chuan Lin, Chen-Cheng Wang, Ming-Shi Chen, and C. Alec Chang, “Using AHP and TOPSIS approaches in customer-driven product design process,” Computers in Industry, vol.59, Issue 1, January 2008, pp.17-31. [7] Zhi-ying Liao and Jens Rittscher, “A multi-objective supplier selection model under stochastic demand conditions,” International Journal of Production Economics, vol.105, Issue 1, January 2007, pp.150-159. [8] G.Barbarosoglu,“A decision support model fore customer value assessment and supply quota allocation,” Production Planning and Control, vol.11, no.6, pp.608 一 616, 2000. [9] Pawlak Z.Rough sets, “Theoretical aspects of reasoning about data,” International Journal of Computer and Information Sciences, 1982, (11), pp.314-356. [10] Sun Bin, Wang Li-jie, “Study of Method for Determining Weight Based on Rough Set Theory,” Computer Engineering and Application, 2006, 29, pp.216-217.