Chapter 12

advertisement

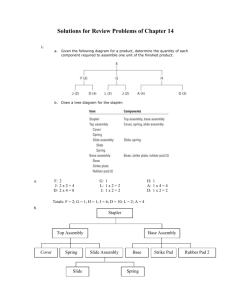

CHAPTER 15: MRP AND ERP Teaching Notes When covering the material the following points should be emphasized: Dependent demand item needs are generated from higher level item needs of which they are a part. The dependent demand needs tend to be lumpy and not dispersed uniformly. Dependent demand item needs are calculated from higher level item needs of which they are a part. MRP creates schedules identifying the parts and materials required to be purchased or manufactured, time of the order release as well as the size of the order or production quantity. MRP keeps track of inventory levels and serves as a link between inventory, purchasing and production. MRP inputs are: a. Master Production Schedule b. Bill of Materials c. Inventory Records Master Production Schedule is the driving force and the control mechanism of the MRP system because it specifies the quantity required of each end item or key assembly by time period. The theme of MRP is producing or purchasing the right materials at the right time and having them available in the right places. The MRP system uses backward scheduling. It uses low-level-coding and starts at the end item level and explodes requirements level-by-level. MRP provides feedback about delayed or cancelled orders, changes in quantities and due dates of open and future orders. MRP nervousness occurs as a result of the high frequency of updating the MRP system and the amount and timing of changes, cancellations, additions, delays in order/manufacturing quantities of an MRP system. If an MRP system is updated too frequently, the system becomes unstable and inefficient. On the other hand, if the system is not updated frequently enough, the system becomes inflexible. The trade-off between stability and flexibility can be balanced with the use of time fences. Time fence is a time period between current date and some time into the future where the schedule is frozen and no changes are allowed in the master production schedule. The shorter the time fence the more flexible and nervous the system is and the longer the time fence the more stable and inflexible the system is. ERP constitutes the most general level of planning, followed by MRP II and MRP, while shop floor scheduling and control involves the most detailed planning. I have found the following approach to work quite well in terms of developing student understanding of MRP: 1. Emphasize the difference between independent and dependent demand, even though it repeats material covered in the previous chapter. Instructor’s Manual, Chapter 15 305 2. Present an overview of MRP. Students find visual aids very helpful. Walk them through Figures 2, 3, 4, 5, 8, and 9. 3. Go back through in more detail, covering low-level coding, lot-for-lot ordering, and working through a product-tree and developing a material requirements plan. 4. Emphasize the inputs of MRP. 5. Solve at least two MRP problems completing two or three MRP tables for each problem. 6. Make copies of the blank MRP tables on the next page and distribute multiple copies to each student. Answers to Discussion and Review Questions 1. Independent demand refers to demand for end items; dependent demand refers to usage of subassemblies and component parts which is dependent on demand for a “parent” item. Independent demand is often random and therefore somewhat unpredictable; dependent demand is derived from demand for end items. 2. MRP is appropriate when requirements planning must be accomplished for items with derived demand. It is best suited to situations in which demand is “lumpy” rather than continual, and where lead times are fairly well known. 3. a. A master schedule specifies the quantity and timing planned for finished goods. b. A bill of materials indicates the components and their quantities needed to make and/or assemble one unit of an end item. c. An inventory status file maintains a record of inventories on-hand and on-order as well as other information concerning suppliers, lead times, order sizes, and so on. d. The gross requirement for an end item or component indicates how much of that item will be needed. e. The net requirement for an item is its gross requirement minus the quantity of that item expected to be on-hand. f. A time-phased plan is essentially a product-tree with the various components displayed on a time-scale utilizing lead times. g. Low-level coding refers to a product structure in which each item is listed at the lowest level that it appears in the tree or BOM. 4. 5. 306 Safety stock is not normally needed for dependent demand items below the end-item level because the usage of these items are calculated from the quantities established for the end item in the master schedule. However, in practice, there are a number of reasons to carry safety stock in an MRP system. Some of these reasons include scrap, defective units, late deliveries due to longer than expected production time of components or late deliveries of parts from the suppliers. Maintaining safety stock is important for multi-level items because a shortage for a lower level item in the BOM will cause a shortage for the end-item. However, if safety stock is carried for all dependent demand items, the main advantage of MRP will be lost. The need for safety stock arises when variability exits in usage and/or lead time. With derived demand, the causes of variability in lead time can be related to vendor deliveries or variabilities in internal processing (e.g., due to scheduling problems, machine breakdowns, material shortages, etc.). Usage variabilities may be due to excessive scrap or increases in order sizes (say, related to independent demand for certain items). Operations Management, 7/e 6. Because of the pyramid relationship that exists for components in an MRP system, it is not realistic to attempt to provide safety stock at all levels because this would result in huge carrying costs. Moreover, because shortage at any level will mean shortages from that point up to the top of the tree, safety stock at lower levels provides only minimal protection. Instead, on items subject to lead time variability, orders are submitted a bit earlier than needed, thereby gaining some “safety time” to compensate for the possibility of increased lead time. 7. A net change system is one that is updated as changes occur, while a regenerative system is updated periodically. The regenerative system is best suited to systems which are fairly stable. It affords lower processing costs than a net change system but it permits a lag between the time a change occurs and the time it can be recorded. Hence, under a regenerative system, management may not have the latest information for planning and control. 8. Successful MRP requires accurate inputs (master schedules, bills of materials, and inventory records). It also requires a computer to process information and generate material requirements plans and plan. 9. Among the usually mentioned advantages of MRP are low levels of in-process inventories, the ability to evaluate material requirements which a given master schedule will entail, and an ability to keep track of very large amounts of information. The disadvantages of MRP are mainly a function of the disillusionment which arises when it takes much longer than expected and/or personnel problems. 10. MRP can contribute to productivity by providing management with the kinds of information it needs to make the best use of available resources. For example, it can be used for capacity planning to help reduce bottlenecks and better smooth demands on the system. 11. MRP II is a second-generation approach to planning that incorporates MRP. It has a broader scope to manufacturing resource planning in that it links business planning, production planning, and the master schedule. [See Figure 15-16.] 12. The term lot sizing refers to selecting a lot size to order. In the case of uniform demand, an EOQ approach will yield an appropriate lot size. Under lumpy demand, it usually makes sense to time orders so that they arrive as needed. The EOQ amount, though, may not equal the quantity needed at a particular point in time. Lot-for-lot ordering is often used instead. However, some other lot size may yield lower total costs. Because of the variations in timing and quantity generally inherent in lumpy demand cases, there may not be a single approach which will consistently yield a reasonably good answer. Planned order receipts refers to a plan for future ordering; scheduled receipts indicates an actual order has been made and when it is expected to arrive. 13. 14. In the 1970s, manufacturers began to recognize the importance of the difference between independent demand which is relatively stable and dependent demand which is rather “lumpy” by nature. Earlier EOQ models which worked well for independent demand items did not work very well for the more “lumpy” dependent demand items. Hence, MRP was developed to handle the more “lumpy” dependent demand items. Adjustments still have to be made under MRP, but it was developed to handle seasonal variations better than the older EOQ models. 15. MRP II (Manufacturing Resource Planning) involves an effort to expand the scope of production resource planning to include other functional areas of the firm in the planning process such as marketing, finance, and purchasing. The integration of these areas in the formulation of the resource plan allows the company to develop a plan that works and is acceptable to different areas of the company. On the other hand ERP is an expanded effort to integrate standardized record keeping that will permit information sharing among different departments in order to make better decisions more rapidly and to manage the system more effectively. While MRP II builds links between the overall business plan, aggregate plan and the master production schedule, ERP Instructor’s Manual, Chapter 15 307 attempts to link and synchronize various independent databases within the firm and integrate them into one system. 16. The unforeseen costs of MRP include the following: a. Training: The workers have to be trained to learn and become proficient with a new system and its processes. b. Integration and testing: Integrating the computer systems associated with different areas of the firm and testing the links between various corporate areas and systems. c. Data conversion and data analysis d. Consultant fees e. Solving implementation problems on an ongoing basis f. Dealing with disappointing short-term results g. Competition for high quality workers especially in the IT field. Memo Writing Exercises 1. It is possible that an intuitive scheduling approach without using MRP may function at an inefficient level. However, the operational inefficiency may be ignored or may go unnoticed. It is very important that Bill of Materials (BOM) and inventory records are accurate for MRP execution because inaccuracies can lead to many problems including shortages, excess inventory, missed schedules and deliveries. It is possible that current BOM is not updated after design changes and stockroom inventories may not match computerized records mainly due to employees not recording transactions. Both inventory records and BOM have to be streamlined before MRP is implemented. In addition, appropriate education and training of employees should help reduce the resistance to change and make implementation smoother. The above preimplementation actions will most likely take considerable time. However, if the implementation begins without proper preparation and correction of problems, significant problems in customer service and production efficiency may be experienced. 2. An end item such as this chair is considered to be an independent demand item with uniform demand. It is appropriate to use EOQ/ROP for the independent demand items because the assumption of continual (uniform) usage and continuous monitoring is met. The components and parts that go into end items are considered to be dependent demand items. Their demand is dependent on the demand for the respective end items. Demand for the parts and components tend to be lumpy and not continuous. Therefore, instead of continuous stocking and monitoring the levels of inventory, these parts need to be stocked just prior to the time they will be needed for manufacturing. This policy of stocking just prior to need on the shop floor will in turn assist in reducing inventory investment. In addition, while demand for independent demand items such as the chair is forecasted, demand for the parts such as the legs, side rails, back support, etc., is calculated based on the demand for the chair. If EOQ/ROP approach is used for the dependent demand parts, a lot of unnecessary time could be spent to forecast each and every individual part. Since each forecast would be independent, there could be great amount of discrepancy and disagreement between the forecast for the end item and the forecast for the various parts. Safety stock will rarely be needed for dependent demand items because the usage rate of the component is based on the parent part, which is very predictable. Therefore, it would be very inefficient to use EOQ/ROP approach for the dependent demand items. For these items, instead of using EOQ/ROP approach, the company should consider installing an MRP system. 308 Operations Management, 7/e Master Schedule for: Week Beg. Inv. 1 2 3 4 5 6 7 8 5 6 7 8 5 6 7 8 5 6 7 8 5 6 7 8 Quantity Week Beg. Inv. 1 2 3 4 Gross requirements Scheduled receipts On hand Net requirements Planned order receipt Planned order release Week Beg. Inv. 1 2 3 4 Gross requirements Scheduled receipts On hand Net requirements Planned order receipt Planned order release Week Beg. Inv. 1 2 3 4 Gross requirements Scheduled receipts On hand Net requirements Planned order receipt Planned order release Week Beg. Inv. 1 2 3 4 Gross requirements Scheduled receipts On hand Net requirements Planned order receipt Planned order release Instructor’s Manual, Chapter 15 309 Solutions 1. F: 2 J: 2 x 2 = 4 D: 2 x 4 = 8 G: 1 L: 1 x 2 = 2 J: 1 x 2 = 2 H: A: C: D: 1 1x4=4 1x2=2 1x2=2 Totals: F = 2; G = 1; H = 1; J = 6; D = 10; L = 2; A = 4; C = 2. 2. a. B: 20 x 2 = 40 - 10 = 30 E: 30 x 2 = 60 - 12 = 48 C: 20 x 1 = 20 - 10 = 10 E: 20 x 2 = 40 D: 20 x 3 = 60 - 25 = 35 E: 35 x 2 = 70 Total: 48 + 20 + 60 = 138 b. End Item B(2) E(2) C F(3) G(2) D(3) E(2) H(4) E(2) Total LT 4 5 5 5 6 The longest sequence is 6 weeks. Week 11 - 6 weeks = Week 5. 5 End Item 3. L(2) B(2) C J(3) G(2) K(3) B(2) H(4) b. Total LT: 5 6 7 6 6 The longest sequence is 7 days. Thus, Day 8 - 7 Days = Day 1 (now). a. L: 2 x 40 = 80 C: 1 x 40 = 40 K: 3 x 40 = 120 -10 -15 -20 70 25 100 B: 2 x 70 = 140 B: 2 x 25 = 50 B: 2 x 100 = 200 -30 110 Total: 110 + 50 + 200 = 360 310 B(2) 6 Operations Management, 7/e Solutions (continued) 4. a. Master Schedule E Week Beg. Inv. 1 2 3 4 5 Quantity LT = 2 wks. 6 80 Beg. Inv. 1 2 3 4 5 Gross requirements 6 80 Scheduled receipts Projected on hand Net requirements 80 Planned-order receipts 80 Planned-order releases B(2) LT = 1 wk. 80 Beg. Inv. 1 2 3 Gross requirements 4 5 6 20 20 5 6 160 Scheduled receipts Projected on hand 60 60 60 60 60 Net requirements 100 Planned-order receipts 120 Planned-order releases J(4) & J(3) LT = 2 wks. 120 Beg. Inv. 1 Gross requirements 2 480 Scheduled receipts Projected on hand 3 20 20 20 4 240 30 30 30 50 80 50 Net requirements 460 160 Planned-order receipts 480 180 Planned-order releases Instructor’s Manual, Chapter 15 480 50 180 311 Solutions (continued) 4. b. Master Schedule E Week Beg. Inv. 1 2 3 4 5 Quantity LT = 2 wks. 6 70 Beg. Inv. 1 2 3 4 5 Gross requirements 6 70 Scheduled receipts Projected on hand Net requirements 70 Planned-order receipts 70 Planned-order releases B(2) LT = 1 wk. 70 Beg. Inv. 1 2 3 Gross requirements 4 5 6 40 40 5 6 140 Scheduled receipts Projected on hand 60 60 60 60 Net requirements 80 Planned-order receipts 120 Planned-order releases J(4) & J(3) LT = 2 wks. 120 Beg. Inv. 1 Gross requirements 2 3 480 Scheduled receipts Projected on hand 60 20 20 20 4 210 30 30 30 50 80 80 Net requirements 460 130 Planned-order receipts 480 180 Planned-order releases 480 80 180 There will be an additional 20 units of B and 30 units of J. 312 Operations Management, 7/e Solutions (continued) 5. a. Product Structure Tree P K 3G L 4H W 2M 2N Beg. Inv. 1 3Z c. Weeks 6 7 100 100 6 7 100 100 Net requirements 100 100 Planned-order receipts 100 100 Master Schedule d. P 2 3 4 5 Quantity LT = 1 wk. Beg. Inv. 1 2 3 4 5 Gross requirements Scheduled receipts Projected on hand Planned-order releases K LT = 2 wk. Beg. Inv. 1 2 3 4 Gross requirements Scheduled receipts 10 Projected on hand 10 100 100 5 6 100 100 30 10 10 Net requirements 90 70 Planned-order receipts 90 70 5 6 Planned-order releases G(3) LT = 1 wk. Beg. Inv. 1 2 Gross requirements 7 90 70 3 4 270 210 7 Scheduled receipts Projected on hand 40 40 40 40 Net requirements 230 210 Planned-order receipts 253 231 Planned-order releases Instructor’s Manual, Chapter 15 253 231 313 Solutions (continued) H(4) LT = 1 wk. Beg. Inv. 1 2 3 4 360 280 200 40 Net requirements 160 240 Planned-order receipts 200 240 Gross requirements 5 6 7 Scheduled receipts Projected on hand Planned-order releases 314 200 200 200 200 240 Operations Management, 7/e Solutions (continued) 6. Day Beg. Inv. 4 5 100 150 4 5 100 150 200 Net requirements 100 150 200 Planned-order receipts 100 110 200 Master Schedule 1 2 3 Quantity Table (Variable LT) Beg. Inv. 1 2 3 Gross requirements 6 7 200 6 7 Scheduled receipts Projected on hand Planned-order releases Wood Sections LT = 2 wks. Beg. Inv. 1 2 Gross requirements Scheduled receipts Projected on hand 100 150 200 3 4 200 300 400 5 6 100 60 60 100 100 Net requirements 100 300 400 Planned-order receipts 100 300 400 Planned-order releases Braces LT = 3 wks. 7 440 Beg. Inv. 1 2 Gross requirements 400 3 4 5 6 300 450 600 7 Scheduled receipts Projected on hand 60 60 60 60 Net requirements 240 450 600 Planned-order receipts 240 450 600 Planned-order releases Legs LT = 4 wks. Beg. Inv. 240 450 600 1 2 3 4 400 600 800 Gross requirements 5 6 7 Scheduled receipts Projected on hand 120 120 120 120 Net requirements 280 600 800 Planned-order receipts 308 660 880 Planned-order releases Instructor’s Manual, Chapter 15 968 880 315 Solutions (continued) 7. Master Schedule for: X Week Beg. Inv. 1 2 3 4 5 Quantity 6 7 80 8 30 Week Part X Beg. Inv. 1 2 3 4 5 Gross requirements Lot size: LFL 6 7 8 80 30 Net requirements 80 30 Planned order receipt 80 30 Scheduled receipts On hand Planned order release 80 30 Week Part B Beg. Inv. 1 2 3 4 Gross requirements 5 6 160 7 8 60 Scheduled receipts Lot size: LFL On hand 30 30 30 30 30 30 0 0 Net requirements 130 60 Planned order receipt 130 60 Planned order release 130 0 60 Week Part D Beg. Inv. 1 2 Gross requirements Lot size = 50 Scheduled receipts On hand 50 20 20 70 3 5 6 7 260 240 120 90 50 50 70 4 10 50 20 0 0 Net requirements 140 180 100 40 Planned order receipt 150 200 100 50 200 100 50 Planned order release 150 *Note that the lead time is a function of the lot size. 316 8 Operations Management, 7/e 10 Solutions (continued) 8. Master Schedule Week A LT = 1 wk. Beg. Inv. 1 2 3 Quantity Beg. Inv. 1 2 3 Gross requirements 4 5 6 40A 60B 30C 4 5 6 5 6 40 Scheduled receipts Projected on hand Net requirements 40 Planned order receipt 40 Planned order release B LT = 1 wk. 40 Beg. Inv. 1 2 3 4 Gross requirements 60 Scheduled receipts Projected on hand 10 10 10 10 10 10 Net requirements 50 Planned order receipt 50 Planned order release C LT = 2 wks. 50 Beg. Inv. 1 2 3 4 5 Gross requirements 6 30 Scheduled receipts Projected on hand 10 10 10 10 10 10 10 Net requirements 20 Planned order receipt 20 Planned order release D LT = 2 wks. 20 Beg. Inv. 1 2 Gross requirements Scheduled receipts Projected on hand 3 4 40 180 125 85 25 125 125 5 95 Planned order receipt Instructor’s Manual, Chapter 15 6 100 Net requirements Planned order release 5 100 100 317 Solutions (continued) 9. Saw A(2) B E(3) D C(3) D(2) F(3) E(2) D(2) D A E F Saw B D D C E 1 2 3 4 5 6 7 8 week 318 Operations Management, 7/e Solutions (continued) 9. (continued) Master Schedule for Saws Week Beg. Inv. 1 2 3 4 5 6 7 Quantity 8 50 Week Item: Saw LT = 2 wks. Beg. Inv. 1 2 3 4 5 6 7 8 Gross requirements Scheduled receipts 50 Projected on hand Net requirements Planned order receipt Planned order release 15 35 35 35 Week Item: A(2) LT = 1 wk. Beg. Inv. 1 2 3 4 5 Gross requirements Scheduled receipts Projected on hand Net requirements Planned order receipt LT = 2 wks. Beg. Inv. 1 2 3 4 5 6 8 7 8 105 30 75 75 75 Beg. Inv. 5 Gross requirements Scheduled receipts 150 180 Projected on hand Net requirements 10 140 180 Planned order receipt 140 180 Instructor’s Manual, Chapter 15 7 60 4 Planned order release 8 10 60 60 Gross requirements Scheduled receipts Projected on hand Net requirements Planned order receipt Planned order release Item: E(3) & E(2) LT = 1 wk. 7 70 Planned order release Item: C(3) 6 1 2 3 140 6 180 319 Solutions (continued) 9. c. E LT = 1 wk. Beg. Inv. 1 2 3 Gross requirements 4 5 150 180 130 80 20 100 100 6 7 8 6 7 8 Scheduled receipts Projected on hand 10 10 30 130 Net requirements Planned order receipt Planned order release 20 10. 20 100 100 100 100 100 Robot C(3) B E F G G(2) H I Master Schedule for Robot Week Beg. Inv. 1 2 3 4 5 Quantity Item: Robot LT = 2 wks. 40 Beg. Inv. 1 2 3 4 5 6 Gross requirements 7 8 40 Scheduled Receipts Projected on hand 10 10 10 10 10 10 10 Net Requirements 30 Planned order receipts 30 Planned order releases 320 10 30 Operations Management, 7/e Solutions (continued) 10. (continued) Item: C(3) LT = 1 wk. Beg. Inv. 1 2 3 4 Gross requirements 5 6 7 8 5 6 7 8 5 5 5 5 90 Scheduled receipts Projected on hand 20 20 20 20 20 20 Net Requirements 70 Planned order receipts 70 Planned order releases Item: G(2C + 1 Robot) LT = 2 wks. 70 Beg. Inv. 1 2 3 Gross requirements 4 170 Scheduled receipts Projected on hand 15 15 15 15 15 Net requirements 155 Planned order receipts 160 Planned order releases Instructor’s Manual, Chapter 15 160 321 Solutions (continued) 11. a. Master Schedule E) Period Beg. Inv. 1 2 3 4 5 Quantity LT = 1 wk. Beg. Inv. 1 2 3 4 5 120 Scheduled receipts 0 Projected on hand 0 Net requirements 120 Planned order receipts 120 Planned order releases LT = 1 wk. Beg. Inv. 1 2 3 6 7 8 4 5 6 7 8 5 6 7 8 240 Scheduled receipts 40 Projected on hand 40 40 Net requirements 200 Planned order receipts 200 Planned order releases LT = 2 wks. 8 120 Gross requirements N(4) 7 120 Gross requirements I(2) 6 200 Beg. Inv. 1 2 Gross requirements 3 4 800 Scheduled receipts Projected on hand 100 100 100 Net requirements 700 Planned order receipts 700 Planned order releases 322 100 700 Operations Management, 7/e Solutions (continued) 11. a. (continued) V LT = 2 wks. Beg. Inv. 1 2 3 Gross requirements 200 Scheduled receipts 10 4 5 6 7 8 4 5 6 7 8 Projected on hand Net requirements 190 Planned order receipts 190 Planned order releases 190 b. Master Schedule for E Period Beg. Inv. 1 2 3 Quantity 100 50 Week E LT = 1 wk. Beg. Inv. 1 2 3 4 5 6 7 8 Gross requirements 100 50 Scheduled receipts 0 0 Projected on hand 0 0 Net requirements 100 50 Planned order receipt 100 50 Planned order release Instructor’s Manual, Chapter 15 100 50 323 Solutions (continued) 11. b. (continued) I(2) LT = 1 wk. Beg. Inv. 1 2 3 Gross requirements 4 5 200 Scheduled receipts 40 Projected on hand 40 6 7 8 6 7 8 660 660 660 6 7 8 150 150 150 100 40 Net requirements 160 100 Planned order receipts 160 100 Planned order releases N(4) LT = 2 wks. 160 Beg. Inv. 1 2 Gross requirements 3 100 4 640 5 400 Scheduled receipts Projected on hand 100 100 100 260 Net requirements 540 140 Planned order receipts 800 800 Planned order releases V LT = 2 wks. 800 Beg. Inv. 1 800 2 3 Gross requirements 160 Scheduled receipts 10 Projected on hand 4 5 100 50 50 Net requirements 150 50 Planned order receipts 200 200 Planned order releases 324 260 200 200 Operations Management, 7/e Solutions (continued) 11. c. Case 1. One week elapsed Week Master Schedule for Quantity E LT = 1 wk. Beg. Inv. 1 2 3 4 5 6 7 8 120 Week Beg. Inv. 1 2 3 4 100 5 6 7 8 Gross requirements 120 100 Scheduled receipts 0 0 Projected on hand 0 0 Net requirements 120 100 Planned order receipt 120 100 Planned order release 120 100 Week I (2) LT = 1 wk. Beg. Inv. 1 2 Gross requirements 3 4 5 6 7 240 Scheduled receipts 40 Projected on hand 40 8 200 0 40 0 Net requirements 200 200 Planned order receipt 200 200 Planned order release 200 200 Week N (4) LT = 2 wks. Beg. Inv. 1 Gross requirements 2 3 4 5 800 6 Net requirements 100 Planned order receipt 100 0 700 800 700 800 Planned order release Gross requirements Scheduled receipts Projected on hand Net requirements Planned order receipt Planned order release Instructor’s Manual, Chapter 15 7 8 0 Projected on hand LT = 2 wks. 8 800 Scheduled receipts V 7 800 Week Beg. Inv. 1 2 3 4 200 10 5 6 200 0 0 200 200 190 190 200 325 Solutions (continued) 11. c. Case 2. Three weeks elapsed Master Schedule for Saws Week Beg. Inv. 1 Quantity 2 3 4 5 6 7 8 7 8 6 7 8 5 6 7 8 5 6 7 8 120 100 Week E LT = 1 wk. Beg. Inv. 1 2 3 4 5 6 Gross requirements 120 100 Scheduled receipts 0 0 Projected on hand 0 0 Net requirements 120 100 Planned order receipt 120 100 Planned order release 120 100 Week I (2) LT = 1 wk. Beg. Inv. Gross requirements 1 2 3 4 5 240 200 Scheduled receipts 0 Projected on hand 40 0 Net requirements 200 200 Planned order receipt 200 200 Planned order release N (4) LT = 2 wks. 200 Week Beg. Inv. 1 2 3 4 Gross requirements 800 Scheduled receipts 0 Projected on hand 0 Net requirements 800 Planned order receipt 800 Planned order release 800 Week V LT = 2 wks. 1 2 3 4 Gross requirements 200 Scheduled receipts 0 Projected on hand 0 Net requirements 200 Planned order receipt 200 Planned order release 326 Beg. Inv. 200 Operations Management, 7/e Solutions (continued) 12. a. Golf Cart Top Supports (4) Base Cover Motor Body Frame Controls Seats (2) Wheels (4) Supports Top b. Cover Cart Motor Frame Body Controls Base Wheels Seats 2 3 4 5 6 7 week Instructor’s Manual, Chapter 15 327 Solutions (continued) 12. c. Master Week Schedule for golf carts Quantity Item: Gold Cart LT = 1 wk. Beg. Inv. 1 2 3 4 5 6 7 8 200 Beg. Inv. 1 2 3 4 5 6 7 Gross requirements 8 200 Scheduled receipts Projected on hand Net requirements 200 Planned order receipts 200 Planned order releases Item: Top LT = 1 wk. 200 Beg. Inv. 1 2 3 4 5 6 Gross requirements 7 8 200 Scheduled receipts Projected on hand 40 40 40 40 40 40 40 40 Net requirements 160 Planned order receipts 160 Planned order releases Item: Supports (4) LT = 1 wk. Gross requirements 160 Beg. Inv. 1 2 3 4 5 6 7 8 640 Scheduled receipts Projected on hand 200 200 200 200 200 Net requirements 440 Planned order receipts 440 Planned order releases 328 0 200 440 Operations Management, 7/e Solutions (continued) 12. c. (continued) Item: Cover LT = 1 wk. Beg. Inv. 1 2 3 4 5 Gross requirements 6 7 8 7 8 160 Scheduled receipts Projected on hand Net requirements 160 Planned order receipts 160 Planned order releases Item: Base LT = 1 wk. 160 Beg. Inv. 1 2 3 4 5 6 Gross requirements 200 Scheduled receipts Projected on hand 20 20 20 20 20 20 20 Net requirements 180 Planned order receipts 180 Planned order releases Item: Motor LT = 2 wks. 180 Beg. Inv. 1 2 3 4 5 Gross requirements 6 7 8 120 120 180 Scheduled receipts Projected on hand Net requirements 300 300 300 300 300 300 (120) Planned order receipts Planned order releases Instructor’s Manual, Chapter 15 329 Solutions (continued) 12. c. (Continued) Item: Body LT = 3 wks. Beg. Inv. 1 2 3 4 5 Gross requirements 6 7 8 7 8 7 8 180 Scheduled receipts Projected on hand 50 50 50 50 50 50 50 Net requirements 130 Planned order receipts 130 Planned order releases Item: Seats LT = 2 wks. 130 Beg. Inv. 1 2 3 4 5 Gross requirements 6 360 Scheduled receipts Projected on hand 120 120 120 120 120 120 120 Net requirements 240 Planned order receipts 240 Planned order releases Item: Frame LT = 1 wk. 240 Beg. Inv. 1 2 Gross requirements 3 4 5 6 130 Scheduled receipts Projected on hand 35 35 Net requirements 95 Planned order receipts 95 Planned order releases 330 35 95 Operations Management, 7/e Solutions (continued) 12. c. (Continued) Beg. Inv. Item: Controls LT = 1 wk. 1 2 3 Gross requirements 4 5 6 7 8 4 5 6 7 8 130 Scheduled receipts Projected on hand Net requirements 130 Planned order receipts 130 Planned order releases 130 Beg. Inv. Item: Wheel Assemblies LT = 1 wk. 1 2 3 Gross requirements 520 Scheduled receipts Projected on hand 240 240 240 240 Net requirements 280 Planned order receipts 280 Planned order releases 280 13. a. Master Schedule for golf carts Week Beg. Inv. 1 2 3 4 5 8 9 100 100 8 9 100 100 100 Net requirements 100 100 100 Planned order receipts 100 100 100 Quantity 6 7 100 b. Item: Golf cart LT = 1 wk. Beg. Inv. 1 2 3 4 5 Gross requirements 6 7 Scheduled receipts Projected on hand Planned order releases Instructor’s Manual, Chapter 15 100 100 100 331 Solutions (continued) 13. b. (continued) Week Beg. Inv. 1 2 3 4 5 Quantity Item: Tops LT = 1 wk. 6 7 8 9 100 100 7 8 9 100 100 100 Beg. Inv. 1 2 3 4 5 Gross requirements 6 100 Scheduled receipts Projected on hand 40 40 40 40 40 40 Net requirements 60 100 100 Planned order receipts 60 100 100 Planned order releases Item: Base LT = 1 wk. 60 Beg. Inv. 1 2 3 4 5 Gross requirements 100 100 6 7 8 100 100 100 9 Scheduled receipts Projected on hand 20 20 20 20 20 20 Net requirements 80 100 100 Planned order receipts 80 100 100 Planned order releases 80 100 100 6 7 c. Master schedule for golf carts Week Beg. Inv. 1 2 3 4 5 8 9 100 100 8 9 100 100 100 Net requirements 100 100 100 Planned order receipts 100 100 100 Quantity Item: Golf Cart LT = 1 wk. 100 Beg. Inv. 1 2 3 4 5 Gross requirements 6 7 Scheduled receipts Projected on hand Planned order releases 332 100 100 Operations Management, 7/e Solutions (continued) 13. c. (continued) Beg. Inv. Week 1 2 3 4 5 6 Quantity 7 8 9 100 100 7 8 9 100 100 100 50 100 50 50 100 Item: Bases LT = 1 wk. Beg. Inv. 1 2 3 4 Gross requirements 5 6 100 Scheduled receipts Projected on hand 20 20 20 20 50 Net requirements Planned order releases EPP = 50 0 Planned order receipts 14. a. 100 30 Setup Cost Carrying cost/unit/month = 30 50 50 50 50 50 50 50 50 50 $11 = 78.56 79 part periods .14 Part Period Model Month (Period) 1 2 3 4 5 6 7 8 Demand 80 10 30 30 30 Lot Size 120** 60** - Part Periods 10 x 1 = 10 30 x 2 = 60 30 x 2 = 60 Extra Cumulative Inventory Part Periods Carried 40 10 30 70* 30 30 60 Total = 130 * 70 is the closest cumulative part period to 79(EPP) ** Manufacture 120 units and 60 units in the second and the 6th month respectively. Total Cost = Carrying cost + Setup cost Total Cost = (130 units) x ($.14/month) = $18.20 Setup Cost = (2 setups) x ($11/setup) = $22.00 Total CostEPP = $18.20 + $22.00 = $40.20 Instructor’s Manual, Chapter 15 333 Solutions (continued) 14. b. EOQ Method Total demand for 8 months = 80 + 10 + 30 + 30 + 30 = 180 units 180 Average demand per month = = 22.5 units/month 8 2DS 2(22.5)(11) 495 EOQ = = = = 3535.71 = 59.46 60 units H .14 .14 EOQ Method Extra Inventory Month Demand Lot Size Carried 1 2 80 120* 40 3 10 30 4 30 5 6 30 60* 30 7 30 8 30 Total = 130 *Two lots are produced (produce 120 units in the second month and 60 units in the 6th month) Total Cost = Carrying cost + Setup cost Carrying cost = (130 units) x ($.14/month) = $18.20 Setup Cost = (2 setups) x ($11/setup) = $22.00 Total CostEOQ = $18.20 + $22.00 = $40.20 c. Fixed Period Ordering: 2 Month Interval Period (Month) 1 2 3 4 5 6 7 8 Demand 80 10 30 30 30 Lot Size 90 30 30 30 Extra Inventory Carried 10 - Total Cost = Carrying cost + Setup cost Carrying cost = (10 units) x ($.14/unit/month) = $1.40 Setup Cost = (4 setups) x ($11/setup) = $44.00 Total Cost = $1.40 + $44.00 = $45.40 Since the total cost for EPP = EOQ = $40.20 we would recommend EPP and EOQ approach over fixed period approach because the total cost for fixed period approach is $45.40 > 40.20 334 Operations Management, 7/e Solutions (continued) 15. EPP = Fixed Cost = Carrying Cost Period 1 3 16. Lot Size 125 1.65 = 75.76 76 Extra Inv. carried Periods carried Part periods Cum. part-periods 40 60 160 0 20 100 0 1 2 0 20 200 0 20* 220 100 120 140 0 20 20 0 1 3 0 20 60 0 20 80* [closest to 76] [closest to 76] 7 80 0 0 0 0 Produce 60 units in period 1; Produce 140 units in period 3; Produce 80 units in period 7. Week 1 2 3 4 Material 40 80 60 70 Week Labor hr. 1 160 Mach. hr. 120 a. Capacity utilization Week 1 Labor 53.3% 2 320 3 240 4 280 240 180 210 2 106.7% 3 80% 4 93.3% Machine 60% 120% 90% 105% b. Capacity utilization exceeds 100% for both labor and machine in week 2, and for machine alone in week 4. Production could be shifted to earlier or later weeks in which capacity is underutilized. Shifting to an earlier week would result in added carrying costs; shifting to later weeks would mean backorder costs. Another option would be to work overtime. Labor cost would increase due to overtime premium, a probable decrease in productivity, and possible increase in accidents. Instructor’s Manual, Chapter 15 335 Solutions (continued) 17. Fabrication Labor Mach. Assembly Labor Mach. Packaging Labor Mach. Day Product Mon A B 400 300 700 200 300 500 300 300 600 200 300 500 200 450 650 100 150 250 Tue A B 800 200 1000 400 200 600 600 200 800 400 200 600 400 300 700 200 100 300 Wed A B 200 200 400 100 200 300 150 200 350 100 200 300 100 300 400 50 100 150 Summary: Labor capacity of 700 hours is exceeded on Tuesday in the Fabrication Department and the Assembly Department. Machine capacity of 500 hours is also exceeded in the same two departments on Tuesday. Shift 150 units of A (300 labor hours, 150 machine hours) to Wednesday in the Fabrication Department. For assembly, a similar shift of 150 units of A could be made, although other combinations are possible (e.g., some A and some B). 336 Operations Management, 7/e Solutions (continued) 18. Master Schedule for #565 Week Beg. Inv. 1 2 3 4 5 Quantity 6 7 8 7 8 6 7 8 6 7 8 180 Week Item: #565 LT = 1 wk. Beg. Inv. 1 2 3 4 5 Gross requirements 6 180 Scheduled receipts On hand Net requirements 180 Planned order receipt 180 Planned order release 180 Week Item: Y36(2) LT = 1 wk. Beg. Inv. 1 2 3 4 Gross requirements 5 360 Scheduled receipts On hand 200 Net requirements 160 Planned order receipt 160 Planned order release 160 Week Item: J27(4) LT = 2 wks. Beg. Inv. 1 2 3 Gross requirements 4 5 640 Scheduled receipts On hand Net requirements 640 Planned order receipt 640 Planned order release Instructor’s Manual, Chapter 15 640 337 Solutions (continued) 18. (continued) Master Schedule for: B Week Beg. Inv. 1 2 3 Quantity 4 5 6 7 8 15 15 15 15 15 4 5 6 7 8 15 15 15 15 15 25 10 0 5 15 15 15 5 15 15 15 15 15 7 8 Week Item: B Beg. LT = 2 wks. Inv. 1 2 3 Gross requirements Scheduled receipts On hand 20 5 25 25 25 Net requirements Planned order receipt Planned order release 5 15 Week Item: W Beg. LT = 2 wks. Inv. Gross requirements 1 2 3 4 5 6 5 15 15 15 Scheduled receipts On hand Net requirements Planned order receipt Planned order release 338 Operations Management, 7/e Reading: ABCs of ERP Answers to Questions 1. ERP (Enterprise Resource Planning) is an integrated information system that is used to plan the resources and processes needed to produce, ship and account for all customer orders both in manufacturing and service organizations. Integration of databases permits standardization of processes, allows easier access to information by various departments and more importantly makes it possible to share information to make better and timely decisions in serving the customers. For example, ERP would make it possible for departments such as accounting, sales, production, materials management having immediate access and to new customer orders within the same system. ERP would also allow the customer service representative to quickly check various databases such as inventory, accounting, and marketing and production to rapidly respond to questions from customers. 2. Following are ways ERP can improve a company’s business performance: a) Improvements in order tracking and order fulfillment b) Rapid completion of orders by customer service representatives due to easy access to various databases within the firm c) Rapid movement of an order through the organization d) Improvement in data analysis to make better decisions due to improved software capabilities and integration of the different databases within the company 3. Obstacles to implementing ERP include: a) Getting employees and departments to cooperate and to agree to a new software system b) Implementation problem due to lack of training c) Technical problems involving the software d) Consultant problems 4. ERP offers a natural platform to connect the firm's internal databases with e-commerce operations of the company. However, due to specialized needs of e-commerce operations, ERP vendors are unable to support all of the requirements and needs of Internet related operations of the firm. The niche Internet software vendors provide firms with specialized e-commerce software that is easy to hook-up and use. Both the ERP and specialized software vendors assist companies with their ecommerce applications. In addition, ERP also provides a natural platform to connect to the databases of suppliers, and customers on the supply chain that permits sharing of information regarding sales forecasts, inventories, production plans, etc. The integration of databases between suppliers and customers assist firms in making better decisions as a result of having additional information from their suppliers and or their customers on the supply chain. Instructor’s Manual, Chapter 15 339 Case: DMD Enterprises Master Schedule for: Arrows Week Master Schedule for: Darts Week Beg. Inv. 1 2 3 4 5 6 7 8 15 15 15 15 15 4 5 6 7 8 10 10 10 10 10 4 5 6 7 8 15 15 15 15 15 10 0 0 0 0 Net requirements 5 15 15 15 Planned order receipt 5 15 15 15 15 15 4 5 6 7 8 10 10 10 10 10 12 2 0 0 0 Net requirements 8 10 10 Planned order receipt 8 10 10 7 8 5 5 Quantity Beg. Inv. 1 2 3 Quantity Lot size: LFL Arrows LT = 2 wks. Week Beg. Inv. 1 2 3 Gross requirements Scheduled receipts On hand 20 5 25 25 25 Planned order release 5 Lot size: LFL Darts LT = 2 wks. Week Beg. Inv. 1 2 3 Gross requirements Scheduled receipts On hand 20 2 2 2 22 22 Planned order release 8 Lot size: 25 Part X LT = 1 wk. 15 10 10 Week Beg. Inv. 1 2 3 4 5 6 5 15 15 15 0 10 20 5 Net requirements 15 5 Planned order receipt 25 25 Gross requirements Scheduled receipts On hand Planned order release 340 5 5 5 5 25 25 Operations Management, 7/e Case: DMD Enterprises (continued) Lot size: LFL Part M LT = 1 wk. Week Beg. Inv. 1 2 3 4 5 6 5 15 15 15 0 0 0 Net requirements 5 15 15 15 Planned order receipt 5 15 15 15 15 15 15 Gross requirements 7 8 7 8 Scheduled receipts On hand 0 0 0 Planned order release 0 5 Lot size: LFL Part K LT = 1 wk. Week Beg. Inv. 1 2 3 4 5 6 16 20 20 0 0 0 Net requirements 13 20 20 Planned order receipt 13 20 20 20 20 Gross requirements Scheduled receipts On hand 3 3 3 3 Planned order release 3 13 Lot size: 30 Part Q LT = 1 wk. Week Beg. Inv. 1 2 Gross requirements Scheduled receipts On hand 15 15 15 3 4 5 13 20 20 2 12 22 18 8 30 30 Net requirements 15 Planned order receipt Planned order release Instructor’s Manual, Chapter 15 0 30 6 7 8 22 22 22 30 341 Case: DMD Enterprises (continued) Lot size: 30 Part F LT = 1 wk. Week Beg. Inv. 1 2 Gross requirements Scheduled receipts On hand 3 4 5 6 25 33 10 10 8 0 27 17 7 7 7 7 8 8 8 15 10 10 25 Net requirements 33 Planned order receipt 60 Planned order release 60 Lot size: 12 Part W LT* = 2 or 3 wks. 7 Week Beg. Inv. 1 2 3 4 5 6 31 55 55 15 1 6 11 8 Net requirements 11 54 49 4 Planned order receipt 12 60 60 12 Gross requirements Scheduled receipts On hand Planned order release 18 2 20 72 20 60 12 *If the lot size is less than 36, then the lead time is 2 weeks, otherwise the lead time is 3 weeks. 342 Operations Management, 7/e Operations Tour: Stickley Furniture 1. Batches of different types of furniture, such as tables, chairs, desks, dressers, etc. Repetitive such as sawing, drilling, finishing, etc., and job shop for expensive one-of-a-kind special orders that may be received. 2. Each job is accompanied by a set of bar codes that I.D. the job and the operation. As each operation is completed, the operator removes a bar code sticker and delivers it to the scheduling office where it is scanned into a computer, thereby enabling production control to keep track of progress on a job, and to know its location in the shop. 3. The information needed to plan, schedule and process the order for 40 mission oak dining room sets: a. Number of finished units presently in inventory. b. Type of wood c. Type of furniture d. Style of furniture e. Number of finished products needed f. List of component parts for each finished product g. Operations required for each component part h. Inventory for each component part i. Sequence of operations for each component j. Sequence of operations for each finished product k. Orders already in progress or scheduled to precede this order l. Unutilized equipment and labor m. Processing times for each component and total processing time for the finished product 4. One benefit would be the stability brought about by the maintenance of a constant size work force. A negative point would be the buildup of inventories during certain quarters of the year. 5. Since you have a dependent demand situation, the installation of an MRP system might be of great help to this company in meeting its orders on time and in keeping inventory costs down. Instructor’s Manual, Chapter 15 343