Link - Universiti Teknologi Malaysia

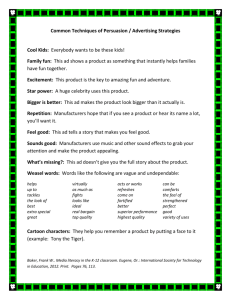

advertisement